When specifying electrical infrastructure for industrial facilities, three terms come up repeatedly: junction box, marshalling panel, and system cabinet. While they may look similar at first glance—metal enclosures housing electrical connections—they serve distinctly different purposes in the electrical distribution hierarchy. Confusing these terms can lead to incorrect equipment selection, project delays, and cost overruns.

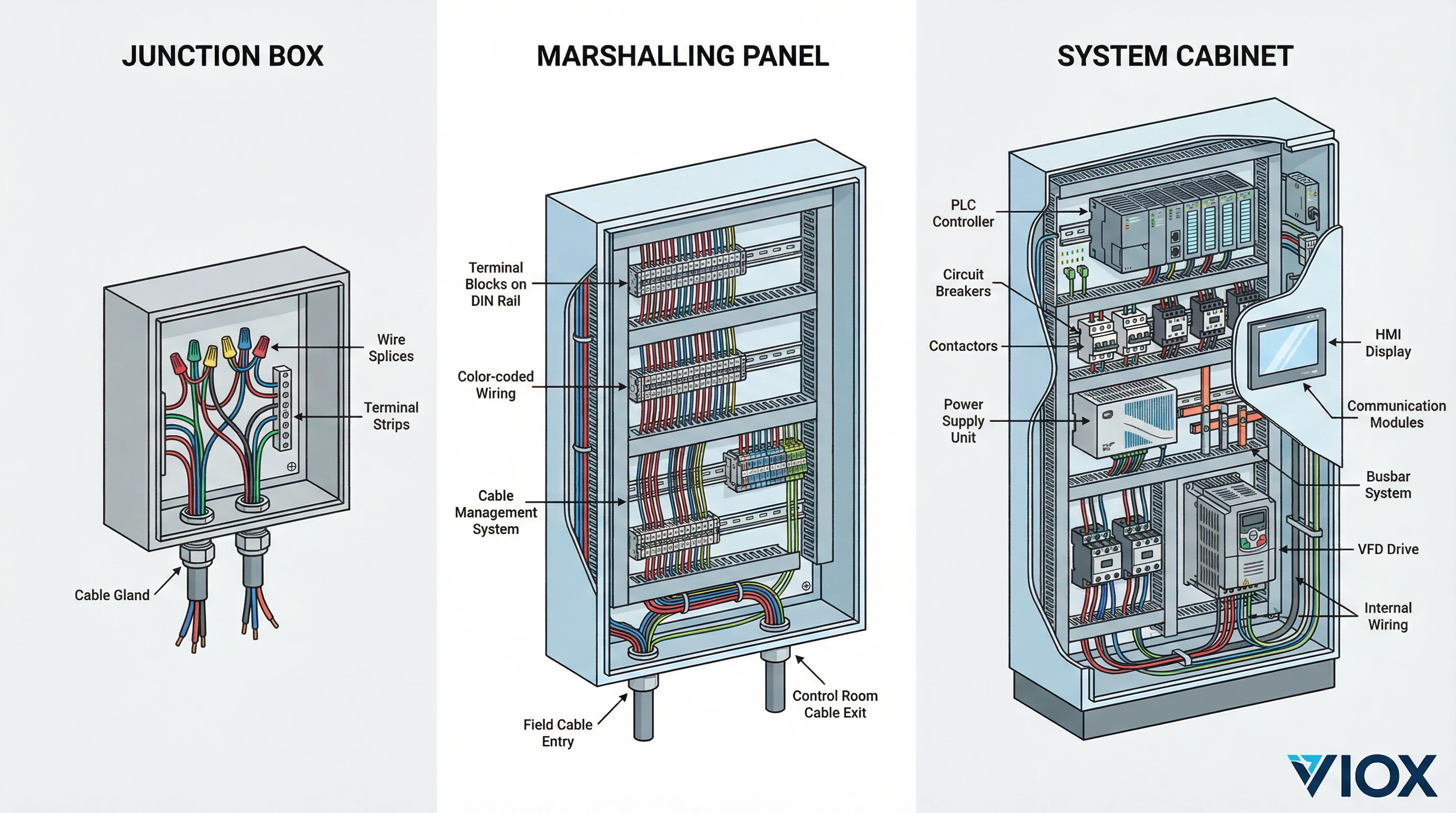

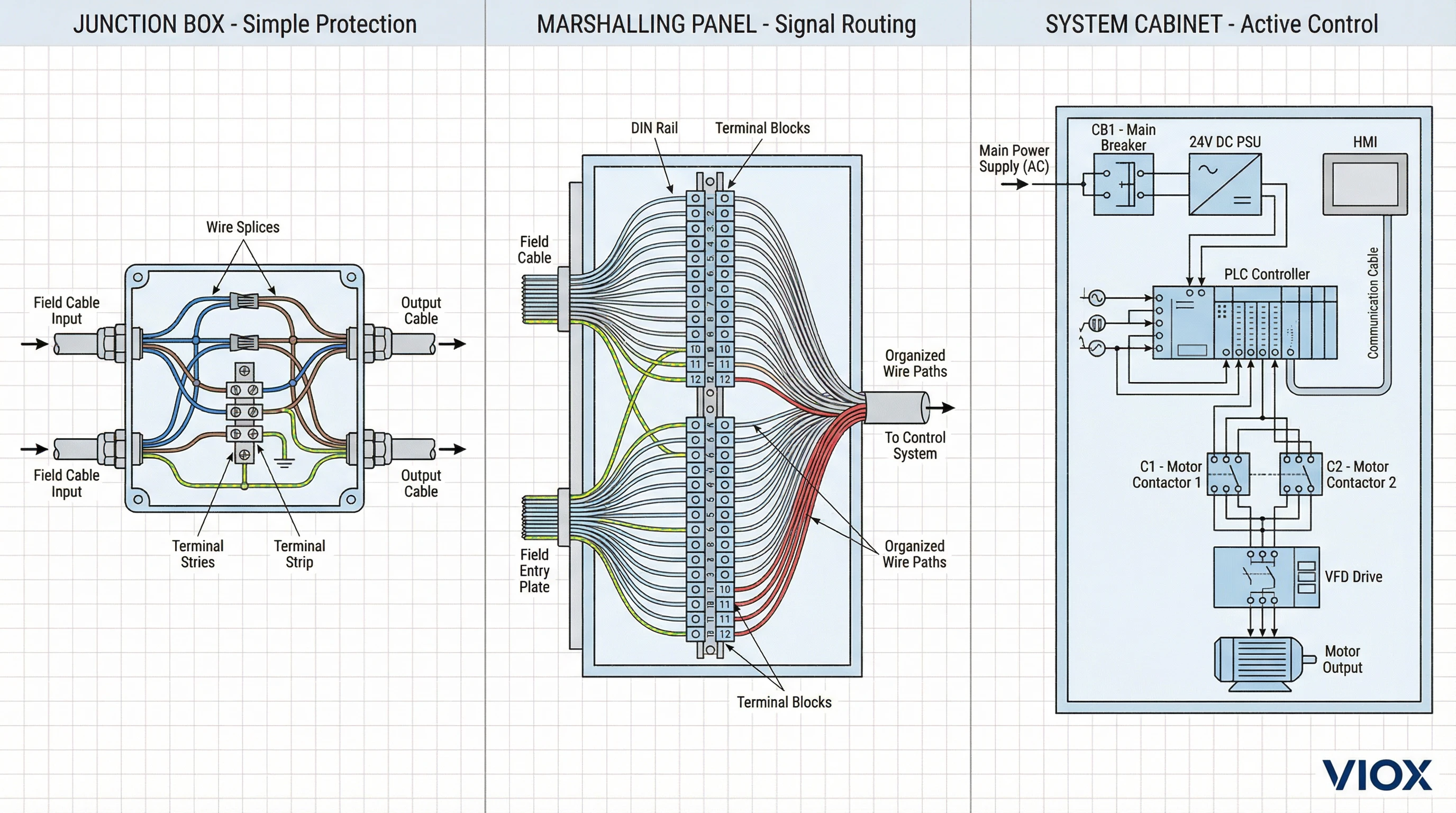

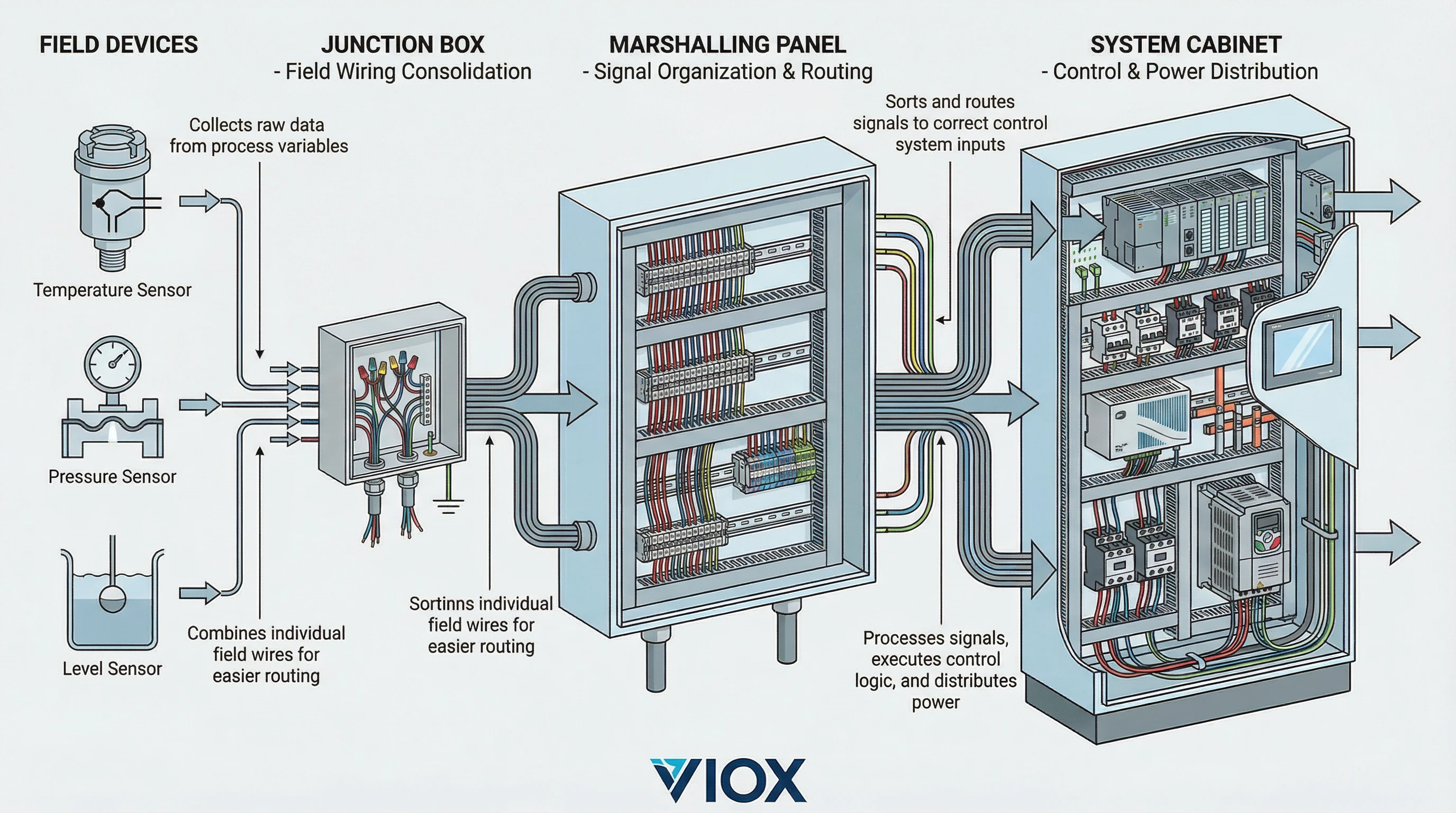

A junction box is a simple protective enclosure for wire connections. A marshalling panel organizes and routes instrumentation signals between field devices and control systems. A system cabinet houses complete control and distribution systems with active components like PLCs, circuit breakers, and contactors.

This guide clarifies the differences between these three essential components, helping electrical contractors, facility managers, and control system integrators select the right equipment for their applications. We’ll examine their construction, typical components, applications, and provide practical selection guidance backed by comparison tables.

What Is a Junction Box?

A junction box is an enclosure that houses the connection points where two or more electrical wires meet. At its core, it’s a protective box—nothing more. The primary function is safeguarding wire splices and terminations from environmental hazards like dust, moisture, physical impact, and chemical exposure that are common in industrial settings.

Junction boxes are passive components. They don’t process signals, control equipment, or distribute power in any intelligent way. They simply protect connections and provide a centralized, accessible point for wiring management. This simplicity makes them the most basic building block in electrical installations.

Typical Construction and Components

Materials: Steel, stainless steel, aluminum, polycarbonate, PVC, or fiberglass-reinforced plastic (FRP). Material selection depends on the environment—stainless steel for food processing and marine applications, aluminum for lightweight durability, and FRP for chemical resistance.

Internal Components:

- Wire splices (wire nuts, crimped connectors)

- Cable glands or conduit entries

- Sometimes basic terminal blocks for organized connections

- Grounding terminals

Typical Sizes: Small boxes (4″×4″) to large enclosures (24″×24″), depending on the number of connections.

Protection Ratings

Junction boxes are classified by NEMA (North America) or IP (International) ratings:

- NEMA 1: General indoor use

- NEMA 3R: Outdoor, rain-resistant

- NEMA 4X: Corrosion-resistant, hose-down applications

- NEMA 7/9: Hazardous locations (explosive gases or combustible dust)

- IP65: Dust-tight, protected against water jets

- IP67: Dust-tight, temporary water immersion

Common Applications

- Consolidating power wiring from multiple motors or lights

- Protecting outdoor cable connections for HVAC and renewable energy systems

- Serving as pull boxes in long conduit runs

- Field-level connection points in manufacturing facilities

- Solar panel array wiring consolidation

Junction boxes work best when you need to protect wire connections without any additional functionality. They’re cost-effective, quick to install, and require minimal maintenance.

What Is a Marshalling Panel?

A marshalling panel is a specialized electrical enclosure that consolidates, organizes, and routes instrumentation signals between field devices (sensors, transmitters, actuators) and control systems (DCS, PLC, SCADA). The term “marshalling” refers to the systematic grouping and redirection of Input/Output (I/O) signals—analog and digital, inputs and outputs—ensuring each signal reaches the correct destination in the control system.

Unlike a junction box, a marshalling panel performs intelligent signal management through cross-wiring. Field cables carrying mixed signal types arrive at the panel, where terminal blocks allow technicians to sort and redirect each signal to the appropriate I/O module. This organized interface is essential in large facilities with hundreds or thousands of instrument connections.

Typical Construction and Components

Enclosure: Larger than junction boxes, typically floor-standing or wall-mounted cabinets ranging from 600mm to 2000mm in height. Usually constructed from steel or stainless steel with environmental protection ratings (IP54 to IP65).

Internal Components:

- Terminal blocks: The core component. Includes feed-through, multi-level (4-8 levels), fuse terminal blocks, and disconnect terminal blocks

- Intrinsic safety (IS) barriers: For hazardous area applications, limiting electrical energy to prevent ignition

- Signal conditioning modules: Converting, isolating, or amplifying signals for control system compatibility

- Cable management systems: DIN rails, wire ducts, cable ties, and labeling systems

- Surge protection devices: Protecting sensitive instrumentation from voltage spikes

Connection Technology: Screw-clamp terminals (traditional, vibration-resistant) or push-in terminals (tool-free, faster installation).

Key Function: Cross-Wiring

Cross-wiring is what distinguishes a marshalling panel from a junction box. A multi-pair field cable might carry 20 different signals—temperature sensors, pressure transmitters, valve position indicators. Inside the marshalling panel, each signal is terminated on a dedicated terminal block, then cross-wired to the appropriate I/O channel on the control system side. This segregation enables:

- Organized signal routing (no tangled mess)

- Easy troubleshooting and maintenance

- Flexibility for system changes and expansions

- Isolation between field wiring and control system wiring

Common Applications

- Process Control Systems: Oil & gas refineries, chemical plants, water treatment facilities

- DCS/PLC Integration: Interfacing field instrumentation with distributed control systems

- Hazardous Areas: Explosion-proof and intrinsically safe marshalling cabinets for explosive atmospheres

- Power Generation: Turbine control, generator monitoring, substation automation

- Building Automation: Large HVAC systems, lighting control, energy management

Marshalling panels are the standard choice when you need organized, maintainable signal routing between extensive field instrumentation and centralized control systems.

What Is a System Cabinet?

A system cabinet (also called a control cabinet, control panel, or switchgear cabinet) is a comprehensive electrical enclosure that houses complete control, automation, and power distribution systems. Unlike the simpler junction box or the signal-routing marshalling panel, a system cabinet is the “brain and muscle” of an electrical installation—it actively controls processes, distributes power, and monitors operations.

System cabinets integrate multiple active components: programmable logic controllers (PLCs), circuit breakers, contactors, motor drives, power supplies, human-machine interfaces (HMIs), and more. They don’t just connect wires or route signals—they execute control logic, switch loads, protect circuits, and provide operator interfaces.

Typical Construction and Components

Enclosure: Large floor-standing or wall-mounted cabinets, typically constructed from steel, stainless steel, or aluminum. Sizes range from small single-door panels (600mm × 800mm) to massive motor control centers (MCCs) spanning multiple meters. Environmental ratings vary from IP54 (indoor industrial) to IP65 (outdoor/washdown).

Internal Components:

- Programmable Logic Controllers (PLCs): The “brain,” executing programmed logic to control automated processes

- Circuit breakers and fuses: Protecting circuits from overcurrent and short circuits

- Contactors and relays: Electrically operated switches controlling high-power loads (motors, heaters)

- Variable frequency drives (VFDs): Controlling motor speed for efficiency and process control

- Power supplies and transformers: Converting AC to DC voltages for control components

- Terminal blocks: Organized connection points (similar to marshalling panels, but integrated with active components)

- HMI/touchscreen panels: Operator interface for monitoring and control

- Push buttons, selector switches, indicator lights: Manual control and status indication

- Surge protection devices (SPDs): Protecting sensitive electronics from voltage transients

Thermal Management: Larger cabinets often include cooling systems (fans, heat exchangers, air conditioning) to dissipate heat from power components.

Types of System Cabinets

By Function:

- Motor Control Centers (MCCs): Dedicated to controlling electric motors with starters, drives, and protective devices

- PLC Cabinets: Housing PLCs and I/O modules for automation systems

- Main Distribution Cabinets: Receiving power from the main supply and distributing to facility loads

- Switchgear Cabinets: Medium/high-voltage switching and protection equipment

By Industry:

- Manufacturing: Controlling robotic arms, assembly lines, CNC machines

- Energy: Power generation control, substation automation

- Water/Wastewater: Pump and valve control, treatment process automation

- Building Systems: HVAC control, lighting management, fire alarm integration

Common Applications

- Industrial machinery control and automation

- Motor control for pumps, fans, conveyors, and compressors

- Process automation in manufacturing plants

- Power distribution in commercial and industrial facilities

- Building management systems

- Renewable energy systems (solar inverters, battery management)

System cabinets are the choice when you need active control, power distribution, and integrated automation—not just connection protection or signal routing.

Key Differences: Side-by-Side Comparison

With each component defined, let’s compare them directly across multiple dimensions.

Primary Function Comparison

| Attribute | Junction Box | Marshalling Panel | System Cabinet |

|---|---|---|---|

| Primary Function | Protect wire connections | Organize and route instrumentation signals | Control, automate, and distribute power |

| Complexity Level | Low (passive enclosure) | Medium (signal routing and conditioning) | High (active control and power management) |

| Active Components | None | Minimal (IS barriers, signal conditioners) | Extensive (PLCs, breakers, drives, contactors) |

| Processing Capability | No processing | No processing (passive routing) | Yes (executes control logic) |

| Power Distribution | No | No | Yes |

| Signal Management | No | Yes (cross-wiring, segregation) | Yes (integrated with control system) |

Construction and Physical Characteristics

| Attribute | Junction Box | Marshalling Panel | System Cabinet |

|---|---|---|---|

| Typical Size Range | 100mm to 600mm | 600mm to 2000mm (height) | 600mm to 3000mm+ (often floor-standing) |

| Weight | Light (1-20 kg) | Medium (50-200 kg) | Heavy (100-1000+ kg) |

| Mounting | Wall-mount, surface-mount | Wall-mount, floor-standing | Floor-standing, wall-mount (smaller units) |

| Enclosure Material | Steel, aluminum, plastic, FRP | Steel, stainless steel | Steel, stainless steel, aluminum |

| Environmental Rating | IP54 to IP67, NEMA 1 to 7/9 | IP54 to IP65 | IP20 (indoor) to IP65 (outdoor/industrial) |

| Thermal Management | Not required | Rarely required | Often required (fans, cooling) |

Internal Components

| Component Type | Junction Box | Marshalling Panel | System Cabinet |

|---|---|---|---|

| Terminal Blocks | Optional (basic) | Extensive (multi-level, fuse, disconnect) | Yes (integrated with other components) |

| PLCs/Controllers | No | No | Yes |

| Circuit Breakers | No | No | Yes |

| Contactors/Relays | No | Rarely | Yes |

| Motor Drives | No | No | Yes (when applicable) |

| Power Supplies | No | No | Yes |

| HMI/Display | No | No | Yes (often) |

| Signal Conditioning | No | Yes (when needed) | Yes (integrated) |

| IS Barriers | No | Yes (hazardous areas) | Possible |

Cost and Complexity Comparison

| Attribute | Junction Box | Marshalling Panel | System Cabinet |

|---|---|---|---|

| Equipment Cost | Low ($20 – $500) | Medium ($500 – $10,000+) | High ($2,000 – $100,000+) |

| Installation Time | Minutes to hours | Hours to days | Days to weeks |

| Design Complexity | Minimal | Moderate (wiring schedules, cross-wiring documentation) | High (control logic, power calculations, compliance) |

| Engineering Required | Basic electrical knowledge | Instrumentation/control engineering | Electrical and control system engineering |

| Maintenance Needs | Minimal (periodic inspection) | Low to moderate (terminal tightness checks) | Moderate to high (component testing, calibration) |

| Typical Lifespan | 20-30 years (enclosure) | 15-25 years | 15-20 years (components may need replacement) |

Application Matrix: Which Equipment for Which Job?

Choosing the right enclosure depends on your specific application. This matrix provides practical guidance.

| Application Scenario | Recommended Equipment | Why This Choice? |

|---|---|---|

| Consolidating power wiring from 5 outdoor lights | Junction Box | Simple protection for wire connections; no signal processing needed |

| Field wiring collection point 200m from control room | Junction Box | Cost-effective transition from field conduits to main cable run |

| Connecting 50 temperature and pressure sensors to DCS | Marshalling Panel | Requires signal organization, cross-wiring, and possibly IS barriers |

| Interface between field instruments and PLC in refinery | Marshalling Panel | Hazardous area requires IS barriers; extensive instrumentation needs organized routing |

| Controlling 10 motors with VFDs, start/stop, and alarms | System Cabinet (MCC) | Active motor control requires drives, contactors, circuit protection, HMI |

| Automated packaging line with PLC, sensors, conveyors | System Cabinet (PLC Cabinet) | Full automation requires PLC, I/O modules, power distribution, operator interface |

| Protecting outdoor solar panel string connections | Junction Box | Simple wire protection; combiner box functionality |

| Building HVAC system with 100+ control points | Marshalling Panel + System Cabinet | Marshalling panel organizes field signals; system cabinet houses BMS controllers |

| Main electrical distribution for manufacturing facility | System Cabinet (Switchgear) | Power distribution requires circuit breakers, metering, protection relays |

| Connecting 3 pumps to existing motor starters | Junction Box | Simple power wiring consolidation; control already exists |

Industry-Specific Guidance

Oil & Gas:

- Field junction boxes for wellhead and pipeline instrumentation

- Marshalling panels with IS barriers for hazardous area signal interface

- System cabinets for compressor control, pump control, and SCADA integration

Manufacturing:

- Junction boxes for machine-level power distribution

- Marshalling panels for large instrumentation networks (100+ sensors)

- System cabinets for machine control, production line automation, motor control centers

Water/Wastewater:

- Junction boxes for field sensor connections (level, flow, pH)

- Marshalling panels for treatment plant instrumentation (SCADA interface)

- System cabinets for pump control, chemical dosing, and process automation

Commercial Buildings:

- Junction boxes for lighting circuits, HVAC power distribution

- System cabinets for building management systems (BMS), elevator control, fire alarm panels

How to Choose the Right Equipment

Use this decision framework to select the appropriate enclosure for your project:

Step 1: Define Your Primary Need

Ask yourself: What is the primary function I need?

- Wire protection only? → Junction Box

- Signal routing and organization? → Marshalling Panel

- Active control, automation, or power distribution? → System Cabinet

Step 2: Evaluate Complexity

Choose a Junction Box if:

- You’re simply protecting wire splices or connections

- No signal processing or control logic is needed

- Budget is limited and functionality is basic

- Installation must be quick and simple

Choose a Marshalling Panel if:

- You have 20+ instrumentation signals to organize

- Signals need to be sorted and routed to specific I/O channels

- You’re interfacing field devices with DCS/PLC/SCADA

- Hazardous area applications require IS barriers

- Future system expansion requires flexible wiring

Choose a System Cabinet if:

- You need to control motors, pumps, or automated machinery

- The application requires a PLC, HMI, or control logic

- Circuit protection (breakers, fuses) is part of the system

- Power distribution to multiple loads is required

- Operator interface and monitoring is essential

Step 3: Consider Environmental Factors

All three equipment types can be specified with appropriate environmental ratings (IP/NEMA). However:

- Outdoor/Harsh Environments: Junction boxes offer the widest range of weatherproof and corrosion-resistant options

- Hazardous Locations: Marshalling panels with IS barriers or explosion-proof enclosures; system cabinets can be specified for Division 1/2 or Zone 1/2 areas

- Clean Rooms/Food Processing: Stainless steel construction available for all three types

Step 4: Budget and Lifecycle Costs

- Junction boxes: Lowest upfront cost, minimal ongoing maintenance

- Marshalling panels: Moderate cost, low maintenance (terminal inspections)

- System cabinets: Highest cost, ongoing maintenance for active components

For VIOX Electric’s complete range of junction boxes, marshalling panel components (terminal blocks, DIN rail accessories), and system cabinet solutions, consult with our technical team to specify the right equipment for your project.

Frequently Asked Questions

Q: Can a marshalling panel replace a junction box?

A: Technically yes, but it’s over-engineered and expensive. A marshalling panel includes terminal blocks and organization features you don’t need for simple wire protection. Use a junction box unless you specifically need signal routing and cross-wiring capabilities.

Q: When would I use both a marshalling panel and a system cabinet?

A: This is common in large control systems. The marshalling panel sits between field instruments and the system cabinet, organizing hundreds or thousands of signals before they connect to the PLC or DCS. The system cabinet houses the controller, power supplies, and operator interface. This separation improves maintainability and allows work on one without disrupting the other.

Q: Are junction boxes always smaller than marshalling panels?

A: Generally yes, but not always. Large junction boxes (24″ × 24″) used as pull boxes in conduit systems can be physically larger than small marshalling panels. The key difference isn’t size—it’s function. Junction boxes protect connections; marshalling panels organize and route signals.

Q: Do I need special training to install a marshalling panel?

A: Installation doesn’t require special certification, but you need understanding of instrumentation wiring, signal types (4-20mA, digital I/O, HART), and cross-wiring documentation. Electricians experienced with control systems can handle it, but it’s more complex than junction box installation.

Q: Can VIOX Electric provide custom system cabinets?

A: Yes. VIOX offers custom-engineered system cabinets for motor control, PLC systems, and power distribution applications. Our engineering team can design, build, and test complete control panels to your specifications, including UL 508A compliance for North American installations.

Q: What’s the difference between a marshalling panel and a PLC cabinet?

A: A PLC cabinet is a type of system cabinet that houses the PLC itself and its I/O modules. A marshalling panel doesn’t contain the PLC—it sits upstream, organizing field signals before they reach the PLC cabinet. In smaller systems, marshalling functionality may be integrated directly into the PLC cabinet.

Q: How do I know what IP rating I need for my junction box?

A: Consider your environment: Indoor dry locations need IP20-IP54. Outdoor or wet industrial areas need IP65 minimum. Areas with high-pressure washdown (food processing) require IP66 or IP67. Temporary water immersion (flooding risk) requires IP67 or IP68. Consult NEC Article 314 and local codes for specific requirements.

Conclusion

Junction boxes, marshalling panels, and system cabinets serve distinct roles in industrial electrical systems. Junction boxes provide simple wire protection. Marshalling panels organize and route instrumentation signals. System cabinets house complete control, automation, and power distribution systems.

Understanding these differences ensures you specify the right equipment—avoiding over-engineering (and overspending) or under-engineering (and compromising functionality). The comparison tables and application matrix in this guide help you select equipment across diverse industrial applications.

VIOX Electric manufactures a comprehensive range of electrical enclosures, terminal blocks, DIN rail components, and control panel solutions for industrial and commercial applications. Whether you need rugged junction boxes for harsh environments, marshalling panel components for instrumentation systems, or custom-engineered system cabinets, our technical team provides expert guidance from specification through installation.

Contact VIOX Electric today to discuss your project requirements and receive customized solutions for your electrical infrastructure needs.