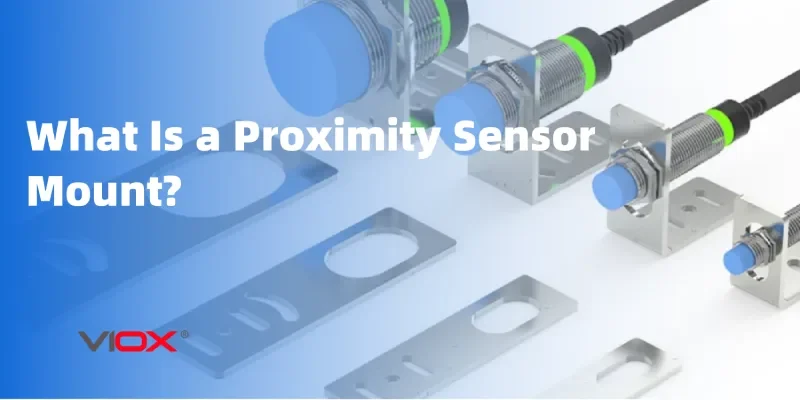

近接センサーマウントは産業オートメーションに不可欠なコンポーネントで、センサーを確実に位置決めして保護すると同時に、さまざまな製造および生産環境で最適な性能を発揮するための精密な調整を可能にするように設計されています。

目的とメリット

近接センサーマウントは、産業環境において複数の重要な機能を果たします。センサを確実に取り付けるための安定したプラットフォームを提供し、正確な検出と信頼性の高い動作を保証します。これらのマウントは、物理的な損傷や環境要因からの保護を提供し、センサの寿命を延ばし、メンテナンスコストを削減します。さらに、多くの設計には調整機能が組み込まれており、工具や大規模な再調整を必要とせずに、正確な位置決めと簡単なセンサ交換が可能です。この柔軟性はシステム全体の効率を高め、メンテナンスやセンサーのアップグレード時のダウンタイムを最小限に抑えます。

センサーマウントの種類

近接センサーマウントは、異なるセンサー設計とアプリケーション要件に対応するために様々なタイプがあります。ここでは、一般的なセンサーマウントの種類をご紹介します:

- シングルプレートタイプ: これらのマウントは、シンプルでフラットなデザインが特徴で、センサーを簡単に取り付けることができます。標準型とZ型があり、さまざまな取り付け方向に柔軟に対応します。

- クイックマウント: 迅速な取り付けと簡単な調整のために設計されたクイックマウントブラケットは、大掛かりな工具を使用せずに効率的なセンサーの位置決めを可能にします。

- 直角マウント: これらのブラケットにより、センサーを90度の角度で取り付けることができ、垂直方向のセンシングが必要なアプリケーションに最適です。

- ポジティブ・ストップ・マウント: 内蔵ストップを備えたこれらのマウントは、センサーに信頼性の高い保護と正確な位置決めを提供し、安定した検出範囲を確保します。

- リミットスイッチ取り付けブラケット: リミットスイッチ用に特別に設計されたこれらのブラケットは、確実な取り付けと適切なアライメントを提供し、正確な終端検出を実現します。

- 調整可能なマウント: これらの多用途ブラケットは、センサー位置の微調整を可能にし、多くの場合、最適な配置のためのスロットや複数の取り付けポイントを組み込んでいる。

各タイプのマウントは、さまざまな産業オートメーションシナリオにおいて、センサーの性能、保護、設置の容易さを高めるように設計されています。

素材とサイズ

近接センサーマウントは、ステンレス(SUS304)、スチール(SPCC)、PPS/ST/ZN複合材など、さまざまな産業環境に適したさまざまな材質をご用意しています。これらの材料は、耐久性と耐腐食性を提供し、厳しい条件下での長寿命を保証します。さまざまなセンサー径に対応するため、サイズはさまざまで、通常M5からM304の範囲です。一部のマウントは、組み立てと調整を容易にする縦型スロットポケット設計を特徴とし、他のマウントは、単一工具による締め付けを可能にする統合保持ギャップを組み込み、取り付け効率を向上させます。

情報源:vn.misumi、hellermanntyton.us

産業用途

製造業やオートメーション分野で広く導入されている近接センサマウントは、生産効率と安全性を高める上で重要な役割を果たしています。正確な物体検出が不可欠なコンベアシステム、梱包装置、ロボット組立ラインなどでよく見られます。これらのマウントは、センサーが製品の流れを正確に監視し、機械操作を制御し、ダイナミックな産業環境での衝突を防止することを可能にします。自動車製造では、部品の適切な配置と組み立てを保証することで、品質管理プロセスを支援します。さらに、近接センサーマウントは、食品や飲料の生産ラインで、製品や包装材を衛生的に非接触で検出するために利用され、製品品質の向上と汚染リスクの低減に貢献しています。