What Separates a $200 ATS from a $2,000 One?

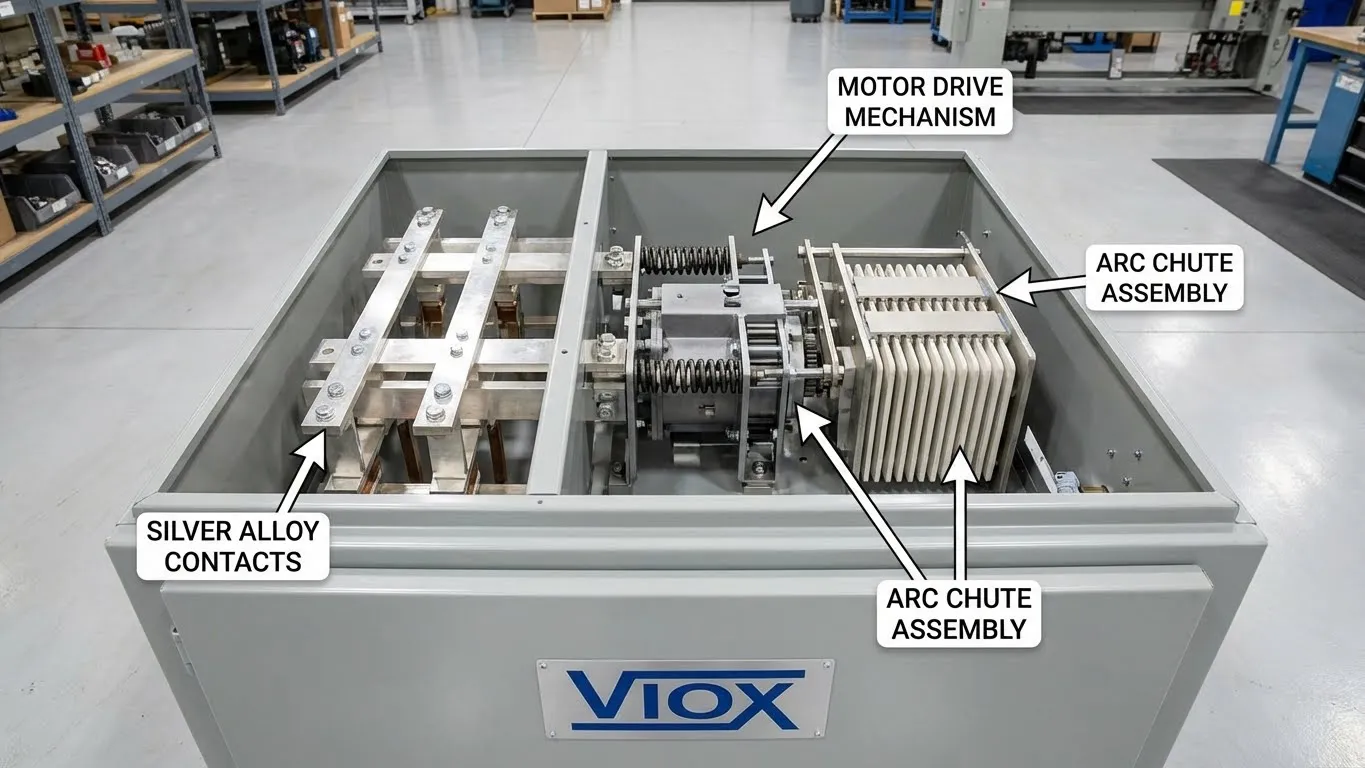

The price gap between budget and premium automatic transfer switches reflects fundamental differences in three critical subsystems: contacts, drive mechanisms, and arc quenching chambers. Quality ATS units feature precision-engineered contacts from silver refractory alloys, motor-driven mechanisms rated for 100,000+ cycles, and arc chambers that safely interrupt 65kA fault currents in under 20 milliseconds.

This article examines the engineering inside high-quality transfer switches. These aren’t marketing features—they’re measurable specifications that determine whether your ATS performs reliably for 20 years or fails catastrophically during its first fault event. Understanding these differences helps you specify equipment that matches your application’s demands.

Part 1: Contact Materials—Where Current Actually Flows

Why Contact Material Selection Matters

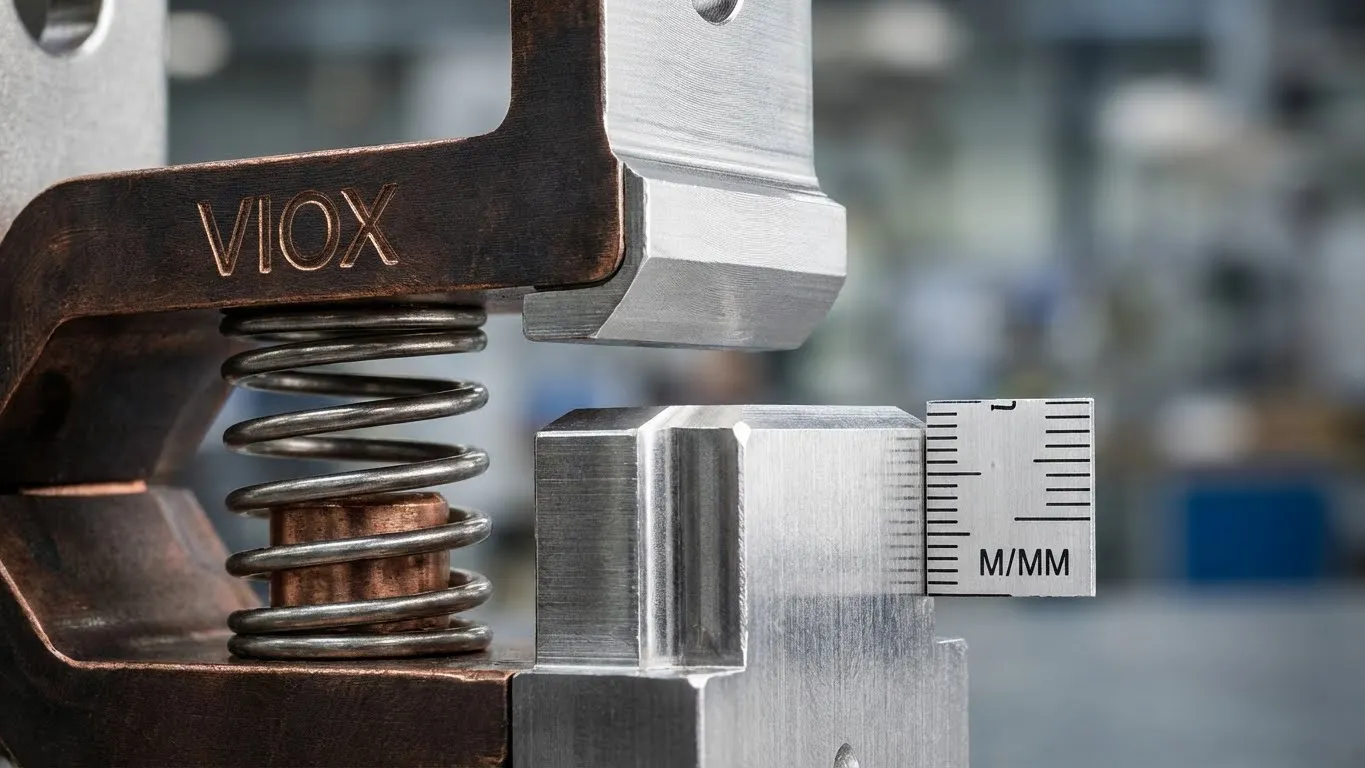

Electrical contacts in an ATS carry 100% of your facility’s power while mechanically cycling thousands of times over their service life. This creates an engineering paradox: you need maximum electrical conductivity (low resistance = less heat) plus mechanical durability to withstand repeated cycling and resist welding during arc events. Contact resistance directly affects operating temperature—a contact pair with just 100 microohms resistance carrying 400A generates 16 watts of continuous heat. Quality contacts maintain resistance below 50 microohms throughout their rated cycle life, which is critical when understanding how contacts function differently from circuit breakers.

The Contact Material Hierarchy

Pure Silver (Ag 99.9%+): Offers the highest electrical conductivity at 105% IACS (International Annealed Copper Standard) with thermal conductivity of 429 W/(m·K). However, pure silver’s hardness of only 75-200 HV makes it too soft for most switching applications—limited to low-current signaling or plating over harder base metals.

Silver-Copper Alloys (AgCu): Sterling silver (92.5% Ag, 7.5% Cu) and coin silver (90% Ag, 10% Cu) achieve hardness of 80-110 HV while retaining 85-90% IACS conductivity. These alloys provide adequate wear resistance for residential and light commercial ATS rated up to 200A. VIOX specifies AgCu alloys in residential-grade units where cost optimization matters but reliability cannot be compromised.

Silver Refractory Materials (AgW, AgWC): Silver tungsten and silver tungsten carbide composites combine silver’s conductivity (50-60% IACS) with exceptional arc erosion resistance. Tungsten’s 3,422°C melting point and tungsten carbide’s extreme hardness (1,500-2,000 HV) resist intense heat from repeated arc interruption. These powder-metallurgy composites handle fault currents reaching 10-20 times rated current. Commercial and industrial ATS units rated 400A and above typically use AgW or AgWC contacts.

Silver-Nickel Composites (AgNi): Fine-grain silver-nickel materials (AgNi 0.15) offer improved properties versus pure silver while maintaining 95-100% IACS conductivity. The nickel addition creates fine-grain microstructure that increases hardness and tensile strength with minimal conductivity penalty, resisting material transfer in DC circuits. These composites suit relay contacts and lighter-duty switching where full refractory arc resistance isn’t required.

Contact Mechanics and Spring Loading

Spring-loaded contact mechanisms solve a critical problem: slowly separating contacts create a “danger zone” where the gap sustains arcs while generating significant heat. High-quality ATS designs use over-center spring mechanisms storing mechanical energy during opening, then releasing rapidly to accelerate contacts through the danger zone in under 10 milliseconds. The spring maintains contact force (typically 5-10 N) during closed state to minimize resistance and prevent chattering. Understanding proper contact operation and wet vs. dry contact principles becomes critical for reliability. As discussed in our ATS Troubleshooting Guide, weakened springs or mechanical wear are common failure modes leading to poor contact performance and eventual welding.

Contact Material Comparison Table

| Material Type | Conductivity (% IACS) | Hardness (HV) | Arc Erosion Resistance | Best Application |

|---|---|---|---|---|

| Pure Silver (Ag 99.9%) | 105% | 75-200 | Poor | Low-current signals, plating only |

| Silver-Copper (AgCu 92.5/7.5) | 85-90% | 80-110 | Fair | Residential ATS, light commercial (≤200A) |

| Silver-Tungsten (AgW) | 50-60% | 140-180 | Excellent | High-power commercial/industrial (≥400A) |

| Silver-Tungsten Carbide (AgWC) | 45-55% | 160-200 | Exceptional | Heavy industrial, fault-current applications |

| Silver-Nickel (AgNi 0.15) | 95-100% | 85-115 | Good | Relays, light-duty switching |

VIOX Contact Material Strategy

VIOX engineers select contact materials based on application requirements rather than cost minimization. Our residential and light commercial units (up to 200A) use sterling silver contacts providing optimal balance for typical backup generator applications. For commercial and industrial installations, VIOX specifies silver-tungsten contacts in all units rated 400A and above, recognizing these applications face higher fault current exposure requiring extended service life. When you’re wiring an ATS to a hybrid inverter, proper contact materials become even more critical due to frequent switching cycles and complex load characteristics.

Part 2: Drive Mechanisms—The Muscle Behind the Transfer

Motor-Operated Transfer Mechanisms

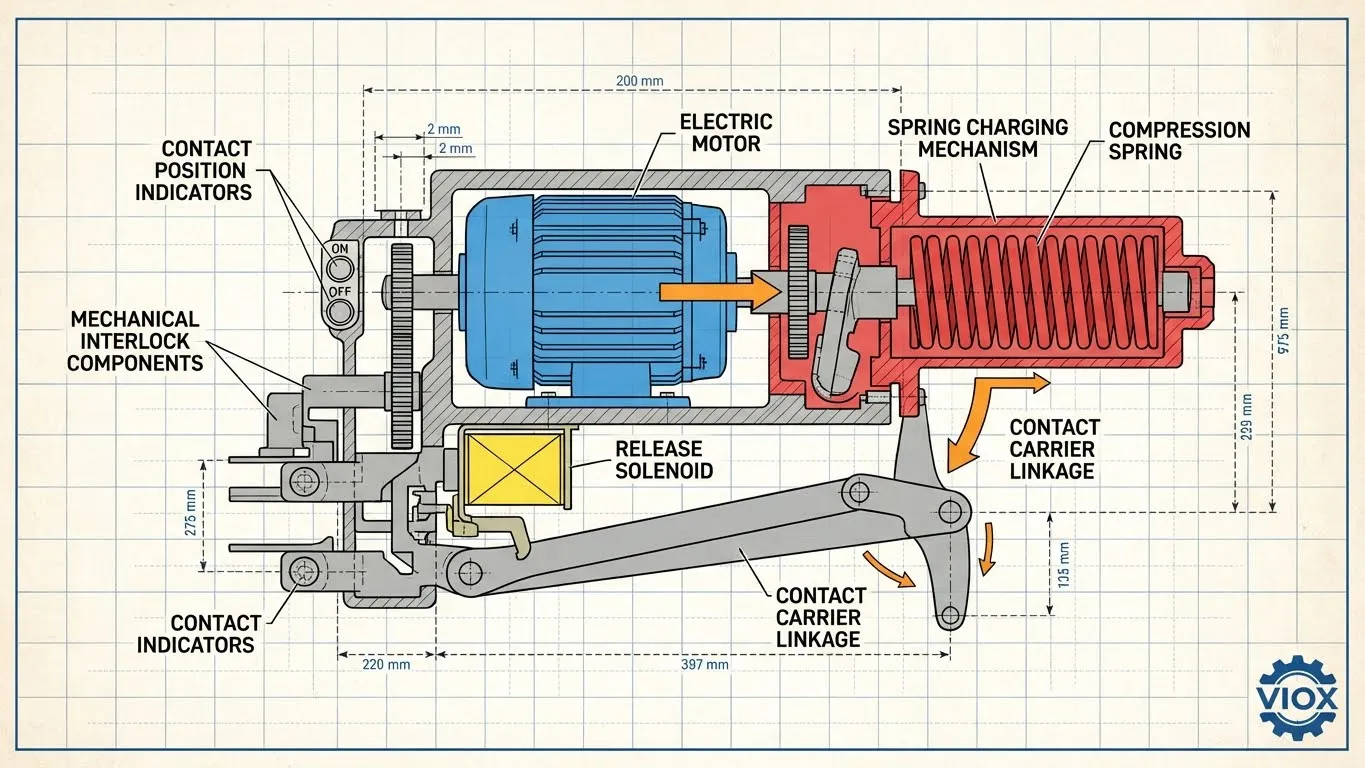

Motor-operated drives represent the most common mechanism in modern ATS equipment rated above 100A. The system uses a small AC motor (typically 120-240V, drawing less than 5W) to charge stored-energy springs. When the controller initiates transfer, an electromagnetic release unlocks the charged spring, rapidly driving the contact assembly through its travel in under 150 milliseconds. Similar principles apply whether you’re selecting between contactors and relays or transfer switches.

This two-stage approach decouples slow motor speed from fast contact motion required for arc suppression. The motor may take 2-3 seconds to charge springs, but once released, spring energy accelerates contacts through the critical separation zone in 10-15 milliseconds. This ensures consistent transfer speed regardless of supply voltage variations and provides mechanical advantage, allowing a small motor to operate heavy-duty contacts carrying 1000A or more.

Motor-operated mechanisms include both electrical and mechanical interlocking preventing simultaneous closure of both power sources. Quality designs incorporate both protection layers because electrical interlocks can fail due to contact welding or control circuit faults.

Solenoid-Operated Mechanisms

Solenoid-driven transfers use electromagnetic coils to directly move the contact assembly without intermediate spring charging. When energized with rated voltage (typically 24-120VDC), the solenoid plunger pulls the contact carrier from one position to the other, offering faster transfer times—often under 100 milliseconds—with simpler construction.

The primary limitation is power consumption. A solenoid moving a 400A contact assembly requires substantial pull force, translating to significant current draw (2-5A at rated voltage) during transfer motion. This limits solenoid mechanisms to smaller transfer switches. Solenoid mechanisms typically use holding coils or mechanical latches maintaining contact position without continuous power.

Spring-Operated/Mechanically Held Systems

These mechanisms store energy in compressed or tension springs during installation or manual charging. An electrical release allows the spring to drive the transfer while contacts remain mechanically held by over-center linkages requiring no power. This offers the advantage of operating even during complete power loss—if the spring is charged and the latch can be manually released, transfer will occur. However, they require manual spring recharging after each operation, limiting them to infrequently-switched applications.

Drive Mechanism Performance Specifications

Transfer time represents total duration from initiation signal to complete contact closure on the alternate source. Motor-operated mechanisms typically achieve 100-150ms total transfer time, while solenoid systems reach 50-100ms. Operating voltage range determines performance under brownout or overvoltage conditions—quality motor operators function across ±15% of nominal voltage. Mechanical cycle life ratings indicate expected operational lifespan: commercial-grade motor mechanisms are rated for 30,000-50,000 operations, while industrial units exceed 100,000 cycles.

Drive Mechanism Comparison Table

| Mechanism Type | Transfer Speed | Design Complexity | Typical Ampacity Range | Maintenance Needs |

|---|---|---|---|---|

| Motor-Operated | 100-150ms | Moderate (motor, springs, linkage) | 100A-5000A | Lubrication every 2-3 years |

| Solenoid-Operated | 50-100ms | Low (coil, plunger, latch) | 30A-400A | Minimal, check latch annually |

| Spring-Operated/Mech. Held | 80-120ms | Moderate (springs, release, latch) | 100A-1200A | Spring inspection, recharge mechanism |

VIOX Drive System Engineering

VIOX automatic transfer switches use motor-operated mechanisms across our commercial and industrial product lines. We selected this topology after extensive reliability analysis showed that decoupling charging and transfer motions provides the most consistent performance across the widest operating conditions. Our motor operators incorporate dual mechanical interlocks—both cam-based and lever-type—ensuring no single-point failure can result in simultaneous contact closure.

The VIOX motor drive system includes position feedback sensors verifying complete transfer before signaling the controller. This closed-loop approach prevents the common failure mode where partial transfer occurs but the control system assumes successful completion. Additionally, our designs incorporate manual emergency operation capability—a handle accessible through the front panel allows mechanical charging and release of the transfer mechanism even during complete electrical failure.

Part 3: Arc Quenching Technology—The Critical Safety System

The Arc Formation Problem

When electrical contacts carrying substantial current begin to separate, the initial air gap measures only micrometers. At this distance, electric field strength can exceed 3,000 V/mm, surpassing air’s breakdown voltage and sustaining a conductive plasma channel—an arc. This plasma consists of ionized gas and vaporized contact material at temperatures ranging from 3,500K in small arcs to over 20,000K during high-current interruption. Understanding what arcs are and how they behave and the essential role of arcs in circuit disconnection is fundamental to proper equipment selection.

For AC circuits, the arc naturally extinguishes at current zero-crossing (every 8.33ms on 60Hz power), but it will reignite on the next half-cycle unless the gap has been sufficiently deionized and cooled. During fault conditions, a 10kA fault current at 480V delivers 4.8 megawatts of power into the arc. Without proper quenching, this energy vaporizes contact material, carbonizes insulation, creates explosive pressure, and can weld contacts permanently closed.

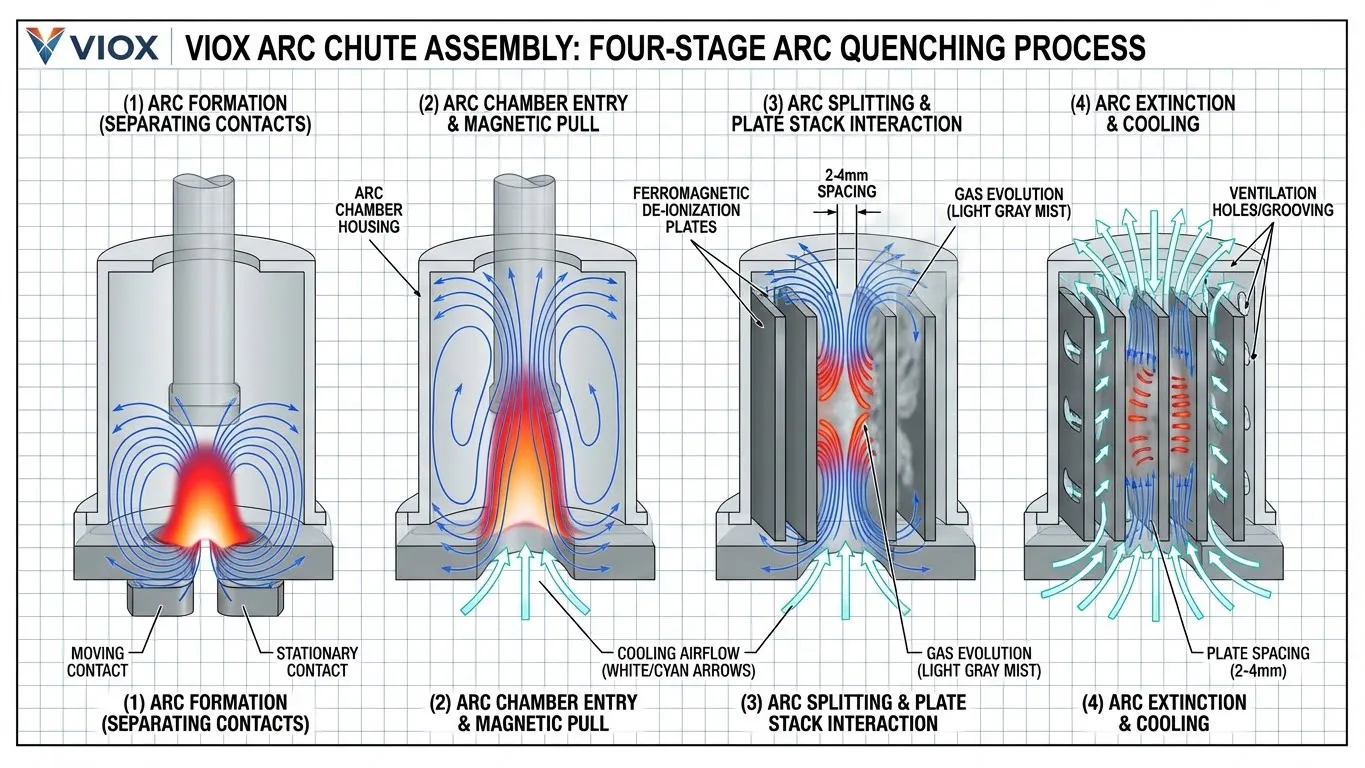

Arc Chute Design and De-Ionization Plates

The arc chute (also called arc chamber) forms the heart of any quality circuit interruption system. Its basic structure consists of a stack of ferromagnetic steel plates arranged parallel to each other with 2-4mm spacing. These de-ionization plates serve multiple functions simultaneously:

The magnetic properties create attraction forces pulling the arc away from contacts toward the stack. As fault current flows through the arc, it generates a magnetic field that interacts with ferromagnetic plates, producing a force vector accelerating the arc into the chute. This magnetic blow-out effect is self-reinforcing—higher fault currents create stronger forces moving the arc more quickly.

Once the arc enters the plate stack, it gets divided into multiple series arcs between adjacent plates. Each individual arc segment requires 20-40V to maintain conduction, so splitting a single arc into 10 segments increases the total arc voltage to 200-400V. When this voltage exceeds system voltage, the arc cannot sustain itself and extinguishes even before current zero-crossing. The large surface area of plates provides massive thermal mass absorbing heat from the plasma, dropping arc temperature from 10,000K+ to below 3,500K.

Advanced arc chute designs incorporate optimized grooving and ventilation holes creating controlled airflow paths that rapidly exhaust ionized gases while introducing cool ambient air. The pressure rise from arc heating creates natural convection currents flushing hot plasma out of the chamber, replacing it with non-ionized air resisting arc reformation. These same principles apply across all interrupting devices, as detailed in our comparison of different circuit breaker ratings.

Gas Evolution and Arc-Quenching Coatings

Quality arc chambers feature specialized coatings that decompose under arc exposure to release nitrogen-rich gases. These materials, often melamine-based resins mixed with high-nitrogen organic compounds, absorb arc energy and emit gases that dilute the plasma and increase its resistivity. Some designs use ablative materials that intentionally sacrifice surface material to generate arc-quenching gases through endothermic processes absorbing energy from the arc while creating turbulent gas flow breaking up the plasma channel.

Advanced Arc Quenching Technologies

Arc Accelerated Rapid Cooling (AARC): Modern high-performance arc chambers employ refined plate geometries and housing designs accelerating arc movement and cooling. AARC systems use high-permeability plate materials with optimized surface grooving increasing airflow velocity through the chamber, reducing arc quenching time by 40-60% compared to traditional designs.

Multi-Chamber Systems: For the highest fault current ratings, some ATS designs implement series-connected arc chambers where the arc must traverse multiple discrete quenching zones. Multi-chamber systems provide redundancy—if one chamber sustains damage, others continue functioning.

Flame-Retardant Grids and Filtered Venting: Premium arc chambers incorporate wire mesh or perforated metal grids at exhaust ports preventing flame propagation outside the chamber while allowing pressure relief. These grids filter hot particles preventing them from depositing on nearby components or igniting external materials.

Why Cheap ATS Arc Chambers Fail

Low-cost transfer switches compromise arc quenching performance through inadequate plate spacing (using fewer, wider-spaced plates) reducing the arc splitting effect. The use of non-magnetic or low-permeability materials eliminates magnetic blow-out force, requiring the arc to migrate into the chamber solely through thermal convection—a much slower process allowing more contact erosion.

Carbonization of chamber walls represents a common failure mode in poorly maintained or under-specified equipment. When arc energy exceeds the chamber’s design capacity, organic materials decompose leaving conductive carbon deposits creating low-resistance paths dramatically reducing arc voltage required for sustainment. Our troubleshooting guide includes inspection procedures for identifying carbonization before it causes complete failure.

Moisture absorption by arc chamber materials degrades insulation performance and arc quenching capability. Cement board and some fiber-reinforced plastics used in economy arc chambers readily absorb atmospheric moisture, conducting electricity more readily when wet.

Arc Quenching Performance Comparison Table

| Arc Quenching Method | Quenching Time | Fault Current Capacity | Typical ATS Class | Design Complexity | Cost Factor |

|---|---|---|---|---|---|

| Basic Plate Stack (non-magnetic) | >20ms | <10kA | Residential | Low | 1.0x |

| Magnetic Blow-Out + Standard Plates | 10-15ms | 10-22kA | Light Commercial | Moderate | 1.8x |

| AARC with Optimized Geometry | 6-10ms | 22-42kA | Commercial/Industrial | High | 2.5x |

| Multi-Chamber System | <6ms | 42-65kA+ | Heavy Industrial | Very High | 3.5x |

VIOX Arc Chamber Engineering

VIOX arc quenching systems are designed using finite element analysis to optimize magnetic field distribution, thermal transfer, and gas flow dynamics. Our commercial-grade ATS units (400-1200A) feature AARC-type chambers with high-permeability plates and engineered grooving achieving arc quenching in under 10 milliseconds at rated short-circuit current. For industrial applications above 1200A, VIOX implements dual-chamber designs providing both performance headroom and failure redundancy. Understanding the differences between PC class and CB class ATS designs helps you select the appropriate arc quenching capacity for your application.

We specify arc-rated melamine coatings with nitrogen-rich additives on all arc chamber interiors. These coatings are applied in controlled thickness (0.5-1.0mm) and cured at precisely controlled temperatures to ensure consistent gas-evolution properties. Field service data from installations with over 20 years of operation shows properly applied arc coatings maintain effectiveness throughout the equipment’s rated lifetime without maintenance or reapplication.

VIOX arc chambers incorporate inspection ports allowing visual examination of plate condition and carbonization without disassembling the entire mechanism. This design feature supports our recommendation for biennial arc chamber inspection in high-cycle applications. When carbonization or plate erosion reaches defined thresholds, we provide factory-calibrated replacement chambers restoring the ATS to original specifications.

Part 4: Quality Testing and Certification Standards

UL 1008 Requirements—More Than a Label

UL 1008 (Standard for Safety – Transfer Switch Equipment) establishes comprehensive testing protocols validating transfer switch performance under normal and fault conditions. Short-Circuit Closing Tests verify that the ATS can close onto an existing fault without welding contacts or failing catastrophically, validating both contact material selection and arc chamber capacity. Temperature Rise Testing measures operating temperatures at rated current under continuous load. UL 1008 specifies maximum temperature rise values (typically 50-65°C above ambient) preventing insulation degradation and ensuring long-term reliability. Endurance Testing cycles the transfer switch through thousands of operations at rated load to verify mechanical reliability and contact wear characteristics. Dielectric Strength Tests apply overvoltage between circuits and between live parts and grounded enclosures to verify insulation integrity.

IEC Standards and Production Testing

IEC 60947-6-1 provides international standards roughly equivalent to UL 1008. Equipment certified to both standards is generally built to the more stringent requirements where the standards differ. IEC testing includes verification of discrimination with protective devices and electromagnetic compatibility (EMC) testing validating immunity to electrical noise.

Beyond certification testing, manufacturers implement production testing verifying individual unit quality. Contact resistance measurement uses precision microhm meters (typically 100A test current) to verify each contact pair measures below specification—usually 50-100 microohms. Thermal imaging during factory testing identifies hot spots indicating poor contact alignment, inadequate terminal torque, or material defects.

VIOX Testing and Quality Control

VIOX subjects all ATS models to full UL 1008 testing prior to certification, then implements 100% production testing verifying critical parameters on every manufactured unit. Our production line includes automated contact resistance measurement (four-wire Kelvin method), thermal imaging at 100% rated current, and drive mechanism timing verification. Units falling outside specification windows are rejected before shipping.

Beyond standard certification, VIOX conducts extended life testing on representative samples from each production run. These units undergo accelerated aging tests (elevated temperature, humidity cycling, mechanical cycling at 2x normal frequency) equivalent to 30 years of typical field service. This commitment to validation testing has produced field failure rates below 0.15% annually across our commercial product line—roughly 3-5x better than industry averages for similar equipment.

Frequently Asked Questions

What contact material should I look for in a quality ATS?

For residential and light commercial applications (up to 200A), silver-copper alloys (sterling silver composition) provide excellent performance at reasonable cost. Above 400A or in applications with frequent switching, specify silver-tungsten (AgW) or silver-tungsten carbide (AgWC) contacts. These refractory materials resist arc erosion and maintain low contact resistance over hundreds of thousands of operations. Avoid ATS specifications that don’t disclose contact materials—this usually indicates economy copper contacts that won’t provide acceptable service life.

How long should an ATS transfer take?

Transfer time depends on mechanism type and ampacity rating. Motor-operated mechanisms in commercial equipment typically complete the transfer in 100-150 milliseconds from initiation signal to stable contact closure. Faster isn’t always better—extremely rapid transfer (under 50ms) can create mechanical shock that reduces component life, while slow transfer (over 200ms) extends voltage interruption and may cause sensitive equipment to drop offline. For critical loads like medical equipment or data centers, specify transfer time under 100ms and verify that the published specification represents complete transfer, not just contact motion time.

What is arc quenching and why does it matter?

Arc quenching is the process of extinguishing the electrical arc that forms between separating contacts. Without effective arc suppression, this plasma channel (reaching temperatures over 10,000K) erodes contacts, damages insulation, and can weld contacts closed during fault conditions. Quality arc quenching systems use magnetic blow-out, de-ionization plate stacks, and gas-evolution coatings to interrupt fault currents in under 20 milliseconds. The arc quenching system is the primary safety feature protecting your facility when short circuits occur—it determines whether your ATS safely interrupts the fault or creates a fireball that destroys the equipment and threatens personnel.

What certifications should a quality ATS have?

At minimum, specify UL 1008 certification for North American installations or IEC 60947-6-1 for international applications. Look for the complete certification marking on the nameplate, not just “UL Listed” without specifying the relevant standard—some manufacturers obtain UL listings under different standards that don’t require the same rigorous testing. For installations in special hazards areas, additional certifications may be required (NEMA 3R, NEMA 4X for environmental protection; Class I Division 2 for hazardous locations). Verify that the certification applies to the specific model and rating you’re purchasing—some manufacturers certify a base model then offer “equivalent” variants that haven’t undergone testing.

Conclusion: Engineering Quality You Can Measure

The difference between adequate and excellent ATS equipment lives in details that aren’t visible from the outside—contact alloy composition, spring force curves, arc chamber plate geometry, coating chemistry. These specifications determine whether your transfer switch provides 20+ years of reliable service or fails catastrophically during its first major fault event.

When evaluating ATS options, request detailed specifications for contact materials (alloy composition and ratings), drive mechanism type and cycle life, and arc chamber construction. Compare published transfer times and verify they represent complete electrical transfer, not just mechanical motion. Check that certifications match your application requirements and cover the specific model and rating you’re specifying.

VIOX designs transfer switches using the engineering principles detailed in this article—silver refractory contacts for durability, motor-operated mechanisms for reliable performance, and advanced arc chambers that protect your facility during fault conditions. Our specifications are published, our testing is comprehensive, and our field reliability demonstrates that properly engineered ATS equipment justifies its cost through decades of maintenance-free operation.

For detailed specifications on VIOX automatic transfer switches including contact materials, drive mechanisms, and arc chamber designs, visit viox.com/ats or contact our technical support team for application-specific recommendations.