If you’ve ever stood in front of an electrical supply catalog trying to figure out the actual difference between a “terminal strip” and a “terminal block,” you’re not alone. These terms get thrown around interchangeably—but they refer to two distinct products with different mounting methods, construction, and ideal use cases.

For electrical engineers, panel builders, and contractors, choosing the wrong type can mean redesigning layouts, wasting rail space, or wrestling with incompatible wire terminations on-site. The good news? Once you understand the core differences, the choice becomes straightforward.

This guide breaks down exactly what each product is, when to use terminal strips vs. terminal blocks, and how to make the right call for your next control panel or industrial installation.

What is a Terminal Strip?

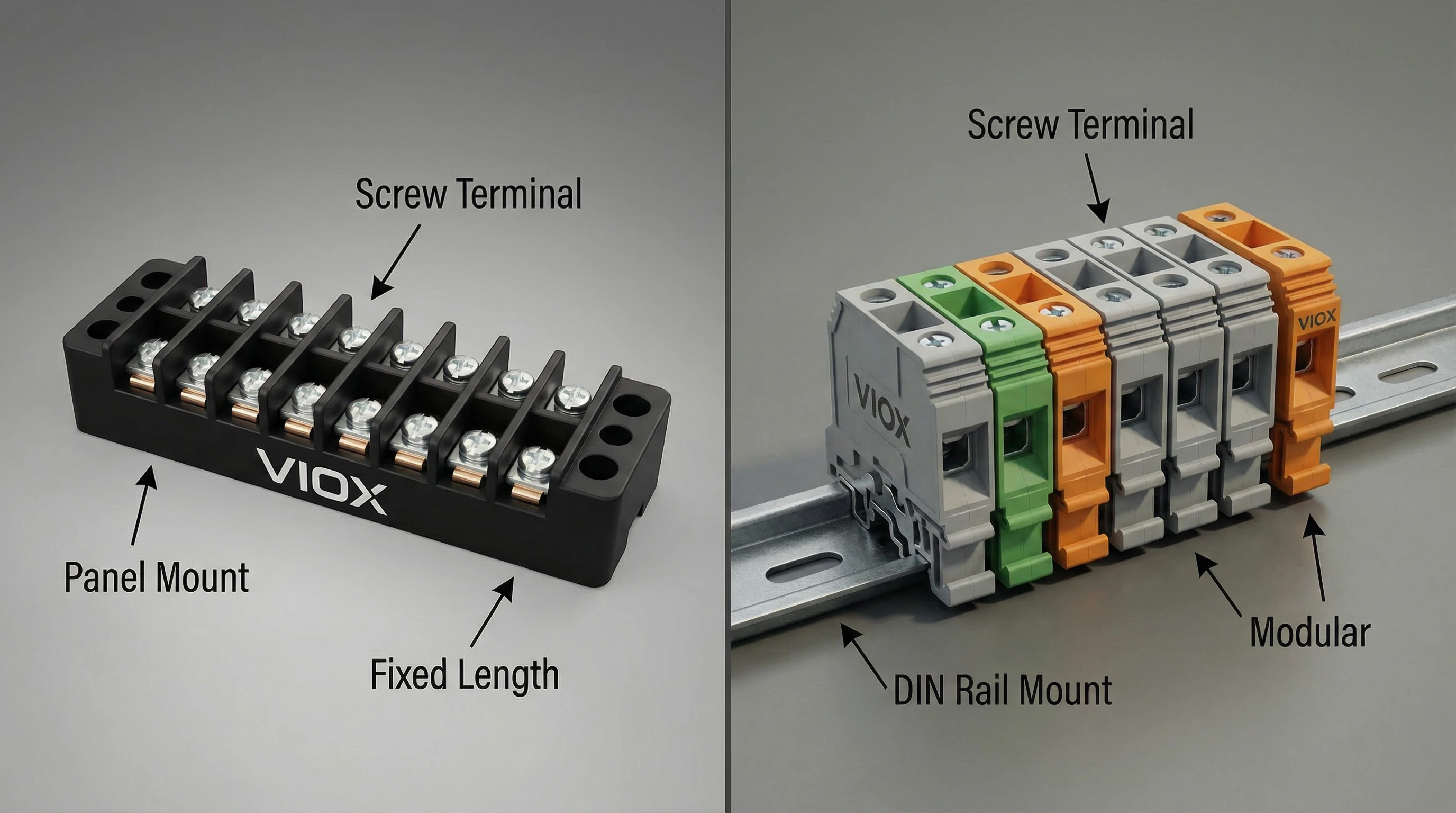

A terminal strip—also called a barrier strip or barrier terminal block—is a panel-mounted row of screw termination points separated by insulating barriers to prevent side-to-side shorting. Think of it as a fixed, organized junction point where multiple wires connect without touching each other.

Key characteristics of terminal strips:

- Panel-mounted construction: Screws or bolts fasten the strip directly to the chassis or panel surface

- Insulating barriers: Raised plastic or phenolic separators between each terminal position prevent accidental shorts

- Screw terminals: Most use captive screws acting on tubular metal conductors housed inside the strip

- Modular design: Many series are cut-to-length, allowing you to snap or cut the strip to the exact number of positions needed

- Dead-front safety: Recessed terminal design keeps live parts protected from accidental contact

- Wire range: Typically accept #6 to #26 AWG solid or stranded conductors without lugs

Barrier strips have been a workhorse in motor controls, power supplies, junction boxes, and equipment terminations for decades. Their straightforward screw-and-tighten approach requires no special tools, and the robust mechanical clamping handles high-current applications—common ratings range from 30A to 65A depending on pitch and wire size.

Typical pitch (center-to-center spacing) ranges from 8mm to 14.5mm, with larger spacings supporting higher current ratings and bigger wire gauges. The larger pitch also makes field wiring more forgiving when working with gloves or in tight enclosures.

What is a Terminal Block?

A terminal block (in this context, specifically DIN rail terminal blocks) is a modular electrical connector designed to mount on standardized metal rails—most commonly TS35 DIN rails—inside control cabinets and distribution panels. Unlike fixed terminal strips, DIN rail blocks snap onto the rail and can be arranged, rearranged, or removed as your system evolves.

Key characteristics of DIN rail terminal blocks:

- DIN rail mounting: Clips onto TS35, TS32, or TS15 standardized rails with spring-loaded or screw-release feet

- Modular assembly: Individual blocks snap side-by-side to create organized wiring runs; add or remove blocks as needed

- Multiple termination technologies: Available in screw, spring-clamp, and push-in variants

- Extensive accessories: End brackets, marking strips, jumpers (for commoning multiple terminals), test plugs, and partitions

- Compact pitch: Ultra-high density possible—some signal blocks as narrow as 3.5mm wide; multi-level blocks stack vertically to save rail space

- Wide conductor range: Standard through-blocks handle 0.14mm² to 25mm² (26-4 AWG); high-current spring-pressure variants reach 185mm² (350 kcmil)

DIN rail terminal blocks dominate industrial automation, BMS, HVAC, power distribution, and control panels because they balance high density with flexibility. The modular ecosystem—including disconnect blocks, fuse blocks, and sensor/actuator variants—lets you build exactly the wiring architecture your system needs.

Spring-clamp and push-in termination technologies are particularly valued in vibration-prone environments (machine building, railway, marine) because they require no torque maintenance and resist connection loosening over time.

Key Differences at a Glance

While both terminal strips and terminal blocks serve the same basic purpose—connecting wires safely and reliably—their design philosophies diverge sharply. Here’s what sets them apart:

1. Mounting Method

Terminal strips are panel-mounted. You drill holes, position the strip, and bolt or screw it directly to the chassis, backplate, or junction box wall. Once installed, the strip is fixed in place.

Terminal blocks are DIN rail-mounted. They clip onto a standardized metal rail with a spring-loaded mechanism. You can slide blocks along the rail, add new ones, or remove them without disturbing adjacent connections—no drilling required.

2. Modularity and Flexibility

Terminal strips are typically fixed-length units. While many can be cut to size before installation, once mounted they stay put. Adding positions means installing a second strip elsewhere.

Terminal blocks are infinitely modular. Need to add a fuse block between two signal terminals? Just unclip, insert the new block, and snap everything back in sequence. This makes them ideal for systems that evolve or require field modifications.

3. Density and Footprint

Terminal strips use larger pitch spacings (8-14.5mm) to accommodate robust screw terminals and ensure adequate creepage/clearance for higher voltages and currents. This means fewer connection points per linear inch but more breathing room for thick wires.

Terminal blocks achieve much higher density. Standard signal blocks can be as narrow as 3.5mm, and multi-level (double-deck, triple-deck) designs stack terminals vertically, conserving precious rail space in crowded panels.

4. Termination Technology

Terminal strips overwhelmingly use screw clamp connections. The captive screw presses directly on the conductor or a tubular brass busbar. It’s simple, proven, and handles high clamping force—but requires a screwdriver and periodic torque checks in vibration environments.

Terminal blocks offer screw, spring-clamp, and push-in termination. Spring-clamp and push-in technologies are maintenance-free, vibration-resistant, and faster to wire (no torque driver needed), though screw variants are still common for compatibility and high-current applications.

5. Accessory Ecosystem

Terminal strips are minimalist. You get the terminals and barriers; labeling and wire management are typically handled separately.

Terminal blocks come with a rich accessory catalog: end brackets, partition plates, marking strips (printed or writable), jumper bars (for commoning adjacent terminals), test plugs, and DIN rail accessories. This ecosystem supports systematic, maintainable panel layouts.

Terminal Strip vs Terminal Block: Feature Comparison

| Feature | Terminal Strip (Barrier Strip) | Terminal Block (DIN Rail) |

| Mounting | Panel/chassis mount (drill and screw) | DIN rail clip-on (TS35/TS32/TS15) |

| Modularity | Fixed length (cut-to-size before install) | Infinitely modular (add/remove blocks) |

| Typical Pitch | 8-14.5mm | 3.5mm to 10mm (multi-level options) |

| Termination | Screw clamp (captive screw on busbar) | Screw, spring-clamp, push-in |

| Current Range | 30-65A typical | 0.5A (signal) to 300A+ (power) |

| Voltage Range | Up to 600V | Up to 1000V (depending on series) |

| Wire Size | #6 to #26 AWG (solid/stranded) | 0.14mm² to 185mm² (26 AWG to 350 kcmil) |

| Accessories | Minimal (covers, basic labels) | Extensive (end brackets, jumpers, test plugs, marking systems) |

| Installation Speed | Moderate (requires drilling, positioning) | Fast (snap onto rail, push-in terminals) |

| Field Modification | Difficult (fixed once mounted) | Easy (unclip, rearrange, add blocks) |

| Vibration Resistance | Good (with proper torque) | Excellent (spring/push-in variants) |

When to Use Terminal Strips

Terminal strips excel in scenarios where simplicity, robustness, and high-current capacity matter more than modularity or ultra-compact density. Here’s where they shine:

1. Simple Power Distribution

When you need to split a single incoming power feed to multiple outgoing circuits—like distributing line, neutral, and ground in a junction box—a barrier strip provides a straightforward, high-current solution. The large pitch and robust screw terminals handle #6 to #10 AWG power conductors easily.

2. Equipment Termination Points

Manufacturers of motors, pumps, HVAC units, and industrial machinery often mount terminal strips directly on equipment chassis to provide field-wiring connection points. The panel-mount design integrates cleanly into the equipment enclosure, and the screw terminals accommodate a wide range of contractor wire practices.

3. Fixed Junction Boxes

In applications where the wiring layout is stable and won’t change—such as residential or light commercial distribution boxes—barrier strips offer a cost-effective, reliable solution without the need for DIN rail infrastructure.

4. High-Vibration Environments (with proper torque)

While screw terminals in vibration environments require periodic torque checks, properly tightened barrier strip connections can handle moderate vibration if you follow manufacturer torque specifications and use lock washers or thread-locking compound where appropriate.

5. Budget-Conscious Projects

Terminal strips are typically less expensive per connection point than DIN rail terminal blocks, especially when you factor in the cost of DIN rail, end brackets, and other accessories. For simple, fixed-wiring applications, this cost advantage can be significant.

Bottom line: Choose terminal strips when you need robust, high-current screw terminations for straightforward point-to-point wiring, and the application doesn’t require frequent modifications or ultra-high density.

When to Use Terminal Blocks (DIN Rail)

DIN rail terminal blocks are the go-to solution when modularity, organization, density, and long-term maintainability drive your design. Here’s where they deliver the most value:

1. Control Panels and Automation Systems

Industrial control panels, PLC systems, BMS, and process control cabinets benefit enormously from DIN rail terminal blocks. The modular design lets you organize I/O wiring logically, use color-coded blocks for different signal types, and add disconnect or fuse blocks inline as needed. Labeling systems keep hundreds of wires traceable.

2. High-Density Signal Wiring

When you’re terminating dozens or hundreds of low-current signals—sensor inputs, relay outputs, communication lines—DIN rail blocks with 3.5-6mm pitch pack far more connections into limited panel space than barrier strips ever could. Multi-level blocks double or triple that density vertically.

3. Systems That Evolve or Require Field Modifications

If your installation will grow over time, or if troubleshooting and rewiring are common (think commissioning phases, pilot plants, or prototyping), the ability to unclip, rearrange, or insert new blocks without drilling or disturbing adjacent wiring is invaluable.

4. Vibration-Prone Environments

Machine builders, railway systems, marine applications, and mobile equipment benefit from spring-clamp or push-in terminal blocks. These connection technologies are inherently vibration-resistant and require zero maintenance—no torque rechecks, no loosened screws.

5. Mixed Circuit Functions

Need to integrate ground blocks, fuse blocks, disconnect blocks, and sensor/actuator power blocks in one organized run? DIN rail systems let you mix and match functional blocks seamlessly. Jumper bars common adjacent terminals (e.g., linking all ground blocks or distributing 24V DC supply across multiple circuits).

Bottom line: Choose DIN rail terminal blocks when you need modular, high-density, maintainable wiring systems with extensive accessory support—especially for control panels, automation, and any application where future changes are likely.

How to Choose: Decision Framework

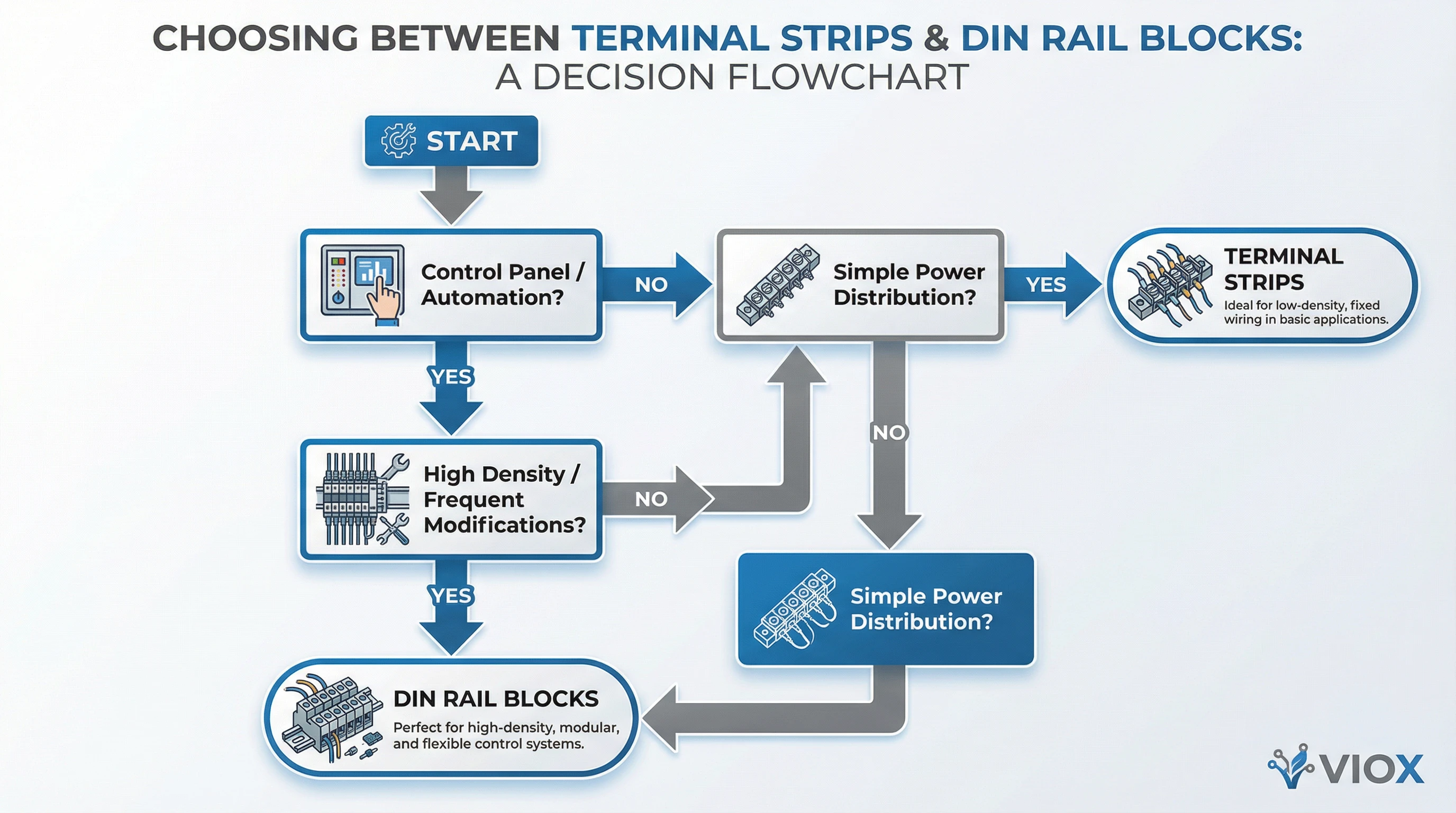

Still not sure which product fits your project? Walk through this quick decision framework:

Step 1: Assess Your Mounting Infrastructure

- Do you already have DIN rails installed? → DIN rail terminal blocks are the natural choice.

- Is this a chassis or panel-mount application with no rail? → Terminal strips integrate directly.

- Are you designing a new panel from scratch? → Consider whether modular DIN rail infrastructure justifies the upfront investment for long-term flexibility.

Step 2: Evaluate Wiring Complexity and Density

- Simple power distribution (under 20 connection points)? → Terminal strips are simpler and more cost-effective.

- High-density signal wiring (50+ connections)? → DIN rail blocks save space and improve organization.

- Mixed circuit types (power, signal, ground, fuse)? → DIN rail modular ecosystem handles this elegantly.

Step 3: Consider Future Changes

- Fixed wiring that won’t change? → Terminal strips work fine.

- Expect modifications, expansions, or troubleshooting rewires? → DIN rail blocks’ modularity pays for itself quickly.

Step 4: Factor in Vibration and Maintenance

- Low-vibration environment? → Either option works; screw terminals are proven.

- High-vibration (machinery, vehicles, marine)? → Spring-clamp or push-in DIN rail blocks eliminate maintenance.

Step 5: Budget and Total Cost of Ownership

- Tight budget, simple application? → Terminal strips cost less per connection.

- Need labeling, commoning, test points, or future expansion? → DIN rail’s accessory ecosystem and labor savings during modifications justify higher upfront cost.

Standards and Compliance

Both terminal strips and DIN rail terminal blocks must meet rigorous safety and performance standards. Understanding these standards helps you select components that pass inspection and perform reliably:

UL 1059 (North America): Component safety standard for terminal blocks and connectors. Defines spacing (creepage and clearance distances) by use group and voltage, plus temperature-rise limits and dielectric withstand testing.

IEC 60947-7-1: International standard for screw-type and screwless-type terminal blocks for copper conductors. Covers mechanical, electrical, and thermal testing.

In UL 508A industrial control panels (U.S.), the panel must declare an SCCR (Short-Circuit Current Rating). Premium DIN rail systems may carry documented SCCR ratings of 100 kA or more, enabling higher panel SCCR ratings when paired with appropriate upstream protection.

Always verify that the terminal products you specify carry approvals appropriate to your region and application (UL, CE, CSA, etc.).

Choose Based on Your System Architecture

The “terminal strip vs terminal block” question isn’t about which product is better—it’s about which one matches your system architecture and operational reality.

Choose terminal strips when you need straightforward, robust screw terminations for fixed wiring, power distribution, or equipment termination points. They deliver proven reliability at a lower cost for applications that don’t require dense signal wiring or frequent modifications.

Choose DIN rail terminal blocks when modularity, high density, maintainability, and system evolution matter. The upfront investment in DIN rail infrastructure and accessories pays off through faster installation (especially with spring/push-in terminals), cleaner organization, and the ability to modify systems without redesign.

Many installations use both: terminal strips for main power distribution and equipment interface points, DIN rail blocks for control wiring and signal terminations inside the panel.

At VIOX Electric, we manufacture both terminal strips and DIN rail terminal blocks built to meet UL and IEC standards. Whether you’re building a simple junction box or a complex automation system, choosing the right termination technology from the start saves time, cost, and headaches down the line.