Introduction

When specifying electrical enclosures for industrial installations, the material decision is far from trivial. A carbon steel enclosure specified for a coastal substation will show rust within months—leading to premature replacement, unplanned downtime, and potential safety hazards. A polycarbonate enclosure installed in a chemical processing facility may craze and crack when exposed to organic solvents, compromising IP ratings and exposing live components.

The cost of choosing the wrong enclosure material extends beyond the equipment itself: failed enclosures trigger emergency replacements, labor-intensive retrofits, and in critical applications, production losses measured in thousands of dollars per hour. According to industry data, enclosure failures account for approximately 15–20% of electrical system maintenance issues in harsh environments—and nearly all of these failures trace back to incorrect material selection.

This guide provides a comprehensive framework for selecting electrical enclosure materials based on environmental conditions, protection requirements, and lifecycle cost considerations. We walk you through material properties (carbon steel, stainless steel 304/316, aluminum, polycarbonate, fiberglass), NEMA and IP rating requirements, and real-world application scenarios to ensure you specify correctly the first time.

Understanding Enclosure Material Requirements

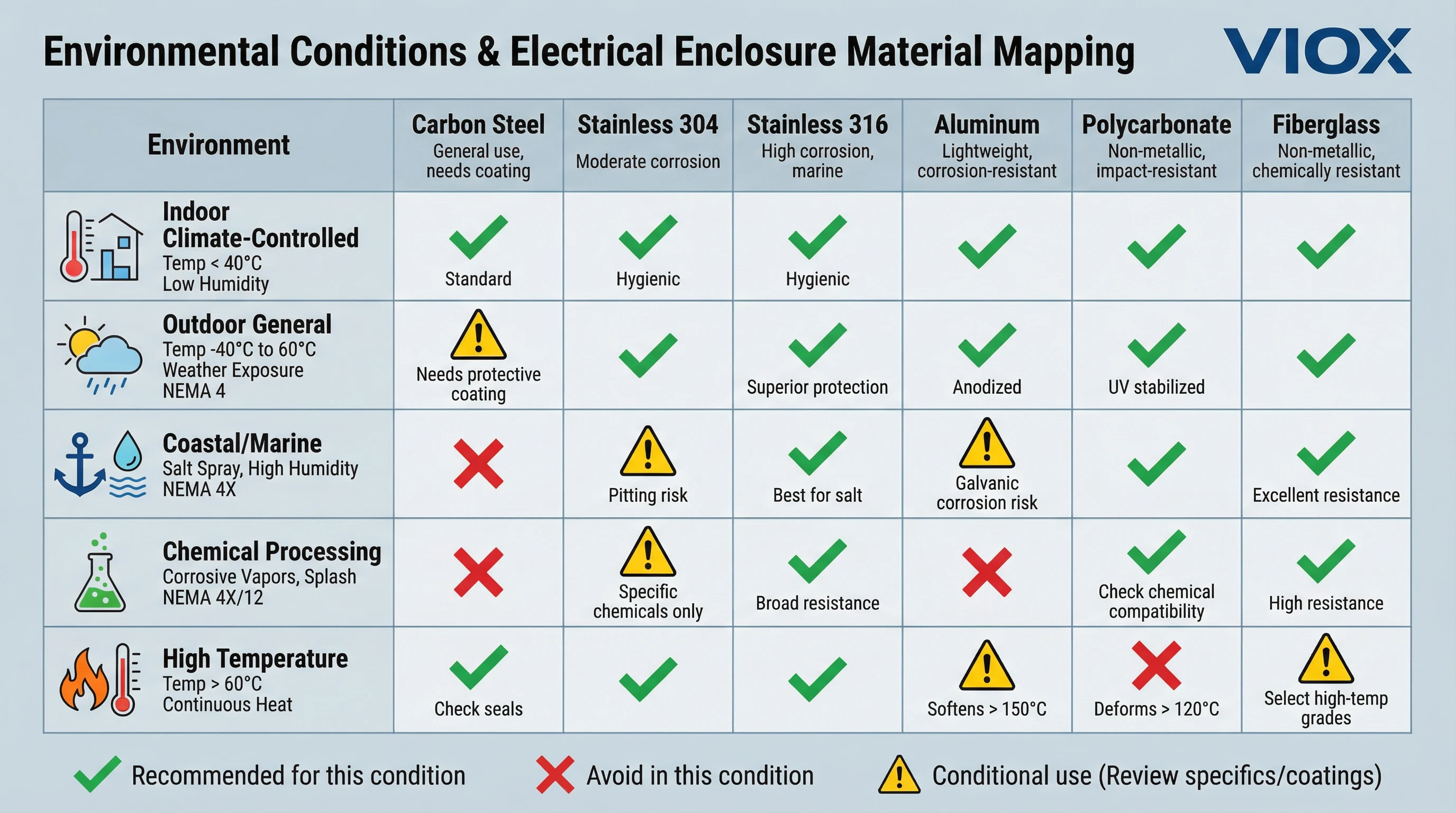

Electrical enclosure material selection is driven by three interconnected factors: environmental exposure, required protection level (NEMA/IP rating), and operational constraints (weight, cost, temperature).

Under NEMA 250 and IEC 60529 (IP ratings), enclosures are tested as complete assemblies—material, gaskets, hardware, and finish work together to achieve the rating. While the material alone doesn’t carry a NEMA or IP rating, certain materials and finishes are essential to meet specific protection requirements. For example, NEMA Type 4X explicitly requires corrosion-resistant construction, making stainless steel or certain coated materials necessary; NEMA Type 12 demands dust-tight seals that carbon steel or aluminum can support with proper gasket design.

The key is matching material properties to environmental challenges: corrosion resistance for coastal or chemical environments, temperature tolerance for high-heat applications, impact resistance for mechanical risk areas, and UV stability for outdoor installations.

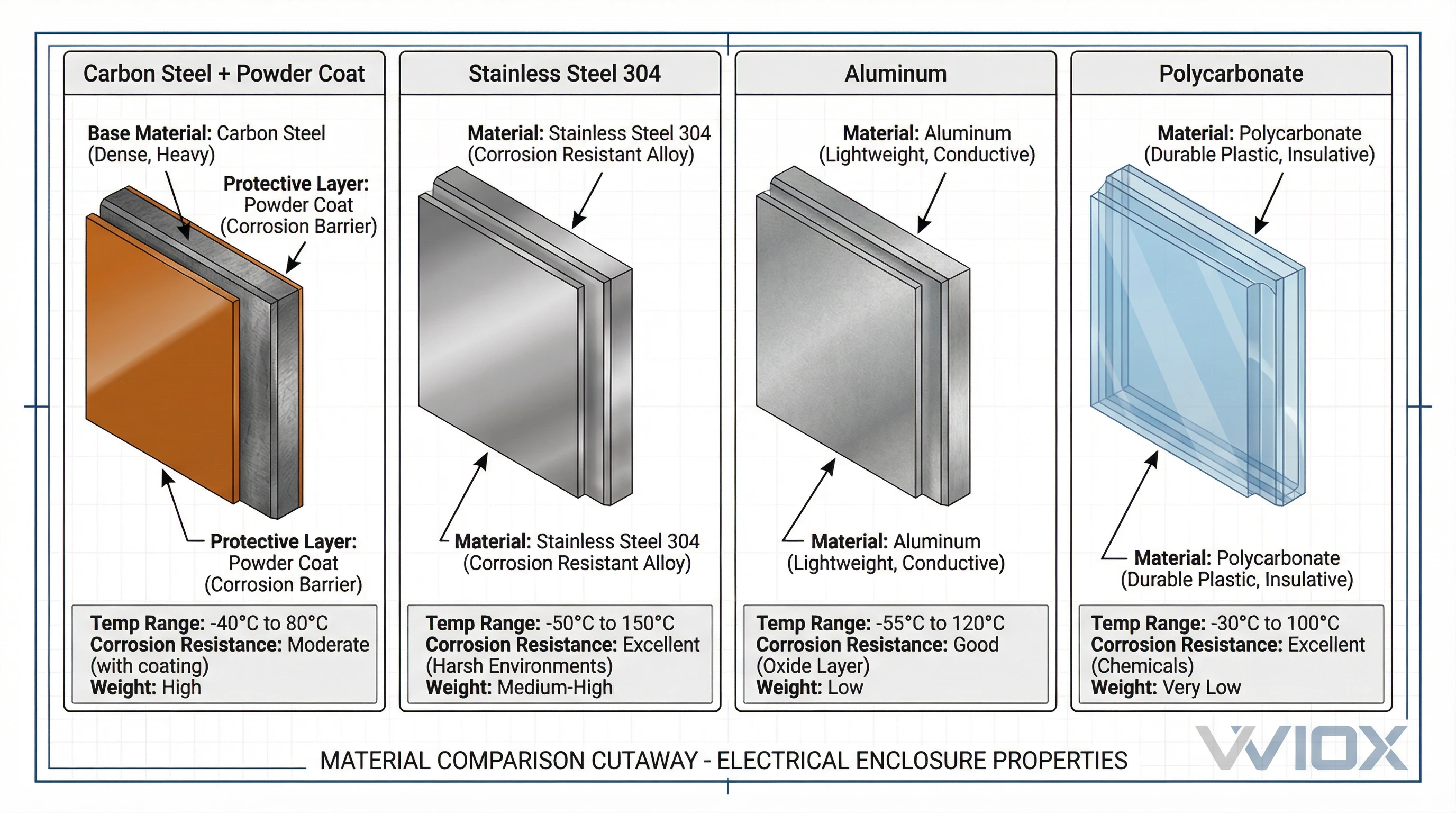

Common Electrical Enclosure Materials

The electrical industry relies on five primary enclosure materials, each optimized for specific environments and applications:

Carbon Steel

Carbon steel offers high mechanical strength and excellent formability at the lowest material cost. It’s the default choice for general-purpose indoor applications where environmental exposure is minimal.

Material Properties:

- Strength: High stiffness and impact resistance; excellent mechanical protection

- Corrosion Resistance: Poor; rusts rapidly without protective coating

- Temperature Range: -40°C to 200°C (-40°F to 392°F) depending on coating

- Weight: Heavy (density ~7.85 g/cm³)

- Typical Finish: Powder coating, zinc plating, or paint for corrosion protection

Best Applications: Indoor control panels, electrical distribution equipment in climate-controlled facilities, cost-sensitive projects without environmental exposure.

Limitations: Unsuitable for outdoor use without robust coating; coating damage exposes substrate to rapid corrosion; heavy weight complicates installation.

Stainless Steel 304

Stainless steel 304 (often called 18-8 for its 18% chromium, 8% nickel composition) provides excellent general-purpose corrosion resistance. It’s the most widely used stainless grade for electrical enclosures.

Material Properties:

- Strength: Very high tensile strength and impact resistance

- Corrosion Resistance: Excellent in most environments; good resistance to oxidizing acids; susceptible to pitting from chlorides above 100 ppm

- Temperature Range: -196°C to 870°C (-320°F to 1598°F)

- Weight: Heavy (density ~8.0 g/cm³)

- Finish: Brushed, polished, or mill finish; no coating required

Best Applications: Outdoor installations in non-marine environments, food and beverage facilities, pharmaceutical manufacturing, indoor harsh environments (washdown areas without high chlorides).

Limitations: Susceptible to chloride pitting in coastal environments; 20–35% more expensive than carbon steel.

Stainless Steel 316

Stainless steel 316 adds 2–3% molybdenum to enhance corrosion resistance, particularly against chlorides and industrial chemicals. It’s the premium choice for the harshest environments.

Material Properties:

- Strength: Very high tensile strength, slightly superior to 304

- Corrosion Resistance: Excellent against chlorides (up to 1000 ppm), acids, and industrial solvents; superior pitting and crevice corrosion resistance

- Temperature Range: -196°C to 870°C (-320°F to 1598°F) with better high-temperature performance than 304

- Weight: Heavy (density ~8.0 g/cm³)

- Finish: Brushed, polished, or mill finish

Best Applications: Marine and coastal installations, chemical processing plants, offshore platforms, areas with de-icing salt exposure, high-chloride washdown environments.

Limitations: Most expensive metal option (60–100% more than carbon steel); more difficult to machine than 304.

Aluminum

Aluminum provides natural corrosion resistance through a protective oxide layer, combined with light weight and good thermal conductivity.

Material Properties:

- Strength: Moderate; good strength-to-weight ratio but more prone to bending than steel

- Corrosion Resistance: Good; natural oxide layer provides protection; susceptible to galvanic corrosion with dissimilar metals

- Temperature Range: -40°C to 200°C (-40°F to 392°F)

- Weight: Lightweight (density ~2.7 g/cm³, about one-third of steel)

- Thermal Conductivity: High; excellent heat dissipation

- Finish: Anodized, powder coated, or bare metal

Best Applications: Outdoor general-purpose use, weight-sensitive installations (wall-mounted or large enclosures), applications requiring heat dissipation, transportation and mobile equipment.

Limitations: Lower mechanical strength than steel; galvanic corrosion risk; not suitable for high-chloride marine environments without coating.

Polycarbonate

Polycarbonate is a transparent or opaque thermoplastic offering exceptional impact resistance and natural corrosion resistance.

Material Properties:

- Strength: High impact resistance (virtually unbreakable in normal use)

- Corrosion Resistance: Excellent against acids, oils, grease, and saltwater; vulnerable to strong bases (ammonia) and organic solvents (acetone)

- Temperature Range: -40°C to 120°C (-40°F to 248°F)

- Weight: Lightweight (density ~1.2 g/cm³)

- UV Resistance: Good with UV stabilizers; may yellow over years without protection

- Electrical Properties: Non-conductive (insulating)

Best Applications: Marine environments without solvent exposure, outdoor general-purpose use, applications requiring transparent covers (visual inspection of components), cost-effective NEMA 4X solutions.

Limitations: Lower temperature maximum than metals; susceptible to organic solvents and strong bases; may craze or crack under chemical attack.

Fiberglass (GRP)

Fiberglass enclosures offer superior chemical resistance across acids, alkalis, oils, and solvents. Temperature range: -35°C to 148°C (-31°F to 300°F). Best for chemical processing plants, wastewater treatment, high-temperature outdoor use. More expensive than polycarbonate but handles the widest range of aggressive chemicals.

Material Comparison: Properties and Cost

Understanding the relative properties of each material helps narrow your selection based on project priorities:

| Property | Carbon Steel | Stainless 304 | Stainless 316 | Aluminum | Polycarbonate | Fiberglass |

|---|---|---|---|---|---|---|

| Corrosion Resistance | Poor (coating required) | Excellent | Superior | Good | Excellent | Excellent |

| Mechanical Strength | Very High | Very High | Very High | Moderate | High (impact) | High |

| Weight | Heavy | Heavy | Heavy | Lightweight | Lightweight | Moderate |

| Temperature Range | -40°C to 200°C | -196°C to 870°C | -196°C to 870°C | -40°C to 200°C | -40°C to 120°C | -35°C to 148°C |

| Chemical Resistance | Low | Good | Excellent | Moderate | Good* | Excellent |

| Relative Cost | Lowest | Moderate | Highest | Moderate | Low-Moderate | Moderate-High |

| Heat Dissipation | Moderate | Low | Low | Excellent | Poor | Poor |

| UV Resistance | N/A (coated) | Excellent | Excellent | Good | Good (stabilized) | Excellent |

*Polycarbonate: Excellent for acids/oils/saltwater; poor for organic solvents and strong bases.

NEMA and IP Rating Overview

NEMA 250 defines enclosure Types by the protection they provide against environmental conditions. Understanding the rating helps clarify material requirements:

Indoor NEMA Types

| NEMA Type | Protection Against | Material Implications |

|---|---|---|

| Type 1 | Access to hazardous parts; falling dirt | Any material with adequate mechanical strength |

| Type 2 | Falling dirt; dripping/light splashing water | Requires gaskets; any material with protective finish |

| Type 12 | Circulating dust, lint, fibers; dripping/light splashing | Requires robust seals; materials that maintain gasket compression |

| Type 13 | Dust; spraying/seeping oil and coolant | Non-absorbent finishes; materials compatible with oils |

Outdoor NEMA Types

| NEMA Type | Protection Against | Material Implications |

|---|---|---|

| Type 3/3R | Rain, sleet, snow; windblown dust; undamaged by external ice | Weatherable coatings or naturally corrosion-resistant metals |

| Type 4 | Hose-directed water; splashing water | Robust seals; corrosion-resistant finish if environmental |

| Type 4X | Hose-directed water; corrosion | Requires corrosion-resistant material or finish |

| Type 6/6P | Temporary/prolonged submersion; 6P adds corrosion resistance | Water-tight construction; 6P requires stainless or coated |

IP Rating Quick Reference

IEC 60529 IP codes use two digits: first digit = solid object protection (0–6); second digit = water protection (0–9).

Common IP Ratings:

- IP65: Dust-tight; protected against water jets (similar to NEMA 4)

- IP66: Dust-tight; protected against powerful water jets

- IP67: Dust-tight; protected against temporary submersion (similar to NEMA 6)

- IP68: Dust-tight; protected against prolonged submersion (similar to NEMA 6P)

Important: NEMA ratings include additional tests (corrosion, gasket aging, ice formation, oil resistance) that IP codes do not. Always specify by NEMA Type for US applications; use IP as complementary international reference.

Selection Criteria and Decision Framework

Use this systematic approach to select the optimal enclosure material:

Step 1: Define Environmental Conditions

Document all environmental factors:

- Indoor or outdoor installation?

- Water exposure level (none / dripping / hose-down / submersion)?

- Corrosive agents present (salt / chemicals / industrial vapors)?

- Temperature range (minimum and maximum ambient)?

- Dust, fibers, or particulates present?

- Mechanical risks (impact, vibration)?

- UV exposure (direct sunlight)?

Step 2: Determine Required NEMA/IP Rating

Map environmental conditions to minimum rating:

- Use NEMA Type 1 or 2 for basic indoor protection

- Use Type 12 when dust-tight sealing is required indoors

- Use Type 3/3R/4 for outdoor general weather protection

- Use Type 4X when corrosion resistance is required

- Use Type 6/6P for submersion applications

Step 3: Match Material to Rating and Environment

Eliminate materials that cannot meet the rating or withstand the environment:

- Eliminate carbon steel for any outdoor application without robust coating

- Eliminate polycarbonate for chemical plants with solvent exposure

- Eliminate Stainless 304 for high-chloride coastal environments (use 316)

- Eliminate aluminum for severe corrosive or high-chloride environments

Step 4: Evaluate Cost and Operational Factors

- Weight: Aluminum or polycarbonate for large wall-mounted enclosures

- Heat Dissipation: Aluminum for electronics generating significant heat

- Cost: Carbon steel (indoor) or polycarbonate (outdoor) for budget projects

- Total Cost of Ownership: Premium materials may justify initial cost through longer service life

Step 5: Verify Certification

Confirm the complete enclosure assembly is certified to the target NEMA Type or IP rating.

Application Examples

| Application | Environment | NEMA Type | Recommended Material | Rationale |

|---|---|---|---|---|

| Indoor control panel | Climate-controlled, minimal exposure | Type 1 | Carbon steel (coated) | Lowest cost; no corrosion risk indoors |

| Outdoor substation (non-coastal) | Rain/snow, -30°C to 45°C, no salt | Type 3R/4 | Aluminum or SS 304 | Natural corrosion resistance, UV stable |

| Coastal marine installation | Salt spray, high humidity, 500m from ocean | Type 4X | Stainless Steel 316 | Superior chloride resistance (up to 1000 ppm) |

| Chemical processing plant | Acids, alkalis, solvents, high temperature | Type 4X | Fiberglass (GRP) | Broadest chemical resistance across all agents |

| Food processing facility | Hose-down, sanitation, cleaning chemicals | Type 4X | Stainless Steel 304 | Food-grade, easy cleaning, corrosion resistant |

Cost and Total Cost of Ownership

Initial purchase price is only one component of enclosure lifecycle cost.

Material Cost Multipliers (vs. Carbon Steel = 1.0):

| Material | Cost Multiplier | Typical Lifespan | Maintenance |

|---|---|---|---|

| Carbon Steel | 1.0× | 10–15 years (indoor) | Recoating every 5–10 years |

| Aluminum | 1.3–1.6× | 20–25 years | Minimal |

| Polycarbonate | 1.2–1.5× | 15–20 years | Minimal |

| Stainless Steel 304 | 1.6–2.0× | 25–30+ years | Minimal |

| Stainless Steel 316 | 2.0–2.5× | 30+ years | Minimal |

| Fiberglass (GRP) | 1.8–2.3× | 25–30+ years | Minimal |

For harsh environments, total cost of ownership often favors premium materials. A $2,000 stainless steel 316 enclosure lasting 30 years costs less than three $800 carbon steel replacements—before accounting for labor and downtime.

FAQ

Q1: Can I use carbon steel enclosures outdoors if they have a powder coating?

You can, but with risk. Any coating damage exposes steel to rapid corrosion. For outdoor reliability, specify materials with inherent corrosion resistance. If carbon steel is required, plan for recoating every 5–10 years.

Q2: What’s the difference between NEMA 4 and NEMA 4X?

The “X” indicates additional corrosion resistance requirements. Type 4 protects against water but doesn’t mandate corrosion-resistant construction. Type 4X requires both water protection and corrosion-resistant materials. Always specify 4X when salt, chemicals, or corrosive conditions are present.

Q3: When should I choose stainless steel 316 instead of 304?

Choose 316 when chloride exposure exceeds 100 ppm: marine environments (within 1–2 km of coast), de-icing salt areas, high-chloride washdown, or chlorinated chemical processing. The 20–35% premium is justified by superior pitting resistance.

Q4: Are polycarbonate enclosures suitable for outdoor use?

Yes, polycarbonate performs well outdoors (rain, snow, UV, temperature cycling) and achieves NEMA 4X ratings. Avoid in applications with organic solvents (acetone, toluene) or strong bases (ammonia), which cause crazing. Maximum temperature is 120°C (248°F).

Q5: How do I prevent galvanic corrosion with aluminum enclosures?

Isolate aluminum from dissimilar metals using insulating washers. Use stainless steel hardware. Apply corrosion-resistant coatings at contact points and ensure drainage. Anodize aluminum for severe environments.

Conclusion

Selecting the right electrical enclosure material is a systematic engineering decision driven by environmental conditions, protection requirements, and lifecycle cost analysis. Carbon steel provides economical mechanical protection for indoor controlled environments. Aluminum offers lightweight corrosion resistance for general outdoor use. Stainless steel 304 serves as the workhorse for outdoor and harsh indoor applications, while 316 handles the most corrosive environments including marine and chemical exposure. Polycarbonate delivers cost-effective NEMA 4X protection for moderate climates without solvent exposure, and fiberglass excels in chemical processing with the broadest chemical resistance.

VIOX Electric manufactures electrical enclosures in all major materials—carbon steel with premium powder coating, stainless steel 304 and 316, aluminum, polycarbonate, and fiberglass—engineered to meet NEMA 250 and IEC 60529 (IP) requirements. Our enclosures are tested and certified to their specified ratings, featuring robust gasket systems, corrosion-resistant hardware, and quality construction for decades of reliable service. We understand that enclosure material selection impacts your project’s safety, compliance, and total cost of ownership, and we provide the technical specifications, environmental guidance, and engineering support to help you choose correctly.

Whether you need a NEMA Type 4X stainless steel 316 enclosure for a coastal substation, a lightweight aluminum NEMA 3R enclosure for rooftop equipment, or a fiberglass Type 4X enclosure for chemical processing, VIOX delivers the material expertise and manufacturing quality your application demands.

Ready to specify the optimal enclosure material for your next project? Contact VIOX Electric’s technical team for material selection assistance, environmental analysis, custom configurations, and detailed submittal documentation. Let’s build electrical infrastructure that’s engineered for your environment and built to last.