Choosing the right time relay manufacturer can mean the difference between a production line that runs for years without incident and one plagued by nuisance trips, field failures, and warranty claims. For procurement engineers and purchasing managers at OEMs and system integrators, the stakes are high. A bad supplier decision doesn’t just affect unit cost—it ripples through your entire operation, from design validation timelines to end-customer satisfaction.

Yet many buying teams still rely on price comparison and cursory spec reviews when qualifying time relay manufacturers. That approach worked when global supply chains were stable and product complexity was lower. Today, with tighter margins, shorter product cycles, and stricter regulatory requirements, you need a more systematic evaluation framework.

This guide provides that framework. Drawing on established procurement best practices and industry standards including IEC 61812-1 and UL 508, we’ll walk through the specific criteria that separate truly reliable time relay manufacturers from those that only look good on a datasheet. Whether you’re qualifying your first supplier or re-evaluating an existing vendor, these principles will help you make confident, risk-managed decisions.

What Makes a Reliable Time Relay Manufacturer?

A reliable time relay manufacturer consistently delivers products that meet specified performance over their rated lifetime, maintains stable production and delivery schedules, demonstrates transparent compliance with applicable standards, and provides responsive technical support when issues arise. These qualities aren’t always visible from marketing materials – you need to look at objective evidence: certifications, test capabilities, production processes, and track record.

Key Selection Criteria for Time Relay Manufacturers

When evaluating a time relay manufacturer, structure your assessment around these core dimensions. Each criterion addresses a specific risk in the supply relationship.

| Criterion | What to Evaluate | Why It Matters | Red Flags |

|---|---|---|---|

| Quality Management System | ISO 9001 certification; documented QMS procedures; evidence of continual improvement | Predicts consistency in manufacturing processes and product quality | No ISO 9001; vague answers about quality procedures; recent certification with no operational history |

| Product Compliance & Standards | IEC 61812-1 compliance for time relays; UL 508 listing for industrial control equipment; CE marking (LVD/EMC) for EU markets | Ensures products meet safety, performance, and regulatory requirements in target markets | Self-declared compliance without test reports; confusion about applicable standards; missing market-specific certifications |

| Testing Capability | In-house or contracted ISO/IEC 17025 accredited lab access; routine and type test execution per IEC 61812-1; environmental and lifecycle testing | Validates that performance claims are based on actual test data, not assumptions | No access to accredited testing; inability to provide test reports; reliance on component supplier data alone |

| Production Capacity & Flexibility | Lead times for standard products; MOQ requirements; ability to scale production; custom configuration capabilities | Affects your ability to launch on schedule, manage inventory, and respond to demand changes | Long, inflexible lead times; high MOQs that force excess inventory; inability to accommodate design changes |

| Technical Support & Documentation | Availability of technical datasheets; wiring diagrams; application notes; responsive engineering support | Speeds up your design validation and troubleshooting; reduces risk of misapplication | Sparse technical documentation; slow or unresponsive technical support; language barriers in critical technical communication |

| Supply Chain & Delivery Performance | On-time delivery track record; component sourcing transparency; inventory management practices | Late deliveries disrupt your production schedule and customer commitments | Consistent late deliveries; inability to provide delivery metrics; opaque component sourcing (especially for critical components like relays) |

| Financial Stability | Years in business; financial health indicators; customer references | Reduces risk of supplier failure mid-program | Very new company with no track record; financial distress signals; reluctance to provide references |

| Environmental & Social Responsibility | ISO 14001 (EMS) certification; RoHS compliance; conflict minerals policy | Meets your corporate sustainability commitments and regulatory requirements | No environmental management system; non-compliant materials; unclear supply chain ethics |

This table gives you a structured scorecard for any time relay manufacturer evaluation. The next section shows you how to weight these criteria and turn qualitative observations into a quantitative decision framework.

Manufacturer Evaluation Framework: Scoring Your Options

Once you’ve gathered information on each criterion, you need a way to compare suppliers objectively. This scoring framework assigns points based on evidence strength, then weights each criterion by its importance to your specific application.

Scoring Scale (0-3 points per criterion)

3 points (Strong): Comprehensive evidence; exceeds baseline requirements; verified by third party

2 points (Adequate): Meets requirements; standard documentation provided; some verification

1 point (Weak): Partial evidence; gaps in documentation; self-declared only

0 points (Insufficient): No evidence; does not meet requirements; significant concerns

Suggested Weighting by Application Risk

| Criterion | Safety-Critical Application | Standard Industrial Application | High-Volume Cost-Sensitive Application |

|---|---|---|---|

| Quality Management System | 15% | 15% | 10% |

| Product Compliance & Standards | 20% | 15% | 10% |

| Testing Capability | 20% | 15% | 10% |

| Production Capacity & Flexibility | 10% | 15% | 25% |

| Technical Support | 15% | 15% | 10% |

| Supply Chain & Delivery | 10% | 15% | 25% |

| Financial Stability | 5% | 5% | 5% |

| Environmental & Social | 5% | 5% | 5% |

| Total | 100% | 100% | 100% |

How to use this framework:

- Score each criterion (0-3) based on evidence you’ve collected during supplier evaluation

- Choose the weighting column that best matches your application risk profile

- Calculate weighted score: (Criterion Score / 3) × Weight %, then sum across all criteria

- Set your threshold: 70%+ typically indicates a qualified supplier; 80%+ indicates a preferred supplier

This framework forces you to document why you’re selecting a supplier, not just that their price was acceptable. It also highlights gaps early – if a manufacturer scores poorly on testing capability but you’re developing a safety-critical application, that’s a dealbreaker regardless of price.

Understanding Quality Standards and Certifications

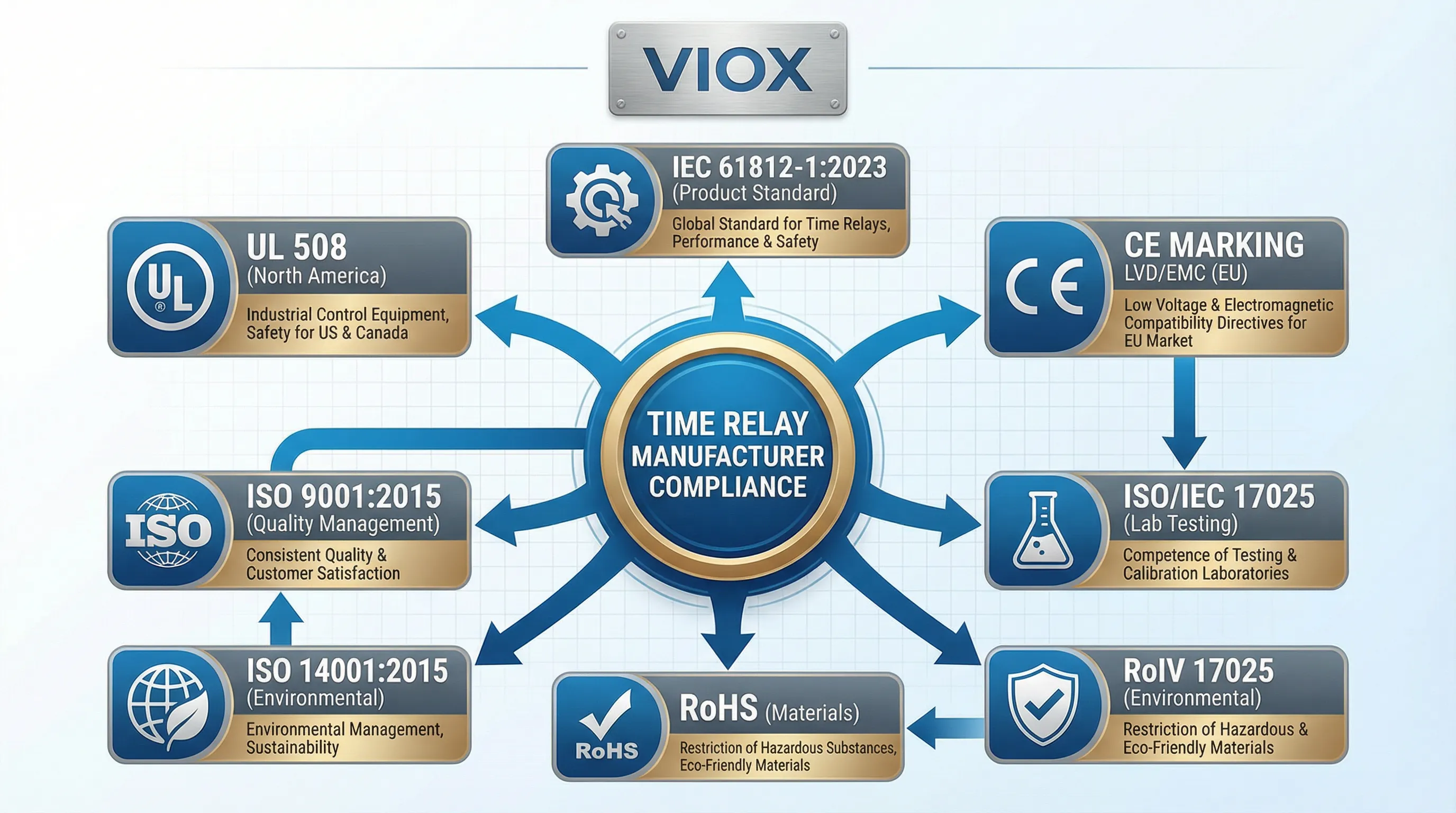

Certifications and standards compliance separate manufacturers who can demonstrate their capabilities from those who simply claim them. Here’s what matters for time relay manufacturers.

Essential Product Standards

IEC 61812-1:2023 is the primary international standard for time relays, defining type tests (performed during development) and routine tests (performed on every production unit). Key test categories include environmental, electrical, and safety testing. Ask manufacturers for type test reports from accredited labs and routine test records.

UL 508 covers industrial control equipment rated 1500V or less, including time-delay relays. For North American markets, UL 508 listing is often mandatory. UL listing means the manufacturer passed extensive testing (temperature, dielectric, short-circuit, endurance) and agreed to ongoing factory inspections.

CE Marking (LVD/EMC) indicates the manufacturer declares conformity with EU directives. Legitimate CE marking requires documented testing to harmonized standards. Ask for the Declaration of Conformity and supporting test reports – manufacturers who can’t provide these put you at regulatory risk.

Critical Management System Certifications

ISO 9001:2015 is the international standard for quality management systems, widely expected in B2B industrial supply chains. An ISO 9001 certified manufacturer has documented processes for design control, production control, inspection, and continual improvement. When reviewing certificates, verify the scope covers relay manufacturing, the certification body is accredited, and dates are current.

ISO 14001:2015 provides the framework for environmental management systems, signaling operational maturity and helping meet corporate sustainability goals.

ISO/IEC 17025 is the standard for testing laboratories. Test reports from ISO/IEC 17025 accredited labs carry far more weight than unaccredited sources, demonstrating technical competence, calibrated equipment, and internationally recognized results.

Compliance Summary Table

| Standard/Certification | Type | Purpose | Verification Method |

|---|---|---|---|

| IEC 61812-1:2023 | Product Standard | Defines performance, safety, and test requirements for time relays | Request type test reports from ISO/IEC 17025 accredited lab; verify routine test procedures |

| UL 508 | Product Certification (North America) | Demonstrates compliance with US/Canada safety standards for industrial control equipment | Check UL Product iQ database; verify UL file number on product label |

| CE Marking (LVD/EMC) | Regulatory Marking (EU) | Self-declaration of conformity with EU safety and EMC directives | Request Declaration of Conformity; review test reports to harmonized standards |

| ISO 9001:2015 | Management System | Quality management system certification | Review certificate for scope, accredited certification body, validity; request audit summaries if high-value relationship |

| ISO 14001:2015 | Management System | Environmental management system certification | Review certificate; often integrated with ISO 9001 |

| RoHS | Regulatory Compliance (EU + others) | Restriction of hazardous substances | Request RoHS declaration and material compliance documentation |

Why VIOX Electric Stands Out as a Time Relay Manufacturer

Now that you understand the evaluation framework, let’s look at how VIOX Electric measures up. Since 2013, VIOX has specialized in industrial control components, with time relays representing a core product line rather than an afterthought in a broad catalog.

Comprehensive Product Range Aligned to Industry Needs

VIOX manufactures a full spectrum of time relay functions—on-delay, off-delay, interval, cyclic, flasher, pulse, star-delta, and multifunction programmable relays. The FCT18 series alone offers over 15 timing function variants, eliminating the need to source different timing functions from multiple suppliers. For panel builders and OEMs, this translates to simplified supplier management, consistent quality across timing applications, and better leverage in commercial negotiations.

Proven Compliance and Certifications

VIOX timer relays carry the certifications that matter for global market access:

- CE marking (LVD and EMC directives) for the European market

- EAC certification for Eurasian Economic Union (Russia, Belarus, Kazakhstan, etc.)

- RoHS compliance for hazardous substance restrictions

- ISO 9001 for quality management systems

These aren’t just checkboxes – they represent tested, documented evidence that VIOX products meet recognized safety, performance, and environmental standards. The combination of product certifications and ISO 9001 QMS certification addresses both the “what” (product compliance) and the “how” (process control) of quality.

Transparent Technical Specifications

VIOX publishes detailed technical specifications that allow for informed design decisions:

Mechanical life: 10⁷ operations (10 million cycles) | Electrical life: 10⁵ operations (100,000 cycles under rated load) | Timing accuracy: ±0.5% error across all models | Power supply range: 12-240 VAC/VDC (wide voltage range reduces SKU count) | Operating temperature: Specified and tested ranges | Anti-interference capability: Designed for industrial EMI environments

These specifications are tested during production, not just claimed on a datasheet. Every VIOX timer relay includes clear wiring diagrams printed on the product side panel – a small detail that significantly reduces installation errors and support calls.

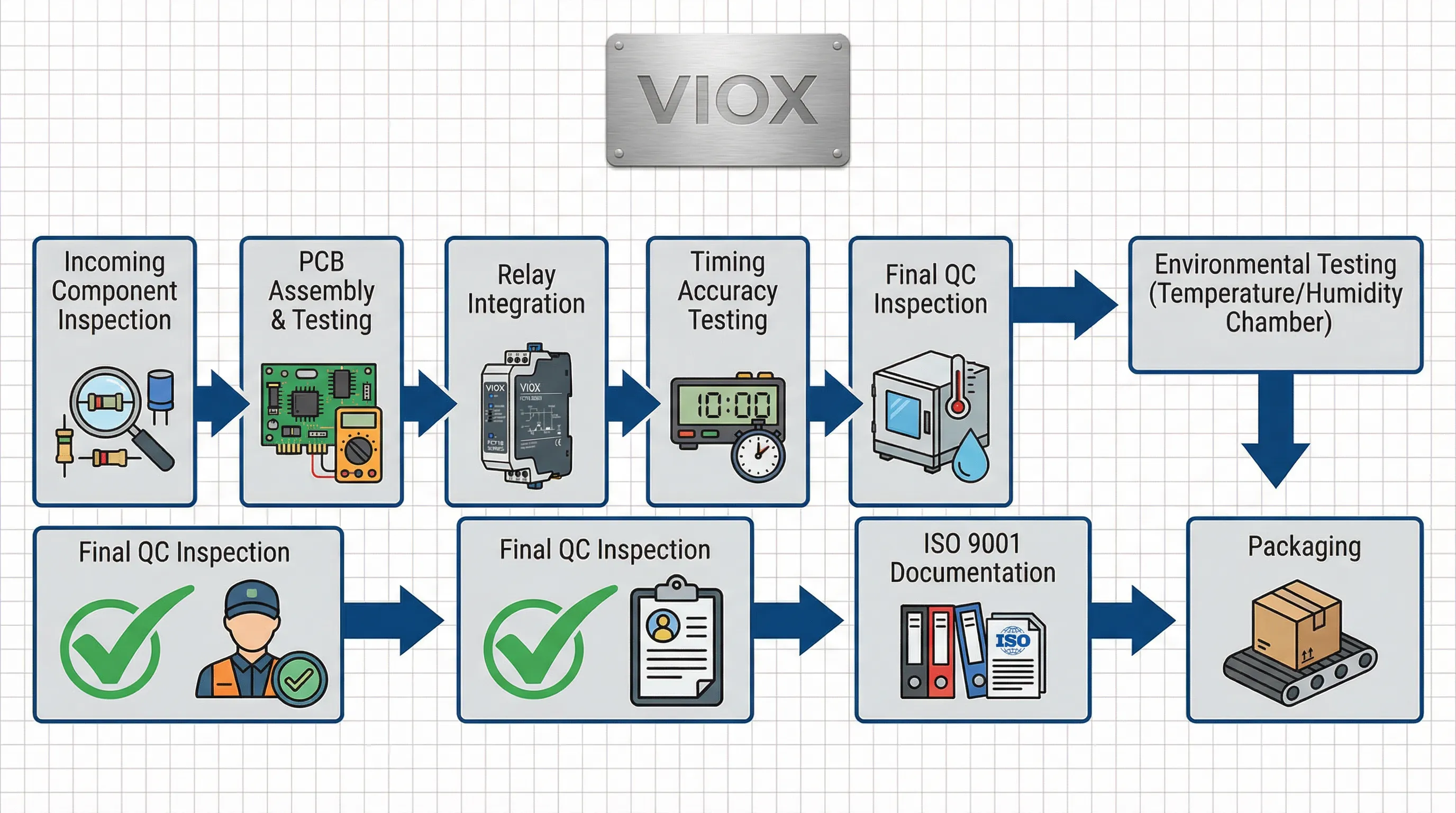

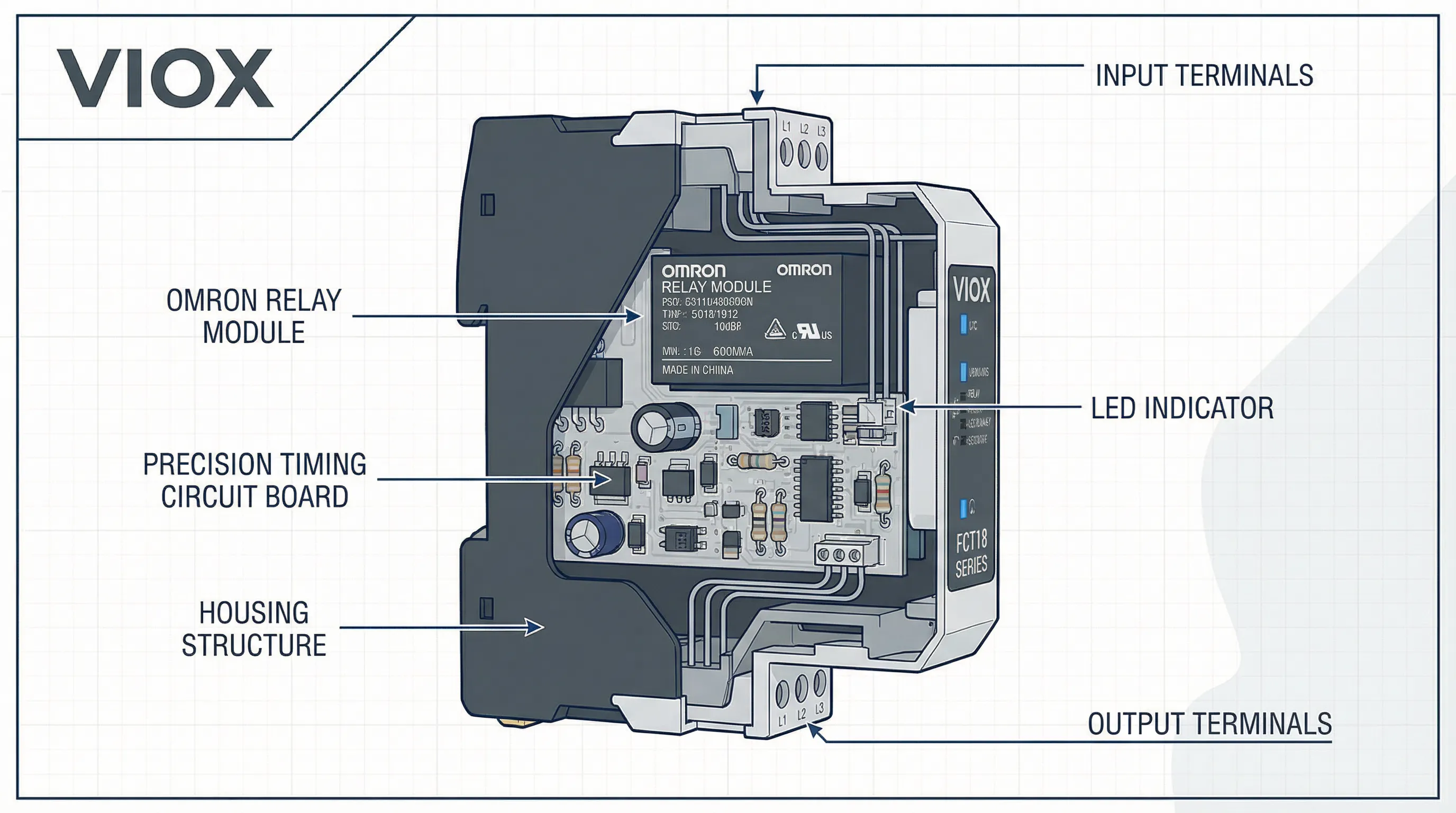

Manufacturing Quality and Component Selection

VIOX uses Omron relays as the internal switching component in their timer relays. Omron is a globally recognized manufacturer of industrial control components with a reputation for reliability. By integrating proven relay technology rather than designing relay contacts from scratch, VIOX reduces one of the most common failure modes in timing relays (contact degradation) and leverages Omron’s decades of materials science and manufacturing optimization.

Each timer relay features LED indicators for output status, self-locking protection to prevent accidental triggering during setup, and two independent relay outputs on many models for flexible control schemes.

Real-World Application Support

VIOX has built its timer relay line around real industrial applications: HVAC compressor protection, motor sequential starting, conveyor staging, and process automation. Application notes, wiring examples, and responsive technical support help customers select and configure timing functions correctly, reducing design validation time and field failure risk.

How VIOX Scores on the Evaluation Framework

Applying the evaluation framework from earlier in this guide:

- Quality Management System: ISO 9001 certified ✓ (2-3 points)

- Product Compliance & Standards: CE, EAC, RoHS; IEC 61812-1 testing ✓ (2-3 points)

- Testing Capability: Routine testing during production; type test reports available ✓ (2 points)

- Production Capacity & Flexibility: Multiple product series; standard and custom configurations ✓ (2 points)

- Technical Support: Detailed datasheets, wiring diagrams on products, responsive support ✓ (2-3 points)

- Supply Chain & Delivery: Established since 2013; stable supply chain ✓ (2 points)

- Financial Stability: 12+ years in operation; growing product portfolio ✓ (2 points)

- Environmental & Social: RoHS compliance; environmental management practices ✓ (2 points)

VIOX consistently scores in the “adequate to strong” range across all criteria, making it a qualified supplier for most industrial time relay applications. For OEMs and system integrators looking for a reliable time relay manufacturer with proven compliance, transparent specifications, and application-focused support, VIOX represents a low-risk choice.

Learn more about VIOX timer relays and request technical specifications at https://viox.com/timer-relay.

Step-by-Step Manufacturer Selection Process

Here’s a practical workflow to qualify a time relay manufacturer, balancing thoroughness with speed.

Phase 1: Initial Screening (1-2 weeks) – Narrow candidates to 3-5 prospects. Define requirements, research manufacturers, review documentation, verify certifications, and send RFQs. Eliminate candidates with missing certifications or poor documentation.

Phase 2: Detailed Evaluation (2-4 weeks) – Score remaining candidates. Request complete datasheets, test reports (IEC 61812-1, UL 508, CE), ISO certificates, and compliance declarations. Conduct technical review, request samples for testing, check customer references, and calculate scores using the evaluation framework.

Phase 3: Supplier Qualification (2-4 weeks) – Verify top candidate(s) can deliver. For high-value applications, conduct site visits. Negotiate commercial terms, place a pilot order, evaluate delivery and quality, then make final selection.

Phase 4: Ongoing Performance Management – Track delivery, quality (PPM), and responsiveness. Re-verify certifications annually and conduct periodic audits for critical suppliers.

Qualification Checklist

- Technical specifications meet or exceed requirements

- Required certifications verified (ISO 9001, UL/CE, RoHS)

- Test reports from accredited labs reviewed

- Samples tested successfully

- Customer references positive

- Evaluation score meets threshold (70%+ qualified, 80%+ preferred)

- Commercial terms agreed

- Pilot order successful

Frequently Asked Questions

Q: How do I verify a manufacturer’s CE marking is legitimate?

A: Request the Declaration of Conformity and test reports to harmonized standards (IEC 61812-1, IEC 61326). Legitimate CE marking requires documented testing, not just a logo. Be cautious with manufacturers who can’t provide test reports.

Q: Is UL listing required for time relays?

A: It depends on your market. UL listing is typically required for North America; CE marking for EU. Global suppliers should hold both.

Q: What’s a reasonable lead time for standard time relays?

A: 2-4 weeks for stock models; 6-8 weeks for custom configurations. Beware of impossibly short lead times—they may indicate quality shortcuts.

Q: Should I prioritize price or quality?

A: Quality first, then price within the qualified pool. A $2 cheaper relay causing field failures can cost hundreds in warranty labor, shipping, and lost goodwill.

Q: How often should I re-qualify my supplier?

A: Annually at minimum. Verify certifications remain current, review performance metrics, and check for organizational changes.

Q: What are common quality issues with time relays?

A: Timing accuracy drift, contact failure, and environmental sensitivity. Evaluate control by asking about routine testing procedures, component selection (e.g., Omron or Panasonic relays), and environmental test protocols.

Conclusion: Make Confident, Risk-Managed Supplier Decisions

Choosing a time relay manufacturer isn’t a decision to rush or base solely on price. The evaluation framework, criteria, and process outlined in this guide give you the tools to assess suppliers systematically, document your decision rationale, and reduce procurement risk.

The best time relay manufacturers distinguish themselves through transparent compliance (verifiable certifications, test reports from accredited labs), proven quality systems (ISO 9001, documented production controls), technical depth (application support, accurate specifications), and operational reliability (on-time delivery, responsive support). Whether you’re evaluating VIOX Electric or any other supplier, apply these criteria consistently and weight them according to your application risk profile.

Your supplier selection directly impacts your product’s reliability, your company’s reputation, and your customers’ satisfaction. Invest the time upfront to qualify the right partner, and you’ll avoid costly problems downstream.

Ready to evaluate VIOX Electric as your time relay manufacturer? Visit https://viox.com/timer-relay to explore our product range, download technical specifications, and request evaluation samples.