ໃນເວລາທີ່ເລືອກວັດສະດຸສໍາລັບອົງປະກອບໄຟຟ້າ, ການເລືອກລະຫວ່າງທອງແດງ, ທອງເຫລືອງ, ແລະທອງສຳລິດສາມາດສົ່ງຜົນກະທົບຢ່າງຫຼວງຫຼາຍຕໍ່ປະສິດທິພາບຂອງລະບົບ, ອາຍຸການໃຊ້ງານ, ແລະປະສິດທິພາບດ້ານຄ່າໃຊ້ຈ່າຍ. ໃນຂະນະທີ່ທອງແດງເດັ່ນໃນສາຍໄຟຟ້າເນື່ອງຈາກການນໍາໄຟຟ້າທີ່ໂດດເດັ່ນ, ທອງເຫລືອງແລະທອງສຳລິດໃຫ້ຂໍ້ໄດ້ປຽບທີ່ເປັນເອກະລັກໃນການນໍາໃຊ້ສະເພາະບ່ອນທີ່ຄວາມແຂງແຮງທາງກົນຈັກ, ການຕໍ່ຕ້ານການກັດກ່ອນ, ຫຼືຄວາມສາມາດໃນການປຸງແຕ່ງແມ່ນມີຄວາມສໍາຄັນກວ່າ. ຄວາມເຂົ້າໃຈກ່ຽວກັບຄຸນສົມບັດທີ່ແຕກຕ່າງກັນຂອງແຕ່ລະໂລຫະຮັບປະກັນວ່າວິສະວະກອນແລະຜູ້ຈັດການຈັດຊື້ເຮັດການຕັດສິນໃຈທີ່ມີຂໍ້ມູນທີ່ສົມດຸນປະສິດທິພາບໄຟຟ້າກັບຄວາມຕ້ອງການໃນການດໍາເນີນງານ.

Key Takeaways

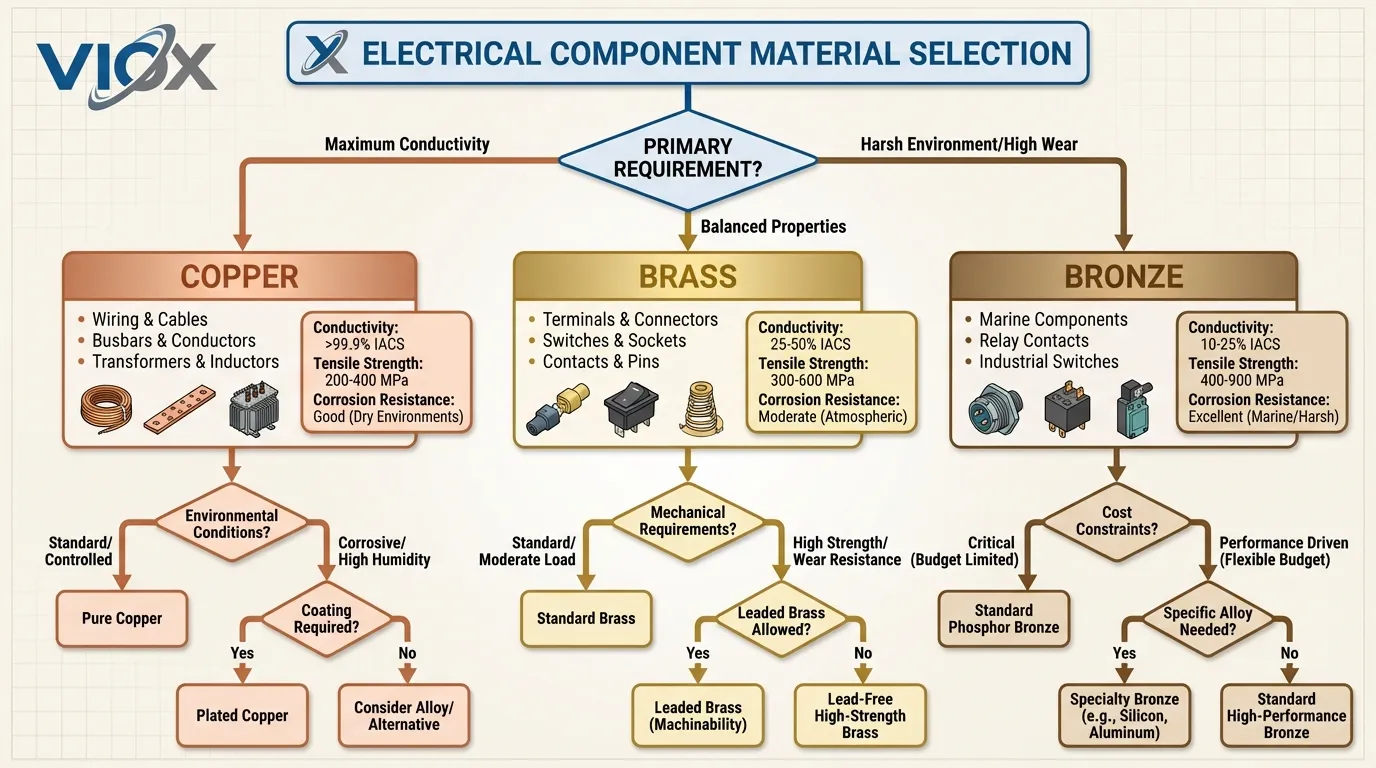

- ທອງແດງ ໃຫ້ການນໍາໄຟຟ້າ 100% IACS, ເຮັດໃຫ້ມັນເປັນມາດຕະຖານສໍາລັບການນໍາໃຊ້ລະບົບສາຍສົ່ງພະລັງງານເຊັ່ນ: ສາຍໄຟ, busbars, ແລະ transformers

- ທອງເຫຼືອງ ໃຫ້ການນໍາໄຟຟ້າປະມານ 28% IACS ດ້ວຍຄວາມແຂງແຮງທາງກົນຈັກທີ່ດີກວ່າ, ເຫມາະສໍາລັບ terminals, connectors, ແລະອົງປະກອບ threaded

- ທອງສຳລິດ ໃຫ້ການນໍາໄຟຟ້າປະມານ 15% IACS ປະສົມປະສານກັບການຕໍ່ຕ້ານການສວມໃສ່ທີ່ໂດດເດັ່ນແລະການປ້ອງກັນການກັດກ່ອນ, ເຫມາະສົມສໍາລັບການນໍາໃຊ້ທາງທະເລແລະສະວິດທີ່ເຮັດວຽກຫນັກ

- ການເລືອກວັດສະດຸແມ່ນຂຶ້ນກັບການດຸ່ນດ່ຽງຄວາມຕ້ອງການການນໍາໄຟຟ້າກັບຄຸນສົມບັດທາງກົນຈັກ, ສະພາບແວດລ້ອມ, ແລະຂໍ້ຈໍາກັດດ້ານຄ່າໃຊ້ຈ່າຍ

- ການຈັບຄູ່ວັດສະດຸທີ່ເຫມາະສົມປ້ອງກັນການກັດກ່ອນ galvanic ແລະຮັບປະກັນປະສິດທິພາບທີ່ດີທີ່ສຸດໃນການປະກອບໂລຫະປະສົມ

ຄວາມເຂົ້າໃຈກ່ຽວກັບໂລຫະສີແດງສາມຊະນິດ: ສ່ວນປະກອບແລະຄຸນສົມບັດ

ທອງແດງ: ແຊ້ມການນໍາໄຟຟ້າ

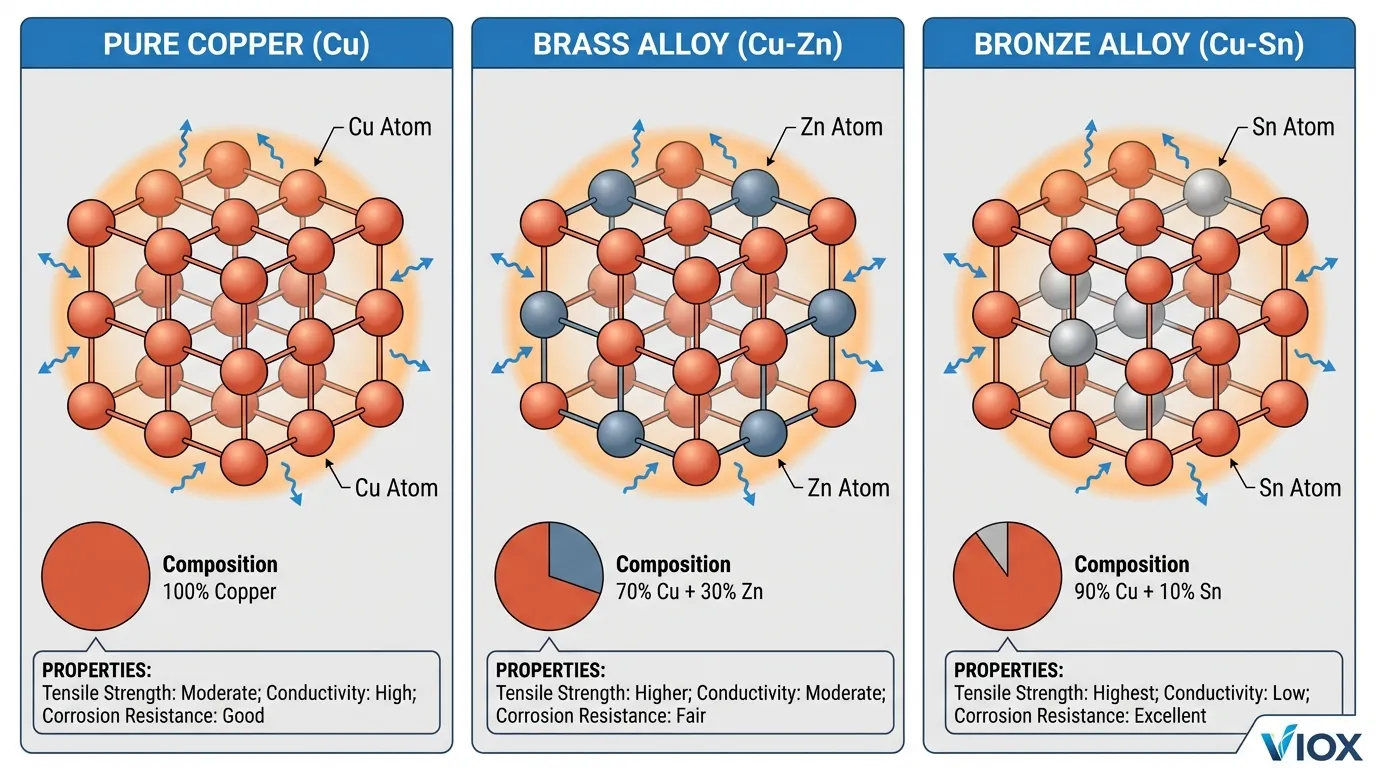

ທອງແດງຢືນເປັນໂລຫະອົງປະກອບບໍລິສຸດ (Cu ໃນຕາຕະລາງແຕ່ລະໄລຍະ) ທີ່ມີການນໍາໄຟຟ້າແລະຄວາມຮ້ອນທີ່ບໍ່ມີໃຜທຽບເທົ່າໃນບັນດາໂລຫະທີ່ບໍ່ມີຄ່າ. ໂຄງສ້າງປະລໍາມະນູຂອງມັນຊ່ວຍໃຫ້ເອເລັກໂຕຣນິກໄຫຼດ້ວຍຄວາມຕ້ານທານຫນ້ອຍທີ່ສຸດ, ບັນລຸປະມານ 59.6 ລ້ານ Siemens ຕໍ່ແມັດ (MS/m) ຫຼື 100% International Annealed Copper Standard (IACS). ປະສິດທິພາບທີ່ໂດດເດັ່ນນີ້ເຮັດໃຫ້ທອງແດງເປັນມາດຕະຖານອ້າງອີງທີ່ວັດແທກວັດສະດຸນໍາໄຟຟ້າອື່ນໆທັງຫມົດ.

ນອກເຫນືອຈາກການນໍາໄຟຟ້າ, ທອງແດງສະແດງໃຫ້ເຫັນເຖິງຄວາມອ່ອນນຸ້ມແລະຄວາມສາມາດໃນການປ່ຽນແປງທີ່ດີເລີດ, ຊ່ວຍໃຫ້ມັນຖືກດຶງເຂົ້າໄປໃນສາຍລະອຽດຫຼືປະກອບເປັນຮູບຮ່າງທີ່ສັບສົນໂດຍບໍ່ມີການແຕກຫັກ. ໂລຫະພັດທະນາ patina ປ້ອງກັນຕາມທໍາມະຊາດເມື່ອສໍາຜັດກັບອົກຊີເຈນ, ສ້າງຊັ້ນ oxide ບາງໆທີ່ປ້ອງກັນການກັດກ່ອນຕື່ມອີກໃນຂະນະທີ່ຮັກສາປະສິດທິພາບໄຟຟ້າ. ລະດັບທົ່ວໄປປະກອບມີ electrolytic tough pitch (ETP) ທອງແດງ (C11000) ສໍາລັບການນໍາໃຊ້ໄຟຟ້າທົ່ວໄປແລະທອງແດງທີ່ບໍ່ມີອົກຊີເຈນ (C10100/C10200) ສໍາລັບເອເລັກໂຕຣນິກທີ່ມີຄວາມຫນ້າເຊື່ອຖືສູງບ່ອນທີ່ຕ້ອງຫຼີກເວັ້ນການ embrittlement ຂອງ hydrogen.

ທອງເຫລືອງ: ໂລຫະປະສົມທີ່ສົມດູນ

ທອງເຫລືອງເປັນຕົວແທນຂອງຄອບຄົວຂອງໂລຫະປະສົມທອງແດງ-ສັງກະສີ, ໂດຍປົກກະຕິມີທອງແດງ 60-70% ແລະສັງກະສີ 30-40%. ການເພີ່ມສັງກະສີປ່ຽນແປງຄຸນສົມບັດຂອງວັດສະດຸຢ່າງພື້ນຖານ, ເພີ່ມຄວາມແຂງແຮງ tensile ແລະຄວາມແຂງໃນຂະນະທີ່ຫຼຸດຜ່ອນການນໍາໄຟຟ້າລົງປະມານ 28% IACS (15-17 MS/m). ການຄ້າຂາຍນີ້ພິສູດໃຫ້ເຫັນເຖິງຄວາມໄດ້ປຽບໃນການນໍາໃຊ້ທີ່ຕ້ອງການທັງຫນ້າທີ່ໄຟຟ້າແລະຄວາມທົນທານທາງກົນຈັກ.

ເນື້ອໃນສັງກະສີໃນທອງເຫລືອງໃຫ້ຜົນປະໂຫຍດທີ່ເປັນປະໂຫຍດຫຼາຍຢ່າງສໍາລັບອົງປະກອບໄຟຟ້າ. ໂລຫະປະສົມສະແດງໃຫ້ເຫັນເຖິງຄວາມສາມາດໃນການປຸງແຕ່ງທີ່ດີກວ່າເມື່ອທຽບກັບທອງແດງບໍລິສຸດ, ເຮັດໃຫ້ມີການ threading ທີ່ຊັດເຈນແລະ geometries ທີ່ສັບສົນທີ່ສໍາຄັນສໍາລັບ terminals ແລະ connectors. ທອງເຫລືອງຍັງສະແດງໃຫ້ເຫັນຄ່າສໍາປະສິດ friction ຕ່ໍາ, ເຮັດໃຫ້ມັນເຫມາະສົມສໍາລັບອົງປະກອບທີ່ມີສ່ວນເຄື່ອນທີ່ເຊັ່ນ: ສະວິດແລະການຕິດຕໍ່ເລື່ອນ. ລະດັບໄຟຟ້າທົ່ວໄປປະກອບມີ C26000 (ທອງເຫລືອງ cartridge, ທອງແດງ 70%) ສໍາລັບການນໍາໃຊ້ທົ່ວໄປແລະ C36000 (ທອງເຫລືອງຕັດຟຣີ) ບ່ອນທີ່ຕ້ອງການເຄື່ອງຈັກຢ່າງກວ້າງຂວາງ.

ທອງສຳລິດ: ຜູ້ຊ່ຽວຊານດ້ານຄວາມທົນທານ

ໂລຫະປະສົມທອງສຳລິດສ່ວນໃຫຍ່ປະສົມທອງແດງກັບກົ່ວ, ເຖິງແມ່ນວ່າສູດທີ່ທັນສະໄຫມອາດຈະປະກອບມີອາລູມິນຽມ, phosphorus, ຫຼື silicon ເພື່ອເພີ່ມຄຸນສົມບັດສະເພາະ. ທອງສຳລິດກົ່ວແບບດັ້ງເດີມມີທອງແດງ 88-95% ແລະກົ່ວ 5-12%, ສົ່ງຜົນໃຫ້ການນໍາໄຟຟ້າປະມານ 15% IACS (ປະມານ 9 MS/m). ໃນຂະນະທີ່ນີ້ສະແດງເຖິງການນໍາໄຟຟ້າຕ່ໍາສຸດໃນບັນດາສາມໂລຫະ, ທອງສຳລິດຊົດເຊີຍດ້ວຍຄວາມແຂງແຮງທາງກົນຈັກທີ່ໂດດເດັ່ນ, ການຕໍ່ຕ້ານການສວມໃສ່, ແລະການປ້ອງກັນການກັດກ່ອນ.

Phosphor bronze (C51000/C52100), ທີ່ມີ phosphorus ໃນປະລິມານຫນ້ອຍ, ສະແດງໃຫ້ເຫັນເຖິງຄຸນສົມບັດພາກຮຽນ spring ທີ່ດີເລີດແລະການຕໍ່ຕ້ານຄວາມເມື່ອຍລ້າ, ເຮັດໃຫ້ມັນເປັນທາງເລືອກທີ່ຕ້ອງການສໍາລັບການຕິດຕໍ່ໄຟຟ້າທີ່ຂຶ້ນກັບການຂີ່ຈັກຍານຊ້ໍາໆ. Aluminum bronze (C61400/C95400) ໃຫ້ຄວາມເຂັ້ມແຂງທີ່ໂດດເດັ່ນແລະການຕໍ່ຕ້ານການກັດກ່ອນໃນສະພາບແວດລ້ອມທາງທະເລແລະອຸດສາຫະກໍາ. Beryllium copper, ເຖິງແມ່ນວ່າເປັນໂລຫະປະສົມທອງສຳລິດທາງດ້ານເຕັກນິກ, ບັນລຸຄວາມເຂັ້ມແຂງສູງສຸດຂອງໂລຫະປະສົມທອງແດງໃດໆໃນຂະນະທີ່ຮັກສາການນໍາໄຟຟ້າທີ່ສົມເຫດສົມຜົນ (15-25% IACS), ເຊິ່ງເປັນເຫດຜົນສໍາລັບການນໍາໃຊ້ໃນ connectors ແລະສະວິດທີ່ມີປະສິດທິພາບສູງເຖິງວ່າຈະມີຄ່າໃຊ້ຈ່າຍວັດສະດຸສູງກວ່າ.

ການປຽບທຽບການນໍາໄຟຟ້າ: ປັດໄຈປະສິດທິພາບທີ່ສໍາຄັນ

| ວັດສະດຸ | ການນໍາໄຟຟ້າ (% IACS) | ການນໍາໄຟຟ້າ (MS/m) | ຄວາມຕ້ານທານປົກກະຕິ (nΩ·m) | ການນໍາຄວາມຮ້ອນ (W/m·K) |

|---|---|---|---|---|

| ທອງແດງບໍລິສຸດ | 100% | 58-62 | 16.78 | 385-401 |

| ທອງແດງ (ETP) | 100% | 59.6 | 17.24 | 391 |

| ທອງເຫລືອງ (70/30) | 28% | 15-17 | ~62 | 120 |

| ທອງເຫລືອງ (85/15) | 40-44% | 23-26 | ~40 | 159 |

| ຟອສເຟີບຣອນ | 15% | 9 | ~110 | 50-70 |

| ທອງສຳລິດອາລູມິນຽມ | 12-15% | 7-9 | ~120 | 70-80 |

| ທອງແດງ Beryllium | 15-25% | 9-15 | ~70-110 | 105-210 |

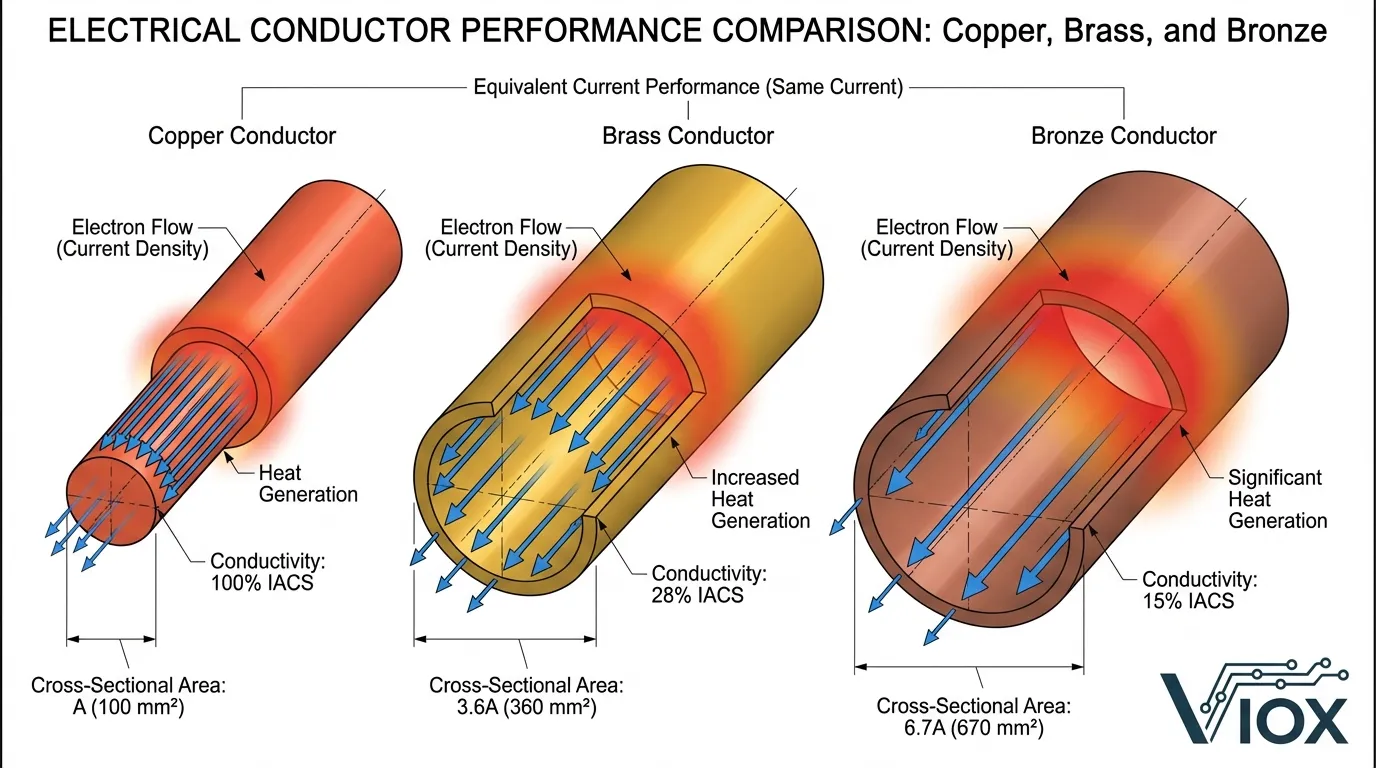

ຄວາມແຕກຕ່າງຂອງການນໍາໄຟຟ້າລະຫວ່າງວັດສະດຸເຫຼົ່ານີ້ສ້າງຜົນກະທົບທີ່ສາມາດວັດແທກໄດ້ຕໍ່ປະສິດທິພາບຂອງລະບົບ. ໃນປົກກະຕິ busbar ຄໍາຮ້ອງສະຫມັກທີ່ບັນທຸກ 1000 amperes, ການປ່ຽນແທນທອງແດງດ້ວຍທອງເຫລືອງຂອງພາກສ່ວນຂ້າມເທົ່າທຽມກັນຈະສ້າງຄວາມຮ້ອນຫຼາຍກວ່າປະມານ 3.6 ເທົ່າເນື່ອງຈາກຄວາມຕ້ານທານເພີ່ມຂຶ້ນ. ການຜະລິດຄວາມຮ້ອນນີ້ຮຽກຮ້ອງໃຫ້ມີພາກສ່ວນຂ້າມຕົວນໍາຂະຫນາດໃຫຍ່ກວ່າຫຼືລະບົບເຮັດຄວາມເຢັນທີ່ປັບປຸງເມື່ອນໍາໃຊ้วັດສະດຸທີ່ມີການນໍາໄຟຟ້າຕ່ໍາກວ່າ.

ການນໍາຄວາມຮ້ອນປະຕິບັດຕາມຮູບແບບທີ່ຄ້າຍຄືກັນ, ໂດຍມີທອງແດງ 391 W/m·K ຊ່ວຍໃຫ້ການລະບາຍຄວາມຮ້ອນທີ່ມີປະສິດທິພາບໃນ transformers ແລະ motor windings. ການນໍາຄວາມຮ້ອນທີ່ຫຼຸດລົງຂອງທອງເຫລືອງ (120 W/m·K) ສາມາດພິສູດໄດ້ວ່າເປັນປະໂຫຍດໃນບາງຄໍາຮ້ອງສະຫມັກ, ເຊັ່ນ: ແຖບຕໍ່ສາຍໄຟ ບ່ອນທີ່ຕ້ອງການການແຍກຄວາມຮ້ອນລະຫວ່າງວົງຈອນທີ່ຢູ່ຕິດກັນ. ການນໍາຄວາມຮ້ອນຕ່ໍາຂອງທອງສຳລິດເຮັດໃຫ້ມັນເຫມາະສົມສໍາລັບການນໍາໃຊ້ບ່ອນທີ່ການຮັກສາຄວາມຮ້ອນຫຼືການໂອນຄວາມຮ້ອນທີ່ຄວບຄຸມແມ່ນເປັນປະໂຫຍດ.

ຄຸນສົມບັດທາງກົນຈັກແລະລັກສະນະຄວາມທົນທານ

| ຊັບສິນ | ທອງແດງ | ທອງເຫລືອງ (70/30) | ຟອສເຟີບຣອນ | ທອງສຳລິດອາລູມິນຽມ |

|---|---|---|---|---|

| ຄວາມແຮງ tensile (MPa) | 210-250 | 338-469 | 410-655 | 550-830 |

| ຄວາມແຂງແຮງຂອງຜົນຜະລິດ (MPa) | 70-120 | 125-435 | 170-520 | 240-550 |

| ຄວາມແຂງ (Brinell) | 40-80 | 55-120 | 80-200 | 150-230 |

| ການຍືດຕົວ (% ) | 30-45 | 15-50 | 5-65 | 12-60 |

| ຄວາມແຂງແຮງຂອງຄວາມເມື່ອຍລ້າ (MPa) | 80-130 | 90-180 | 140-280 | 200-350 |

ຄວາມແຕກຕ່າງຂອງຄຸນສົມບັດທາງກົນຈັກອະທິບາຍວ່າເປັນຫຍັງທອງເຫລືອງແລະທອງສຳລິດເດັ່ນໃນການນໍາໃຊ້ໄຟຟ້າບາງຢ່າງເຖິງວ່າຈະມີການນໍາໄຟຟ້າຕ່ໍາກວ່າ. ຄວາມແຂງແຮງ tensile ທີ່ສູງຂຶ້ນຂອງທອງເຫລືອງ (338-469 MPa ທຽບກັບທອງແດງ 210-250 MPa) ຊ່ວຍໃຫ້ອົງປະກອບທີ່ມີກໍາແພງບາງໆໃນ connectors ໄຟຟ້າ ແລະ terminals, ອາດຈະຊົດເຊີຍຄວາມຕ້ອງການສໍາລັບພາກສ່ວນຂ້າມຂະຫນາດໃຫຍ່ເພື່ອຮັກສາການນໍາໄຟຟ້າ. ຄວາມສາມາດໃນການປຸງແຕ່ງທີ່ດີກວ່າຂອງວັດສະດຸ (ດັດຊະນີ chip ~100 ທຽບກັບທອງແດງ ~20) ຫຼຸດຜ່ອນຄ່າໃຊ້ຈ່າຍໃນການຜະລິດສໍາລັບອົງປະກອບ threaded ທີ່ຊັດເຈນ.

ໂລຫະປະສົມທອງສຳລິດເກັ່ງໃນການນໍາໃຊ້ທີ່ກ່ຽວຂ້ອງກັບຄວາມກົດດັນທາງກົນຈັກ, ການສັ່ນສະເທືອນ, ຫຼືການສວມໃສ່. ຄຸນສົມບັດພາກຮຽນ spring ທີ່ໂດດເດັ່ນຂອງ phosphor bronze ແລະການຕໍ່ຕ້ານຄວາມເມື່ອຍລ້າເຮັດໃຫ້ມັນເຫມາະສົມສໍາລັບ relay contacts ແລະອົງປະກອບສະວິດທີ່ຜ່ານຫຼາຍລ້ານຮອບວຽນ. ວັດສະດຸຮັກສາຄວາມກົດດັນຕິດຕໍ່ທີ່ສອດຄ່ອງກັນໃນໄລຍະເວລາທີ່ຍາວນານ, ຮັບປະກັນການເຊື່ອມຕໍ່ໄຟຟ້າທີ່ເຊື່ອຖືໄດ້ເຖິງວ່າຈະມີການດໍາເນີນງານກົນຈັກຊ້ໍາໆ. ການປະສົມປະສານຂອງຄວາມເຂັ້ມແຂງແລະການຕໍ່ຕ້ານການກັດກ່ອນຂອງອາລູມິນຽມທອງສຳລິດພິສູດໃຫ້ເຫັນວ່າມີຄຸນຄ່າໃນ switchgear ທາງທະເລແລະການຕິດຕັ້ງໄຟຟ້າ offshore.

ການຕໍ່ຕ້ານການກັດກ່ອນແລະປະສິດທິພາບດ້ານສິ່ງແວດລ້ອມ

ພຶດຕິກໍາການກັດກ່ອນສົ່ງຜົນກະທົບຢ່າງຫຼວງຫຼາຍຕໍ່ການເລືອກວັດສະດຸສໍາລັບອົງປະກອບໄຟຟ້າ, ໂດຍສະເພາະໃນສະພາບແວດລ້ອມທີ່ຮຸນແຮງ. ທອງແດງປະກອບເປັນຊັ້ນ cuprous oxide ປ້ອງກັນຕາມທໍາມະຊາດ (Cu₂O) ທີ່ປ້ອງກັນການ oxidation ເລິກ, ເຖິງແມ່ນວ່າ patina ນີ້ສາມາດເພີ່ມຄວາມຕ້ານທານຕິດຕໍ່ໃນບາງຄໍາຮ້ອງສະຫມັກ. ໂລຫະສະແດງໃຫ້ເຫັນເຖິງການຕໍ່ຕ້ານທີ່ດີເລີດຕໍ່ການກັດກ່ອນຂອງບັນຍາກາດແຕ່ພິສູດວ່າມີຄວາມສ່ຽງຕໍ່ສານປະກອບຊູນຟູຣິກ, ammonia, ແລະອາຊິດບາງຊະນິດ.

ທອງເຫລືອງສະແດງໃຫ້ເຫັນເຖິງການຕໍ່ຕ້ານການກັດກ່ອນທົ່ວໄປທີ່ດີ, ເຖິງແມ່ນວ່າມັນຍັງມີຄວາມສ່ຽງຕໍ່ການ dezincification ໃນສະພາບແວດລ້ອມສະເພາະ - ຂະບວນການກັດກ່ອນ selective ບ່ອນທີ່ສັງກະສີ leaches ຈາກໂລຫະປະສົມ, ເຮັດໃຫ້ທອງແດງ porous. Naval brass (C46400/C46500) ປະກອບມີກົ່ວ 1% ເພື່ອຕ້ານປະກົດການນີ້, ເຮັດໃຫ້ມັນເຫມາະສົມສໍາລັບອຸປະກອນໄຟຟ້າທາງທະເລແລະການຕິດຕັ້ງແຄມຝັ່ງທະເລ. ການຕໍ່ຕ້ານຂອງໂລຫະປະສົມຕໍ່ການກັດກ່ອນຂອງນ້ໍາເຄັມເກີນປະສິດທິພາບຂອງທອງແດງບໍລິສຸດໃນຫຼາຍໆສະຖານະການ, ເຊິ່ງເປັນເຫດຜົນສໍາລັບການນໍາໃຊ້ໃນ marine terminal blocks ແລະພື້ນຖານໂຄງລ່າງແຄມຝັ່ງທະເລ.

ໂລຫະປະສົມທອງສຳລິດໃຫ້ການຕໍ່ຕ້ານການກັດກ່ອນທີ່ດີກວ່າໃນທົ່ວສະພາບແວດລ້ອມທີ່ຫຼາກຫຼາຍ. Aluminum bronze ສ້າງຊັ້ນຫນ້າດິນອາລູມິນຽມ oxide ທີ່ແຂງແຮງທີ່ປ້ອງກັນນ້ໍາທະເລ, ບັນຍາກາດອຸດສາຫະກໍາ, ແລະສານເຄມີຈໍານວນຫຼາຍ. ຄວາມທົນທານທີ່ໂດດເດັ່ນນີ້ເຮັດໃຫ້ອາລູມິນຽມທອງສຳລິດເປັນທາງເລືອກທີ່ຕ້ອງການສໍາລັບ propellers ເຮືອ, ຮາດແວທາງທະເລ, ແລະ ກ່ອງແຍກ ໃນສະພາບແວດລ້ອມອຸດສາຫະກໍາທີ່ກັດກ່ອນ. Phosphor bronze ຕ້ານທານການແຕກຂອງການກັດກ່ອນຄວາມກົດດັນແລະຮັກສາຄຸນສົມບັດໄຟຟ້າທີ່ຫມັ້ນຄົງໃນສະພາບທີ່ຊຸ່ມຊື່ນ, ອະທິບາຍເຖິງຄວາມແຜ່ຫຼາຍຂອງມັນໃນອຸປະກອນໄຟຟ້າກາງແຈ້ງແລະພື້ນຖານໂຄງລ່າງໂທລະຄົມມະນາຄົມ.

ການເລືອກວັດສະດຸສະເພາະສໍາລັບການນໍາໃຊ້

ການນໍາໃຊ້ທອງແດງ: ຄວາມຕ້ອງການການນໍາໄຟຟ້າສູງສຸດ

ທອງແດງເດັ່ນໃນການນໍາໃຊ້ບ່ອນທີ່ປະສິດທິພາບໄຟຟ້າເປັນສິ່ງສໍາຄັນທີ່ສຸດແລະຄ່າໃຊ້ຈ່າຍສາມາດຖືກຕ້ອງຕາມກົດຫມາຍໂດຍຜົນປະໂຫຍດດ້ານປະສິດທິພາບ. ລະບົບການແຜ່ກະຈາຍພະລັງງານແມ່ນອີງໃສ່ທອງແດງ busbars ເພື່ອຫຼຸດຜ່ອນການຫຼຸດແຮງດັນແລະການຜະລິດຄວາມຮ້ອນໃນເສັ້ນທາງທີ່ມີກະແສໄຟຟ້າສູງ. ມາດຕະຖານສາຍໄຟຟ້າທົ່ວໂລກກໍານົດທອງແດງເປັນວັດສະດຸຕົວນໍາເລີ່ມຕົ້ນ, ໂດຍມີອາລູມິນຽມພິຈາລະນາພຽງແຕ່ເມື່ອຂໍ້ຈໍາກັດດ້ານນ້ໍາຫນັກຫຼືຄ່າໃຊ້ຈ່າຍລົບລ້າງຄວາມຕ້ອງການການນໍາໄຟຟ້າ.

Transformer windings ໃຊ້ທອງແດງຢ່າງເປັນເອກະພາບເພື່ອເພີ່ມປະສິດທິພາບສູງສຸດແລະຫຼຸດຜ່ອນອຸນຫະພູມຫຼັກ. ການປະສົມປະສານຂອງວັດສະດຸຂອງການນໍາໄຟຟ້າສູງແລະປະສິດທິພາບຄວາມຮ້ອນຊ່ວຍໃຫ້ການອອກແບບກະທັດຮັດທີ່ມີຄວາມຫນາແຫນ້ນຂອງພະລັງງານທີ່ດີທີ່ສຸດ. ຕົວເລີ່ມຕົ້ນມໍເຕີ ແລະອົງປະກອບ switchgear ໃຊ້ແຖບຕິດຕໍ່ທອງແດງເພື່ອຈັດການກະແສໄຟຟ້າສູງໂດຍບໍ່ມີຄວາມຮ້ອນຫຼາຍເກີນໄປ. ລະບົບ grounding ກໍານົດທອງແດງເພື່ອຮັບປະກັນເສັ້ນທາງທີ່ມີຄວາມຕ້ານທານຕ່ໍາສໍາລັບກະແສໄຟຟ້າຜິດພາດ, ເຊິ່ງສໍາຄັນຕໍ່ຄວາມປອດໄພຂອງບຸກຄະລາກອນແລະການປົກປ້ອງອຸປະກອນ.

ການນໍາໃຊ້ເອເລັກໂຕຣນິກຮຽກຮ້ອງໃຫ້ມີການນໍາໄຟຟ້າຂອງທອງແດງສໍາລັບຮ່ອງຮອຍຂອງແຜງວົງຈອນພິມ, ກອບນໍາວົງຈອນປະສົມປະສານ, ແລະການຫຸ້ມຫໍ່ semiconductor. ຄວາມຫນ້າເຊື່ອຖືຂອງວັດສະດຸແລະຄຸນສົມບັດໄຟຟ້າທີ່ສອດຄ່ອງກັນສະຫນັບສະຫນູນຄວາມຕ້ອງການທີ່ເຂັ້ມງວດຂອງໂທລະຄົມມະນາຄົມ, ຄອມພິວເຕີ້, ແລະລະບົບຄວບຄຸມ. ເຖິງແມ່ນວ່າໃນການນໍາໃຊ້ທີ່ມີຄວາມອ່ອນໄຫວຕໍ່ຄ່າໃຊ້ຈ່າຍ, ທອງແດງຍັງຄົງເປັນທາງເລືອກທໍາອິດເມື່ອປະສິດທິພາບໄຟຟ້າສົ່ງຜົນກະທົບໂດຍກົງຕໍ່ຫນ້າທີ່ຂອງລະບົບຫຼືປະສິດທິພາບດ້ານພະລັງງານ.

ການນໍາໃຊ້ທອງເຫລືອງ: ການດຸ່ນດ່ຽງການນໍາໄຟຟ້າກັບຄວາມຕ້ອງການທາງກົນຈັກ

ທອງເຫລືອງພົບເຫັນຊ່ອງຫວ່າງຂອງມັນຢູ່ໃນອົງປະກອບໄຟຟ້າບ່ອນທີ່ການນໍາໄຟຟ້າປານກາງພຽງພໍແລະຄຸນສົມບັດທາງກົນຈັກກາຍເປັນປັດໃຈທີ່ແຕກຕ່າງກັນ. ສະຖານີໄຟຟ້າ ແລະຕົວເຊື່ອມຕໍ່ມັກຈະໃຊ້ທອງເຫລືອງສໍາລັບໃສ່ກະທູ້, ເສົາຍຶດ, ແລະສະກູ. ຄວາມສາມາດໃນການປຸງແຕ່ງທີ່ດີເລີດຂອງວັດສະດຸຊ່ວຍໃຫ້ການເຮັດກະທູ້ທີ່ຊັດເຈນທີ່ຮັກສາຄວາມສົມບູນຜ່ານຮອບວຽນການເຊື່ອມຕໍ່ຊ້ໍາໆ, ໃນຂະນະທີ່ຄວາມແຂງຂອງມັນປ້ອງກັນບໍ່ໃຫ້ກະທູ້ເສຍຫາຍພາຍໃຕ້ແຮງບິດໃນການຕິດຕັ້ງ.

ອົງປະກອບສະວິດໃຊ້ປະໂຫຍດຈາກການປະສົມປະສານຂອງການນໍາໄຟຟ້າແລະຄວາມຕ້ານທານການສວມໃສ່ຂອງທອງເຫລືອງ. ສະວິດປ່ຽນ, ເຄື່ອງເລືອກຫມຸນ, ແລະ ປຸ່ມກົດ ປະກອບມີຫນ້າສໍາຜັດທອງເຫລືອງແລະຕົວປະຕິບັດທີ່ທົນທານຕໍ່ຮອບວຽນກົນຈັກໃນຂະນະທີ່ຮັກສາປະສິດທິພາບໄຟຟ້າທີ່ພຽງພໍ. ຄ່າສໍາປະສິດຄວາມກົດດັນຕ່ໍາຂອງໂລຫະປະສົມເມື່ອທຽບກັບທອງແດງຊ່ວຍຫຼຸດຜ່ອນການສວມໃສ່ໃນຫນ້າສໍາຜັດເລື່ອນແລະປັບປຸງຄວາມຮູ້ສຶກໃນການດໍາເນີນງານໃນສະວິດຄູ່ມື.

ອຸປະກອນແລະຕົວປັບໄຟຟ້າໄດ້ຮັບຜົນປະໂຫຍດຈາກຄວາມຕ້ານທານການກັດກ່ອນແລະຄວາມດຶງດູດດ້ານຄວາມງາມຂອງທອງເຫລືອງ. ຕ່ອມສາຍເຄເບີ້ນ, ອຸປະກອນທໍ່ແລະຮາດແວ enclosure ໃຊ້ທອງເຫລືອງເພື່ອສົມທົບການເຮັດວຽກກັບຮູບລັກສະນະທີ່ເປັນມືອາຊີບ. ຄຸນສົມບັດຕ້ານຈຸລິນຊີຂອງວັດສະດຸໃຫ້ມູນຄ່າເພີ່ມເຕີມໃນສະພາບແວດລ້ອມການດູແລສຸຂະພາບແລະການປຸງແຕ່ງອາຫານບ່ອນທີ່ມີຄວາມກັງວົນກ່ຽວກັບການປົນເປື້ອນຂອງພື້ນຜິວ. ຄຸນລັກສະນະທີ່ບໍ່ມີປະກາຍໄຟຂອງທອງເຫລືອງເຮັດໃຫ້ມັນມີຄວາມຈໍາເປັນສໍາລັບອົງປະກອບໄຟຟ້າໃນບັນຍາກາດທີ່ລະເບີດແລະສະຖານທີ່ຈັດການວັດສະດຸທີ່ຕິດໄຟໄດ້.

ຄໍາຮ້ອງສະຫມັກທອງແດງ: ສະພາບທີ່ຮ້າຍແຮງແລະລະບົບຄວາມຫນ້າເຊື່ອຖືສູງ

ໂລຫະປະສົມທອງແດງໃຫ້ບໍລິການຄໍາຮ້ອງສະຫມັກໄຟຟ້າບ່ອນທີ່ສິ່ງທ້າທາຍດ້ານສິ່ງແວດລ້ອມຫຼືຄວາມຕ້ອງການກົນຈັກເກີນຄວາມສາມາດຂອງທອງເຫລືອງ. ລະບົບໄຟຟ້າທາງທະເລໃຊ້ທອງແດງຢ່າງກວ້າງຂວາງສໍາລັບ ຕົວເຊື່ອມຕໍ່ສະຖານີຍ່ອຍ, ອົງປະກອບ switchgear, ແລະການສິ້ນສຸດສາຍເຄເບີ້ນທີ່ສໍາຜັດກັບການສີດນ້ໍາເຄັມແລະຄວາມຊຸ່ມຊື່ນ. ຄວາມຕ້ານທານການກັດກ່ອນທີ່ໂດດເດັ່ນຂອງທອງແດງອາລູມິນຽມຮັບປະກັນການບໍລິການທີ່ເຊື່ອຖືໄດ້ຫຼາຍສິບປີໃນເວທີນອກຝັ່ງ, ເຮືອ, ແລະພື້ນຖານໂຄງລ່າງການແຈກຢາຍພະລັງງານແຄມຝັ່ງທະເລ.

ຫນ້າສໍາຜັດໄຟຟ້າທີ່ມີຮອບວຽນສູງລະບຸທອງແດງຟອສເຟີສໍາລັບຄຸນສົມບັດພາກຮຽນ spring ທີ່ດີເລີດແລະຄວາມຕ້ານທານຄວາມເມື່ອຍລ້າ. ຫນ້າສໍາຜັດ Relay, terminals circuit breaker, ແລະ pins ເຊື່ອມຕໍ່ທີ່ເຮັດຈາກທອງແດງຟອສເຟີຮັກສາຄວາມກົດດັນຕິດຕໍ່ທີ່ສອດຄ່ອງກັນຜ່ານການດໍາເນີນງານຫຼາຍລ້ານຄັ້ງ. ຄວາມຕ້ານທານຂອງວັດສະດຸຕໍ່ການຜ່ອນຄາຍຄວາມກົດດັນຮັບປະກັນການເຊື່ອມຕໍ່ໄຟຟ້າທີ່ເຊື່ອຖືໄດ້ໃນໄລຍະການບໍລິການທີ່ຍາວນານ, ເຊິ່ງສໍາຄັນໃນອຸປະກອນໂທລະຄົມມະນາຄົມ, ການຄວບຄຸມອຸດສາຫະກໍາ, ແລະລະບົບໄຟຟ້າລົດຍົນ.

ຄໍາຮ້ອງສະຫມັກອຸດສາຫະກໍາຫນັກໃຊ້ປະໂຫຍດຈາກຄວາມຕ້ານທານການສວມໃສ່ແລະຄວາມເຂັ້ມແຂງຂອງທອງແດງ. Contactor ອົງປະກອບ, ສະວິດກະແສໄຟຟ້າສູງ, ແລະອຸປະກອນຄວບຄຸມມໍເຕີໃຊ້ໂລຫະປະສົມທອງແດງເພື່ອທົນທານຕໍ່ການເກີດໄຟຟ້າ, ການສັ່ນສະເທືອນກົນຈັກ, ແລະຮອບວຽນຄວາມຮ້ອນ. Beryllium copper, ເຖິງວ່າຈະມີຄ່າໃຊ້ຈ່າຍສູງກວ່າ, ໃຫ້ປະສິດທິພາບທີ່ບໍ່ມີໃຜທຽບເທົ່າໃນການບິນອະວະກາດແລະການທະຫານບ່ອນທີ່ຄວາມຫນ້າເຊື່ອຖືບໍ່ສາມາດຖືກປະນີປະນອມ. ການປະສົມປະສານຂອງຄວາມເຂັ້ມແຂງ, ການນໍາໄຟຟ້າ, ແລະຄວາມຕ້ານທານຄວາມເມື່ອຍລ້າຂອງໂລຫະປະສົມພິສູດໃຫ້ເຫັນເຖິງການນໍາໃຊ້ໃນຕົວເຊື່ອມຕໍ່ທີ່ສໍາຄັນແລະສະພາບແວດລ້ອມທີ່ມີການສັ່ນສະເທືອນສູງ.

ຂໍ້ຄວນພິຈາລະນາກ່ຽວກັບຄ່າໃຊ້ຈ່າຍແລະການຄ້າທາງເສດຖະກິດ

| ປັດໄຈ | ທອງແດງ | ທອງເຫຼືອງ | ທອງສຳລິດ |

|---|---|---|---|

| ຄ່າໃຊ້ຈ່າຍວັດຖຸດິບ (ພີ່ນ້ອງ) | ສູງ (100%) | ກາງ (70-85%) | ກາງ-ສູງ (80-110%) |

| ຄວາມສາມາດໃນການປຸງແຕ່ງ | ບໍ່ດີ (ດັດຊະນີ ~20) | ດີເລີດ (ດັດຊະນີ 100) | ດີ (ດັດຊະນີ 40-60) |

| ຄວາມສັບສົນໃນການຜະລິດ | ປານກາງ | ຕໍ່າ | ປານກາງ |

| ຂະຫນາດຕົວນໍາທີ່ຕ້ອງການ | 1.0x (ເສັ້ນຖານ) | 3.6x (ສໍາລັບຄວາມຕ້ານທານເທົ່າທຽມກັນ) | 6.7x (ສໍາລັບຄວາມຕ້ານທານເທົ່າທຽມກັນ) |

| ຕົ້ນທຶນຕະຫຼອດອາຍຸການນຳໃຊ້ | ຕ່ໍາ (ປະສິດທິພາບສູງ) | ກາງ (ອົງປະກອບຂະຫນາດໃຫຍ່) | ກາງ (ຄໍາຮ້ອງສະຫມັກພິເສດ) |

ຄ່າໃຊ້ຈ່າຍວັດສະດຸມີການປ່ຽນແປງກັບຕະຫຼາດສິນຄ້າ, ແຕ່ຄວາມສໍາພັນທີ່ກ່ຽວຂ້ອງຍັງຄົງສອດຄ່ອງ. ທອງແດງປົກກະຕິແລ້ວມີລາຄາພິເສດເນື່ອງຈາກຄວາມຕ້ອງການສູງຈາກອຸດສາຫະກໍາໄຟຟ້າແລະເອເລັກໂຕຣນິກ. ທອງເຫລືອງສະຫນອງຂໍ້ໄດ້ປຽບດ້ານຄ່າໃຊ້ຈ່າຍໂດຍຜ່ານການຫຼຸດຜ່ອນເວລາການປຸງແຕ່ງແລະການສວມໃສ່ເຄື່ອງມື, ມັກຈະຊົດເຊີຍປະລິມານວັດສະດຸທີ່ສູງຂຶ້ນທີ່ຕ້ອງການສໍາລັບການນໍາໄຟຟ້າທຽບເທົ່າ. ລາຄາທອງແດງແຕກຕ່າງກັນຢ່າງຫຼວງຫຼາຍຕາມປະເພດໂລຫະປະສົມ, ໂດຍມີທອງແດງຟອສເຟີມາດຕະຖານທຽບເທົ່າກັບທອງເຫລືອງໃນຂະນະທີ່ທອງແດງ beryllium ມີລາຄາແພງກວ່າຢ່າງຫຼວງຫຼາຍ.

ການວິເຄາະຄ່າໃຊ້ຈ່າຍທັງຫມົດຕ້ອງພິຈາລະນາຜົນກະທົບໃນລະດັບລະບົບນອກເຫນືອຈາກລາຄາວັດຖຸດິບ. ການໃຊ້ທອງເຫລືອງໃນ ແຖບຕໍ່ສາຍໄຟ ອາດຈະເພີ່ມຂະຫນາດອົງປະກອບແຕ່ຫຼຸດຜ່ອນຄ່າໃຊ້ຈ່າຍໃນການຜະລິດໂດຍຜ່ານການປັບປຸງຄວາມສາມາດໃນການປຸງແຕ່ງ. ອາຍຸການບໍລິການທີ່ຍາວກວ່າຂອງທອງແດງໃນສະພາບແວດລ້ອມທີ່ກັດກ່ອນຈະກໍາຈັດຄ່າໃຊ້ຈ່າຍໃນການປ່ຽນແທນທີ່ຈະສະສົມກັບທາງເລືອກທອງແດງຫຼືທອງເຫລືອງ. ການຄິດໄລ່ປະສິດທິພາບພະລັງງານເປີດເຜີຍວ່າການນໍາໄຟຟ້າທີ່ດີກວ່າຂອງທອງແດງຊ່ວຍຫຼຸດຜ່ອນຄ່າໃຊ້ຈ່າຍໃນການດໍາເນີນງານໃນຄໍາຮ້ອງສະຫມັກກະແສໄຟຟ້າສູງ, ເຊິ່ງອາດຈະພິສູດໃຫ້ເຫັນເຖິງການລົງທຶນເບື້ອງຕົ້ນທີ່ສູງຂຶ້ນ.

ຍຸດທະສາດການຈັດຊື້ຄວນປະເມີນຄວາມຕ້ອງການສະເພາະຂອງແອັບພລິເຄຊັນຕໍ່ກັບຄຸນລັກສະນະຂອງວັດສະດຸ. ຜະລິດຕະພັນຜູ້ບໍລິໂພກທີ່ມີປະລິມານສູງອາດຈະເພີ່ມປະສິດທິພາບສໍາລັບປະສິດທິພາບການຜະລິດຂອງທອງເຫລືອງ, ໃນຂະນະທີ່ການລົງທຶນພື້ນຖານໂຄງລ່າງທີ່ສໍາຄັນສະຫນັບສະຫນູນປະສິດທິພາບຂອງທອງແດງແລະຄວາມທົນທານຂອງທອງແດງ. ວິທີການປະສົມປະສານໂດຍໃຊ້ທອງແດງສໍາລັບອົງປະກອບທີ່ບັນຈຸກະແສໄຟຟ້າແລະທອງເຫລືອງສໍາລັບອົງປະກອບກົນຈັກມັກຈະໃຫ້ຄວາມສົມດູນຂອງຄ່າໃຊ້ຈ່າຍແລະປະສິດທິພາບທີ່ດີທີ່ສຸດໃນການປະກອບທີ່ສັບສົນເຊັ່ນ: ເຄື່ອງຕັດວົງຈອນ ແລະ switchgear.

ຄໍາແນະນໍາການອອກແບບແລະການປະຕິບັດທີ່ດີທີ່ສຸດ

ຄວາມເຂົ້າກັນໄດ້ຂອງວັດສະດຸແລະການກັດກ່ອນ Galvanic

ການປະສົມໂລຫະທີ່ແຕກຕ່າງກັນໃນການປະກອບໄຟຟ້າຮຽກຮ້ອງໃຫ້ມີການພິຈາລະນາຢ່າງລະມັດລະວັງກ່ຽວກັບທ່າແຮງການກັດກ່ອນ galvanic. ເມື່ອທອງແດງແລະທອງເຫລືອງຕິດຕໍ່ໃນທີ່ປະທັບຂອງ electrolytes, ຊຸດ galvanic ຄາດຄະເນຄວາມສ່ຽງຕໍ່ການກັດກ່ອນຫນ້ອຍທີ່ສຸດເນື່ອງຈາກທ່າແຮງຂອງ electrode ທີ່ຄ້າຍຄືກັນ (ທອງແດງ: +0.34V, ທອງເຫລືອງ: +0.30V). ຢ່າງໃດກໍ່ຕາມ, ໂລຫະປະສົມທອງແດງທີ່ມີເນື້ອໃນກົ່ວຫຼືອາລູມິນຽມທີ່ສໍາຄັນອາດຈະສະແດງຄວາມແຕກຕ່າງທີ່ອາດມີຫຼາຍກວ່າເກົ່າ, ເຊິ່ງຮຽກຮ້ອງໃຫ້ມີມາດຕະການປ້ອງກັນ.

ຍຸດທະສາດການອອກແບບເພື່ອຫຼຸດຜ່ອນການກັດກ່ອນ galvanic ປະກອບມີການນໍາໃຊ້ platings ປ້ອງກັນ (ກົ່ວ, ເງິນ, ຫຼື nickel), ການນໍາໃຊ້ສິ່ງກີດຂວາງ insulating ລະຫວ່າງໂລຫະທີ່ແຕກຕ່າງກັນ, ແລະຮັບປະກັນການຜະນຶກທີ່ເຫມາະສົມຕໍ່ກັບຄວາມຊຸ່ມຊື່ນ. Busbar connections ການເຂົ້າຮ່ວມອົງປະກອບທອງແດງແລະທອງເຫລືອງຄວນໃຊ້ສານຕ້ານອະນຸມູນອິດສະລະແລະຮັກສາຄວາມກົດດັນຕິດຕໍ່ທີ່ພຽງພໍເພື່ອຫຼຸດຜ່ອນຄວາມຕ້ານທານ interfacial. ໂປໂຕຄອນການກວດກາແລະການບໍາລຸງຮັກສາເປັນປົກກະຕິແມ່ນມີຄວາມສໍາຄັນໃນສະພາບແວດລ້ອມທີ່ຮຸນແຮງບ່ອນທີ່ຜົນກະທົບ galvanic ເລັ່ງ.

ການຄຸ້ມຄອງຄວາມຮ້ອນແລະຄວາມສາມາດໃນປະຈຸບັນ

ຂະຫນາດຕົວນໍາຕ້ອງຄໍານຶງເຖິງການນໍາໄຟຟ້າຂອງວັດສະດຸເພື່ອຮັກສາອຸນຫະພູມທີ່ເພີ່ມຂຶ້ນທີ່ຍອມຮັບໄດ້ພາຍໃຕ້ການໂຫຼດ. ມາດຕະຖານອຸດສາຫະກໍາເຊັ່ນ IEC 60204-1 ແລະ NEC ໃຫ້ ປັດໄຈຫຼຸດອັດຕາ ອີງຕາມອຸນຫະພູມອາກາດລ້ອມຮອບ, ການຈັດກຸ່ມ, ແລະວັດສະດຸຕົວນໍາ. A brass busbar ຮຽກຮ້ອງໃຫ້ມີປະມານ 3.6 ເທົ່າຂອງພື້ນທີ່ຫນ້າຕັດຂອງທອງແດງເພື່ອປະຕິບັດກະແສໄຟຟ້າທຽບເທົ່າກັບອຸນຫະພູມທີ່ເພີ່ມຂຶ້ນທີ່ຄ້າຍຄືກັນ, ເຊິ່ງມີຜົນກະທົບຕໍ່ຂະຫນາດ enclosure ແລະຄວາມສັບສົນໃນການຕິດຕັ້ງ.

ຄ່າສໍາປະສິດການຂະຫຍາຍຕົວທາງຄວາມຮ້ອນແຕກຕ່າງກັນລະຫວ່າງສາມໂລຫະ (ທອງແດງ: 16.5 µm/m·°C, ທອງເຫລືອງ: 18-21 µm/m·°C, ທອງແດງ: 17-18 µm/m·°C), ສ້າງຄວາມກົດດັນທີ່ອາດເກີດຂຶ້ນໃນການປະກອບໂລຫະປະສົມທີ່ຖືກຄວາມຮ້ອນ. ການເຊື່ອມຕໍ່ປາຍສາຍ ຕ້ອງຮອງຮັບການຂະຫຍາຍຕົວທີ່ແຕກຕ່າງກັນເພື່ອປ້ອງກັນການວ່າງແລະການເພີ່ມຂຶ້ນຂອງຄວາມຕ້ານທານຕິດຕໍ່ໃນໄລຍະເວລາ. ເຄື່ອງຊັກຜ້າພາກຮຽນ spring, ເຄື່ອງຊັກຜ້າ Belleville, ຫຼືຕົວເຊື່ອມຕໍ່ພິເສດຮັກສາຄວາມກົດດັນເຖິງວ່າຈະມີຮອບວຽນຄວາມຮ້ອນ.

ການປິ່ນປົວພື້ນຜິວແລະທາງເລືອກ Plating

ການປິ່ນປົວພື້ນຜິວຊ່ວຍເພີ່ມປະສິດທິພາບແລະອາຍຸຍືນໃນທົ່ວທັງສາມໂລຫະພື້ນຖານ. Tin plating ໃຫ້ solderability ທີ່ດີເລີດແລະການປ້ອງກັນການກັດກ່ອນສໍາລັບ terminals ທອງແດງແລະທອງເຫລືອງ, ເຖິງແມ່ນວ່າມັນຫຼຸດຜ່ອນການນໍາໄຟຟ້າເລັກນ້ອຍຢູ່ທີ່ການໂຕ້ຕອບ. Silver plating ເພີ່ມປະສິດທິພາບການນໍາໄຟຟ້າແລະປ້ອງກັນການຜຸພັງແຕ່ມີຄ່າໃຊ້ຈ່າຍຫຼາຍກວ່າຢ່າງຫຼວງຫຼາຍແລະອາດຈະເສື່ອມເສຍໃນສະພາບແວດລ້ອມທີ່ມີຊູນຟູຣິກ. Nickel plating ສະຫນອງການປ້ອງກັນການກັດກ່ອນທີ່ເຂັ້ມແຂງແລະຄວາມຕ້ານທານການສວມໃສ່, ເຫມາະສົມສໍາລັບຄໍາຮ້ອງສະຫມັກອຸດສາຫະກໍາທີ່ຮຸນແຮງເຖິງວ່າຈະມີຄວາມຕ້ານທານຕິດຕໍ່ສູງຂຶ້ນ.

ອົງປະກອບທອງແດງມັກຈະຕ້ອງການການປິ່ນປົວພື້ນຜິວຫນ້ອຍທີ່ສຸດເນື່ອງຈາກຄວາມຕ້ານທານການກັດກ່ອນທີ່ມີມາແຕ່ກໍາເນີດ, ເຖິງແມ່ນວ່າການ plating ເລືອກຂອງພື້ນທີ່ຕິດຕໍ່ສາມາດເພີ່ມປະສິດທິພາບໄຟຟ້າ. ສາຍສາກ ແລະຕົວເຊື່ອມຕໍ່ການບີບອັດປົກກະຕິແລ້ວລະບຸທອງແດງທີ່ເຮັດດ້ວຍກົ່ວສໍາລັບຄວາມສົມດູນທີ່ດີທີ່ສຸດຂອງການນໍາໄຟຟ້າ, ຄວາມຕ້ານທານການກັດກ່ອນ, ແລະຄ່າໃຊ້ຈ່າຍ. ຄວາມເຂົ້າໃຈກ່ຽວກັບການໂຕ້ຕອບລະຫວ່າງໂລຫະພື້ນຖານແລະ plating ຮັບປະກັນການຄັດເລືອກທີ່ເຫມາະສົມສໍາລັບຄວາມຕ້ອງການດ້ານສິ່ງແວດລ້ອມແລະໄຟຟ້າສະເພາະ.

ມາດຕະຖານອຸດສາຫະກໍາແລະຂໍ້ກໍານົດ

ການຄັດເລືອກວັດສະດຸສໍາລັບອົງປະກອບໄຟຟ້າຕ້ອງປະຕິບັດຕາມມາດຕະຖານທີ່ກ່ຽວຂ້ອງທີ່ຄວບຄຸມອົງປະກອບ, ຄຸນສົມບັດ, ແລະປະສິດທິພາບ. ASTM B152/B152M ກໍານົດແຜ່ນທອງແດງ, ແຖບ, ແຜ່ນ, ແລະແຖບມ້ວນສໍາລັບຄໍາຮ້ອງສະຫມັກໄຟຟ້າ, ກໍານົດຄວາມຕ້ອງການການນໍາໄຟຟ້າແລະຄຸນສົມບັດກົນຈັກ. UL 486A-486B ກວມເອົາຕົວເຊື່ອມຕໍ່ສາຍແລະ lugs soldering, ສ້າງຕັ້ງມາດຕະຖານປະສິດທິພາບສໍາລັບວັດສະດຸຕ່າງໆແລະທາງເລືອກ plating.

ມາດຕະຖານຊຸດ IEC 60947 ກ່າວເຖິງ switchgear ແຮງດັນຕ່ໍາແລະ controlgear, ລວມທັງຄວາມຕ້ອງການວັດສະດຸສໍາລັບ contactors, circuit breakers, ແລະອຸປະກອນຄວບຄຸມ. ຂໍ້ກໍານົດເຫຼົ່ານີ້ມັກຈະອ້າງອີງເຖິງການນໍາໄຟຟ້າຂອງວັດສະດຸ, ຄວາມຕ້ານທານຕິດຕໍ່, ແລະຄວາມຕ້ອງການຄວາມອົດທົນກົນຈັກທີ່ມີອິດທິພົນຕໍ່ການຄັດເລືອກວັດສະດຸ. ການປະຕິບັດຕາມມາດຕະຖານຮັບປະກັນການເຮັດວຽກຮ່ວມກັນ, ຄວາມປອດໄພ, ແລະປະສິດທິພາບທີ່ຄາດເດົາໄດ້ໃນທົ່ວຄໍາຮ້ອງສະຫມັກທີ່ຫຼາກຫຼາຍແລະເງື່ອນໄຂການດໍາເນີນງານ.

ຂໍ້ກໍານົດທາງທະຫານແລະການບິນອະວະກາດ (MIL-STD, AS) ກໍານົດຄວາມຕ້ອງການທີ່ເຂັ້ມງວດກ່ຽວກັບອົງປະກອບຂອງວັດສະດຸ, ການຕິດຕາມ, ແລະການທົດສອບ. ຄໍາຮ້ອງສະຫມັກເຫຼົ່ານີ້ມັກຈະລະບຸ beryllium copper ຫຼື phosphor bronze ສໍາລັບຕົວເຊື່ອມຕໍ່ທີ່ສໍາຄັນແລະຫນ້າສໍາຜັດບ່ອນທີ່ຄວາມຫນ້າເຊື່ອຖືບໍ່ສາມາດຖືກປະນີປະນອມ. ຄວາມເຂົ້າໃຈມາດຕະຖານທີ່ນໍາໃຊ້ໄດ້ໃນຕົ້ນໆຂອງຂະບວນການອອກແບບປ້ອງກັນການອອກແບບໃຫມ່ທີ່ມີລາຄາແພງແລະຮັບປະກັນການປະຕິບັດຕາມກົດລະບຽບຕະຫຼອດວົງຈອນຊີວິດຂອງຜະລິດຕະພັນ.

ຖາມເລື້ອຍໆ

ຖາມ: ຂ້ອຍສາມາດໃຊ້ terminals ທອງເຫລືອງກັບສາຍທອງແດງໂດຍບໍ່ມີບັນຫາບໍ?

A: ແມ່ນແລ້ວ, terminals ທອງເຫລືອງທີ່ມີສາຍທອງແດງເປັນຕົວແທນຂອງການປະສົມປະສານທົ່ວໄປແລະເປັນທີ່ຍອມຮັບໃນການຕິດຕັ້ງໄຟຟ້າ. ຄວາມແຕກຕ່າງທີ່ອາດມີ galvanic ລະຫວ່າງທອງແດງແລະທອງເຫລືອງແມ່ນຫນ້ອຍທີ່ສຸດ (ປະມານ 0.04V), ເຊິ່ງກໍ່ໃຫ້ເກີດຄວາມສ່ຽງຕໍ່ການກັດກ່ອນທີ່ບໍ່ສໍາຄັນໃນສະພາບແວດລ້ອມສ່ວນໃຫຍ່. ຢ່າງໃດກໍ່ຕາມ, ໃຫ້ແນ່ໃຈວ່າແຮງບິດທີ່ເຫມາະສົມໃນລະຫວ່າງການຕິດຕັ້ງເພື່ອຮັກສາຄວາມຕ້ານທານຕິດຕໍ່ຕ່ໍາ, ແລະພິຈາລະນານໍາໃຊ້ສານຕ້ານອະນຸມູນອິດສະລະໃນຄໍາຮ້ອງສະຫມັກກາງແຈ້ງຫຼືຄວາມຊຸ່ມຊື່ນສູງ. terminal ທອງເຫລືອງຄວນຈະມີຂະຫນາດທີ່ເຫມາະສົມເພື່ອຈັດການກັບກະແສໄຟຟ້າໂດຍບໍ່ມີຄວາມຮ້ອນຫຼາຍເກີນໄປ, ໂດຍຄໍານຶງເຖິງການນໍາໄຟຟ້າຕ່ໍາເມື່ອທຽບກັບທອງແດງ.

ຖາມ: ເປັນຫຍັງ busbars ຈຶ່ງເຮັດດ້ວຍທອງແດງແທນທີ່ຈະເປັນທອງເຫລືອງຖ້າທອງເຫລືອງແຂງແຮງກວ່າ?

A: Busbars ຈັດລໍາດັບຄວາມສໍາຄັນຂອງການນໍາໄຟຟ້າຫຼາຍກວ່າຄວາມເຂັ້ມແຂງກົນຈັກເພາະວ່າຫນ້າທີ່ຕົ້ນຕໍຂອງພວກເຂົາແມ່ນການແຈກຢາຍກະແສໄຟຟ້າທີ່ມີປະສິດທິພາບໂດຍມີການສູນເສຍຫນ້ອຍທີ່ສຸດ. ການນໍາໄຟຟ້າ 100% IACS ຂອງທອງແດງເມື່ອທຽບກັບ 28% ຂອງທອງເຫລືອງຫມາຍຄວາມວ່າ busbar ທອງເຫລືອງຈະຕ້ອງການ 3.6 ເທົ່າຂອງພື້ນທີ່ຫນ້າຕັດເພື່ອໃຫ້ກົງກັບປະສິດທິພາບຂອງທອງແດງ, ເຊິ່ງກໍ່ໃຫ້ເກີດການຕິດຕັ້ງຂະຫນາດໃຫຍ່, ຫນັກກວ່າ, ແລະລາຄາແພງກວ່າ. ຄວາມຮ້ອນທີ່ເກີດຈາກຄວາມຕ້ານທານທີ່ສູງຂຶ້ນຂອງທອງເຫລືອງຈະຮຽກຮ້ອງໃຫ້ມີລະບົບເຮັດຄວາມເຢັນທີ່ປັບປຸງ, ເຊິ່ງເພີ່ມຄ່າໃຊ້ຈ່າຍຕື່ມອີກ. ໃນຂະນະທີ່ທອງເຫລືອງສະຫນອງຄວາມເຂັ້ມແຂງກົນຈັກທີ່ດີກວ່າ, busbars ປົກກະຕິແລ້ວປະສົບກັບຄວາມກົດດັນກົນຈັກຫນ້ອຍທີ່ສຸດ, ເຮັດໃຫ້ຂໍ້ໄດ້ປຽບການນໍາໄຟຟ້າຂອງທອງແດງຕັດສິນໃຈ.

ຖາມ: ຂ້ອຍຄວນເລືອກທອງແດງແທນທອງແດງຫຼືທອງເຫລືອງສໍາລັບອົງປະກອບໄຟຟ້າເມື່ອໃດ?

A: ເລືອກທອງແດງເມື່ອຄໍາຮ້ອງສະຫມັກຕ້ອງການຄວາມຕ້ານທານການກັດກ່ອນທີ່ໂດດເດັ່ນ, ຄວາມຕ້ານທານການສວມໃສ່, ຫຼືຄຸນສົມບັດພາກຮຽນ spring ທີ່ທອງແດງແລະທອງເຫລືອງບໍ່ສາມາດສະຫນອງໄດ້. ສະພາບແວດລ້ອມທາງທະເລ, ການຕັ້ງຄ່າອຸດສາຫະກໍາທີ່ມີການສໍາຜັດສານເຄມີ, ແລະການຕິດຕັ້ງກາງແຈ້ງໄດ້ຮັບຜົນປະໂຫຍດຈາກການປ້ອງກັນການກັດກ່ອນທີ່ດີກວ່າຂອງທອງແດງອາລູມິນຽມ. Phosphor bronze ເກັ່ງໃນຄໍາຮ້ອງສະຫມັກທີ່ມີຮອບວຽນສູງເຊັ່ນ: ຫນ້າສໍາຜັດ relay, springs ສະວິດ, ແລະ pins ເຊື່ອມຕໍ່ບ່ອນທີ່ຄວາມຕ້ານທານຄວາມເມື່ອຍລ້າແລະຄວາມກົດດັນຕິດຕໍ່ທີ່ສອດຄ່ອງກັນແມ່ນສໍາຄັນ. ເຖິງວ່າຈະມີການນໍາໄຟຟ້າຕ່ໍາ (15% IACS), ຄວາມທົນທານຂອງທອງແດງມັກຈະເຮັດໃຫ້ຄ່າໃຊ້ຈ່າຍໃນວົງຈອນຊີວິດຕ່ໍາໂດຍຜ່ານອາຍຸການບໍລິການທີ່ຍາວນານແລະການບໍາລຸງຮັກສາຫຼຸດລົງໃນສະພາບແວດລ້ອມທີ່ທ້າທາຍ.

ຖາມ: ການນໍາໄຟຟ້າສົ່ງຜົນກະທົບຕໍ່ປະສິດທິພາບພະລັງງານໃນການແຈກຢາຍພະລັງງານແນວໃດ?

A: ການນໍາໄຟຟ້າຕ່ໍາໂດຍກົງເພີ່ມການສູນເສຍ resistive, ປ່ຽນພະລັງງານໄຟຟ້າເປັນຄວາມຮ້ອນສິ່ງເສດເຫຼືອ. ໃນ busbar ທອງແດງ 100 ແມັດທີ່ບັນທຸກ 1000A ທີ່ມີພື້ນທີ່ຫນ້າຕັດ 1000 ມມ², ການສູນເສຍພະລັງງານປະມານ 270W. ການປ່ຽນແທນດ້ວຍທອງເຫລືອງທີ່ມີຂະຫນາດເທົ່າທຽມກັນຈະເພີ່ມການສູນເສຍເປັນປະມານ 970W - ເພີ່ມຂຶ້ນ 700W ທີ່ສະສົມຢ່າງຕໍ່ເນື່ອງໃນລະຫວ່າງການປະຕິບັດງານ. ໃນໄລຍະຫນຶ່ງປີ, ຄວາມແຕກຕ່າງນີ້ສະແດງເຖິງ 6,132 kWh ຂອງພະລັງງານທີ່ເສຍໄປ. ສໍາລັບຄໍາຮ້ອງສະຫມັກກະແສໄຟຟ້າສູງຫຼືໄລຍະທາງໄກ, ການນໍາໄຟຟ້າທີ່ດີກວ່າຂອງທອງແດງໃຫ້ປະຫຍັດພະລັງງານຢ່າງຫຼວງຫຼາຍທີ່ພິສູດໃຫ້ເຫັນເຖິງຄ່າໃຊ້ຈ່າຍວັດສະດຸເບື້ອງຕົ້ນທີ່ສູງຂຶ້ນ. ຂໍ້ໄດ້ປຽບດ້ານປະສິດທິພາບກາຍເປັນທີ່ໂດດເດັ່ນກວ່າໃນ ໝໍ້ແປງໄຟຟ້າ ແລະມໍເຕີບ່ອນທີ່ການສູນເສຍສ້າງຄວາມຮ້ອນທີ່ຕ້ອງໄດ້ລະບາຍອອກ.

ຖາມ: ມີຄໍາຮ້ອງສະຫມັກໄຟຟ້າໃດແດ່ທີ່ທອງແດງດີກວ່າທອງແດງ?

A: ທອງແດງປະສົມປະສານມີປະສິດທິພາບດີກວ່າທອງແດງໃນການນຳໃຊ້ທີ່ຄຸນສົມບັດທາງກົນຈັກ, ຄວາມທົນທານຕໍ່ການກັດກ່ອນ, ຫຼືຄຸນລັກສະນະການສວມໃສ່ມີຄວາມສຳຄັນກວ່າຄວາມຕ້ອງການການນຳໄຟຟ້າທີ່ບໍລິສຸດ. ໜ້າສຳຜັດໄຟຟ້າທີ່ຖືກຮອບວຽນຊ້ຳໆໄດ້ຮັບຜົນປະໂຫຍດຈາກຄຸນສົມບັດຂອງພາກຮຽນ spring ທີ່ດີກວ່າຂອງທອງແດງຟົດສະຟໍແລະຄວາມຕ້ານທານຕໍ່ຄວາມເມື່ອຍລ້າ, ຮັກສາຄວາມກົດດັນຕິດຕໍ່ທີ່ສອດຄ່ອງກັນໄດ້ດົນກວ່າທາງເລືອກທອງແດງ. ເຄື່ອງປ່ຽນໄຟຟ້າທາງທະເລແລະຕົວເຊື່ອມຕໍ່ທີ່ສໍາຜັດກັບການກັດກ່ອນຂອງນໍ້າເຄັມສະແດງໃຫ້ເຫັນຄວາມຫນ້າເຊື່ອຖືໃນໄລຍະຍາວທີ່ດີກວ່າດ້ວຍທອງແດງອາລູມິນຽມເຖິງວ່າຈະມີການນໍາໄຟຟ້າຕ່ໍາ. ໜ້າສຳຜັດເລື່ອນແລະຊຸດແປງຖ່ານມີການສວມໃສ່ນ້ອຍກວ່າດ້ວຍໂລຫະປະສົມທອງແດງ, ເຊິ່ງຊ່ວຍຍືດໄລຍະການບໍລິການແລະຫຼຸດຜ່ອນຄ່າໃຊ້ຈ່າຍໃນການບຳລຸງຮັກສາ. ໃນການນຳໃຊ້ພິເສດເຫຼົ່ານີ້, ການປະສົມປະສານທີ່ເປັນເອກະລັກຂອງຄຸນສົມບັດຂອງທອງແດງປະສົມປະສານໃຫ້ປະສິດທິພາບໂດຍລວມທີ່ດີກວ່າເຖິງວ່າຈະມີການນຳໄຟຟ້າຕ່ຳກວ່າ.

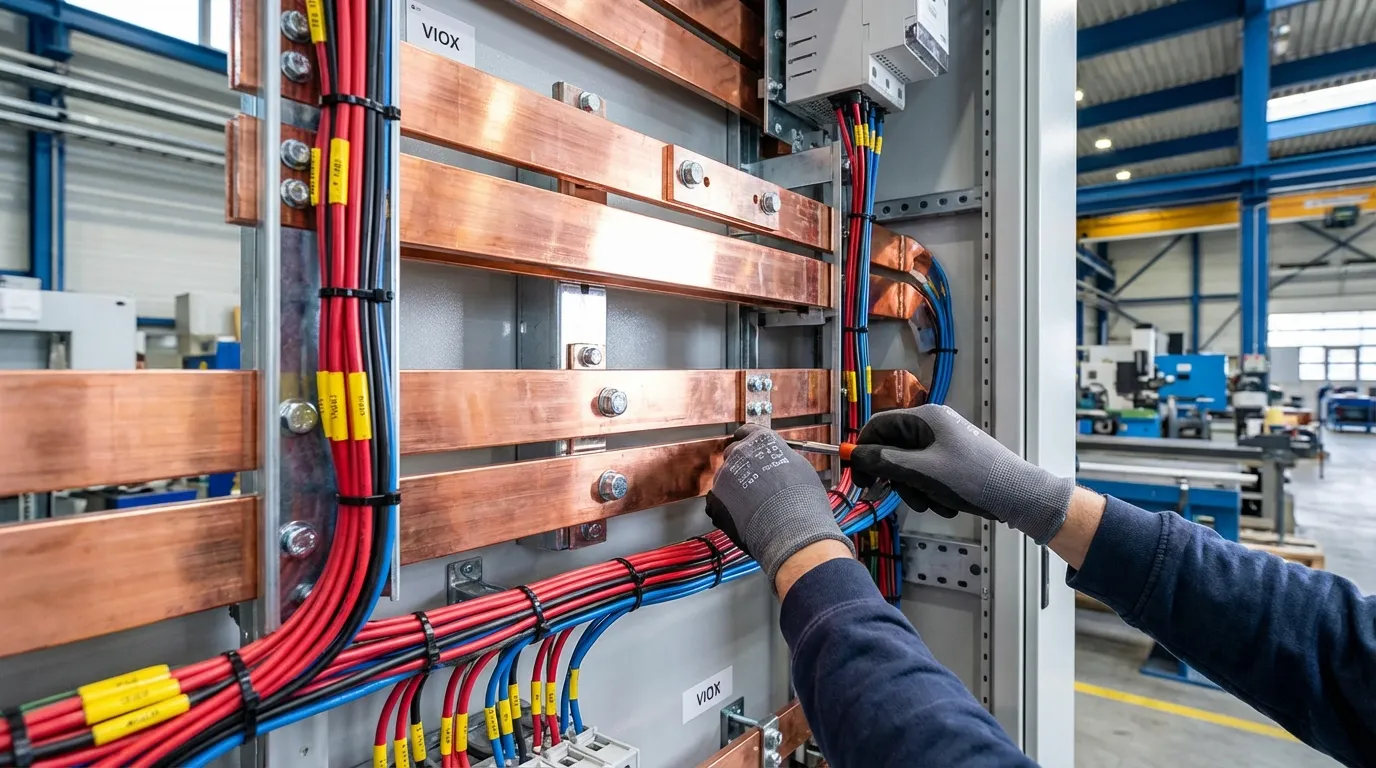

VIOX Electric ມີຄວາມຊ່ຽວຊານໃນການຜະລິດອົງປະກອບໄຟຟ້າທີ່ມີຄຸນນະພາບສູງໂດຍນໍາໃຊ້ການຄັດເລືອກວັດສະດຸທີ່ດີທີ່ສຸດສໍາລັບແຕ່ລະຄໍາຮ້ອງສະຫມັກ. ທີມງານວິສະວະກໍາຂອງພວກເຮົາໃຫ້ຄໍາແນະນໍາຜູ້ຊ່ຽວຊານກ່ຽວກັບຂໍ້ກໍານົດຂອງວັດສະດຸສໍາລັບ ແຜງຄວບຄຸມອຸດສາຫະກໍາ, ລະບົບແຈກຢາຍພະລັງງານ, ແລະອຸປະກອນໄຟຟ້າພິເສດ. ຕິດຕໍ່ພວກເຮົາສໍາລັບການປຶກສາດ້ານວິຊາການກ່ຽວກັບໂຄງການຕໍ່ໄປຂອງທ່ານ.