A faulty RCCB (Residual Current Circuit Breaker) won’t protect you when it matters most. During a ground fault, a malfunctioning RCCB fails silently—the contacts don’t trip, current continues flowing through the fault path, and the risk of electric shock or fire remains unmitigated. The sobering reality: many RCCBs sit in distribution boards for years without verification, quietly degrading until they’re needed and don’t respond.

Regular functionality testing isn’t optional maintenance—it’s mandated by IEC 61008-1 and embedded in electrical safety codes worldwide. The standard is clear: verify your RCCB’s trip mechanism at specified intervals to confirm it will disconnect the circuit within 300 milliseconds when residual current reaches the rated threshold (IΔn). This guide walks you through three testing methods—from the quick monthly test button check to professional instrument testing—plus maintenance schedules, troubleshooting steps, and replacement criteria.

Who should test RCCBs? Professional electricians, facility managers, and maintenance technicians managing commercial or industrial installations.

Method 1: Monthly Test Button Check

Every RCCB includes a built-in test button marked “T” or “TEST.” This is your first-line verification tool, designed for regular functional checks without external equipment.

What the Test Button Does

When pressed, the test button creates an intentional imbalance in the RCCB’s toroidal current transformer by routing a small current through an internal resistor circuit. This simulates a ground fault condition at approximately 1×IΔn (the rated residual operating current). If the trip mechanism is working correctly, the RCCB should disconnect immediately—typically within 30-40 milliseconds.

Critical requirement: The RCCB must be energized for the test button to function. Most devices require a minimum operating voltage (often 100V or higher) to power the internal test circuit. Testing a de-energized RCCB will yield no result, not because the device is faulty, but because the test circuit isn’t powered.

Step-by-Step Test Button Procedure

- Verify supply voltage – Confirm the RCCB is energized and the handle is in the ON position.

- Press the test button firmly – Apply steady pressure; don’t tap it quickly.

- Observe the trip response – The RCCB handle should immediately move to the OFF (0) position with an audible click.

- Reset the device – Move the handle back to ON to restore power.

- Document the result – Record the date, device location, and pass/fail status.

Interpreting Test Button Results

PASS – Immediate trip: The sensing mechanism, electromagnetic trip coil, and contact assembly are functioning. The device met its basic operational requirement.

FAIL – No trip or delayed trip: Three possibilities exist:

- No supply voltage – Check upstream breakers and verify line voltage with a multimeter.

- Miswiring – Confirm neutral is correctly connected through the RCCB; incorrect neutral routing bypasses the current transformer.

- Device failure – If installation is correct and the RCCB still won’t trip, the unit is defective. Replace it immediately. Do not attempt to open or repair the device—RCCBs are not field-serviceable.

Manufacturers recommend monthly test button checks for critical installations or semi-annual testing for residential use.

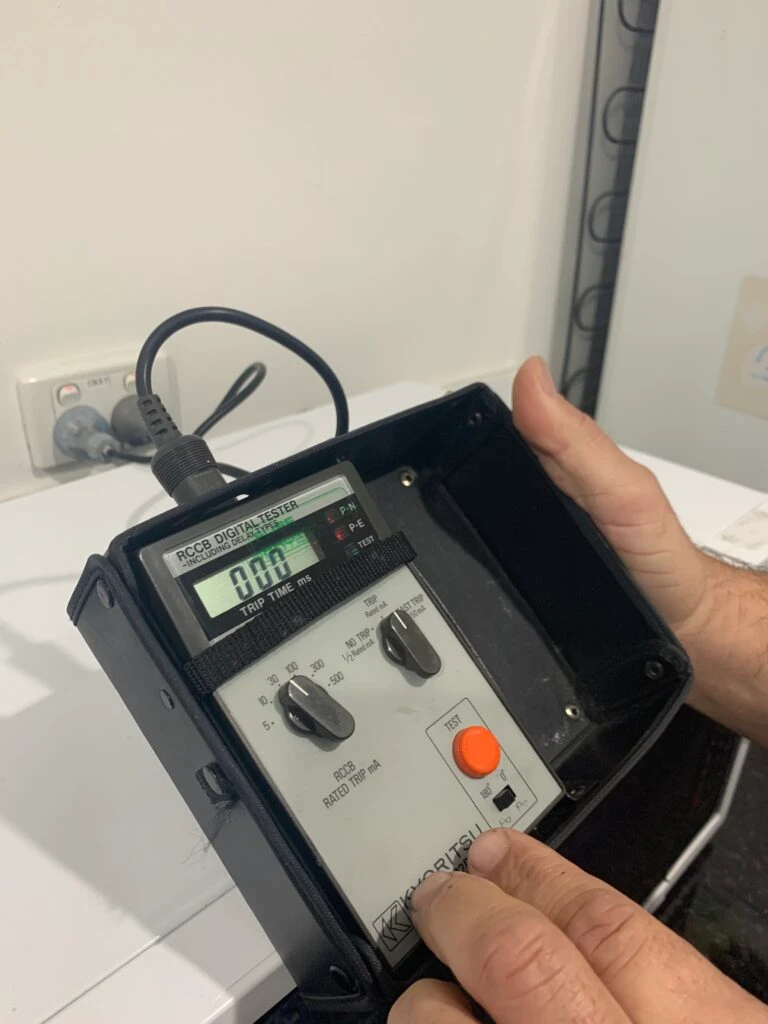

Method 2: Professional RCD Tester (IEC 61008-1 Compliance)

The test button confirms basic functionality, but it doesn’t verify compliance with IEC 61008-1 performance criteria—specifically, that the RCCB trips within the mandated 300 milliseconds at rated residual current. For installation commissioning, periodic inspections, and regulatory compliance, you need a calibrated RCD tester (conforming to BS EN 61557-6 or equivalent).

Required Equipment

- RCD/RCCB tester with adjustable test current (0.5×IΔn, 1×IΔn, 5×IΔn)

- Test leads rated for the circuit voltage

- Personal protective equipment (PPE) if performing live testing

- Multimeter for voltage verification

IEC 61008-1 Compliance Test Procedure

Per BS 7671:2018+A2:2022 requirements, the mandatory compliance check is:

- Isolate downstream circuits (recommended) – Disconnect outgoing wiring from the load side to eliminate cable capacitance effects on trip timing.

- Configure the tester – Set to AC test mode at 1×IΔn (typically 30mA, 100mA, or 300mA).

- Connect test leads – Attach between upstream and downstream terminals.

- Initiate the test – Press start to inject residual current and measure trip time.

- Verify trip time – Must disconnect within ≤300 ms (general) or 130-500 ms (Type S).

- Record results – Document device ID, IΔn, trip time, pass/fail, tester model, and date.

Additional Diagnostic Tests (Optional)

These tests help diagnose borderline devices or troubleshoot nuisance tripping:

- 0.5×IΔn non-trip test – Confirms the RCCB does NOT trip below its threshold.

- 5×IΔn high-current test – Verifies rapid disconnection (≤40 ms) at high residual currents.

- Ramp test – Determines exact tripping threshold for aging devices.

Safety Precautions

- De-energize when possible. If live testing is required, follow your organization’s live-work procedures and wear appropriate PPE (insulated gloves, face shield, arc-rated clothing).

- Confirm tester calibration. Use only recently calibrated testers with valid certification.

- Mind polarity. Some testers have phase/neutral-specific connections; incorrect hookup may yield false results.

Method 3: Additional Diagnostic Checks

Beyond functional and compliance testing, these supplementary checks help assess RCCB condition and diagnose intermittent issues.

Leakage Current Measurement

Purpose: Quantify standing leakage current in the protected circuit to identify sources of nuisance tripping.

Procedure: Use a leakage current clamp meter around all conductors downstream. Normal installations show ≤0.3×IΔn. Leakage approaching 0.5×IΔn increases nuisance trip risk.

Common leakage sources: EMC/EMI filters in variable frequency drives (VFDs), switch-mode power supplies, long cable runs (capacitive coupling), water heaters, and degraded insulation.

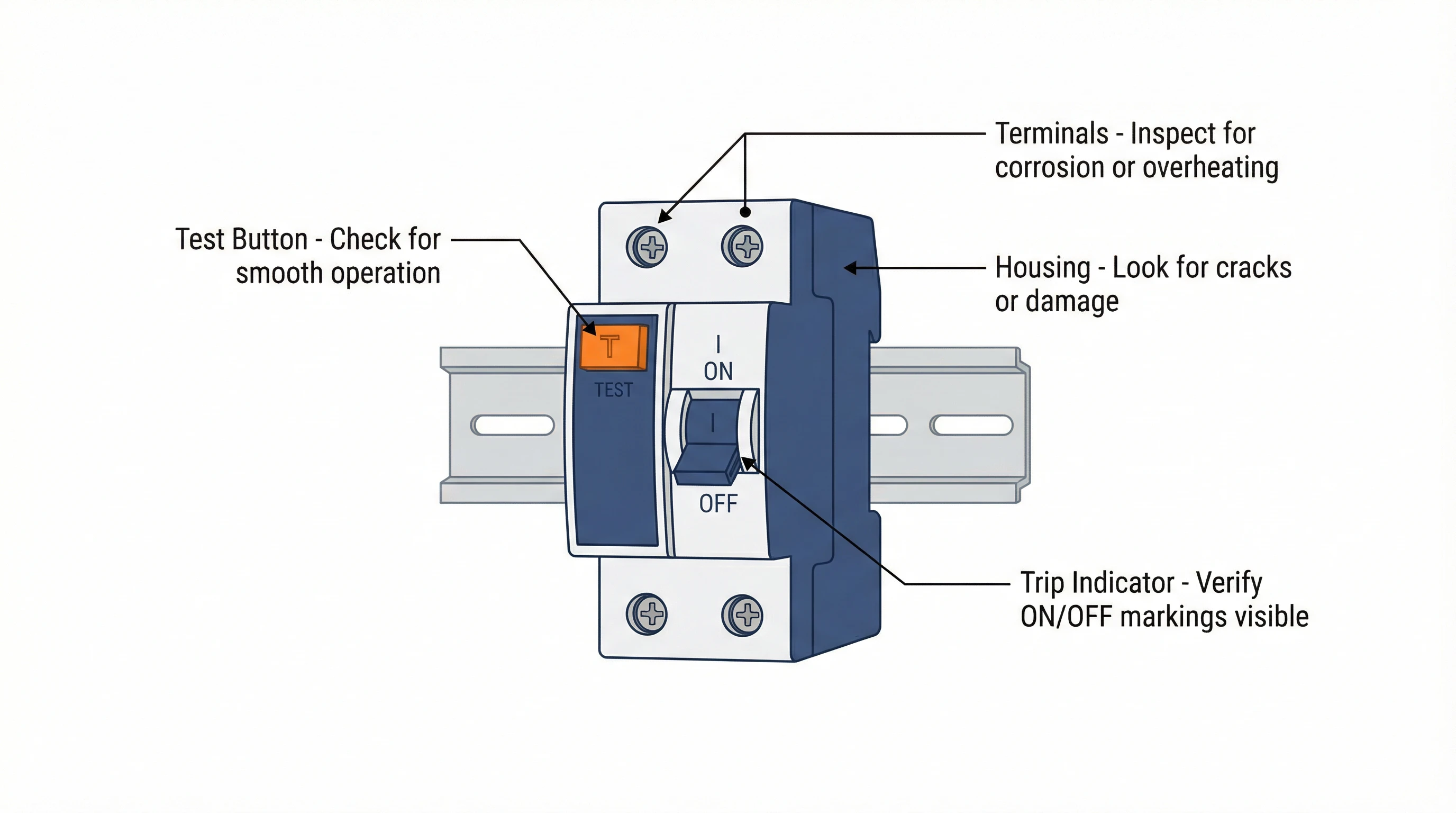

Visual Inspection

- Test button: Ensure it moves freely and isn’t stuck or mechanically damaged.

- Measuring insulation resistance with a megohmmeter (500V DC) can identify degraded components, but only test with the RCCB OFF and all conductors disconnected.

- Terminals: Check for corrosion, loose connections, or signs of overheating (discoloration, melted insulation).

- Housing: Look for cracks, moisture ingress, or evidence of arcing.

Recommended Maintenance Schedule

Establish a tiered testing program based on installation risk level and regulatory requirements:

| Testing Method | Frequency | Performed By | Purpose |

|---|---|---|---|

| Test button check | Monthly (critical facilities) Semi-annual (residential) |

Facility staff or electrician | Quick functional verification |

| RCD tester (compliance) | Annual (minimum) Quarterly (high-risk) |

Qualified electrician | IEC 61008-1 compliance; trip time verification |

| Visual inspection | Annual | Electrician during routine inspection | Identify physical degradation |

| Leakage measurement | As needed | Electrician | Troubleshoot nuisance tripping |

| Full diagnostic | After any fault event or suspected malfunction | Electrician | Comprehensive evaluation |

Documentation requirements: Maintain a testing log with device location, serial number, test date, method, measured values, pass/fail result, and technician name. Many jurisdictions require these records for insurance and regulatory compliance.

Common Issues and Troubleshooting

Issue 1: RCCB Won’t Trip on Test Button

Possible causes:

- No supply voltage – Verify upstream breakers are closed and measure line voltage.

- Incorrect neutral connection – Neutral must pass through the RCCB’s current transformer. If neutral is bonded upstream or bypasses the device, the internal test circuit won’t create the necessary imbalance.

- Defective test button or internal resistor – Mechanical failure or open test circuit. Replace the RCCB.

- Failed trip mechanism – Electromagnetic coil or latch failure. Replace immediately.

Issue 2: Nuisance Tripping (Frequent False Trips)

Possible causes:

- High standing leakage – Measure leakage with a clamp meter. If >0.3×IΔn, identify and isolate leaky circuits or equipment.

- Transient surges – Lightning, grid switching, or motor starting can produce brief leakage spikes. Consider upgrading to a “super-resistant” Type K RCCB or installing surge protection devices (SPDs).

- Capacitive coupling – Long cable runs accumulate capacitive leakage. Reduce cable length, use shielded cables, or increase IΔn rating (where safe).

- Incorrect RCCB type – Type AC RCCBs can be “blinded” by DC components from electronic loads (LED drivers, VFDs, EV chargers). Upgrade to Type A minimum, or Type B/F for high-frequency DC applications.

- Overloading – Excessive load current can induce small imbalances. Verify the load does not exceed the RCCB’s rated current (In).

Issue 3: Slow or Delayed Tripping

Possible causes:

- Aging or worn contacts – Contact erosion increases resistance and delays trip response. Replace the RCCB.

- Environmental contamination – Dust, moisture, or corrosion on the trip mechanism. Clean (if accessible) or replace.

- Incorrect Type S selection – Selective RCCBs have intentional time delays (130-500 ms). Confirm the correct type is installed for the application.

Issue 4: RCCB Trips Immediately Upon Closing

Possible causes:

- Actual ground fault downstream – The RCCB is working correctly. Isolate circuits one by one to locate the fault.

- Neutral-ground fault – Neutral and ground conductors are improperly bonded downstream of the RCCB.

- Incorrect wiring – Reversed phase/neutral or mixed neutrals from multiple circuits.

When to Replace Your RCCB

RCCBs are safety-critical devices designed for long service life—typically 15-20 years under normal conditions. However, certain conditions mandate immediate replacement:

- Failure to trip on test button (after confirming supply voltage and correct wiring)

- Trip time exceeds 300 ms at 1×IΔn during professional testing

- Repeated nuisance tripping that cannot be resolved through circuit modifications

- Visible damage: Cracked housing, melted terminals, burn marks, or corrosion

- Mechanical wear: Stiff or binding operating handle, damaged test button

- After a fault event: If the RCCB cleared a significant ground fault, inspect and test; replace if trip time has degraded

- Age and obsolescence: Devices over 20 years old or Type AC RCCBs in modern installations with electronic loads

Important: RCCBs are not field-repairable. Do not open the housing or attempt to adjust internal components. Replacement is the only acceptable corrective action for a failing device.

Frequently Asked Questions

Q: How often should I test my RCCB?

A: Press the test button monthly for critical installations (commercial, industrial, medical facilities) or semi-annually for residential use. Professional RCD tester verification should occur annually at minimum, or quarterly for high-risk environments. Always test after any electrical work on protected circuits.

Q: Can I use the test button as my only verification method?

A: No. The test button confirms the trip mechanism works but doesn’t verify IEC 61008-1 compliance (trip time ≤300 ms). Annual professional testing with a calibrated RCD tester is required for code compliance and insurance purposes.

Q: What does it mean if my RCCB trips immediately when I close it?

A: The device is detecting a ground fault in the downstream circuit. This is correct operation. Isolate branch circuits one by one to identify the faulty circuit, then troubleshoot that specific branch for insulation breakdown, damaged equipment, or neutral-ground faults.

Q: My RCCB won’t trip on the test button. Is it broken?

A: Not necessarily. First verify the RCCB is energized—most test buttons require minimum operating voltage (typically 100V). Check that upstream breakers are closed and measure line voltage with a multimeter. If supply voltage is present and neutral wiring is correct, then yes, the RCCB is defective and must be replaced.

Q: Can I repair an RCCB that’s not working properly?

A: No. RCCBs are sealed safety devices and are not field-repairable. Attempting to open the housing voids any warranty and may create a lethal safety hazard. Always replace a malfunctioning RCCB with a new unit that meets current IEC 61008-1 standards.

Q: Why does my RCCB trip when it rains or during high humidity?

A: Moisture is creating leakage paths to ground through degraded insulation, damaged outdoor equipment, or compromised cable entries. Check outdoor receptacles, junction boxes, and equipment for water ingress. Measure standing leakage current to identify the affected circuit, then repair or replace damaged components.

Q: What’s the difference between testing with the button versus an RCD tester?

A: The test button creates a simple imbalance to verify the trip mechanism functions, but it doesn’t measure trip time or current threshold accuracy. An RCD tester injects precise test currents (0.5×, 1×, 5×IΔn) and measures trip time in milliseconds, verifying the device meets IEC 61008-1 performance specifications. Professional testing is required for commissioning and regulatory compliance.

VIOX Electric manufactures Type A, Type F, and Type B+ RCCBs with IEC 61008-1 and IEC 62423 certification. For technical specifications and product selection assistance, visit www.viox.com or contact our engineering team.