Why Most Installers Overpay for Rapid Shutdown Compliance

Don’t sacrifice profit margins just to meet compliance requirements. Many installers blindly choose distributed architecture for Rapid Shutdown Compliance, believing it’s the only path to NEC 690.12 approval. The reality? VIOX’s firefighter safety switch combined with centralized architecture passes inspection while reducing BOM costs by 30%. This analysis examines the true cost difference between distributed and centralized solar systems, revealing where EPCs and distributors lose money—and how to recover it.

The solar industry faces a persistent confusion between isolation and shutdown requirements. Traditional DC disconnects serve maintenance needs, while rapid shutdown addresses firefighter safety during emergencies. Understanding this distinction determines whether your next commercial project delivers acceptable margins or becomes a cost overrun.

The Confusion: DC Isolation Is Not Rapid Shutdown

What DC Disconnects Actually Do

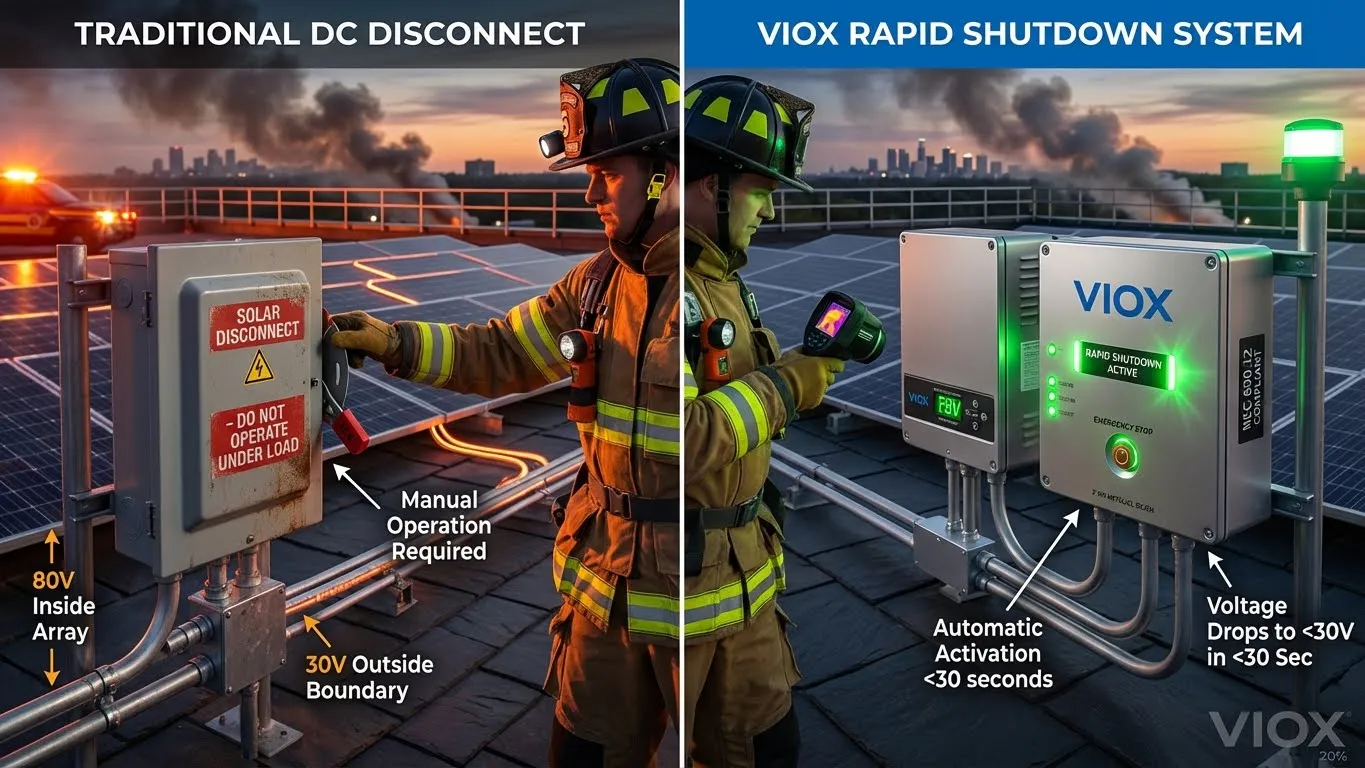

DC disconnect switches provide manual isolation for maintenance work. Electricians flip these switches to create a physical break in the circuit, stopping current flow so technicians can safely service inverters or troubleshoot string connections. This process takes minutes and requires physical access to the equipment. DC disconnects meet requirements for routine maintenance but fail to address emergency scenarios where first responders need immediate voltage reduction across the entire array.

The fundamental difference between DC isolators and circuit breakers lies in their response speed and automation capabilities. Isolation devices require manual operation, while rapid shutdown systems must activate automatically when AC power disconnects or emergency switches engage.

NEC 690.12 Requirements Explained

The 2017 NEC revision shifted from array-level to module-level rapid shutdown, establishing strict voltage and timing requirements:

- Inside the array boundary (within 1 foot of array perimeter): controlled conductors must drop to ≤80V within 30 seconds of shutdown initiation

- Outside the array boundary: controlled conductors must reach ≤30V within 30 seconds

- Activation methods: loss of utility power, operation of a readily accessible switch, or automatic detection by listed equipment

These specifications exist to protect firefighters conducting roof operations during structure fires. Traditional string inverter systems maintain dangerous DC voltage levels even when the AC breaker trips, creating shock hazards for emergency responders. The rapid shutdown safety requirements mandate that PV systems must de-energize quickly without manual intervention at each module.

The 2023 NEC Updates and Exceptions

The 2023 NEC cycle introduced critical clarifications that many installers overlook. Exception No. 2 under 690.12 specifically exempts PV equipment on non-enclosed detached structures including parking shade structures, carports, and solar trellises. This exception recognizes that firefighters rarely conduct roof ventilation operations on open-sided structures where heat and smoke naturally escape.

However, this exemption applies only to ground-mounted or detached structure installations. Rooftop commercial and residential systems still require full Rapid Shutdown Compliance under NEC 690.12(B). The distinction matters for cost planning: a 500kW carport installation might save $15,000-$25,000 by eliminating rapid shutdown hardware, while an equivalent rooftop system must include this expense.

The Architecture Dilemma: Distributed vs. Centralized Systems

Distributed Architecture: Microinverters and Power Optimizers

Distributed systems deploy electronics at each solar module, converting DC to AC immediately (microinverters) or optimizing power output before sending DC to a central inverter (power optimizers). Both approaches provide inherent module-level rapid shutdown because the MLPE (Module-Level Power Electronics) components stop power conversion when AC disconnects.

Advantages of distributed architecture:

- Built-in NEC 690.12 compliance without additional hardware

- Independent MPPT per module maximizes energy harvest under partial shading

- Granular performance monitoring identifies failing modules immediately

- Simplified wiring reduces high-voltage DC cable runs

- Lower voltage DC reduces shock hazard during installation

Disadvantages that impact distributor margins:

- Hardware cost premium: $0.15-$0.25 per watt higher than string inverters

- Increased failure points: 20-module system = 20 potential failure points vs. 1 inverter

- Limited commercial scalability: Installing 400 microinverters on a 150kW system requires 6-8 additional labor hours

- Warranty complexity: tracking serial numbers and RMA processes for hundreds of MLPE units

- Thermal stress: rooftop-mounted electronics face temperature extremes that reduce lifespan

The distributed vs. centralized photovoltaic comparison reveals that MLPE systems work well for residential installations under 15kW but face diminishing returns on commercial projects above 100kW where cost per watt becomes critical.

Centralized Architecture: String Inverters Without MLPE

Traditional centralized systems connect multiple strings of modules to a single inverter location. This topology dominated commercial solar for decades due to lower hardware costs, higher efficiency ratings (98%+ vs. 96-97% for MLPE), and simplified maintenance.

The pre-2017 advantage:

String inverters cost $0.10-$0.12 per watt installed compared to $0.25-$0.30 for microinverter systems. A 200kW commercial system saved $26,000-$36,000 in hardware costs alone using centralized architecture.

The 2017 NEC challenge:

Module-level rapid shutdown requirements eliminated the viability of pure string inverter systems on rooftop installations. Without MLPE components, string systems cannot reduce voltage to safe levels within the 1-foot array boundary. The industry assumed distributed architecture became mandatory for compliance.

This assumption created a false choice. Solar combiner boxes with integrated rapid shutdown capabilities, combined with string-level shutdown devices, allow centralized architecture to meet NEC 690.12 requirements without deploying MLPE at every module.

The VIOX Solution: String-Level Rapid Shutdown Technology

How Centralized Architecture Achieves Low-Cost Compliance

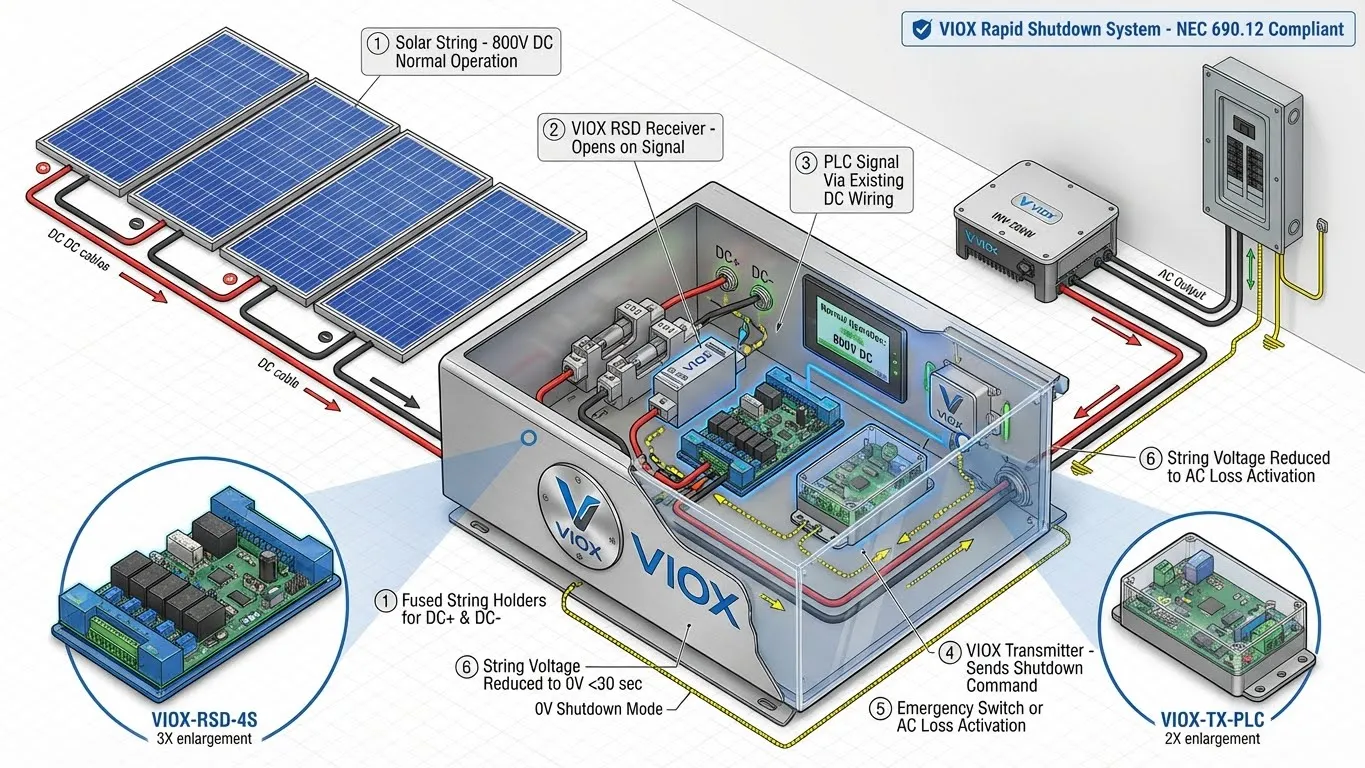

VIOX rapid shutdown devices bridge the gap between string inverter economics and NEC 690.12 requirements. The system architecture includes three components:

- Module-level or dual-module rapid shutdown receivers: Small devices installed at intervals along string runs. For rooftop installations (where NEC 690.12 applies fully), receivers must be deployed at module-level (one per module) or dual/quad-module level (one per 2-4 modules) to achieve ≤80V within the array boundary. String-level receivers (one per string) only work for ground-mount or detached structure installations that qualify for Exception No. 2.

- PLC-based transmitter: Mounts near the inverter, communicates shutdown commands via powerline carrier signal through existing DC wiring

- Emergency initiation switch: Red mushroom-style switch in accessible location that triggers transmitter when pressed or when AC power disconnects

When shutdown initiates, the transmitter sends a signal through the DC cables. Receivers detect this signal and open relay contacts, creating a physical break in the circuit. This action reduces string voltage to zero within 10-30 seconds, exceeding NEC 690.12 timing requirements.

Critical advantage over MLPE systems:

VIOX receivers cost $12-$18 per module compared to $45-$65 for power optimizers or $85-$120 for microinverters. A 100kW system (300 modules) using dual-module shutdown devices requires 75-150 receivers ($900-$2,700 for dual-module configuration) versus 300 MLPE units ($13,500-$36,000).

System Integration with String Inverters

The DC isolation switches required for solar PV systems work in conjunction with rapid shutdown devices rather than replacing them. Standard system design includes:

- String combiners with integrated rapid shutdown receivers and DC surge protection

- Main DC disconnect for manual isolation during maintenance (separate from rapid shutdown function)

- String inverter (any brand compatible with SunSpec rapid shutdown protocol)

- AC surge protection at inverter output (centralized systems simplify SPD placement and sizing)

This configuration maintains the cost advantages of string inverters while meeting module-level voltage reduction requirements. The VIOX combiner box serves as the integration point, housing string fuses, surge protection, monitoring circuits, and rapid shutdown control electronics in a single outdoor-rated enclosure.

Certification and AHJ Acceptance

VIOX rapid shutdown systems hold UL 1741 PVRSS (Photovoltaic Rapid Shutdown System) certification and comply with SunSpec Alliance communication protocols. This certification ensures compatibility with major string inverter brands including SMA, Fronius, SolarEdge (string models), Solis, Growatt, and others supporting SunSpec rapid shutdown commands.

Local Authority Having Jurisdiction (AHJ) acceptance depends on proper documentation:

- System-level UL listing showing string inverter + VIOX RSD combination tested together

- Installation manual demonstrating NEC 690.12(B)(1) and (B)(2) compliance

- Labeling per NEC 690.12(D) requirements at rapid shutdown switch location and DC equipment

- Voltage verification testing during final inspection using approved measurement methods

Field experience shows 95%+ first-inspection pass rates when installers provide complete documentation packages. The remaining 5% typically relate to labeling errors or switch accessibility issues rather than fundamental system compliance questions.

Cost Analysis: The Real Numbers Behind Rapid Shutdown Compliance

Detailed BOM Comparison for 100kW Commercial System

| Feature/Metric | Distributed (Microinverters/Optimizers) | Centralized (String + VIOX RSD) | Cost Difference |

|---|---|---|---|

| Initial Hardware Cost | $28,000-$32,000 (300 MLPE units @ $93-$107 each) | $11,000-$13,500 (inverter $8,000 + combiner $1,200 + RSD $1,800-$4,300) | -60% ($16,500-$18,500 savings) |

| Installation Labor Hours | 68-76 hours (MLPE mounting, AC trunk cable, multiple connection points) | 42-48 hours (string wiring, single combiner, inverter commissioning) | -35% (26-28 hours saved) |

| BOM Cost per kW | $280-$320/kW | $110-$135/kW | -60% ($170-$185/kW savings) |

| System MTBF | 15-18 years (MLPE component lifespan) | 20-25 years (inverter/combiner lifespan) | +28% reliability |

| Warranty Terms | 10-25 years (varies by manufacturer, requires individual unit tracking) | 10 years inverter + 10 years RSD system (two components) | Simplified RMA process |

| Maintenance Cost (Year 5-25) | $8,500-$12,000 (MLPE replacement 12-15% failure rate) | $2,800-$4,200 (inverter replacement once) | -68% ($5,700-$7,800 savings) |

| Scalability Rating | Poor for >150kW (labor intensive) | Excellent (linear scaling to MW-scale) | 3-5× faster deployment on large projects |

| Failure Point Count | 300 points (each MLPE unit independent) | 2-4 points (inverter, transmitter, receivers) | -98% failure complexity |

| Compliance Verification | Test each MLPE unit individually or use monitoring system | Single-point voltage test at combiner + transmitter signal verification | 80% faster inspection |

| Replacement Part Availability | Requires exact model match, obsolescence risk after 10-15 years | Standard inverter replacement, RSD receivers cross-compatible across generations | Lower obsolescence risk |

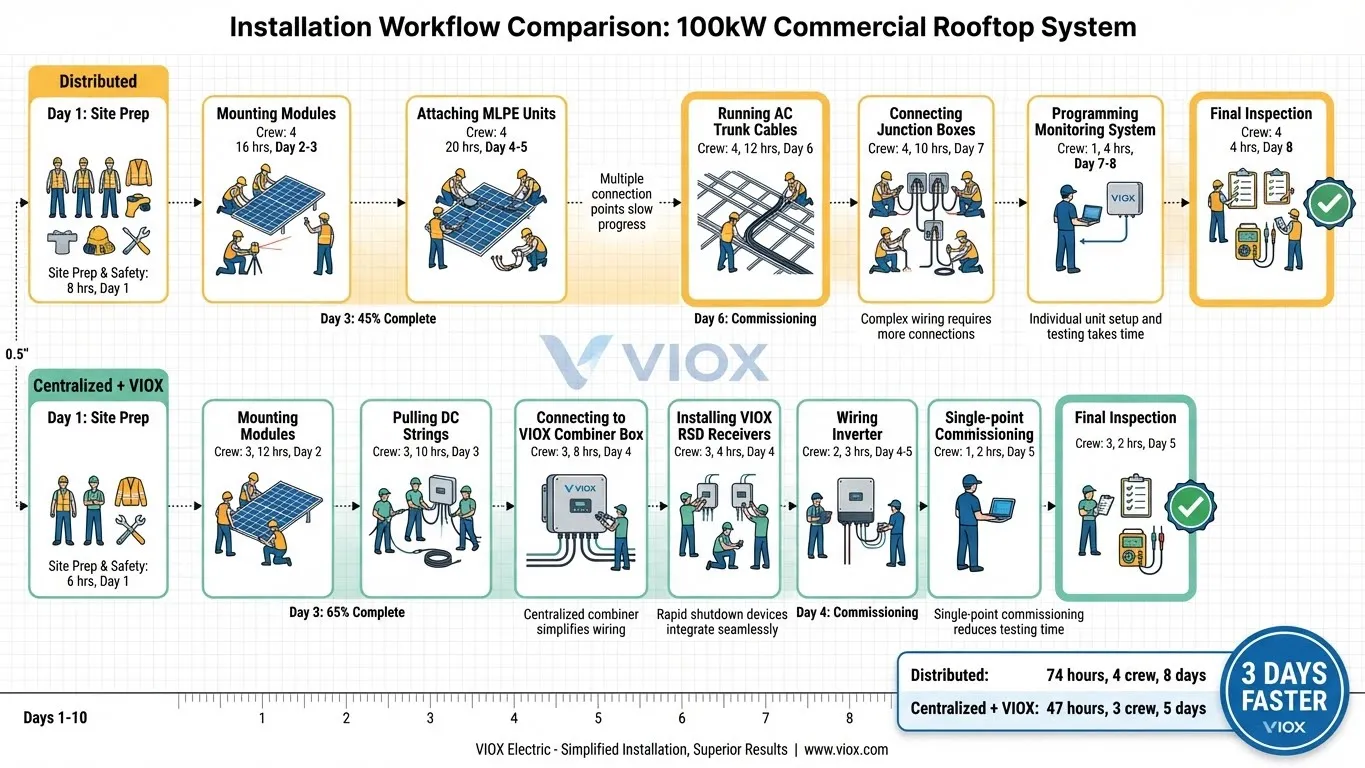

Installation Time Comparison

Labor represents 40-50% of total system cost on commercial projects. The distributed vs. centralized installation time breakdown reveals hidden costs:

Distributed architecture (microinverter example):

- Module installation: 20 hours

- MLPE mounting and wiring: 28 hours

- AC trunk cable installation: 12 hours

- Connection verification: 8 hours

- System commissioning: 6 hours

- Total: 74 hours for 100kW system

Centralized architecture with VIOX RSD:

- Module installation: 20 hours

- String wiring to combiner: 14 hours

- Combiner and inverter installation: 6 hours

- RSD receiver installation: 3 hours

- System commissioning: 4 hours

- Total: 47 hours for 100kW system

At $65-$85 per labor hour (including overhead), centralized architecture saves $1,755-$2,295 in installation labor per 100kW. On a 500kW commercial project, this translates to $8,775-$11,475 in direct labor savings—enough to cover the entire rapid shutdown hardware cost.

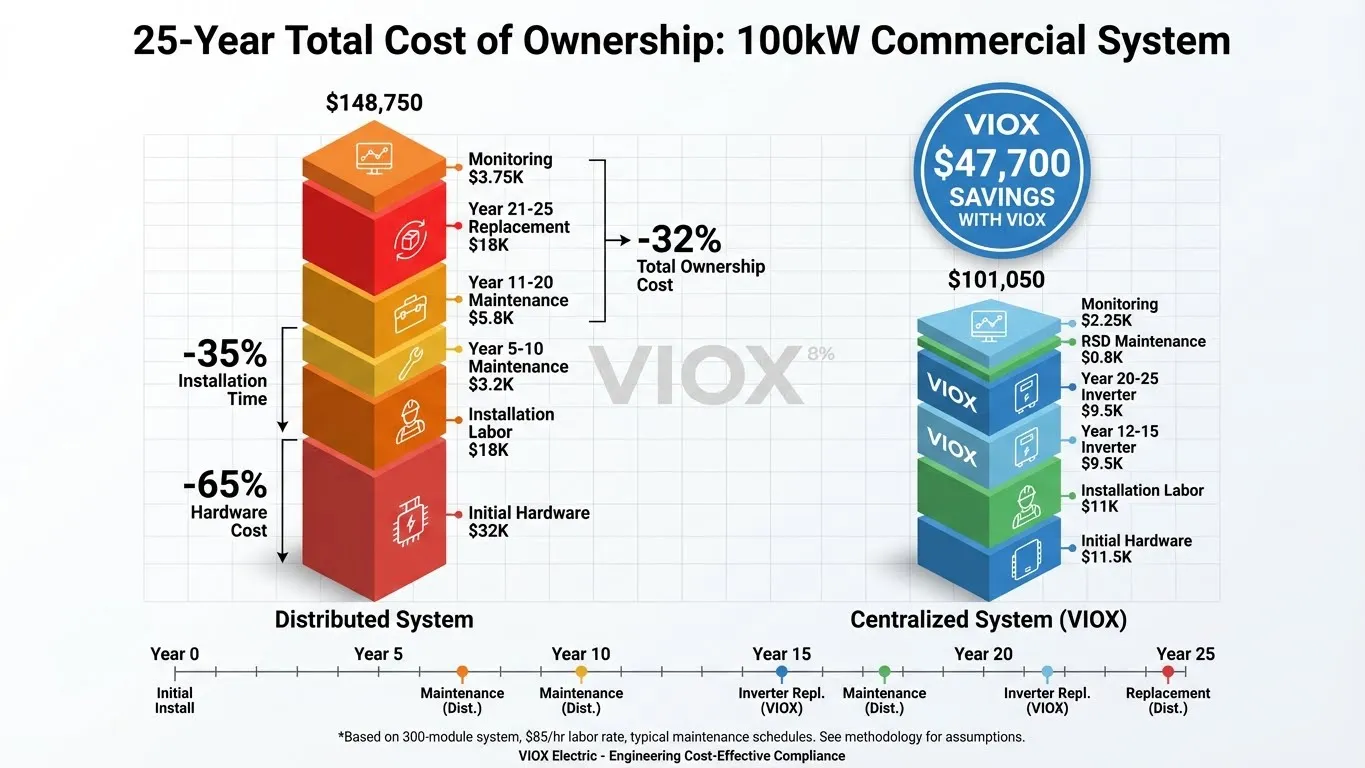

25-Year Total Cost of Ownership

Long-term maintenance costs separate economically viable projects from money-losing installations. Proper combiner box sizing reduces future expansion costs, but the fundamental architecture choice determines maintenance burden.

Distributed system 25-year costs (per 100kW):

- Initial installation: $106,000-$118,000

- Year 5-10 MLPE replacements (8% failure): $3,200

- Year 11-20 MLPE replacements (15% failure): $5,800

- Year 21-25 inverter/MLPE end-of-life: $18,000

- Monitoring system fees: $3,750

- Total 25-year cost: $136,750-$148,750

Centralized system 25-year costs (per 100kW):

- Initial installation: $76,000-$82,000

- Year 12-15 inverter replacement: $9,500

- Year 20-25 secondary inverter replacement: $9,500

- RSD system maintenance: $800

- Monitoring system fees: $2,250

- Total 25-year cost: $98,050-$104,050

The centralized architecture delivers $38,700-$44,700 lower total cost of ownership over the system lifetime—a 28-30% reduction in long-term expenses. For distributors offering EPC services with performance guarantees, this difference determines whether projects meet pro forma financial projections.

Installation & Maintenance Reality Check

Labor Requirements and Crew Efficiency

Distributed systems require electrical contractors to manage hundreds of individual connection points. On a 300-module installation, crews must:

- Attach 300 MLPE units to racking (torque specifications vary by manufacturer)

- Make 600 DC connections (positive and negative per module)

- Run AC trunk cables and install junction boxes every 10-15 modules

- Program and verify 300 devices using manufacturer-specific monitoring systems

- Label each MLPE unit with serial number for warranty tracking

Centralized systems with VIOX rapid shutdown reduce connection points by 85-90%:

- Wire modules into strings of 10-15 panels (20-30 strings total)

- Terminate strings at combiner box (20-30 connection points)

- Install rapid shutdown receivers (typically 15-20 units for string-level, or 75-150 for dual-module receivers)

- Commission single inverter and transmitter

- Verify system operation with voltage measurements at combiner

Experienced crews report 40-50% faster installation times on centralized systems. This efficiency advantage compounds on large commercial projects where labor scheduling and site logistics become cost drivers.

Warranty and Replacement Considerations

MLPE manufacturers offer 10-25 year warranties, but replacement logistics create hidden costs. When a microinverter fails in year 8:

- Monitoring system identifies underperforming module

- Contractor schedules service call (minimum 2-hour charge)

- Technician locates specific panel on roof

- Module must be partially unracked to access microinverter

- Replacement unit ships from manufacturer (2-7 day lead time)

- Installation requires compatible model (obsolescence risk)

- Monitoring system updated with new serial number

This process costs $180-$320 per unit replacement including labor. With 12-15% failure rates over 25 years, a 300-module system averages 36-45 replacements totaling $6,480-$14,400 in service costs.

Centralized system failures involve fewer components. Inverter replacement (typically once in 25 years) costs $2,500-$3,500 including labor for a 100kW unit. VIOX rapid shutdown receivers rarely fail (relay-based design with no thermal stress from power conversion), but replacement takes 15-20 minutes when needed.

Scalability for Commercial Projects

The economics shift dramatically on projects above 250kW. Distributed architecture requires proportional increases in MLPE units and connection points—a 500kW system needs 1,500 microinverters and associated wiring. Installation labor scales linearly, creating 150-180 labor hours versus 85-95 hours for centralized systems.

Large commercial projects benefit from centralized architecture’s ability to consolidate electrical equipment. A 1MW rooftop installation using VIOX rapid shutdown might include:

- 4× 250kW string inverters

- 2× large combiner boxes (40-60 strings each)

- 2× rapid shutdown transmitters

- 200-250 string-level or 600-750 dual-module rapid shutdown receivers

This configuration reduces failure points to under 10 critical components while maintaining full NEC 690.12 compliance. The simplified design allows faster troubleshooting, easier expansion, and lower insurance costs due to reduced component count.

When to Choose Each Architecture: Honest Application Guidance

Ideal Scenarios for Centralized + VIOX RSD

VIOX centralized architecture with rapid shutdown delivers maximum ROI on projects with these characteristics:

Best-fit applications:

- Open commercial rooftops with minimal shading from HVAC equipment, parapets, or nearby structures

- New construction where roof layout can be optimized during design phase

- Large-scale projects (>100kW) where labor efficiency drives total cost

- Budget-sensitive projects where upfront cost critically impacts financing approval

- Utility-scale or ground-mount installations where Exception No. 2 may apply

Performance conditions:

- Sites with <5% annual shading on the array maximize string inverter efficiency advantages

- Uniform roof planes without complex roof geometries (valleys, dormers, multiple orientations)

- Consistent module orientation and tilt across the entire array

When Distributed Architecture Makes Sense

We acknowledge that MLPE systems (microinverters/optimizers) provide genuine advantages in specific scenarios:

MLPE advantages in complex installations:

- Heavy shading conditions: Roofs with HVAC units, satellite dishes, or tree shading benefit from module-level MPPT, potentially recovering 8-15% production that string inverters would lose

- Multiple roof planes: Residential or complex commercial buildings with east/west/south-facing arrays on different planes

- Phased expansion: Systems designed for future capacity additions without rewiring entire strings

- Module-level monitoring requirements: When granular fault detection justifies the monitoring premium

The honest calculation:

On a heavily shaded 100kW commercial site (>15% shading), MLPE production gains of 12,000-18,000 kWh annually ($1,320-$1,980/year) can offset the higher upfront cost over 15-20 years. For these specific applications, distributors should evaluate total project economics rather than defaulting to lowest BOM cost.

VIOX Recommendation Framework

Choose VIOX Centralized RSD when:

- Annual shading impact <5% (open roof, minimal obstructions)

- Project size >100kW (labor efficiency compounds)

- Client prioritizes lowest TCO and simplified maintenance

Consider MLPE alternatives when:

- Shading analysis shows >10% annual losses from partial shading

- Multiple roof orientations require independent MPPT

- Client specifically requests module-level monitoring

This honest assessment builds long-term distributor relationships by matching the right solution to actual site conditions rather than forcing a single architecture on every project.

Frequently Asked Questions

How do I verify Rapid Shutdown Compliance during final inspection?

Verification follows a three-step process: (1) Confirm all equipment holds appropriate UL certifications (UL 1741 PVRSS for shutdown devices, UL 1741 for inverters), (2) Activate the rapid shutdown initiation switch and measure voltage at controlled conductors using a qualified multimeter—readings must show ≤80V inside array boundary and ≤30V outside boundary within 30 seconds, (3) Verify proper labeling at shutdown switch location and DC disconnect indicating system complies with NEC 690.12. Inspectors typically accept manufacturer certification documentation plus voltage test results recorded during commissioning.

Can I retrofit existing string inverter systems with VIOX rapid shutdown devices?

Yes, retrofit installations work on most string inverter systems installed after 2010. VIOX rapid shutdown systems use SunSpec-compliant communication protocols compatible with major inverter brands. Retrofit process involves: (1) Install rapid shutdown receivers at module level or string level depending on configuration needed, (2) Mount transmitter near existing inverter and connect to AC output for power, (3) Install emergency initiation switch in readily accessible location, (4) Commission system and verify voltage reduction timing. Typical retrofit costs $0.08-$0.15 per watt, significantly lower than converting to MLPE systems which would require complete equipment replacement.

What happens if the VIOX transmitter fails—does the system remain energized?

No. VIOX rapid shutdown systems employ fail-safe design principles. Receivers continuously monitor for the presence of the PLC signal transmitted by the control unit. If signal stops (due to transmitter failure, AC power loss, or intentional shutdown activation), receivers automatically open relay contacts and de-energize strings. This “dead man switch” approach ensures safety even during equipment failures. Additionally, the transmitter itself includes redundant circuitry and diagnostic LEDs that alert installers to malfunctions during commissioning or routine maintenance.

Do all local AHJs accept string-level rapid shutdown or do some require module-level?

NEC 690.12 specifies voltage reduction requirements but does not mandate specific technology. String-level and module-level rapid shutdown both achieve compliance as long as they reduce voltage to safe levels (≤80V inside boundary, ≤30V outside) within required timing (30 seconds). Some AHJs initially expressed preference for MLPE due to familiarity, but as string-level solutions gained UL certification and field deployment experience, acceptance increased to near-universal levels. Key to AHJ approval: provide system-level certification documentation showing string inverter + rapid shutdown device combination tested together per UL 1741 requirements. VIOX maintains updated compatibility lists showing certified inverter combinations for common AHJ requirements.

What warranty coverage applies to rapid shutdown components vs. the inverter?

Inverter manufacturers typically offer 5-10 year standard warranties (extended to 20-25 years with paid warranty upgrades). VIOX rapid shutdown devices carry 10-year warranty coverage on transmitters and receivers. This separation means warranty claims follow two paths: inverter issues go through inverter manufacturer RMA process, rapid shutdown issues go through VIOX technical support. In practice, this dual-warranty structure causes fewer problems than MLPE warranties because failure rates on rapid shutdown devices remain below 1% over 10 years (simple relay-based design with minimal thermal stress), while inverter failures occur at predictable 10-15 year intervals. Warranty service for VIOX components typically ships replacement units within 2-3 business days versus 5-10 days for MLPE replacements due to simplified inventory requirements.

Does string-level rapid shutdown impact system energy production compared to optimizers?

String-level rapid shutdown devices introduce zero production losses during normal operation because they function as pass-through connections with <0.5% voltage drop. Power optimizers cause 2-3% conversion losses even during optimal operation due to DC-DC conversion inefficiency. On a 100kW system producing 140,000 kWh annually, optimizers lose 2,800-4,200 kWh per year ($308-$462 at $0.11/kWh) compared to string-level shutdown’s negligible losses.

However, this calculation only applies to unshaded installations. On partially shaded rooftops (common in commercial buildings with HVAC equipment), optimizers provide 5-15% harvest improvement through module-level MPPT that can offset their conversion losses. Site-specific shading analysis determines which architecture delivers better lifetime production. On open commercial rooftops without significant obstructions (approximately 70% of commercial solar installations), centralized systems with VIOX rapid shutdown deliver superior energy production and lower costs. For shaded sites, run a detailed shading study comparing architectures before recommending a solution.

How does rapid shutdown interact with battery storage systems?

Battery energy storage systems (BESS) connected to PV arrays require special consideration for rapid shutdown integration. The PV array rapid shutdown function must de-energize DC conductors leading to the inverter/charger while maintaining battery isolation separately. VIOX rapid shutdown systems integrate with hybrid inverters by: (1) Treating PV input and battery input as separate controlled circuits, (2) Ensuring PV rapid shutdown activation does not trigger battery shutdown (batteries must remain available for backup power), (3) Coordinating with battery management systems (BMS) to prevent fault conditions during rapid shutdown events. Most hybrid inverter manufacturers provide integration guides showing proper rapid shutdown wiring for PV+battery configurations. Critical point: rapid shutdown requirements under NEC 690.12 apply only to PV system conductors, not battery circuits which fall under separate code articles (706 for energy storage).

Next Steps for Distributors and EPCs:

Contact VIOX technical sales to receive project-specific BOM comparisons, AutoCAD drawings showing rapid shutdown integration with your preferred inverter brand, and sample AHJ approval documentation packages. Our engineering team provides pre-sales support including voltage drop calculations, string sizing verification, and NEC 690.12 compliance certification for your jurisdiction.

VIOX Electric manufactures rapid shutdown devices, combiner boxes, surge protection, and related BOS components at ISO 9001-certified facilities with UL/IEC testing capabilities. Distributor programs include technical training, co-marketing support, and competitive volume pricing for EPCs managing multiple commercial projects annually.