Why SPD Installation Mistakes Cost More Than You Think

A single lightning strike near an overhead power line generates electromagnetic fields that induce voltage surges exceeding 6,000 volts. When Surge Protective Devices (SPDs) fail due to improper installation, the consequences extend far beyond equipment damage. Facility downtime, production losses, and safety incidents create financial impacts that dwarf the initial cost of proper installation.

Industry data reveals that incorrectly installed SPDs fail at rates 20% higher within the first year compared to properly maintained units. Yet many electrical contractors continue making the same installation errors that compromise protection effectiveness. This article examines the ten most critical SPD installation mistakes and provides technical solutions based on IEC 61643, UL 1449, and NEC Article 285 standards.

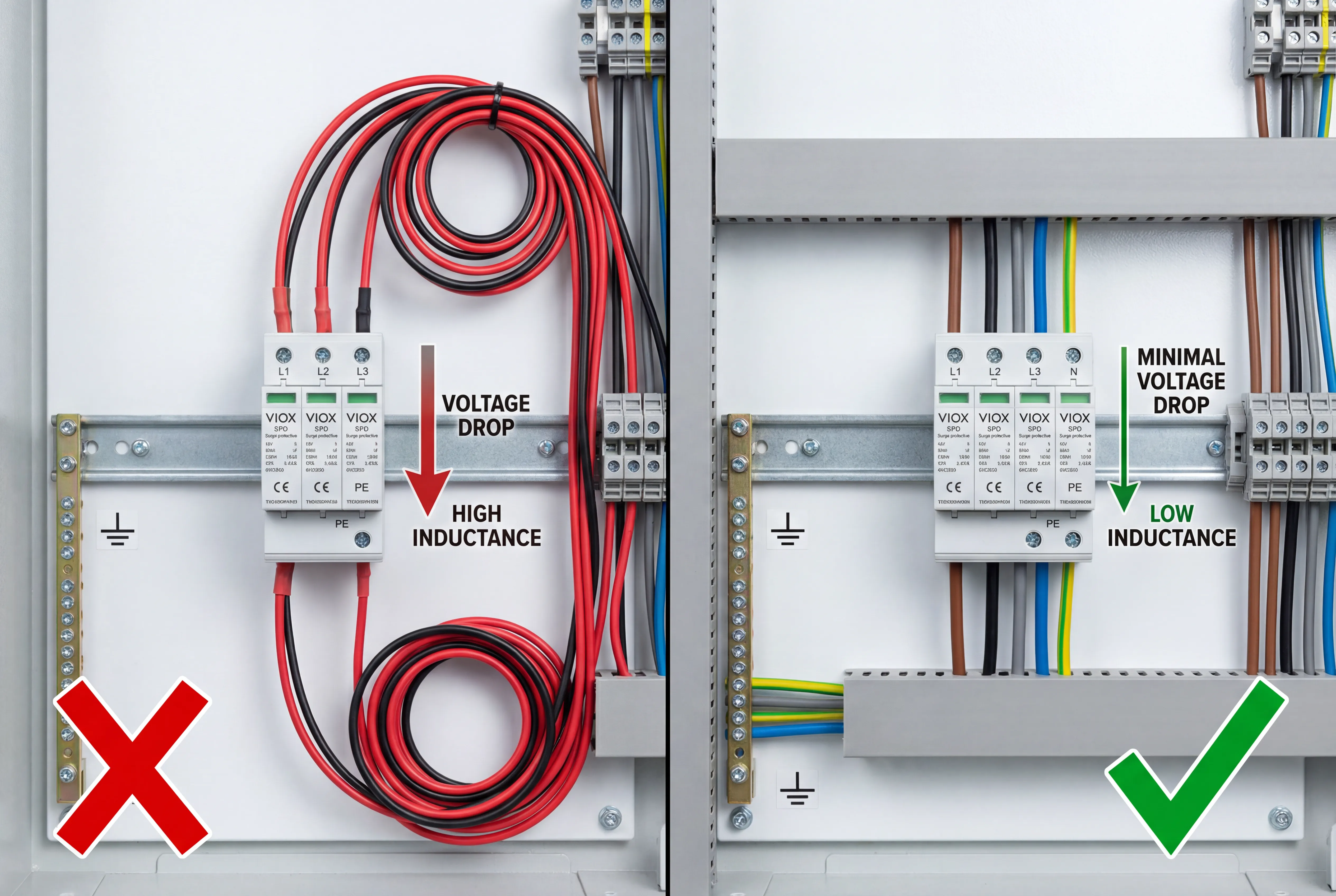

Mistake #1: Excessive Lead Length Reducing Protection Effectiveness

Each inch of conductor length between the SPD and protected equipment adds 15-25 volts to the let-through voltage. When installers run excessive wire lengths—often for aesthetic reasons or convenience—they systematically degrade the device’s protection capability.

Consider an SPD rated at 400V under UL 1449 test conditions (6 inches of lead). Installing that same device with 14 inches of #14 AWG wire adds approximately 300V to the suppression voltage. Your equipment now faces nearly 700V during surge events instead of the specified 400V.

Solution: Keep total conductor length under 0.5 meters (approximately 20 inches) as specified in installation standards. Route phase, neutral, and ground conductors together, maintaining equal lengths. When crossing other wires is unavoidable, do so at right angles to minimize electromagnetic interference. Install SPDs as close as possible to the service entrance or distribution panel to minimize conductor runs.

Mistake #2: Improper Conductor Sizing Creating Fire Hazards

Using undersized conductors for SPD connections creates resistance that generates heat during surge events. This poses fire risks and reduces the device’s ability to divert surge current effectively. Many installers incorrectly assume that standard branch circuit wire sizing applies to SPD connections.

The conductor must handle the SPD’s maximum discharge current (Imax) without overheating. Additionally, the wire size must comply with the device’s Short Circuit Current Rating (SCCR) and the available fault current at the installation point.

Solution: Follow manufacturer specifications for minimum conductor sizes, typically requiring #14 AWG minimum for residential applications and #10 AWG or larger for commercial installations. Verify that conductor ampacity exceeds the SPD’s nominal discharge current (In). For Type 1 SPDs handling high-energy lightning strikes, #6 AWG or larger may be necessary. Never reduce conductor size below what the manufacturer specifies, regardless of local code minimums.

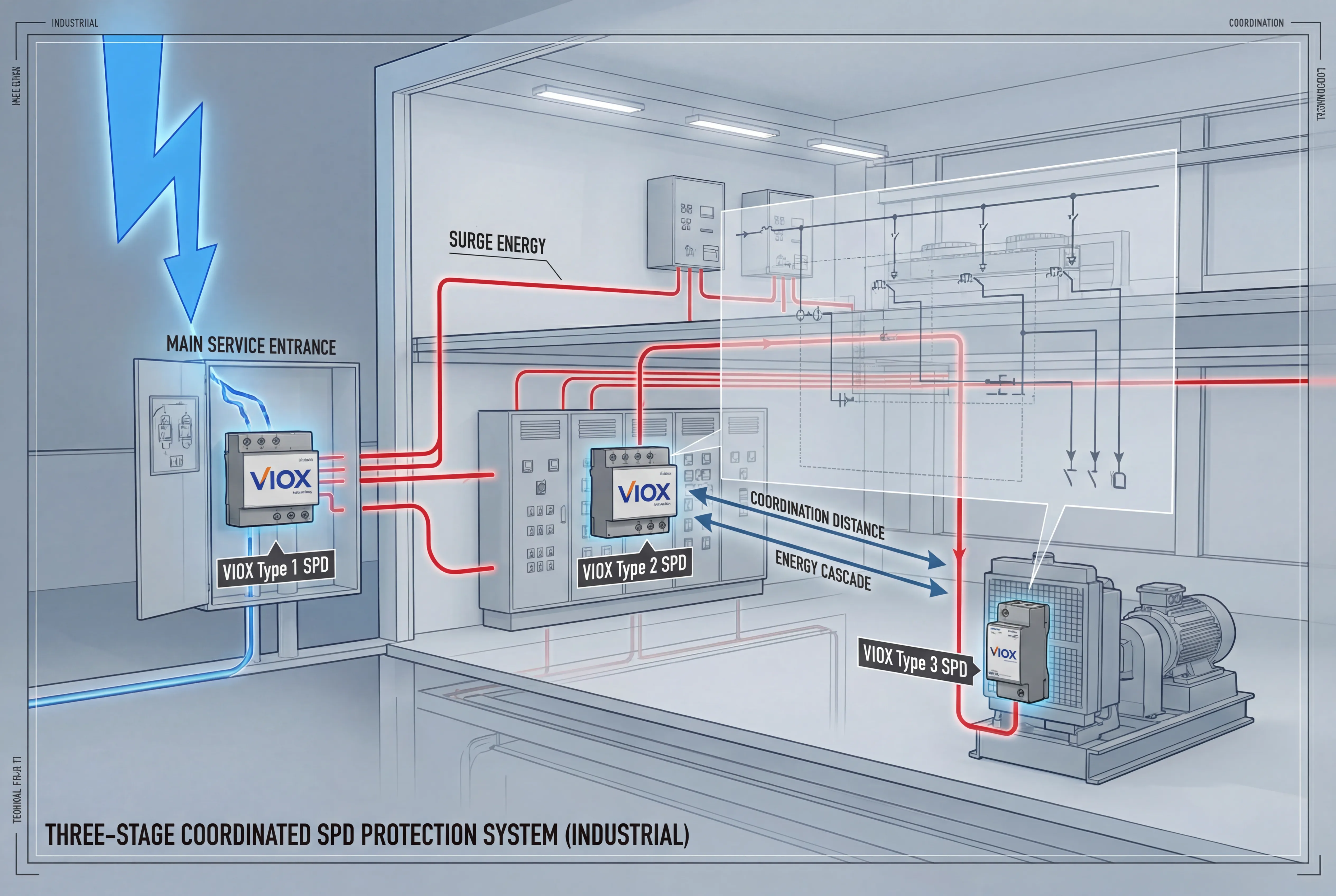

Mistake #3: Selecting the Wrong SPD Type for Installation Location

The three SPD types serve distinct functions in the electrical system. Type 1 devices install at service entrances to handle direct lightning strikes with high discharge capacity. Type 2 devices protect distribution panels against indirect lightning and switching surges. Type 3 devices provide point-of-use protection for sensitive equipment.

Installing only Type 2 SPDs without Type 1 protection leaves systems vulnerable to high-energy lightning currents. Conversely, attempting to protect terminal equipment solely with Type 1 devices fails to address the transient voltages that Type 3 devices handle effectively.

Solution: Implement coordinated protection using multiple SPD types. Install Type 1 at the service entrance where utility power enters the facility. Add Type 2 devices at distribution panels serving critical loads. Include Type 3 protection for sensitive electronics and control systems. Verify that each SPD type matches its installation location according to IEC 61643 classification and UL 1449 requirements.

Mistake #4: Failing to Coordinate Multiple SPDs Properly

When multiple SPDs protect different points in the electrical system, they must coordinate to prevent damage. Without proper coordination, the upstream device may fail to operate correctly, leaving downstream devices exposed to energy levels exceeding their ratings.

Coordination requires maintaining sufficient electrical distance (typically 10 meters of conductor or decoupling inductors) between protection stages. This allows energy cascade, where each SPD handles appropriate surge levels without interference.

Solution: Maintain minimum 10-meter conductor distance between Type 1 and Type 2 devices, and between Type 2 and Type 3 devices. When physical distances are shorter, install decoupling inductors between stages. Verify that upstream devices have higher Imax ratings than downstream units. Document the coordination scheme in system drawings and verify voltage protection levels (Up) decrease at each stage toward the protected equipment.

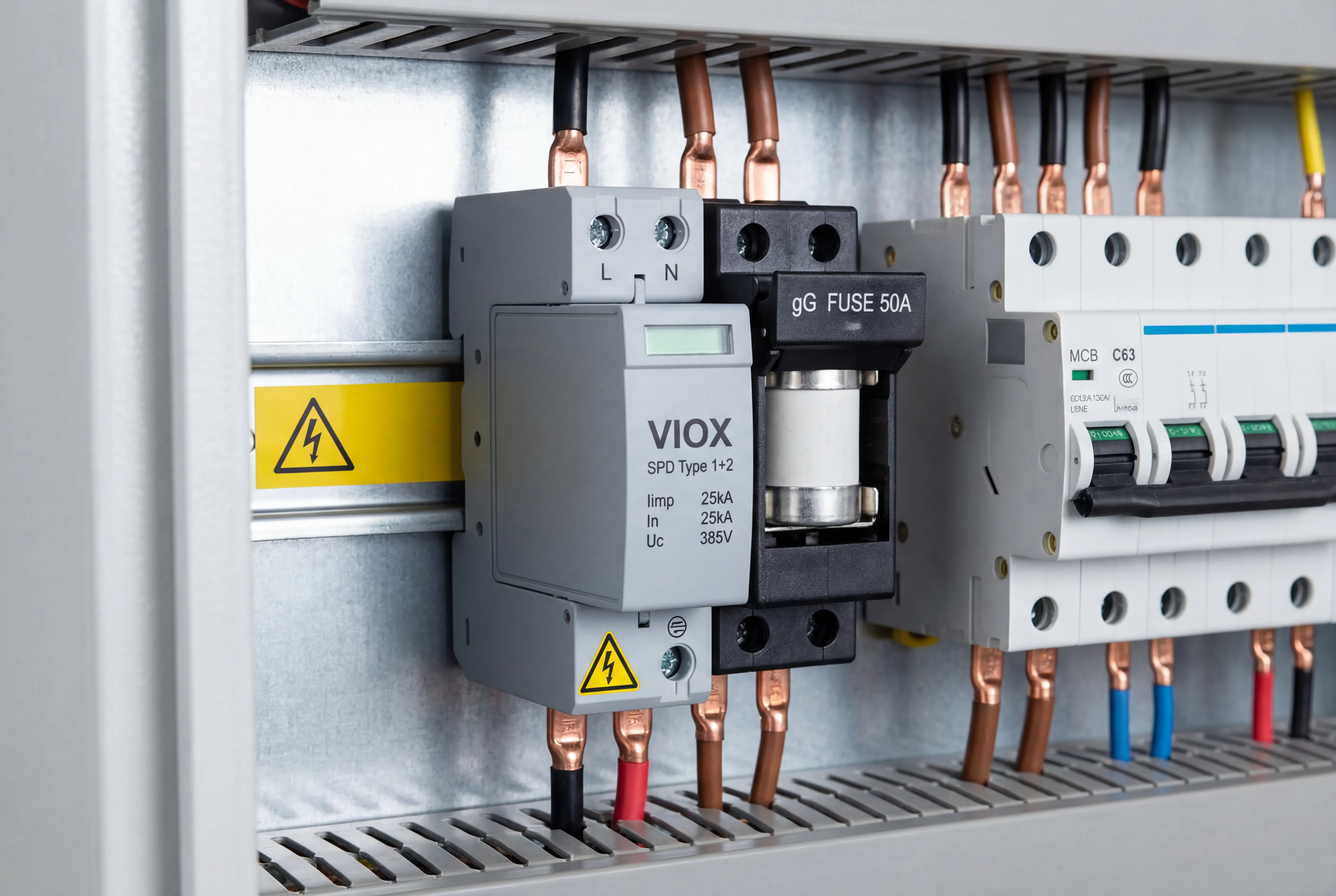

Mistake #5: Neglecting Backup Overcurrent Protection

SPDs contain components that sacrifice themselves during surge events. Metal Oxide Varistors (MOVs) degrade with each surge until they fail, potentially creating short-circuit conditions. Without dedicated backup protection, a failed SPD can trip the main breaker, causing unnecessary facility-wide outages.

Many installers overlook this requirement or select backup fuses with incorrect ratings. An oversized fuse fails to provide adequate protection, while an undersized fuse may nuisance-trip during normal SPD operation.

Solution: Install dedicated backup overcurrent protection rated according to manufacturer specifications. Most Type 1 and Type 2 SPDs require gG-type fuses sized between 80A and 125A, depending on the device. The backup protection must coordinate with the SPD’s internal thermal disconnector. Never connect SPDs to the main service disconnect without separate overcurrent protection. For installations requiring ultra-fast response, select the fuse type specified in the SPD installation manual.

Mistake #6: Inadequate Grounding System Integration

SPD effectiveness depends entirely on the grounding system’s ability to safely dissipate surge energy. A high-impedance ground connection or improper bonding compromises protection, potentially creating dangerous voltage potentials within the facility.

The grounding system must meet NEC Article 250 requirements with resistance typically below 5 ohms for residential installations and below 2 ohms for commercial facilities. Additionally, ferrous metal raceways containing grounding conductors require bonding at both ends per NEC 250.64(E).

Solution: Test ground resistance before SPD installation using fall-of-potential or clamp-on methods. Verify that grounding electrode conductors meet minimum sizes specified in NEC Table 250.66. Bond all grounding connections per NEC 250.8 using listed methods (exothermic welding, listed compression connectors, or listed ground clamps). When installing grounding conductors in ferrous metal raceways, provide bonding at both ends to prevent inductive impedance. Route AC, DC, and data cables together with their associated bonding conductors to minimize loop areas.

Mistake #7: Ignoring SPD Monitoring and Status Indicators

Modern SPDs include status indicators (typically LED lights) showing operational status. Green indicates active protection, while red signals device failure. Yet many installations lack anyone monitoring these indicators, resulting in failed SPDs remaining in place without providing protection.

One industrial survey found that 20% of SPDs without regular maintenance failed within the first year, while properly monitored units had failure rates below 2%. The difference represents unnecessary equipment damage and downtime.

Solution: Establish quarterly visual inspection protocols for all SPD status indicators. For critical installations, specify SPDs with remote monitoring capabilities that integrate with building management systems. Document all inspections, recording the date, inspector, and device status. When red indicators appear, immediately schedule SPD replacement—the device no longer provides protection. Consider SPDs with modular designs that allow rapid field replacement without extensive electrical work.

Mistake #8: Overlooking Environmental Operating Limits

SPDs have specific environmental ratings for temperature, humidity, and altitude. Installing devices outside these parameters accelerates degradation and reduces service life. Outdoor installations without proper enclosures expose SPDs to moisture and temperature extremes that compromise their metal oxide varistor components.

Additionally, altitude affects SPD performance. At elevations above 2,000 meters, air density decreases, reducing the device’s ability to dissipate heat and lowering its insulation capabilities.

Solution: Verify that SPD environmental ratings match installation conditions. For outdoor applications, specify NEMA 3R or IP65-rated enclosures minimum. In harsh industrial environments with temperature extremes, corrosive atmospheres, or high humidity, select SPDs with appropriate environmental protection ratings. For installations above 2,000 meters altitude, consult manufacturers regarding derating requirements or select devices specifically rated for high-altitude operation. Maintain ambient temperature within manufacturer specifications, typically -40°C to +85°C for industrial-grade devices.

Mistake #9: Incorrect Terminal Connections and Wiring Configuration

Connecting phase, neutral, or ground conductors to wrong terminals renders the SPD ineffective or creates dangerous conditions. This error is particularly common in three-phase systems where installers confuse line connections or incorrectly handle neutral-to-ground bonding.

The wiring configuration must match the system grounding arrangement (TN, TT, or IT systems per IEC 60364). Type 1+2 combination devices require specific neutral-to-earth modules depending on whether the system uses a solidly grounded or high-impedance grounded configuration.

Solution: Study the SPD manufacturer’s wiring diagrams before making any connections. Verify system grounding configuration and voltage levels match SPD specifications. For three-phase systems, clearly label L1, L2, L3, neutral, and ground conductors before connecting. When installing combination Type 1+2 devices, confirm that the neutral-to-earth protection module configuration matches your electrical system. Use voltage testers to verify correct connections before energizing the circuit. For complex installations, consult factory technical support to validate the wiring scheme.

Mistake #10: DIY Installation Without Proper Qualifications

Electrical code requirements mandate that licensed electricians perform SPD installations. Yet some facility maintenance personnel attempt installations without adequate training, creating safety hazards and code violations that void equipment warranties and insurance coverage.

Unqualified installers typically lack knowledge of surge coordination principles, proper grounding techniques, and code compliance requirements. The resulting installations may appear functional but fail to provide effective protection.

Solution: Require that only licensed electrical contractors perform SPD installations. Verify that installers have specific training in surge protection principles and applicable standards (NEC Article 285, IEC 61643, UL 1449). Request documentation of installer qualifications before work begins. For large commercial or industrial projects, consider factory-certified installation services or direct manufacturer oversight. Ensure that local authorities inspect and approve installations before placing systems into service. Maintain complete installation documentation including wiring diagrams, test results, and commissioning reports.

Compliance and Code Requirements

NEC Article 285 establishes minimum requirements for SPD installation in North America. The 2020 NEC introduced mandatory surge protection for dwelling unit services under Section 230.67, while the 2023 NEC expanded requirements for fire alarm systems and critical safety circuits.

International installations must comply with IEC 62305 series standards for lightning protection systems and IEC 61643 for SPD specifications. European installations follow EN 62305 and integrate SPD requirements into national electrical codes.

Key compliance points include:

- SPDs must be UL 1449 listed (North America) or CE marked (Europe)

- Installation must follow manufacturer instructions without deviation

- Conductor sizing must meet code minimums and manufacturer specifications

- Grounding must comply with NEC Article 250 or equivalent regional standards

- Backup overcurrent protection is mandatory for most installations

- Regular inspection and maintenance records demonstrate due diligence

Frequently Asked Questions

How often should SPDs be inspected and tested?

Perform visual inspections quarterly, checking status indicators and physical condition. Conduct comprehensive testing annually using surge-current generators and voltage testers per IEC 61643-12. In lightning-prone areas or high-exposure locations, increase inspection frequency to monthly. Replace any SPD showing red status indicators immediately.

Can I install Type 2 SPDs on the line side of service overcurrent protection?

No. NEC Section 242.12(A) and (B) explicitly prohibit Type 2 SPD installation on the line side of service overcurrent devices. Only Type 1 SPDs are permitted in this location. Type 2 devices must install on the load side of the main disconnect.

What is the typical service life of an SPD?

Quality SPDs typically last 5-10 years depending on technology, environmental conditions, and surge activity. Devices rated at 250 kA per phase provide 25+ year life expectancy in high-exposure locations. Regular monitoring and immediate replacement of failed units ensures continuous protection. Service life varies significantly based on local lightning activity and power quality conditions.

Do surge protection strips provide adequate protection?

Power strips offer only minimal point-of-use protection and cannot protect hardwired equipment like HVAC systems, water heaters, or building wiring. Effective protection requires coordinated SPDs installed at the service entrance, distribution panels, and sensitive equipment locations. Consider power strips as supplementary Type 3 protection, not primary defense.

Is surge protection mandatory in all locations?

Requirements vary by jurisdiction. The 2020 NEC mandates SPDs for dwelling unit services in North America. The 2023 NEC requires SPDs for fire alarm control panels and critical safety circuits. International requirements follow IEC 60364-4-44, which mandates SPDs where overvoltage could endanger life, interrupt public services, or cause significant financial loss. Consult local authorities for specific requirements.

How do I verify my SPD is still protecting my facility?

Check the status indicator regularly—green means protection is active, red means replace the device. For installations without visual indicators, annual testing by qualified electricians using specialized equipment verifies performance. Monitor for electrical equipment failures or damage patterns that might indicate compromised surge protection. Maintain inspection logs documenting device status and any surge events.

Protect Your Investment with VIOX SPD Solutions

Proper SPD installation requires technical expertise, quality components, and adherence to international standards. VIOX manufactures industrial-grade Surge Protective Devices engineered for maximum protection effectiveness and service life. Our Type 1, Type 2, and Type 3 devices meet UL 1449 and IEC 61643 requirements while providing industry-leading warranty protection.

Contact VIOX technical support for installation guidance, product selection assistance, and coordinated protection system design. Our engineering team provides comprehensive specifications, wiring diagrams, and commissioning support to ensure your SPD installation delivers reliable protection for years to come.

Visit viox.com to explore our complete surge protection portfolio and access technical resources including installation guides, compliance documentation, and training materials. Protect your facility with SPD solutions engineered for performance.