컨택터와 릴레이의 주요 차이점은 전류 용량과 적용 범위입니다. 컨택터는 모터 및 HVAC 시스템과 같이 높은 전류 부하(일반적으로 9암페어 초과)를 위해 설계된 강력한 전자 스위치인 반면, 릴레이는 낮은 전류 제어 회로(일반적으로 10암페어 미만) 및 신호 스위칭을 위한 정밀 스위치입니다. 올바른 장치를 선택하면 전기 안전, 규정 준수를 보장하고 장비 고장을 방지할 수 있습니다.

이러한 차이점을 이해하는 것은 산업 엔지니어, 전기 계약자 및 시설 관리자에게 매우 중요합니다. 잘못 선택하면 접점이 용접되고, 불필요한 고장이 발생하며, NEC Article 430에 따라 잠재적인 규정 위반이 발생할 수 있습니다. 이 가이드에서는 각 장치를 언제 사용해야 하는지, 적절한 크기를 결정하는 방법, 규정을 준수하는 전기 시스템에 통합하는 방법을 명확히 설명합니다.

접촉기와 릴레이는 무엇인가?

접촉기 정의

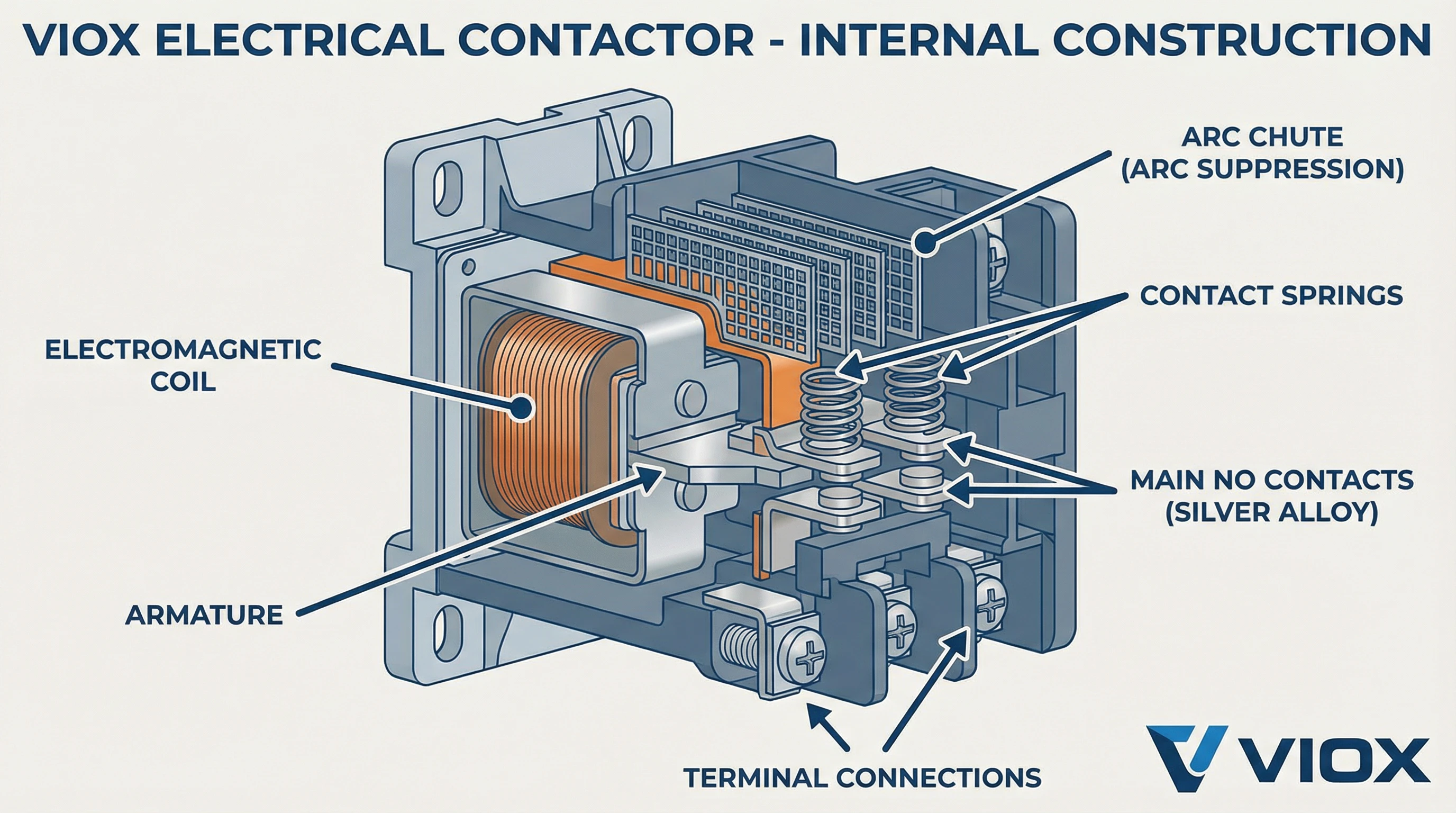

A 접촉기 은 고전력 부하 회로(가장 일반적으로 3상 모터, 대형 팬, HVAC 압축기 및 산업용 발열체)를 연결하고 분리하는 전기적으로 제어되는 스위치입니다. 컨택터는 내장된 아크 억제 메커니즘을 통해 부하 상태에서 빈번한 스위칭을 위해 설계되었습니다.

주요 특징:

- 은 합금 또는 텅스텐 접점을 사용한 견고한 구조

- 제어 전원 손실 시 개방되는 Normally-open(NO) 주 접점

- 고에너지 회로의 안전한 차단을 위한 내장형 아크 슈트

- 9암페어에서 1000암페어 이상의 전류 정격

- IEC 60947-4-1 및 UL 508 표준에 따라 설계

and auxiliary contacts for industrial motor control applications.png)

릴레이 정의

A 계전기 은 작은 제어 신호를 사용하여 별도의 회로를 제어하는 접점을 작동시키는 전자기 스위칭 장치입니다. 릴레이는 정밀도와 컴팩트한 크기가 요구되는 제어 로직, 자동화 인터페이스 및 신호 스위칭에 탁월합니다.

주요 특징:

- DIN 레일 또는 PCB 장착에 최적화된 컴팩트한 구조

- 다중 접점 구성: SPDT, DPDT, NO, NC, 전환

- 일반적으로 0.1~10암페어의 전류 정격

- 빠른 스위칭 속도(1~20밀리초)

- IEC 61810 및 UL 508 표준에 따라 설계

주요 차이점: 컨택터 대 릴레이

종합 비교표

| 기능 | 접촉기 | 릴레이 |

|---|---|---|

| 현재 평가 | 9-1000+ 암페어 | 0.1~10 암페어 |

| 1차 응용 프로그램 | 전원 회로 스위칭 | 제어 회로 스위칭 |

| 연락처 구성 | NO 주 접점 + 보조 | NO, NC, SPDT, DPDT 옵션 |

| 아크 억제 | 내장형 아크 슈트 | 최소 또는 없음 |

| 물리적 크기 | 대형(3-12인치) | 컴팩트(0.5~3인치) |

| 전압 평가 | 120V~1000V AC | 5V~480V AC/DC |

| 전환 속도 | 중간(50-100ms) | 빠름(1~20ms) |

| 비용 범위 | $50-500+ | $5-100 |

| 일반적인 표준 | IEC 60947-4-1, UL 508 | IEC 61810, UL 508 |

| 기계 수명 | 1~1000만 건의 작업 | 1000만~1억 건의 작업 |

부하 용량 및 전압

주요 차이점은 전류 처리 용량에 있습니다. 컨택터는 모터 시동 시 일반적인 높은 돌입 전류(종종 작동 전류의 6~8배)를 처리합니다. 릴레이는 이러한 조건을 견딜 수 없으며 전원 회로에 잘못 적용하면 용접되거나 조기에 고장납니다.

컨택터는 최대 1000V의 3상 AC 전원 시스템용으로 제작되었습니다. 릴레이는 단상 또는 저전압 DC/AC 제어 회로에 사용됩니다. 모터 애플리케이션은 항상 주 전원 경로에 릴레이가 아닌 컨택터가 필요합니다.

아크 에너지 관리

고전류 부하를 스위칭할 때 개방 접점 사이에 전기 아크가 형성됩니다. 컨택터에는 아크를 안전하게 분할, 냉각 및 소멸시키는 금속 장벽인 아크 슈트가 통합되어 있습니다. 이 기능은 릴레이에 없으므로 고에너지 차단에 적합하지 않습니다.

릴레이는 유도성 제어 부하를 스위칭할 때 외부 억제(플라이백 다이오드, RC 스너버)가 필요합니다. 억제가 없으면 접점 수명이 급격히 감소합니다.

접점 구성 및 보조 기능

컨택터는 일반적으로 상태 표시 및 인터로킹을 위한 보조 접점과 함께 NO 주 접점을 특징으로 합니다. 이 구성은 제어 전원 손실 시 회로가 개방되는 안전 장치 동작을 제공합니다.

릴레이는 제어 로직에 필수적인 유연한 접점 형태(NO, NC, 전환)를 제공합니다. 단일 릴레이는 여러 회로를 동시에 연결하고 끊을 수 있어 복잡한 자동화 시퀀스를 가능하게 합니다.

응용 프로그램 및 사례

접촉기를 사용할 때

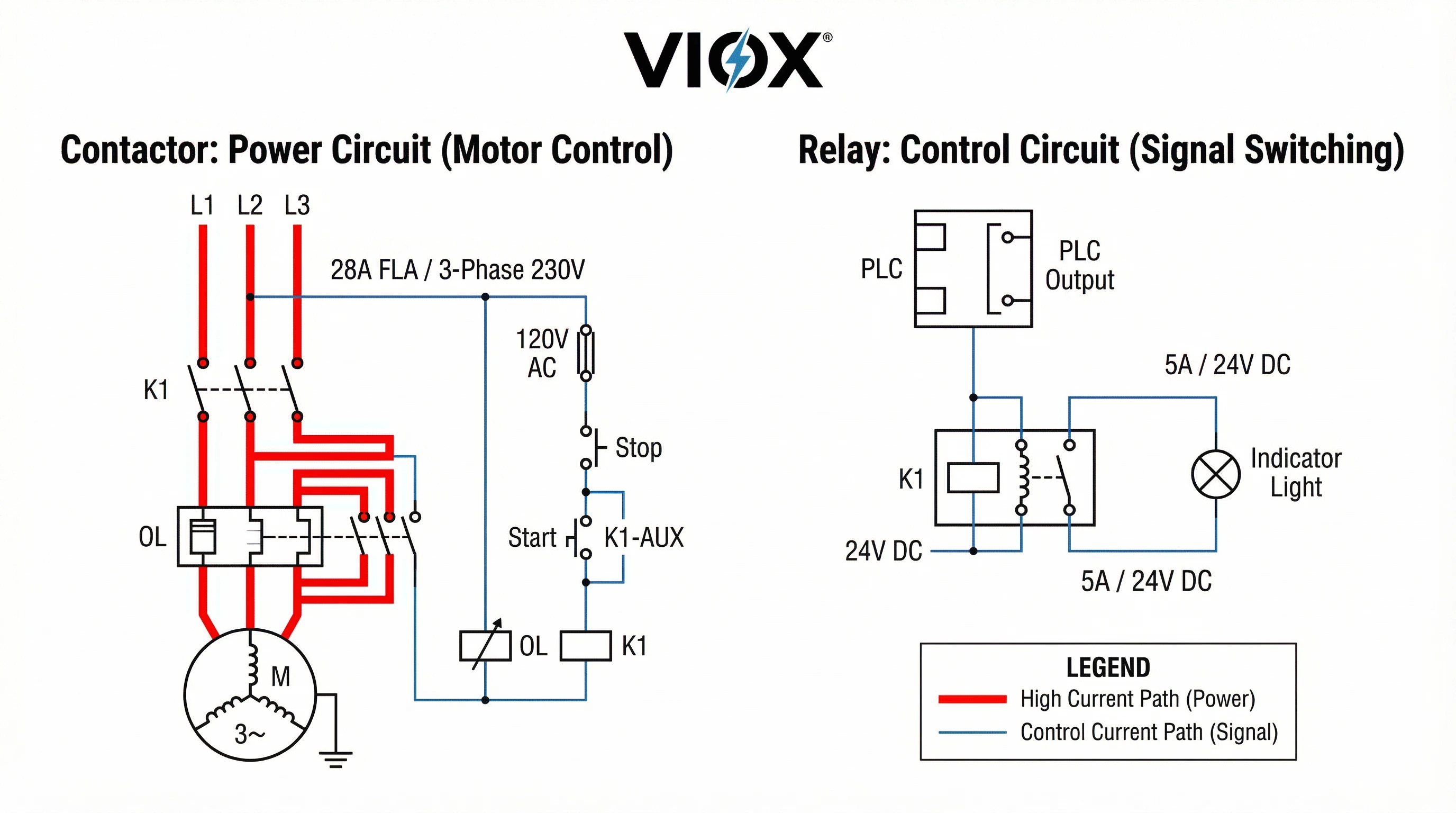

3상 모터 제어

모터 시동은 컨택터 애플리케이션의 대표적인 예입니다. NEC Article 430에서는 과부하 장치 및 분기 회로 단락 보호를 포함한 적절한 모터 회로 보호를 요구합니다. 컨택터는 모터 시동기의 제어 스위칭 요소 역할을 합니다.

- 펌프 및 압축기: 5~200HP 산업용 모터

- 컨베이어 시스템: 빈번한 시작/정지 듀티 사이클

- 공작 기계: 조정된 다중 모터 제어

- 팬 및 송풍기: HVAC 및 산업 환기

컨택터 크기 조정은 NEC 430.83을 따릅니다. 장치는 NEC 표 430.251(B)에 따라 고정 로터 전류를 처리해야 합니다. 10HP, 230V 3상 모터(FLA 28A)의 경우 적절한 돌입 기능을 갖춘 최소 35A 연속 정격의 컨택터를 선택하십시오.

HVAC 전원 회로

상업용 및 산업용 HVAC 시스템은 컨택터를 사용하여 압축기, 응축기 및 전기 발열체를 전환합니다. 이러한 부하는 높은 돌입 전류를 소비하며 IEC 60947-4-1에 따라 AC-3 듀티 정격을 가진 장치가 필요합니다.

- 옥상 장치: 30~90A 정격의 압축기 컨택터

- 냉각기 시스템: 시퀀스 시작을 위한 다중 컨택터

- 전기 히터: 높은 정상 상태 전류를 갖는 저항성 부하

고용량 조명

산업 시설, 주차장 및 스포츠 경기장에서는 중앙 집중식 조명 제어를 위해 컨택터를 사용합니다. 개별 회로는 20A 미만일 수 있지만 여러 회로를 동시에 스위칭하려면 컨택터의 견고성이 필요합니다.

릴레이를 사용하는 경우

제어 회로 스위칭

릴레이는 산업 제어 로직의 중추를 형성합니다. PLC, 센서 및 제어 장치 간에 인터페이스하여 전기적 절연 및 로직 기능을 제공합니다.

- 안전 인터록: 비상 정지 회로, 가드 모니터링

- 순차 제어: 단계별 공정 자동화

- 경보 시스템: 고장 표시 및 이벤트 로깅

- PLC I/O 확장: 이산 입력/출력 모듈

제어 회로는 일반적으로 24V DC 또는 120V AC에서 작동합니다. 릴레이 코일은 제어 전압과 일치하고 접점은 부하 회로를 전환하여 제어 도메인과 전력 도메인 간에 전기적 절연을 달성합니다.

신호 및 데이터 스위칭

릴레이는 계측, 통신 및 테스트 장비에서 저전류 신호를 처리합니다. 빠른 스위칭과 깨끗한 접점 폐쇄는 정밀한 타이밍 및 라우팅 애플리케이션에 이상적입니다.

- 오디오/비디오 라우팅: 스튜디오 스위칭 매트릭스

- 테스트 장비: 자동화된 측정 시스템

- 빌딩 자동화: 온도 조절 장치 인터페이스, 조명 제어

- 자동차 시스템: 연료 펌프, 시동 모터, 액세서리 제어

파일럿 듀티 애플리케이션

릴레이는 종종 접촉기 코일을 제어하여 제어 계층 구조를 만듭니다. PLC에서 작동하는 작은 24V DC 릴레이는 120V AC 전원을 접촉기 코일로 전환하고, 그런 다음 3상 모터를 전환합니다. 이 캐스케이딩 제어는 절연을 제공하고 제어 배선 비용을 줄이며 원격 작동을 가능하게 합니다.

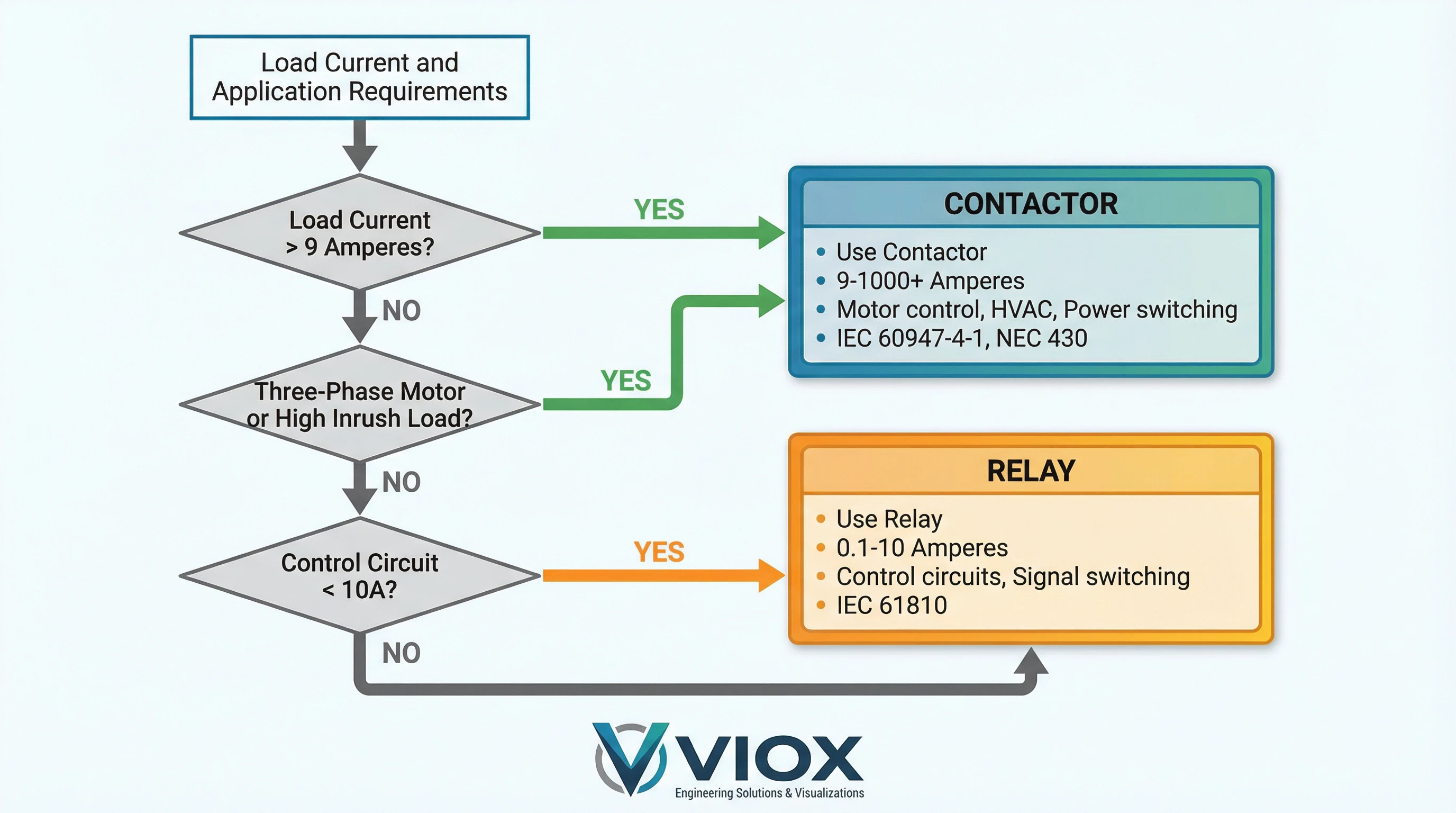

선택 기준: 선택 방법

1단계: 부하 전류 계산

부하의 정상 상태 전류 및 돌입 전류를 결정합니다. 모터의 경우 명판 FLA(전부하 전류)를 사용하고 NEC 표 430.251(B)에서 고정 로터 전류를 계산합니다.

히터와 같은 저항성 부하의 경우 돌입 전류는 정상 상태와 같습니다. 커패시티브 부하(전원 공급 장치, LED 드라이버)의 경우 제조업체에 돌입 전류 사양을 측정하거나 요청하십시오.

경험 법칙: 정상 상태 전류가 9-10암페어를 초과하거나 돌입 전류가 상당한 경우 접촉기를 사용하십시오.

2단계: 전압 및 위상 일치

시스템 전압 및 위상 구성을 확인합니다. 3상 모터 회로에는 3극 접촉기가 필요합니다. 단상 부하는 전류에 따라 접촉기 또는 고부하 릴레이를 사용할 수 있습니다.

DC 회로의 경우 DC 아크가 AC 아크보다 소멸하기 어렵다는 점에 유의하십시오. 적절한 전압 정격으로 DC 작동에 특별히 정격된 장치를 사용하십시오.

3단계: 듀티 사이클 및 스위칭 빈도 평가

- AC-3: 정상 모터 듀티(시작, 실행, 중지)

- AC-4: 헤비 모터 듀티(플러깅, 조깅, 인칭)

릴레이에는 기계적 및 전기적 수명 사양이 있습니다. 5A에서 1천만 번 작동하도록 정격된 릴레이는 최대 정격 전류에서 100,000번만 작동할 수 있습니다.

4단계: 제어 인터페이스 고려

제어 시스템과 일치하는 코일 전압을 선택합니다. 일반적인 옵션: 24V DC(PLC 제어), 120V AC(파일럿 듀티), 24V AC(HVAC 제어).

상태 피드백, 인터로킹 또는 다운스트림 제어에 보조 접점이 필요한지 확인합니다. 접촉기에는 일반적으로 추가 보조 접점 블록이 포함되거나 지원됩니다.

빠른 선택 가이드

| 부하 전류 | 애플리케이션 유형 | 장치 선택 | 주요 표준 |

|---|---|---|---|

| < 5A | 제어 회로 | 범용 릴레이 | IEC 61810 |

| 5-9A | 경전력 스위칭 | 전원 릴레이 또는 소형 접촉기 | UL508 |

| 9-30A | 단상/3상 모터 | 접촉기(AC-3 정격) | NEC 430, IEC 60947-4-1 |

| 30-100A | 산업용 모터, HVAC | 표준 접촉기 | NEC 430.83 |

| > 100A | 중공업 | 중부하 접촉기 | IEC 60947-4-1 |

설치 및 안전 요구 사항

모터 회로 보호(NEC Article 430)

과부하 보호

- 모터 FLA의 125% 서비스 계수가 ≥1.15이거나 40°C 온도 상승이 있는 모터의 경우

- 모터 FLA의 115% 기타 모든 모터의 경우

과부하 릴레이는 종종 모터 시동기 어셈블리에 접촉기와 통합됩니다. 1.15 서비스 계수가 있는 28A FLA 모터의 경우 과부하 트립을 최대 35A(28A × 1.25)로 설정합니다.

분기 회로 보호

- 반한시 차단기: 28A × 2.5 = 최대 70A

- 순시 트립 차단기: 28A × 8 = 최대 224A

- 시간 지연 퓨즈: 28A × 1.75 = 최대 49A

도체 크기 조정

NEC 430.22에서는 도체를 모터 FLA의 최소 125%로 크기를 조정해야 합니다. 28A 모터의 경우: 28A × 1.25 = 최소 35A 정격 전류. 설치 조건에 따라 NEC 표 310.16 또는 310.17에서 도체를 선택합니다.

제어 회로 설치

- 적절한 전선 크기 조정: 제어 회로 전류 및 온도 정격 일치

- 유도성 부하 억제: DC 코일용 플라이백 다이오드, AC 부하용 RC 스너버

- 명확한 문서화: 회로도에 따라 접점 형식(NO/NC) 및 단자 번호 라벨링

- 과전류 보호: Class 1 제어 회로용 NEC 725에 따른 퓨즈 또는 차단기

문제 해결 빠른 가이드

- 부하 상태에서 멀티미터로 코일 전압 확인

- 제어 회로 연속성 및 보호 장치 점검

- 기계적 장애물 또는 마모된 연결부 검사

- 코일 저항 테스트 (일반적으로 정격에 따라 10-1000옴)

- 부하 전류 측정; 접촉기 정격 내에 있는지 확인

- 과도한 돌입 전류 또는 단락 상태 점검

- 아크 슈트 상태 및 접점 정렬 검사

- 적절한 AC-3/AC-4 범주로 더 높은 정격 장치로 업그레이드

- 부하 전류 대 접점 정격 평가

- 유도성 부하에 대한 억제 추가 (다이오드, 스너버)

- 오염된 환경을 위해 밀폐형 릴레이로 교체

- 스위칭 빈도가 정격 전기적 수명을 초과하지 않는지 확인

자주 묻는 질문

고전력 애플리케이션에서 접촉기를 더 안전하게 만드는 요인은 무엇입니까?

접촉기는 고전류 회로를 차단할 때 발생하는 전기 아크를 분할, 냉각 및 소멸시키는 아크 슈트를 통합합니다. 이러한 내장형 아크 억제 기능은 견고한 접점 재료 및 기계적 구조와 결합되어 표준 릴레이를 파괴할 수 있는 모터 및 기타 고에너지 부하의 안전한 반복 스위칭을 가능하게 합니다.

릴레이가 모터 제어를 위해 접촉기를 대체할 수 있습니까?

아니요. 모터 주 회로 스위칭에 릴레이를 사용하는 것은 위험하며 NEC 430조항을 위반합니다. 모터 기동 전류(정상 작동 전류의 6~8배)는 릴레이 접점을 용접시켜 화재 위험을 초래할 수 있습니다. 릴레이는 모터 회로에 필요한 아크 억제, 접점 질량 및 전류 용량이 부족합니다. 모터 애플리케이션에는 NEC 430.83에 따라 정격된 접촉기를 사용하십시오.

3상 모터용 접촉기 크기는 어떻게 결정합니까?

모터 명판의 FLA와 NEC 표를 활용하십시오. IEC 60947-4-1에 따라 적절한 AC-3 정격으로 모터 FLA의 최소 125%를 처리할 수 있는 정격의 접촉기를 선택하십시오. NEC 표 430.251(B)에 따라 접촉기가 구속 회전자 전류를 처리할 수 있는지 확인하십시오. 50 HP, 460V 모터(65A FLA)의 경우 최소 81A 연속 정격(65A × 1.25)의 접촉기를 선택하십시오.

보조 접점은 언제 사용해야 합니까?

- PLC 상태 모니터링 (접촉기 닫힘/열림 표시)

- 안전 인터록 (여러 접촉기가 동시에 닫히는 것을 방지)

- 순차 제어 (접촉기 A가 닫혀야 접촉기 B가 작동)

- 경보 회로 (예상치 못한 접촉기 상태를 운영자에게 알림)

결론

고전류 전력 스위칭용 접촉기 선택 특히 3상 모터, HVAC 압축기, 아크 억제를 통해 빈번한 스위칭이 필요한 산업 부하의 경우 9암페어 초과. 제어 회로용 릴레이 선택 정밀도, 속도, 유연한 접점 형식 및 컴팩트한 크기가 우선 순위인 10암페어 미만.

적절한 선택은 전기 안전, NEC Article 430에 따른 코드 준수 및 안정적인 시스템 작동을 보장합니다. 항상 장치 정격을 부하 특성, 듀티 사이클 및 보호 장치와 조정하십시오. 의심스러운 경우 NEC 표, 장비 데이터 시트를 참조하고 중요한 응용 분야에 대한 전문 엔지니어링 검토를 고려하십시오.

VIOX Electric은 산업용 등급 접촉기 및 릴레이를 제조합니다. B2B 애플리케이션용. 당사의 엔지니어링 팀은 모터 제어, HVAC 및 자동화 시스템에 대한 애플리케이션 지원을 제공합니다. 프로젝트 요구 사항에 맞는 장치 선택 지원 및 기술 사양에 대해서는 당사에 문의하십시오.