⚠️ AVVISO CRITICO: L'utilizzo di un interruttore automatico CA in un'applicazione CC può causare guasti catastrofici alle apparecchiature, incendi elettrici e gravi rischi per la sicurezza. La differenza fondamentale nel comportamento dell'arco tra i sistemi CA e CC rende questa sostituzione estremamente pericolosa e potenzialmente letale.

Un Interruttore automatico CC è un dispositivo di protezione specializzato progettato per interrompere automaticamente il flusso di corrente continua (CC) quando si verificano condizioni pericolose come sovracorrente, cortocircuiti o guasti elettrici. A differenza degli interruttori CA standard, gli interruttori automatici CC incorporano una tecnologia avanzata di soppressione dell'arco per interrompere in sicurezza il flusso di corrente continua, una sfida che rende la protezione CC fondamentalmente più complessa della protezione CA.

Questi dispositivi di sicurezza essenziali fungono da difesa primaria nei sistemi elettrici CC, proteggendo installazioni solari fotovoltaiche, sistemi di accumulo di energia a batteria, infrastrutture di ricarica per veicoli elettrici, apparecchiature di telecomunicazione e sistemi elettrici marini.

La fisica dietro gli interruttori automatici CC: perché gli interruttori CA non possono proteggere i sistemi CC

Comprendere la sfida del punto di attraversamento dello zero

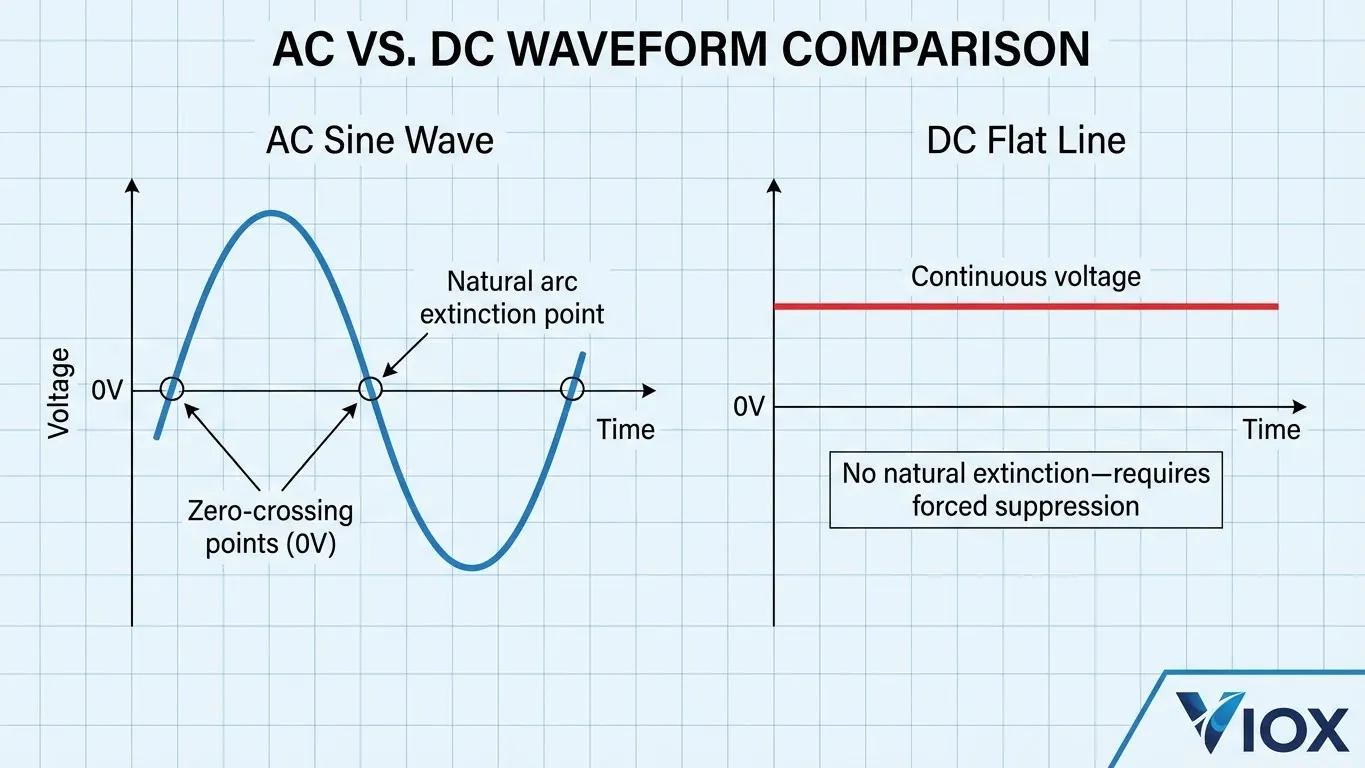

La differenza critica tra la protezione del circuito CA e CC risiede nel punto di attraversamento dello zero—il momento in cui la tensione della corrente alternata scende naturalmente a zero volt.

Nei sistemi CA, la corrente oscilla attraverso la tensione zero 100-120 volte al secondo (a seconda della frequenza di 50 Hz o 60 Hz). Questo attraversamento dello zero naturale crea condizioni ottimali per l'estinzione dell'arco. Quando un interruttore CA apre i suoi contatti, l'arco si estingue naturalmente al successivo punto di attraversamento dello zero.

I sistemi CC non hanno un punto di attraversamento dello zero. La corrente continua scorre continuamente a tensione costante, creando un arco elettrico sostenuto che si rifiuta di autoestinguersi. Questa differenza fondamentale rende l'interruzione dell'arco CC esponenzialmente più impegnativa e pericolosa.

Interruttore automatico CA vs CC: confronto critico

| Funzione | Interruttore automatico CA (MCB) | Interruttore automatico CC (MCB CC) |

|---|---|---|

| Estinzione dell'arco | Naturale all'attraversamento dello zero (ogni 8-10 ms) | Richiede l'estinzione magnetica forzata |

| Attraversamento dello zero | 100-120 volte al secondo | Non si verifica mai |

| Sensibilità alla polarità | Nessun requisito di polarità | Spesso polarizzato (la direzione +/- è importante) |

| Progettazione della camera di estinzione dell'arco | Configurazione standard della rete | Potenziato con bobine di estinzione magnetica |

| Capacità di interruzione | Valutazioni inferiori sufficienti | Valutazioni più elevate richieste per la stessa corrente |

| Valutazione Di Tensione | Tipicamente 230-400 V CA | Da 12 V a 1500 V CC |

| Dimensione | Più piccolo per una valutazione equivalente | 20-30% più grande a causa della soppressione dell'arco |

| Costo | Più basso | 30-50% più alto |

| Modalità di Guasto | Guasto di intervento sicuro | Rischio di incendio se valutato in modo errato |

Nota tecnica: Non sostituire mai un interruttore CA con una valutazione di 250 V CA in un'applicazione CC, anche a tensioni CC inferiori. Un interruttore CA da 250 V può guastarsi catastroficamente a soli 48 V CC a causa di capacità di soppressione dell'arco inadeguate.

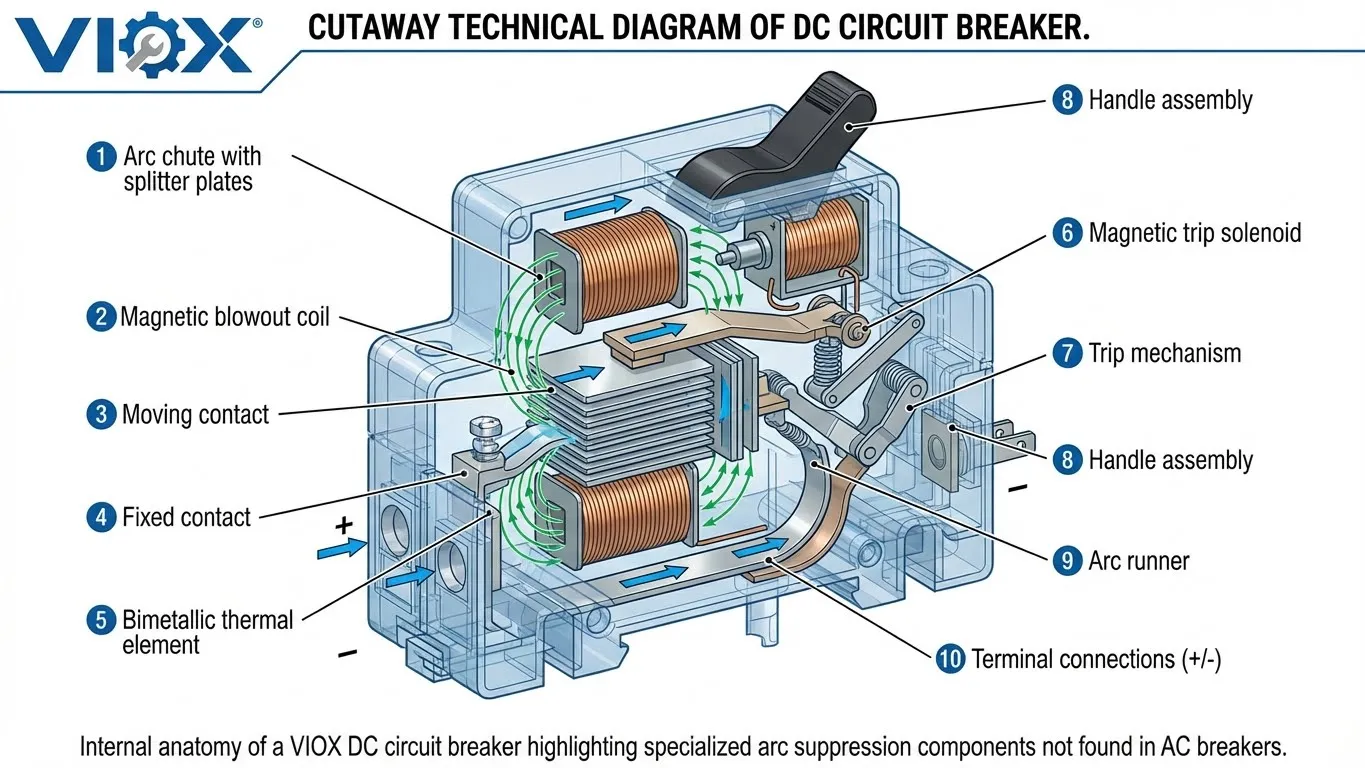

Anatomia interna: come gli interruttori automatici CC ottengono la soppressione dell'arco

Componenti critici per la protezione CC

Il Camera di estinzione dell'arco: Il cuore della protezione CC

Il camera di estinzione dell'arco rappresenta il componente più critico che differenzia gli interruttori CC dagli interruttori CA. Questo assieme è costituito da:

- Piastre divisorie: Più piastre metalliche disposte in serie che dividono l'arco in segmenti più piccoli

- Corridori ad arco: Guide in rame o acciaio che guidano l'arco verso l'alto nelle piastre divisorie

- Camera di raffreddamento: Area di contenimento estesa che raffredda rapidamente i gas dell'arco

Bobine di estinzione magnetica: forzatura dell'estinzione dell'arco

Bobine di estinzione magnetica creano potenti campi magnetici che spingono fisicamente l'arco elettrico verso l'alto nella camera di estinzione dell'arco. L'interazione tra la corrente dell'arco e il campo magnetico genera una forza di Lorentz che:

- Allunga la lunghezza dell'arco (aumentando la resistenza)

- Spinge l'arco nelle piastre divisorie (dividendo e raffreddando)

- Forza i gas dell'arco nelle camere di raffreddamento

- Ottiene l'estinzione dell'arco attraverso la dissipazione di energia

Questa soppressione forzata dell'arco sostituisce il meccanismo naturale di attraversamento dello zero assente nei sistemi CC.

Sicurezza critica: polarità e cablaggio dell'interruttore automatico CC

Interruttori CC polarizzati vs non polarizzati

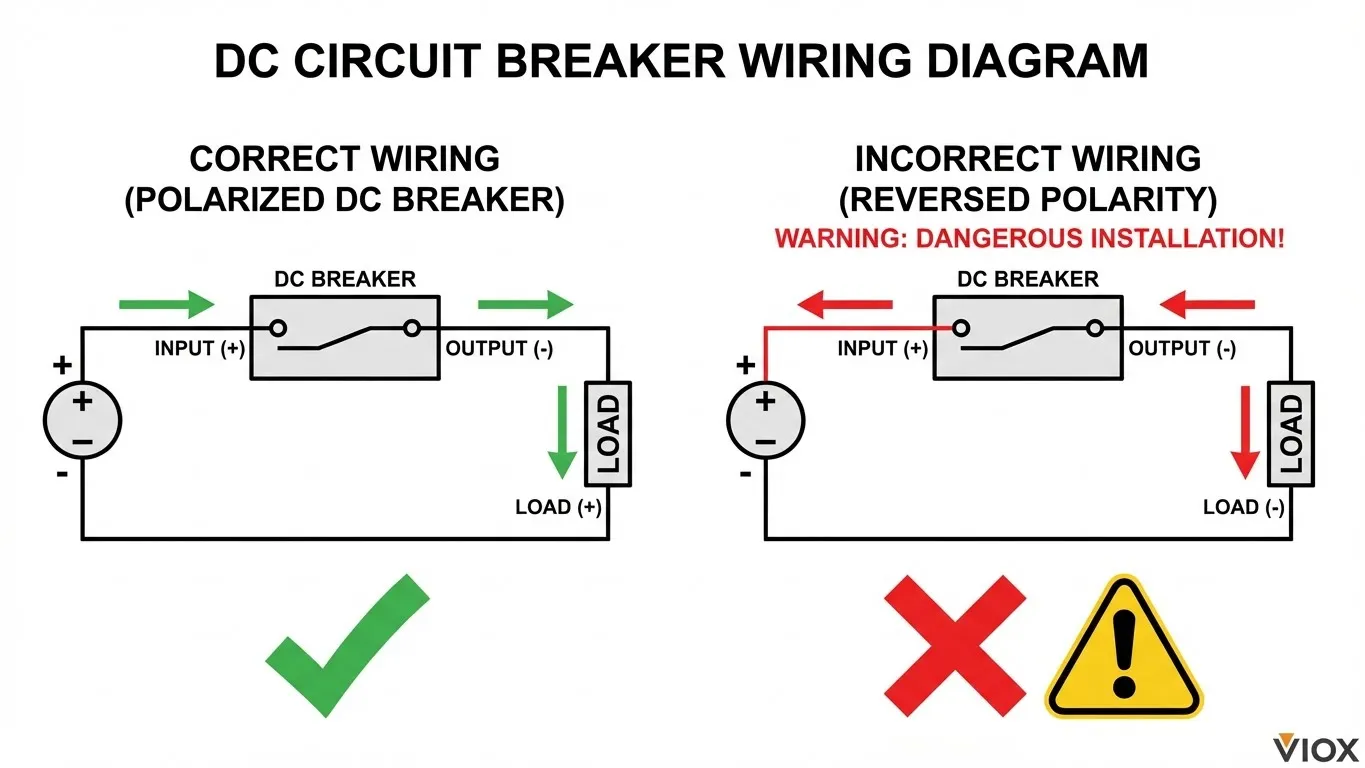

Interruttori CC polarizzati devono essere cablati con la polarità corretta per funzionare in sicurezza. Il meccanismo di soppressione dell'arco dipende dalla direzione della corrente attraverso la bobina di estinzione magnetica.

⚠️ ATTENZIONE: L'inversione della polarità nel cablaggio degli interruttori DC polarizzati può causare:

- Mancata soppressione dell'arco

- Saldatura dei contatti

- Fuga termica

- Pericolo di incendio

Interruttori DC non polarizzati (come la serie avanzata VIOX) funzionano correttamente indipendentemente dalla direzione della polarità, offrendo maggiore sicurezza e flessibilità di installazione.

Lista di controllo per la sicurezza dell'installazione

- Verificare che la tensione nominale DC dell'interruttore superi la tensione massima del sistema

- Confermare l'orientamento corretto della polarità (controllare i contrassegni + e –)

- Assicurarsi che la sezione del cavo soddisfi i requisiti di amperaggio dell'interruttore

- Verificare che la capacità di interruzione dell'interruttore superi la corrente di guasto calcolata

- Installare in un luogo ben ventilato, lontano da materiali infiammabili

- Etichettare chiaramente i circuiti per la sicurezza della manutenzione

Come dimensionare il tuo interruttore DC: la regola 1,25x spiegata

A differenza dei sistemi AC in cui la corrente oscilla naturalmente e fornisce intervalli di raffreddamento, i carichi DC, specialmente nelle applicazioni solari fotovoltaiche e di accumulo di energia a batteria, sostengono correnti elevate continuamente per periodi prolungati. Questo flusso di corrente sostenuto genera calore cumulativo nei conduttori e nei contatti dell'interruttore, richiedendo agli ingegneri di applicare fattori di sicurezza che prevengano lo scatto intempestivo, il surriscaldamento dei contatti e il guasto prematuro delle apparecchiature.

Sia il National Electrical Code (NEC) che gli standard della Commissione Elettrotecnica Internazionale (IEC) impongono che gli interruttori DC siano dimensionati per gestire il 125% della corrente di carico continua, garantendo un funzionamento affidabile in condizioni di corrente elevata sostenuta.

1. Valutazione Di Tensione Selezione (Vinterruttore)

La tensione nominale dell'interruttore deve superare la tensione massima del sistema per fornire un'adeguata capacità di soppressione dell'arco e rigidità dielettrica.

Regola di ingegneria:

Vinterruttore ≥ Vsistema_max

Per un margine di sicurezza ottimale, selezionare una tensione nominale dell'interruttore di almeno il 125% della tensione massima del sistema:

Esempio 1: Sistema di batterie a 48 V con tensione di carica massima di 58 V

- Tensione nominale minima dell'interruttore: 58 V × 1,25 = 72,5 V → Selezionare un interruttore con tensione nominale di 80 V

⚠️ Avviso critico: Non sostituire mai un interruttore AC da 230 V in applicazioni DC, anche a tensioni DC inferiori. Un interruttore AC da 250 V potrebbe guastarsi catastroficamente a soli 48 V DC a causa di meccanismi di soppressione dell'arco DC inadeguati. Le tensioni nominali AC sono fondamentalmente incompatibili con i requisiti di interruzione DC.

2. Calcolo della corrente nominale (Iinterruttore)

Secondo l'articolo 690.8(B) del NEC e gli standard IEC 60947-2, gli interruttori che proteggono i carichi continui (funzionamento >3 ore) devono essere dimensionati al 125% della corrente di carico continua.

La formula del fattore di sicurezza 1,25x:

Iinterruttore = Icarico_continuo × 1,25

Questo fattore di sicurezza tiene conto di:

- Generazione di calore sostenuta nei sistemi DC senza periodi di raffreddamento naturali

- Variazioni della temperatura ambiente che influenzano le caratteristiche termiche dell'interruttore

- Aumento della resistenza del conduttore con la temperatura

- Tolleranze di produzione nelle caratteristiche di intervento dell'interruttore

Esempio pratico 1 – Array solare fotovoltaico:

Hai un array solare fotovoltaico che produce 20 Ampere continuamente durante le ore di picco solare.

- Calcolo: 20 A × 1,25 = 25A

- Selezione: scegliere la dimensione standard successiva → Interruttore DC da 25 A o 32 A

Esempio pratico 2 – Regolatore di carica solare:

- Regolatore di carica solare: 3000 W ÷ 48 V = 62,5 A

- Corrente nominale dell'interruttore richiesta: 62,5 A × 1,25 = 78,125 A → Selezionare un interruttore da 80 A o 100 A

Correnti nominali standard degli interruttori: Quando si applica la regola 1,25x, arrotondare alla corrente nominale standard successiva disponibile: 6 A, 10 A, 16 A, 20 A, 25 A, 32 A, 40 A, 50 A, 63 A, 80 A, 100 A, 125 A.

3. Capacità di interruzione (corrente di corto circuito nominale)

La capacità di interruzione deve superare la corrente di guasto massima disponibile. Per i sistemi di batterie con bassa resistenza interna, le correnti di guasto possono raggiungere livelli pericolosi che gli interruttori standard non possono interrompere in sicurezza.

Stima della corrente di guasto:

Iguasto = Vbatteria / Rtotale

Dove Rtotale include la resistenza interna della batteria, la resistenza del conduttore e la resistenza di connessione.

Esempio: Banco batterie a 48 V con resistenza totale di 0,01 Ω

- Corrente di guasto: 48 V ÷ 0,01 Ω = 4.800 A

- Corrente di corto circuito nominale richiesta: Minimo 6kA, raccomandato 10kA

Linee guida per la selezione dell'AIC per applicazione:

- Sistemi solari residenziali (piccoli banchi di batterie): 5kA minimo

- Installazioni solari commerciali: 10kA minimo

- Accumulo di energia a batteria industriale (grandi banchi): 15-20kA minimo

- Applicazioni su scala industriale: richiesti 25kA+

Sottodimensionare la capacità di interruzione crea un rischio di guasto catastrofico: l'interruttore può esplodere o saldarsi in posizione chiusa durante condizioni di guasto, eliminando tutta la protezione del circuito.

Guida alla selezione degli interruttori automatici CC in base alla tensione del sistema

| Tensione del sistema | Applicazioni Tipiche | Corrente nominale dell'interruttore consigliata | Gamma attuale | AIC minimo |

|---|---|---|---|---|

| 12 V CC | Automobilistico, illuminazione per camper, elettronica marina | 24V o 32V | 5-100A | 5kA |

| 24 V CC | Telecomunicazioni, piccoli sistemi solari | 48V o 60V | 10-125A | 5kA |

| 48 V CC | Solare off-grid, data center, telecomunicazioni | 80V o 100V | 20-250A | 10kA |

| 120-250V CC | Solare commerciale, ricarica EV | 400V o 500V | 32-400A | 15kA |

| 600-1000V CC | Solare su scala industriale, BESS | 1000V o 1500V | 63-630A | 20kA+ |

Tipi di interruttori automatici CC

Interruttori automatici miniaturizzati (MCB CC)

- Gamma attuale: Da 6A a 125A

- Applicazioni: Solare residenziale, sistemi per camper, telecomunicazioni

- Vantaggi: Compatto, montaggio su guida DIN, economico

Interruttori automatici scatolati (DC MCCB)

- Gamma attuale: Da 100 A a 2500 A

- Applicazioni: Solare commerciale, sistemi di batterie industriali, ricarica EV

- Caratteristiche: Impostazioni di intervento regolabili, maggiore capacità di interruzione

Caratteristiche della curva di intervento

| Curva di viaggio | Campo di Intervento Magnetico | Migliori applicazioni | Idoneità CC |

|---|---|---|---|

| Tipo B | 3-5× corrente nominale | Illuminazione, solare residenziale | Buono |

| Tipo C | 5-10× corrente nominale | Commerciale generale, sistemi di batterie | Eccellente |

| Tipo D | 10-20× corrente nominale | Circuiti motore, carichi con elevata corrente di spunto | Buono |

| Tipo K/Z | Regolabile | Telecomunicazioni, apparecchiature sensibili | Eccellente |

Applicazioni critiche degli interruttori automatici CC

Sistemi solari fotovoltaici

Gli interruttori automatici CC proteggono gli array FV, i combinatori di stringa e gli ingressi dell'inverter. I requisiti chiave includono:

- Tensioni nominali fino a 1000 V o 1500 V

- Funzionamento ad alta temperatura (apparecchiature montate sul tetto)

- Involucri resistenti ai raggi UV

Sistemi di accumulo dell'energia a batteria (BESS)

La protezione per i banchi di batterie agli ioni di litio e al piombo-acido richiede:

- Gestione della corrente bidirezionale (carica/scarica)

- Elevate correnti di cortocircuito nominali (>10kA) a causa della bassa impedenza della batteria

- Integrazione del monitoraggio termico

Le Infrastrutture Di Ricarica Di Veicoli Elettrici

I caricabatterie rapidi CC richiedono una protezione specializzata:

- Correnti nominali da 125 A a 500 A

- Tempi di risposta rapidi (<5ms)

- Protocolli di comunicazione per la ricarica intelligente

Data Center e Telecomunicazioni

Le applicazioni mission-critical richiedono:

- Elevata affidabilità (MTBF >100.000 ore)

- Capacità di monitoraggio remoto

- Coordinamento selettivo con la protezione a monte

Domande frequenti sugli interruttori automatici CC

Posso utilizzare un interruttore automatico AC per applicazioni DC?

No, assolutamente no. Gli interruttori automatici CA non dispongono dei meccanismi specializzati di soppressione dell'arco necessari per l'interruzione della corrente CC. L'utilizzo di un interruttore CA in un'applicazione CC crea seri rischi di incendio e danni alle apparecchiature. L'assenza di punti di attraversamento dello zero nei sistemi CC significa che gli interruttori CA non possono estinguere in modo affidabile gli archi, portando potenzialmente alla saldatura dei contatti e a condizioni di fuga termica.

Cosa causa lo scatto di un interruttore automatico CC?

Gli interruttori automatici CC scattano a causa di: (1) Condizioni di sovracorrente dove la corrente di carico supera la corrente nominale termica dell'interruttore per periodi prolungati, (2) Cortocircuiti creazione di correnti di guasto elevate istantanee che attivano i meccanismi di sgancio magnetico, (3) Guasti a terra in sistemi con protezione contro i guasti a terra, e (4) Guasti da arco negli interruttori dotati di rilevamento di guasti da arco. Il design termomagnetico fornisce una protezione coordinata sia contro i sovraccarichi prolungati che contro i guasti istantanei.

La polarità è importante quando si cablano interruttori automatici CC?

Sì, per la maggior parte degli interruttori automatici CC. Gli interruttori CC polarizzati devono essere cablati con il terminale positivo (+) collegato alla fonte di alimentazione e il terminale negativo (-) al carico. L'inversione di polarità può disabilitare i meccanismi di soppressione dell'arco e creare rischi di incendio. Tuttavia, gli avanzati Interruttori CC non polarizzati VIOX funzionano correttamente indipendentemente dalla direzione di connessione, eliminando questo rischio di installazione e fornendo una maggiore flessibilità.

Come calcolo la dimensione corretta dell'interruttore automatico per il mio sistema solare?

Calcola le dimensioni dell'interruttore utilizzando questa formula: Valore nominale dell'interruttore = Corrente massima × 1,25. Ad esempio, un array solare da 5kW a 48V produce 104A (5000W ÷ 48V). Applica il fattore di sicurezza 125%: 104A × 1,25 = 130A, quindi seleziona un Interruttore automatico CC da 150A. Verificare sempre che la tensione nominale dell'interruttore superi la tensione massima del sistema e che la capacità di interruzione superi la corrente di guasto calcolata.

Qual è la differenza tra AIC e valori nominali di tensione?

Tensione nominale indica la tensione massima di esercizio continua che l'interruttore può gestire in sicurezza (ad esempio, 1000 V CC). AIC (Capacità di Interruzione in Ampere) specifica la corrente di guasto massima che l'interruttore può interrompere in sicurezza senza danni (ad esempio, 10 kA). Entrambi i valori nominali sono fondamentali: la tensione nominale deve superare la tensione del sistema, mentre l'AIC deve superare la corrente di guasto massima disponibile. Sottodimensionare uno dei due parametri crea rischi per la sicurezza.

Con quale frequenza devono essere testati e sottoposti a manutenzione gli interruttori automatici CC?

Test iniziale: Entro 30 giorni dall'installazione, azionare manualmente l'interruttore 3-5 volte per verificarne il funzionamento meccanico. Manutenzione ordinaria: Ispezionare trimestralmente per individuare segni di surriscaldamento (scolorimento, isolamento fuso), verificare la coppia sui collegamenti dei terminali (secondo le specifiche del produttore) e testare la funzione di sgancio semestralmente. Criteri di sostituzione: Sostituire gli interruttori che mostrano erosione dei contatti, danni all'involucro o che hanno interrotto correnti di guasto importanti superiori all'80% del loro valore nominale AIC. Le applicazioni ad alta affidabilità possono richiedere un'ispezione termografica annuale.

Conclusione: selezione dell'interruttore automatico CC corretto

Gli interruttori automatici CC rappresentano il componente di sicurezza più critico nei sistemi elettrici a corrente continua. Comprendere le differenze fondamentali tra la protezione CA e CC, in particolare la sfida dell'attraversamento dello zero e i requisiti di soppressione dell'arco, consente una corretta specifica e installazione.

Quando si selezionano gli interruttori automatici CC, dare la priorità a tre fattori essenziali:

- Tensione nominale deve superare la tensione massima del sistema del 25%

- Valutazione attuale dovrebbe essere il 125% della corrente di carico continua

- Capacità di interruzione deve superare la corrente di guasto calcolata

Per i sistemi solari fotovoltaici, l'accumulo di energia a batteria, l'infrastruttura di ricarica dei veicoli elettrici e le applicazioni di telecomunicazione, Interruttori automatici CC VIOX offrono un'affidabilità comprovata con funzionalità avanzate tra cui il funzionamento non polarizzato, un'elevata capacità di interruzione fino a 20 kA e tensioni nominali fino a 1500 V CC.

Non scendere mai a compromessi sulla protezione del circuito CC: il piccolo investimento relativo in interruttori automatici di qualità previene danni catastrofici alle apparecchiature, incendi elettrici e rischi per la sicurezza. Contatta il team di ingegneri di VIOX Electric per la selezione di interruttori CC specifici per l'applicazione e il supporto tecnico.

Informazioni su VIOX Electric: In qualità di produttore B2B leader di apparecchiature di protezione del circuito CC, VIOX Electric è specializzata in interruttori automatici CC ad alte prestazioni per applicazioni di energia rinnovabile, industriali e di trasporto. Il nostro team di ingegneri fornisce supporto tecnico per requisiti complessi di protezione CC in tutto il mondo.