The Old Blueprint Dilemma

Picture this scenario: You’re the lead procurement engineer for a facility modernization project. The electrical drawings from 1995 explicitly specify HRC Fuses for the main distribution panel. You open your supplier’s latest catalog—perhaps even VIOX Electric’s current product line—and suddenly, you can’t find “HRC” anywhere. Every specification sheet shows HBC Fuses instead.

Your pulse quickens. Did industrial standards change? Is “Breaking Capacity” somehow inferior to “Rupturing Capacity”? Are you about to compromise the electrical safety of your entire facility by ordering the wrong protection device?

Take a breath. According to industry standards bodies and electrical engineering consensus, you’re experiencing a linguistic evolution, not a technical downgrade.

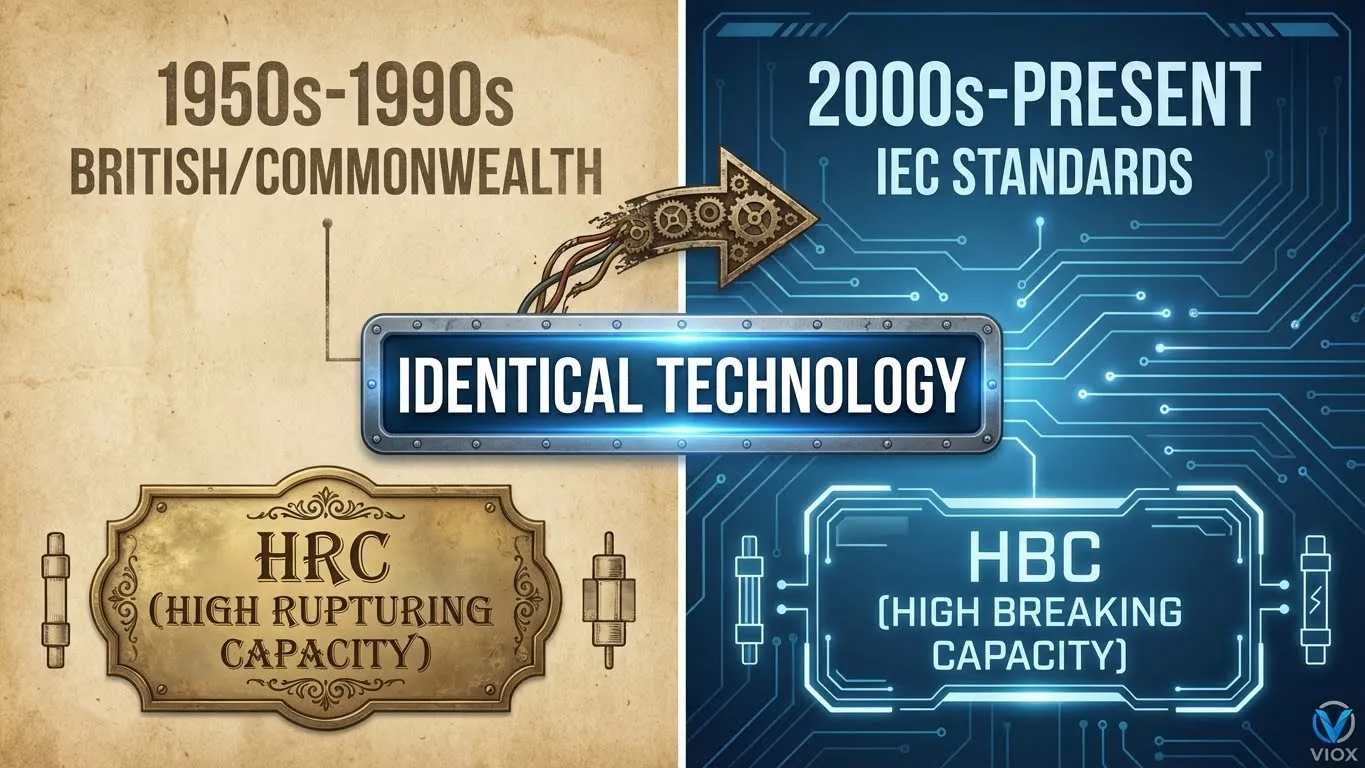

The direct answer: There is zero technical difference between HRC and HBC fuses. They represent identical technology with different terminology—like calling the same device a “lift” versus an “elevator.”

Failure vs. Function. Left: A glass fuse that shattered violently during a fault. Right: A VIOX HRC ceramic fuse that safely contained the arc with no external damage.

Failure vs. Function. Left: A glass fuse that shattered violently during a fault. Right: A VIOX HRC ceramic fuse that safely contained the arc with no external damage.Understanding the Terminology Evolution: HRC vs. HBC

The distinction between these acronyms reflects the electrical industry’s evolving standardization language rather than any engineering innovation. Let’s examine why both terms coexist in today’s specifications.

HRC: High Rupturing Capacity

Origin and Context:

- Era of Prevalence: 1950s through 1990s

- Geographic Strongholds: United Kingdom, India, Australia, Commonwealth nations

- Technical Philosophy: The term “rupturing” emphasizes the violent, physical destruction of the fuse element during fault conditions

Linguistic Characteristics:

The word “rupture” carries visceral connotations—it suggests forceful breaking, similar to medical terminology describing tissue damage or pressure vessel failures. While technically accurate (the fuse element does rupture), this terminology became less favored as safety communication evolved toward more controlled, professional language.

Current Usage:

HRC terminology persists in legacy documentation, older British Standard specifications, and regions maintaining traditional Commonwealth electrical practices.

HBC: High Breaking Capacity

Origin and Context:

- Era of Adoption: 2000s to present

- Standardization Alignment: IEC 60269 international standards

- Technical Philosophy: “Breaking” emphasizes controlled circuit interruption—aligning with circuit breaker terminology

Linguistic Advantages:

Modern electrical codes prioritize precise, safety-oriented language. “Breaking” suggests controlled interruption rather than violent destruction, presenting a more professional image to facility managers and safety regulators. The terminology harmonizes with international standards documents that use “breaking capacity” as the universal metric.

Industry Adoption:

Major manufacturers, including VIOX Electric, have transitioned to HBC terminology in technical documentation while maintaining HRC recognition for backward compatibility and search optimization.

Comparative Analysis: HRC vs. HBC Terminology

| Aspect | HRC (High Rupturing Capacity) | HBC (High Breaking Capacity) |

|---|---|---|

| Dominant Era | 1950s-1990s | 2000s-Present |

| Geographic Preference | UK, India, Australia, Commonwealth | Global (IEC member countries) |

| Standards Association | BS 88, legacy national standards | IEC 60269, EN 60269 |

| Technical Definition | Maximum fault current safely ruptured | Maximum fault current safely interrupted |

| Linguistic Tone | Visceral, emphasizes physical destruction | Professional, emphasizes controlled action |

| Current Industry Use | Legacy specs, SEO keywords, informal use | Official datasheets, procurement specs |

| Technical Equivalence | Identical to HBC | Identical to HRC |

Critical Point for Procurement: When comparing fuses across suppliers, ignore the acronym entirely. Focus exclusively on the breaking capacity rating in kiloamperes (kA) as specified in compliance with IEC 60269 or BS 88 standards.

The Engineering Reality: What Makes HRC/HBC Fuses Special?

Regardless of terminology, what distinguishes these fuses from standard Low Breaking Capacity (LBC) devices is sophisticated arc-quenching engineering designed to safely interrupt massive fault currents that would destroy conventional fuses.

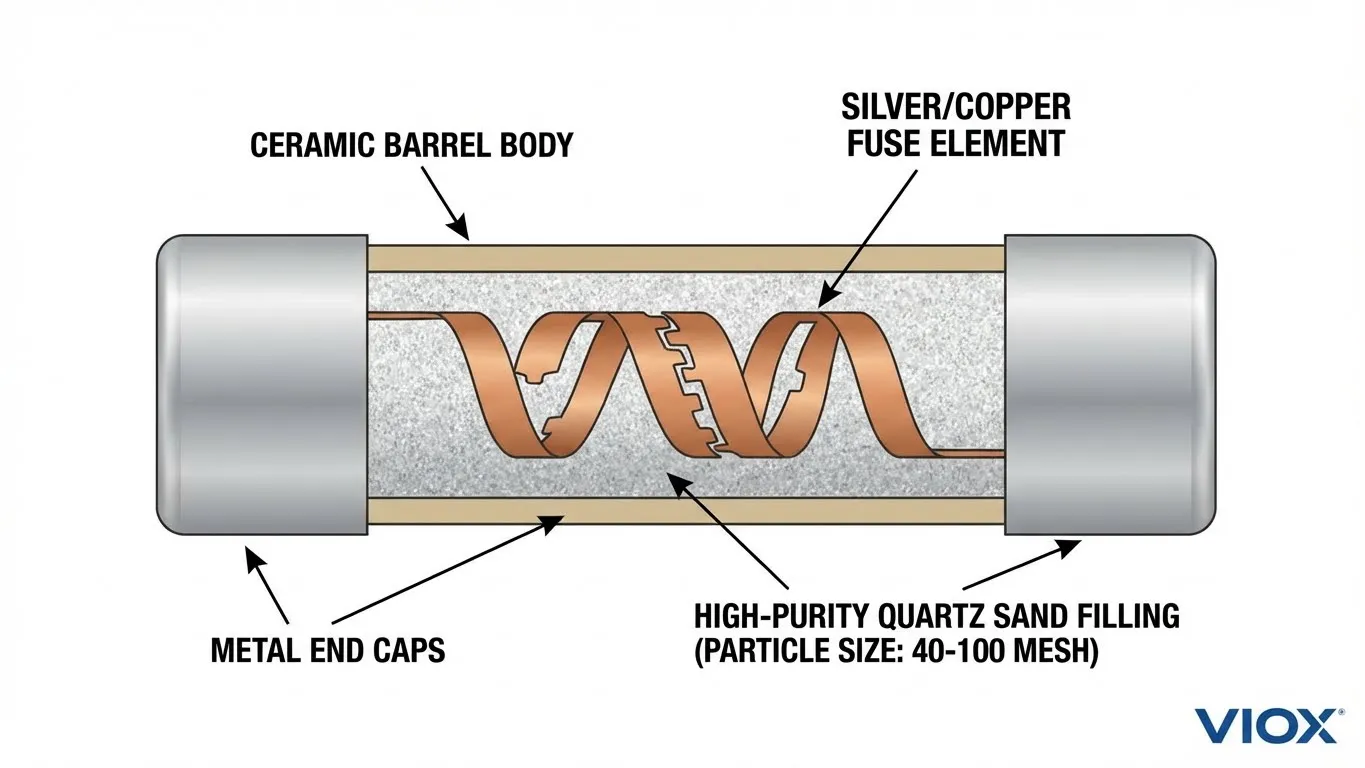

The Ceramic Construction Advantage

Unlike household glass fuses with visible elements, industrial HRC/HBC fuses employ robust ceramic barrels engineered to withstand extreme internal conditions during fault interruption.

Material Properties:

- Body Material: High-strength ceramic (alumina or steatite) capable of withstanding internal pressures exceeding 100 bar

- Thermal Resistance: Ceramic maintains structural integrity at temperatures exceeding 1000°C

- Dielectric Strength: Provides superior electrical insulation compared to glass, preventing external flashover

Comparison with Glass Fuses:

Standard glass fuses serve consumer electronics and low-voltage applications effectively, but they suffer catastrophic failure under industrial fault conditions. A typical glass M205 fuse has an interrupting rating of only 10× its rated current—meaning a 16A glass fuse can safely interrupt just 160A maximum. In contrast, ceramic HRC/HBC fuses of identical physical size can interrupt 1500A or higher, regardless of their amperage rating.

The “Sand Magic”: Arc-Quenching Science

The transformative technology inside every HRC/HBC fuse is the arc-quenching medium—high-purity crystalline quartz sand that performs sophisticated physics during fault interruption.

Quartz Sand Specifications (IEC 60269 Requirements):

- Chemical Purity: Minimum 99.5% SiO₂ (silicon dioxide)

- Particle Size: 40-100 mesh (150-400 micrometers)

- Mineralogical Form: Crystalline quartz, completely anhydrous (moisture-free through fire-drying)

- Packing Density: Optimized grain size distribution ensuring adequate void space for arc expansion while maximizing surface area for heat absorption

Why Sand Purity Matters:

Impurities or moisture in the quartz sand can generate unwanted gases during arcing, increasing internal pressure to dangerous levels. High-purity crystalline quartz ensures predictable, controlled arc extinction.

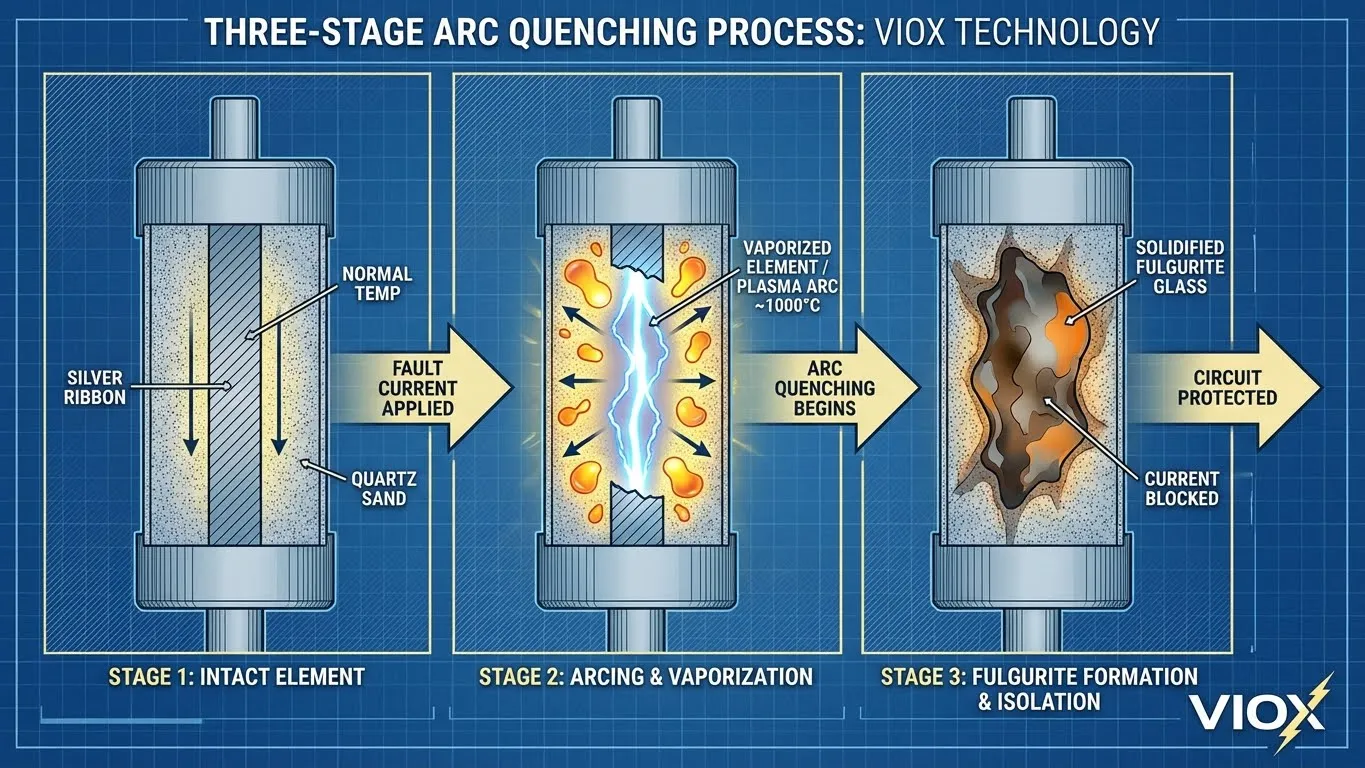

The Three-Phase Fault Interruption Process

When a short circuit sends tens of thousands of amperes through an HRC/HBC fuse, a precisely engineered sequence unfolds in milliseconds:

Phase 1: Pre-Arcing (Element Melting)

- The silver or copper fuse element heats rapidly due to I²R losses

- At strategically designed constriction points (notches), the element reaches its melting point (961°C for silver)

- Molten metal forms at multiple points simultaneously along the element length

- Duration: Varies from milliseconds (high fault) to seconds (moderate overload)

Phase 2: Arcing (Plasma Formation)

- The molten element vaporizes into metallic plasma

- Multiple electric arcs form in series at each constriction point

- Arc temperature reaches 3000-5000°C locally

- The intense heat immediately melts surrounding quartz sand grains

- Arc voltage increases dramatically as the element extends and sand absorbs energy

- Duration: 1-5 milliseconds for high fault currents

Phase 3: Extinction (Fulgurite Formation)

- Molten silica (SiO₂) from the sand mixes with vaporized metal

- This mixture rapidly solidifies into a glass-like structure called fulgurite

- The fulgurite forms a non-conductive tunnel through the sand, physically encasing the arc path

- As the mixture cools and solidifies, arc resistance increases exponentially

- At the next current zero-crossing (in AC systems), the arc cannot reignite due to high resistance

- The circuit is permanently interrupted until the fuse is replaced

The Fulgurite Phenomenon:

Named after the Latin fulgur (lightning), fulgurites are naturally occurring glass tubes formed when lightning strikes sandy soil. In fuses, controlled fulgurite formation is the key to safe current interruption—the glass structure acts as a permanent insulating barrier preventing arc re-ignition.

Technical Specifications: Breaking Capacity Ratings

The defining characteristic that separates industrial-grade fuses from consumer devices is breaking capacity—the maximum prospective fault current the fuse can safely interrupt without rupturing its enclosure or causing external arcing.

Standard Breaking Capacity Ranges

Low-Voltage HRC/HBC Fuses (IEC 60269):

- Typical Ratings: 80 kA to 120 kA at 400-690 VAC

- Application: General industrial distribution, motor protection, transformer primaries

- Test Conditions: Short-circuit current including DC component and asymmetrical current peaks

High-Performance Applications:

- Semiconductor Protection: Up to 200 kA for specialized aR-rated fuses

- Ultra-High Breaking Capacity: Specialized designs tested to 300 kA for extreme fault environments

Medium-Voltage HRC Fuses:

- Voltage Range: 1 kV to 36 kV

- Breaking Capacity: Rated in MVA (megavolt-amperes) rather than kA

- Applications: Utility substations, industrial HV distribution, transformer protection

Standard Current Ratings (IEC 60269)

| Current Rating (A) | Typical Applications | Common Fuse Types |

|---|---|---|

| 2, 4, 6, 10, 16 | Control circuits, instrumentation | Cylindrical cartridge (10×38mm) |

| 25, 30, 50, 63 | Small motor protection, distribution feeders | NH00, cartridge fuses |

| 80, 100, 125, 160 | Medium motor circuits, panel boards | NH1, NH2 |

| 200, 250, 320, 400 | Large motors, distribution transformers | NH2, NH3 |

| 500, 630, 800 | Industrial feeders, main distribution | NH3, NH4 |

| 1000, 1250 | Heavy industrial applications | NH4, BS88 bolted types |

Note: Ratings conform to IEC 60269 preferred values. Custom ratings available for specific applications.

Ceramic vs. Glass Fuses: A Critical Comparison

Understanding the fundamental differences between ceramic HRC/HBC fuses and glass LBC (Low Breaking Capacity) fuses is essential for proper circuit protection specification.

| Feature | Ceramic HRC/HBC Fuses | Glass LBC Fuses |

|---|---|---|

| Body Material | High-strength ceramic (alumina/steatite) | Borosilicate glass |

| Arc-Quenching Medium | High-purity quartz sand (SiO₂ >99.5%) | Air or minimal filler |

| Breaking Capacity | 1500A to 300,000A (80-300 kA typical) | 10× rated current (max ~160A for 16A fuse) |

| Interruption Mechanism | Fulgurite formation, controlled arc extinction | Simple element melting, limited arc control |

| Voltage Rating | 240V to 690V (LV), up to 36kV (MV) | Typically 32V to 250V maximum |

| Internal Pressure Tolerance | >100 bar, hermetically sealed | Limited; ruptures under high fault |

| Failure Mode Under Extreme Fault | Contained within ceramic body, no external arcing | Violent rupture, glass shrapnel, external arc |

| Visual Inspection | Opaque; requires electrical testing | Transparent; element visible |

| Typical Applications | Industrial distribution, motor protection, transformers | Consumer electronics, automotive, low-power circuits |

| Standards Compliance | IEC 60269, BS 88, UL Class J/L/T | IEC 60127, UL 248-14 |

| Cost Factor | Higher initial cost, superior protection value | Lower cost, suitable for low-energy applications |

Safety Implication: Specifying a glass fuse in a circuit where prospective short-circuit current exceeds its breaking capacity creates a serious fire and personnel hazard. Always calculate maximum available fault current and ensure fuse breaking capacity provides adequate safety margin (typically 125-150% of calculated fault current).

Practical Guidance for Procurement and Specification

What to Look for on a Datasheet

When evaluating HRC or HBC fuses for your facility, focus on these critical specifications rather than the acronym used:

- Breaking Capacity (Interrupting Rating): Expressed in kA at rated voltage (e.g., “100 kA at 415 VAC”)

- Current Rating: Nominal current in amperes (e.g., 250A)

- Voltage Rating: Maximum system voltage (e.g., 690 VAC)

- Utilization Category: IEC 60269 designation (gG, gL, aM, aR) indicating application type

- Standards Compliance: IEC 60269, BS 88, UL marking as applicable

- Physical Dimensions: Ensure compatibility with existing fuse holders (NH size, cartridge dimensions)

Making the Specification Decision

For New Installations:

Specify fuses using modern HBC terminology with explicit reference to IEC 60269 standards. This ensures international compatibility and aligns with current industry practice.

For Replacement/Retrofit:

When replacing existing fuses, either HRC or HBC terminology is acceptable provided the technical specifications match:

- Identical current rating

- Equal or greater breaking capacity

- Same voltage rating

- Compatible physical form factor

- Equivalent time-current characteristic (utilization category)

Engineering Reality: A 250A HRC fuse rated at 100 kA to BS 88 standards is functionally identical to a 250A HBC fuse rated at 100 kA to IEC 60269 standards if physical dimensions match. The terminology difference is purely nomenclature.

VIOX Electric’s Approach

At VIOX Electric, our product catalogs reference both HRC and HBC terminology to ensure customers can locate appropriate products regardless of their documentation’s nomenclature. Our technical datasheets prioritize standardized specifications:

- Breaking capacity clearly stated in kA

- IEC 60269 compliance verification

- Detailed time-current curves

- Physical dimension drawings

- Application guidance

This dual-nomenclature approach eliminates procurement confusion while maintaining rigorous technical accuracy.

Frequently Asked Questions

Are HRC and HBC fuses electrically different?

No. HRC (High Rupturing Capacity) and HBC (High Breaking Capacity) refer to identical fuse technology. The only difference is terminology preference—HRC represents traditional British/Commonwealth usage, while HBC aligns with modern IEC international standards. Both describe fuses with high fault current interruption capability achieved through ceramic construction and quartz sand arc-quenching.

Why do some catalogs still use “HRC” instead of “HBC”?

Three primary reasons: (1) Legacy compatibility—engineers searching for replacement fuses use terminology from original equipment documentation; (2) Geographic convention—Commonwealth countries retain HRC terminology in common usage; (3) SEO strategy—manufacturers maintain both terms to ensure product discoverability online. Technically rigorous manufacturers like VIOX Electric use both terms with clear specification that they represent identical technology.

What is the breaking capacity range for HRC/HBC fuses?

Low-voltage industrial HRC/HBC fuses typically offer breaking capacities of 80 kA to 120 kA at 400-690 VAC. Specialized semiconductor protection fuses can achieve 200 kA, while ultra-high-performance designs are tested to 300 kA. Medium-voltage fuses (1-36 kV) are rated in MVA rather than kA. In contrast, standard glass LBC fuses typically interrupt only 10× their rated current—a 16A glass fuse manages just 160A maximum.

Can I replace an HRC fuse with an HBC fuse?

Yes, absolutely—they are the same device. When replacing any fuse, verify that the replacement matches: (1) current rating, (2) voltage rating, (3) breaking capacity (equal or greater), (4) utilization category (gG, aM, etc.), and (5) physical dimensions. Whether the label says HRC or HBC is irrelevant if specifications match.

What makes the “sand” inside so important?

The quartz sand inside HRC/HBC fuses performs critical arc-quenching physics. When fault current vaporizes the fuse element, the intense arc (3000-5000°C) melts surrounding sand grains. This molten silica (SiO₂) mixes with metal vapor and rapidly solidifies into a glass-like structure called fulgurite. This fulgurite acts as a permanent insulator, absorbing arc energy and preventing current re-ignition. Without sand, the arc would continue conducting, potentially causing fuse explosion. The sand must meet strict specifications: >99.5% SiO₂ purity, 40-100 mesh particle size, completely anhydrous.

How do I identify if a fuse is HRC/HBC rated?

Look for these indicators: (1) Body material—ceramic or steatite (never glass); (2) Marking—”HRC,” “HBC,” or breaking capacity printed in kA (e.g., “80kA”); (3) Standards marking—IEC 60269, BS 88, or equivalent; (4) Physical construction—robust metal end caps with hermetic sealing; (5) Opacity—ceramic fuses are opaque (cannot see internal element). If markings are unclear, consult manufacturer datasheets or test documentation.

Why can’t glass fuses handle high fault currents?

Glass fuses contain air rather than arc-quenching sand. Under high fault conditions, the fuse element vaporizes and creates a plasma arc. Without sand to absorb energy and form insulating fulgurite, the arc continues conducting within the glass tube. The expanding arc pressure and heat shatter the glass body, ejecting molten material and creating external arcing—a severe fire and personnel hazard. Glass fuses are engineered for low-energy applications (consumer electronics, automotive) where prospective fault currents remain within their 10× rated current interrupting capacity.

Conclusion: Focus on Performance, Not Acronyms

The HRC versus HBC terminology debate represents linguistic evolution within electrical engineering standards, not technical differentiation. Whether your specifications reference High Rupturing Capacity or High Breaking Capacity, the underlying physics—ceramic construction, silver fuse elements, and quartz sand arc-quenching—remains identical.

For procurement professionals and facility engineers, the critical takeaway is straightforward: Evaluate fuses based on their breaking capacity in kiloamperes, current rating, voltage rating, and standards compliance rather than the acronym on the label.

When specifying protection for industrial electrical systems, the sophisticated engineering inside HRC/HBC fuses—particularly the fulgurite-forming arc extinction mechanism—provides life-safety protection and asset preservation that standard glass fuses cannot deliver. The terminology may vary, but the protection performance standards remain consistent across quality manufacturers.

Why Choose VIOX Electric for HRC/HBC Fuses?

VIOX Electric manufactures industrial-grade fuses that meet both legacy HRC and modern HBC nomenclature with full IEC 60269 and BS 88 compliance. Our product lines feature:

- Verified Breaking Capacity: Testing documented to 120 kA at rated voltage

- High-Purity Materials: SiO₂ content >99.5% in arc-quenching medium

- Comprehensive Range: Current ratings from 2A to 1250A across NH, BS88, and cartridge formats

- Technical Support: Engineering assistance for proper fuse selection and application

- Quality Assurance: ISO 9001 certified manufacturing with batch traceability

Whether your documentation specifies HRC or HBC, VIOX Electric delivers the electrical protection performance your facility requires. Contact our technical sales team for application-specific recommendations and detailed product specifications.

For technical inquiries regarding HRC/HBC fuse selection for your specific application, consult VIOX Electric’s engineering support team or reference our comprehensive product catalog.