MCCB full form is “Disjoncteur à boîtier moulé“ – a crucial electrical protection device that automatically interrupts electrical current flow when it detects overcurrent, short circuit, or ground fault conditions. Understanding the MCCB full form is essential for electrical professionals, as these devices are critical safety components that protect circuits and equipment from electrical damage while ensuring personnel safety.

MCCB Full Form: What Does MCCB Stand For?

MCCB full form is “Molded Case Circuit Breaker” – an automatically operated electrical switch designed to protect electrical circuits from damage caused by overcurrent conditions, including overloads and short circuits. The MCCB full form explains each component:

- M = Molded: Refers to the insulating housing made of molded thermoplastic

- C = Case: The protective enclosure that houses all components

- C = Circuit: The electrical pathway being protected

- B = Breaker: The switching mechanism that interrupts current flow

The “molded case” in the MCCB full form specifically refers to the insulating housing made of molded thermoplastic or thermoset plastic materials that encases the entire protection mechanism.

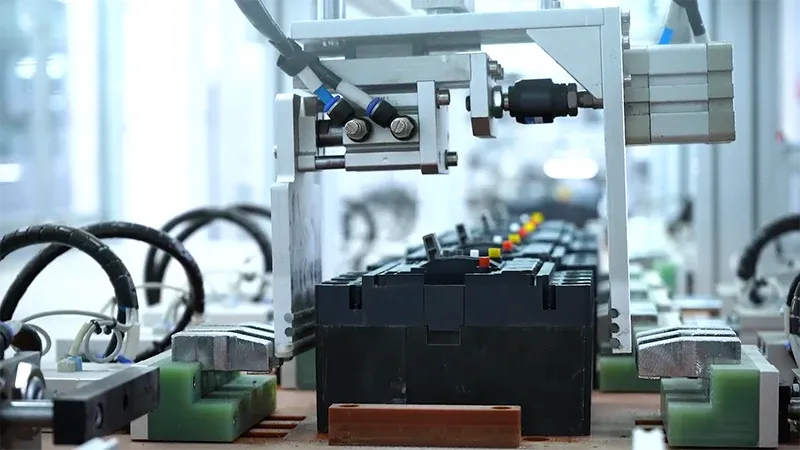

Key MCCB Components:

- Mécanisme de fonctionnement: Controls opening and closing of contacts

- Arc extinction system: Safely interrupts electrical arcs during switching

- Trip unit: Detects fault conditions and triggers protective action

- Molded case housing: Provides insulation and mechanical protection

- Current carrying contacts: Conduct normal electrical current

MCCB Full Form vs Other Circuit Breaker Abbreviations: Complete Comparison

| Fonctionnalité | MCCB | MCB | ACB | VCB |

|---|---|---|---|---|

| Formulaire complet | Disjoncteur à boîtier moulé | Disjoncteur miniature | Disjoncteur à air | Disjoncteur à vide |

| Valeur nominale actuelle | 100A – 2500A | 6A – 63A | 800A – 6300A | 1000A – 50000A |

| Voltage Level | Jusqu'à 1000 V CA | Up to 440V AC | Jusqu'à 15 kV | Up to 38kV |

| Pouvoir De Coupure | 10kA – 200kA | 3kA – 25kA | 50kA – 100kA | 25kA – 80kA |

| Applications | Industrial, Commercial | Residential, Light Commercial | Industrie lourde | Power Transmission |

| Ajustabilité | Paramètres de voyage réglables | Fixed trip settings | Highly adjustable | Highly adjustable |

| Coût | Moyen | Faible | Haut | Très élevé |

Understanding MCCB Full Form: Types and Their Applications

1. Electronic Trip MCCBs

- Advanced microprocessor-based protection

- Applications: Critical industrial processes, data centers

- Caractéristiques: Precise trip curves, communication capabilities, metering functions

2. Thermal-Magnetic MCCBs

- Combination of thermal and magnetic protection

- Applications: General industrial and commercial use

- Caractéristiques: Reliable overload and short-circuit protection

3. Magnetic-Only MCCBs

- Instantaneous magnetic protection only

- Applications: Motor protection, transformer protection

- Caractéristiques: Fast response to short circuits

MCCB Selection Criteria and Technical Specifications

Primary Selection Parameters:

| Paramètre | Considérations | Les Valeurs Typiques |

|---|---|---|

| Courant nominal (In) | Load current + 25% safety margin | 100A, 160A, 250A, 400A, 630A |

| Breaking Capacity (Icu) | Must exceed fault current at installation point | 25kA, 36kA, 50kA, 70kA, 100kA |

| La Tension Nominale De La | System voltage + safety factor | 415V, 440V, 690V, 1000V |

| Nombre de pôles | Single-phase (2P) or three-phase (3P, 4P) | 2P, 3P, 3P+N, 4P |

| Courbe de déplacement | Load characteristics (B, C, D curves) | B (3-5×In), C (5-10×In), D (10-20×In) |

🔧 Conseil d'expert: Always calculate the prospective fault current at the installation point before selecting an MCCB. The breaking capacity must exceed this value by at least 20% for safe operation.

MCCB Working Principle and Operation

Normal Operation Mode:

- Les courants actuels through closed contacts

- Thermal element monitors continuous current

- Magnetic element monitors instantaneous current

- Trip unit remains in armed position

Fault Detection and Tripping:

- État de surcharge: Thermal element heats up gradually, triggers trip mechanism

- Court-circuit: Magnetic element responds instantly, forces immediate tripping

- Extinction d'arc: Arc chutes and SF6 gas (in some models) extinguish electrical arc

- Séparation des contacts: Contacts open, interrupting current flow

Installation Guidelines and Safety Requirements

⚠️ Avertissement de sécurité

MCCB installation must comply with IEC 60947-2, NEC Article 240, and local electrical codes. Always use qualified electricians for installation and maintenance.

Step-by-Step Installation Process:

- Isolation électrique: Ensure complete system de-energization

- Mounting preparation: Install MCCB on DIN rail or panel mounting

- Cable sizing: Use cables rated 125% of MCCB rating minimum

- Torque specifications: Apply manufacturer-specified torque values

- Procédure de test: Perform insulation and functional tests

- Étiquetage: Clearly mark circuit identification and ratings

Critical Installation Requirements:

| Exigence | Spécifications | Référence du code |

|---|---|---|

| Température ambiante | De -25°C à +70°C | CEI 60947-2 |

| Mounting Orientation | Vertical preferred, horizontal acceptable | Manufacturer specs |

| Clearance Space | Minimum 150mm on all sides | NEC 110.26 |

| Ventilation | Natural air circulation required | Local codes |

Applications et cas d'utilisation

Applications industrielles :

- Centres de contrôle des moteurs: Protection of industrial motors and drives

- Distribution de l'énergie: Main and feeder circuit protection

- Circuits d'éclairage: Large commercial and industrial lighting systems

- Systèmes CVC: Protection of heating, ventilation, and air conditioning equipment

Applications commerciales :

- Building main distribution: Electrical service entrance protection

- Panel board feeders: Sub-distribution circuit protection

- Systèmes d'urgence: Critical load circuit protection

- Centres de données: Server and UPS system protection

Troubleshooting Common MCCB Issues

Frequent Tripping Problems:

| Problème | Causes Possibles | Solutions |

|---|---|---|

| Les déclenchements intempestifs | Incorrect sizing, loose connections | Verify load calculations, check connections |

| Failure to trip | Worn contacts, faulty trip unit | Replace MCCB, test trip mechanism |

| Surchauffe | Poor ventilation, overloading | Improve airflow, reduce load |

| Contact welding | High fault currents, inadequate breaking capacity | Upgrade to higher breaking capacity |

🔧 Conseil d'expert: Keep maintenance records for all MCCBs including trip events, testing dates, and any anomalies. This data helps predict replacement needs and improve system reliability.

MCCB Ratings and Standards Compliance

Normes internationales :

- CEI 60947-2: Low-voltage switchgear and controlgear

- UL 489: Molded-case circuit breakers standards

- IS 13947-2: Indian standard for low-voltage switchgear

- NEMA AB1: American standard for molded-case circuit breakers

Key Rating Parameters:

| Rating Type | Symbole | Description | Les Valeurs Typiques |

|---|---|---|---|

| Courant Nominal | En | Continuous current capacity | 100A – 2500A |

| Tension nominale | Ue | Maximum operating voltage | 240V – 1000V |

| Pouvoir De Coupure | Icu | Interruption maximale du courant de défaut | 25 kA – 200 kA |

| Making Capacity | Icm | Maximum current for closing operation | 2.1 × Icu |

Maintenance and Testing Procedures

Routine Maintenance Schedule:

| Fréquence | Activité de maintenance | Exigences |

|---|---|---|

| Mensuel | Inspection visuelle | Check for damage, overheating signs |

| Trimestriel | Étanchéité de la connexion | Verify torque specifications |

| Annuellement | Trip testing | Functional test of protection system |

| 3-5 ans | Comprehensive testing | Insulation resistance, contact resistance |

🔧 Conseil d'expert: Document all maintenance activities and test results. Many electrical failures can be prevented through proper preventive maintenance programs.

Future Trends and Smart MCCB Technology

Technologies émergentes :

- Connectivité IoT: Remote monitoring and diagnostics

- Maintenance prédictive: AI-powered failure prediction

- Digital communication: L'intégration avec les systèmes de gestion du bâtiment

- Suivi énergétique: Real-time power quality analysis

Foire aux questions (FAQ)

What is the MCCB full form in electrical engineering?

MCCB full form is “Molded Case Circuit Breaker”, which is a type of electrical protection device with a molded plastic case housing the switching mechanism and protection elements. The MCCB full form indicates its construction method and primary function.

What is the difference between MCCB and MCB?

The main differences are current rating (MCCB: 100-2500A vs MCB: 6-63A), applications (MCCB for industrial vs MCB for residential), and adjustability (MCCB has adjustable trip settings while MCB has fixed settings).

How do you select the right MCCB for an application?

Select based on load current (add 25% safety margin), fault current levels at installation point, voltage rating, number of poles required, and environmental conditions. Always consult electrical codes and manufacturer specifications.

What is the typical lifespan of an MCCB?

A properly maintained MCCB typically lasts 15-25 years under normal operating conditions. However, frequent fault interruptions or harsh environmental conditions may reduce lifespan.

Can MCCB be used for motor protection?

Yes, MCCBs are commonly used for motor protection, especially larger motors. However, they should be combined with motor protection relays or thermal overload relays for comprehensive protection.

What safety precautions are required when working with MCCBs?

Always de-energize circuits before maintenance, use proper PPE, follow lockout/tagout procedures, verify proper installation torque, and ensure compliance with electrical codes. Only qualified electricians should perform installation and maintenance.

How often should MCCBs be tested?

Annual functional testing is recommended for critical applications, with comprehensive testing every 3-5 years. High-duty cycle applications may require more frequent testing.

What causes MCCB failure?

Common causes include electrical overloads, short circuits exceeding breaking capacity, environmental factors (moisture, temperature), mechanical wear, and inadequate maintenance.

Conclusion: Understanding MCCB Full Form for Electrical Safety

Comprendre la MCCB full form and functionality is crucial for electrical safety and system reliability. MCCB full form – Molded Case Circuit Breaker – represents essential protection devices that provide reliable fault protection in industrial and commercial applications.

Key takeaways: The MCCB full form indicates a molded construction that houses sophisticated protection mechanisms. Always size MCCBs properly for your application, follow installation codes, maintain regular testing schedules, and consult qualified electrical professionals for complex installations. Proper MCCB selection and maintenance ensure both personnel safety and equipment protection in electrical systems.

For complex electrical installations or when in doubt about MCCB selection, always consult with certified electrical engineers and follow local electrical codes and standards.