Electrical cabinet fires pose a serious threat to industrial operations, data centers, and critical infrastructure. A single fire incident can result in costly equipment damage, extended downtime, and potential safety hazards. Traditional fire suppression systems—while effective—often require external power, complex piping, and regular maintenance, making them impractical for compact electrical enclosures.

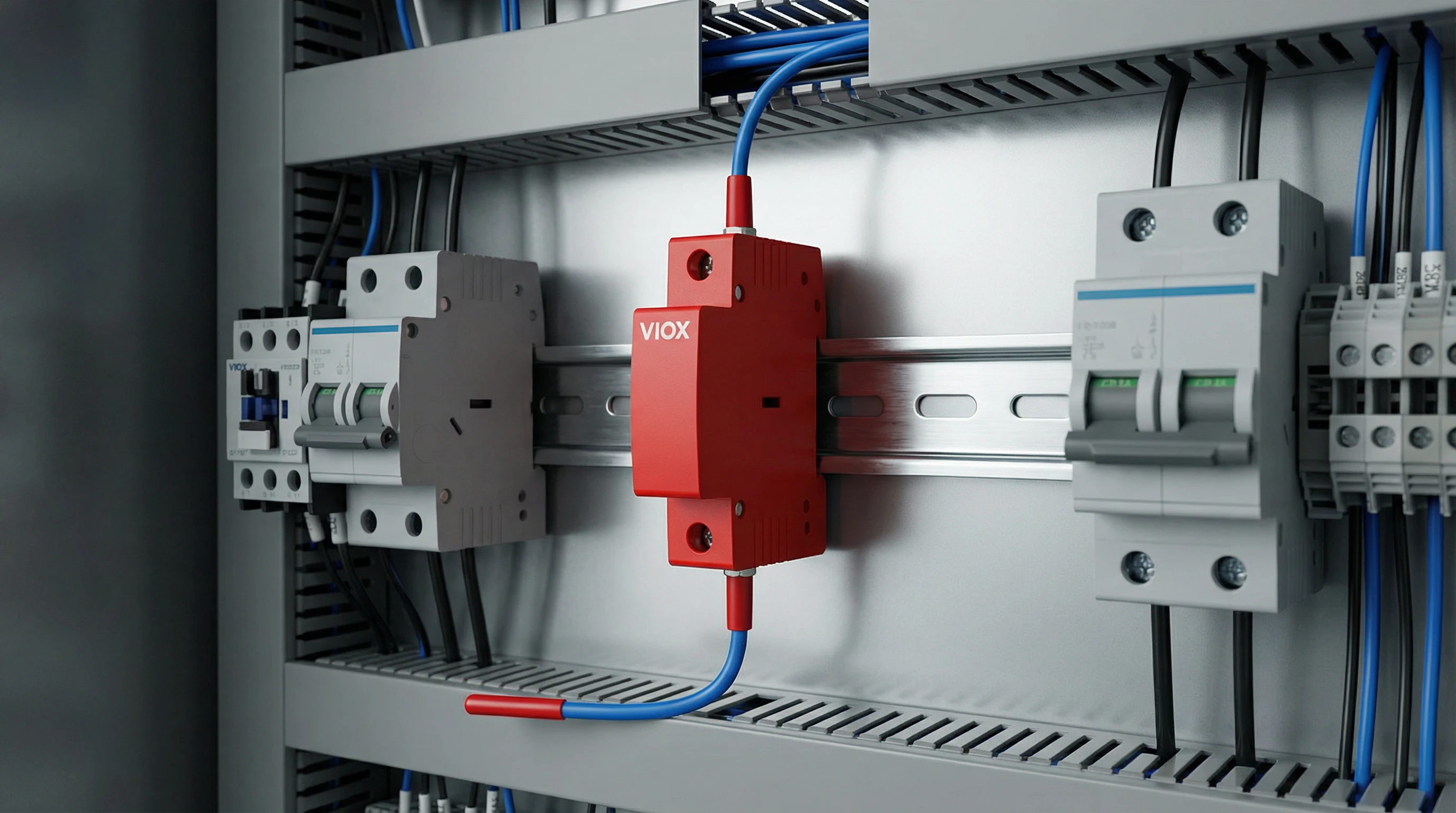

The DIN rail aerosol fire extinguisher offers a modern solution specifically engineered for electrical cabinet protection. VIOX Electric’s QRR0.01G/S Series combines compact 18mm width design with automatic thermal activation, delivering rapid fire suppression directly at the source without external power requirements. This complete guide covers everything electrical contractors, OEM manufacturers, and facility managers need to know about selecting, installing, and maintaining DIN rail aerosol fire extinguishers for maximum protection.

What Is a DIN Rail Aerosol Fire Extinguisher?

A DIN rail aerosol fire extinguisher is a compact, self-contained fire suppression device designed to mount directly onto standard 35mm DIN rails inside electrical cabinets, control panels, and distribution boxes. Unlike traditional fire suppression systems that protect entire rooms, these devices provide localized, direct-to-source protection for individual enclosures.

How Aerosol Fire Suppression Works

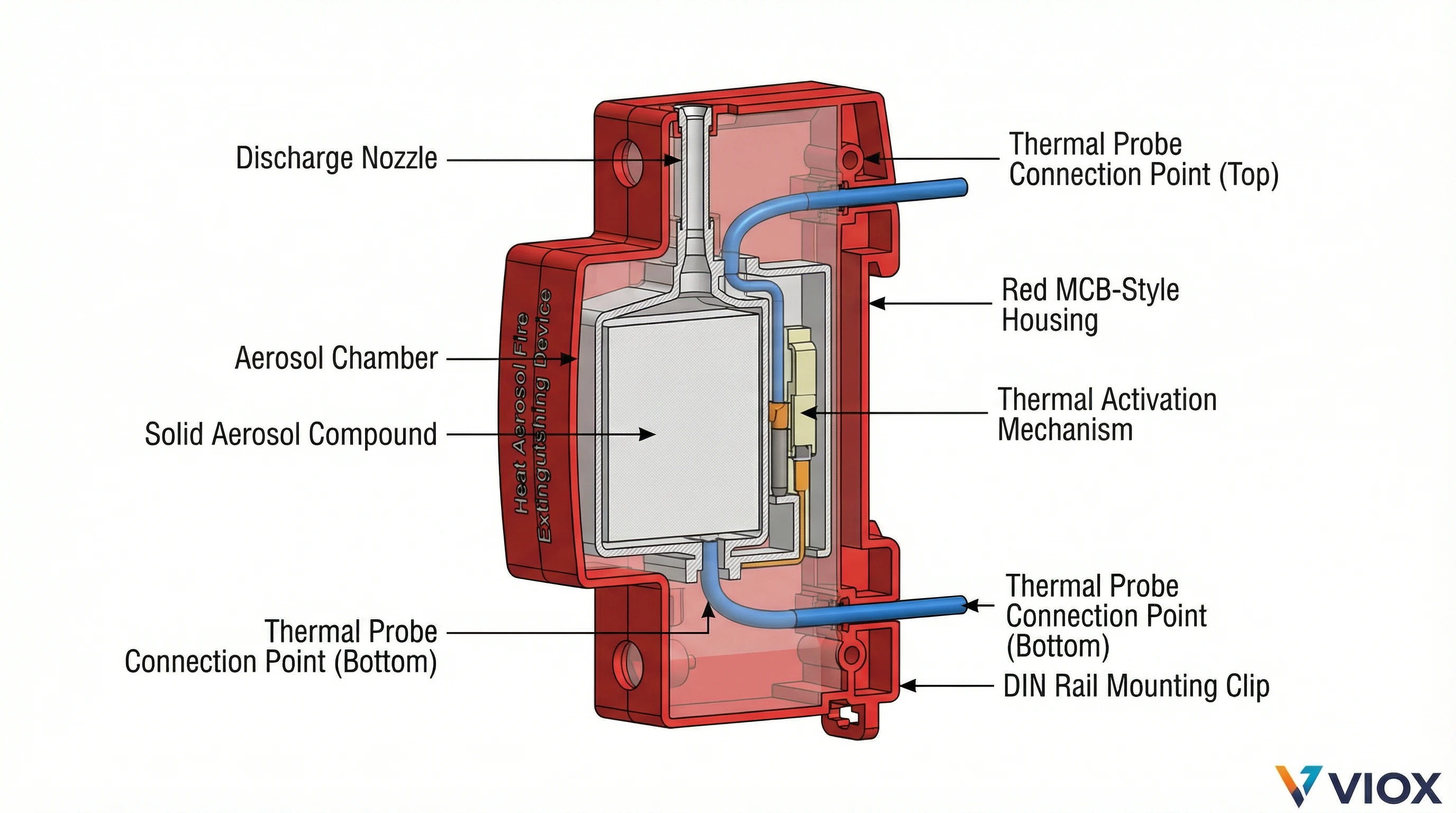

The technology relies on condensed aerosol fire extinguishing agents—typically solid compounds containing strontium nitrate and potassium nitrate. When activated by heat, these compounds undergo a controlled reaction that generates a fine aerosol mist consisting of microscopic solid particles and inert gases.

This aerosol works through two mechanisms:

- Chemical chain reaction interruption: The ultra-fine particles (typically 0.1-10 microns) interfere with the combustion process at a molecular level, breaking the fire’s chemical chain reaction

- Heat absorption: The aerosol absorbs thermal energy from the flame, cooling the fire below its ignition temperature

The entire discharge completes in 6 seconds or less, flooding the protected enclosure and suppressing fires before they can spread. The aerosol remains suspended for several minutes, preventing re-ignition while the cabinet cools.

Why DIN Rail Mounting?

DIN rail mounting offers seamless integration with existing electrical components. The VIOX QRR0.01G/S Series occupies just 18mm of width—equivalent to a single-pole miniature circuit breaker—allowing installation directly alongside MCBs, contactors, relays, and other DIN rail devices. This “single-pole” (1P) footprint maximizes space efficiency in crowded cabinets while ensuring the fire suppression device sits exactly where protection is needed most.

Key Features & Benefits

The VIOX QRR0.01G/S Series delivers a comprehensive fire protection solution tailored specifically for electrical cabinet applications. Here’s what sets this system apart:

Automatic Thermal Activation – No Power Required

The device activates automatically at 170°C (338°F). Two thermal probes monitor heat continuously. Once triggered, the system activates within 15 seconds and discharges in 6 seconds or less. Purely thermal activation ensures protection even during power outages.

Ultra-Compact 18mm Width

At just 18mm wide—equivalent to a 1-pole MCB—the device fits seamlessly alongside existing DIN rail components without sacrificing space. Compatible side-by-side with VIOX’s T Series circuit protection products.

Rapid Fire Suppression

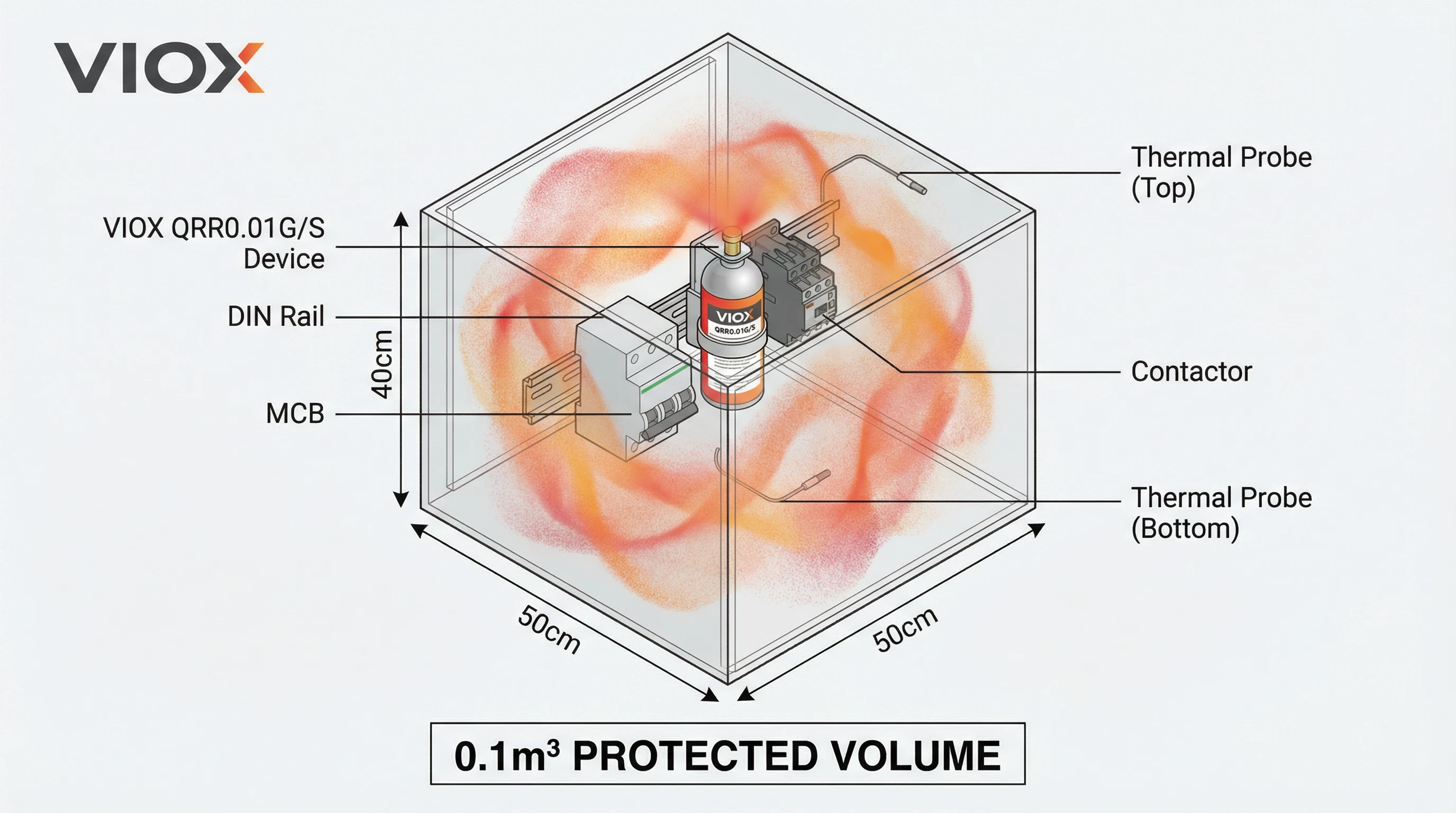

Once activated, the 10g aerosol discharges within 6 seconds, flooding the 0.1m³ protected volume. Ultra-fine particles (0.1-10 microns) reach all corners, suppressing fire before it spreads. The aerosol remains suspended for minutes, preventing re-ignition.

Electrically Non-Conductive Agent

The aerosol is electrically non-conductive, safe for energized equipment. Unlike water-based systems that cause short circuits, the aerosol suppresses fire without harming electronics or control systems.

10-Year Service Life with Zero Maintenance

Traditional fire suppression systems require regular inspections, pressure checks, and agent refills. The QRR0.01G/S Series operates maintenance-free for up to 10 years. The solid aerosol compound remains stable throughout its service life, with no risk of leakage, pressure loss, or degradation. This dramatically reduces total cost of ownership while ensuring reliable protection.

Environmentally Friendly

The aerosol agent has zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP). It’s non-toxic and non-corrosive, though proper ventilation is required after discharge.

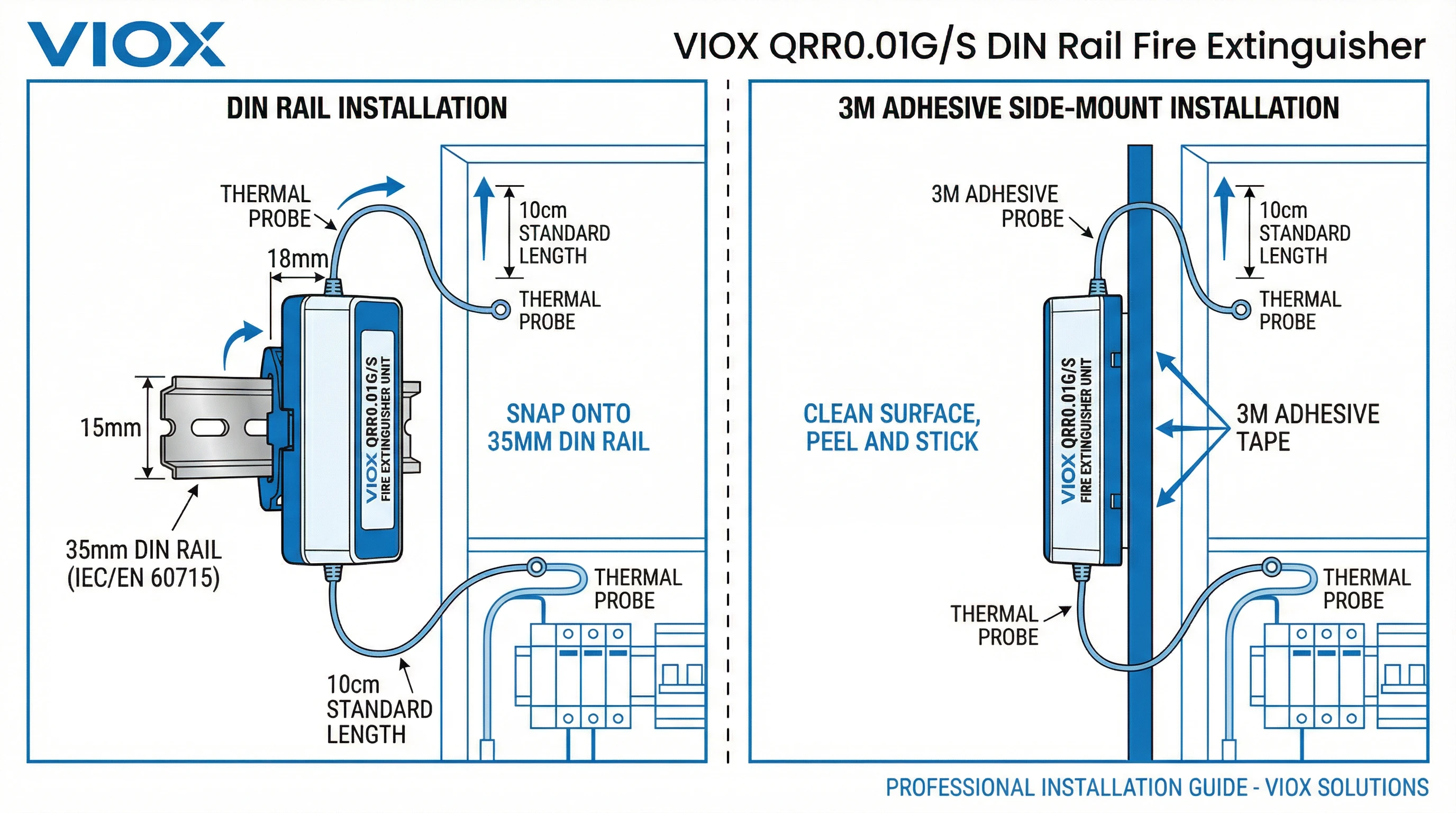

Simple Installation

Installation requires no specialized tools or training. The device snaps onto standard 35mm DIN rail in seconds. Thermal probe cables (10cm standard, customizable up to 50cm) allow flexible placement for optimal heat detection. Optional 3M adhesive backing provides an alternative mounting method for non-DIN-rail applications.

Technical Specifications

The VIOX QRR0.01G/S Series is engineered to meet the demanding requirements of industrial electrical cabinet protection. Below are the complete technical specifications:

| Specification | Value |

| Model | QRR0.01G/S Series |

| Extinguishing Agent | Condensed aerosol (strontium nitrate, potassium nitrate) |

| Agent Dosage | 10g |

| Protected Volume | Up to 0.1m³ (enclosed spaces) |

| Activation Method | Thermal (no external power required) |

| Activation Temperature | 170°C (338°F) |

| Response Time | Within 15 seconds after reaching activation temperature |

| Discharge Duration | ≤6 seconds |

| Mounting Options | 35mm DIN-rail (snap-on) or 3M adhesive side-mount |

| Device Width | 18mm (1P footprint) |

| Housing Material | High-temperature resistant plastic |

| Housing Color | Red |

| Thermal Probes | 2 probes (top and bottom detection) |

| Probe Cable Length | Standard: 10cm per probe Customizable: 10-50cm per probe |

| Operating Temperature Range | -50°C to +90°C (-58°F to +194°F) |

| Humidity Tolerance | <95%RH (non-condensing) |

| Service Life | Up to 10 years |

| Maintenance Requirements | None (maintenance-free) |

| Environmental Properties | Non-toxic, non-corrosive, zero ODP, low GWP |

| Electrical Conductivity | Non-conductive (safe for energized equipment) |

Performance Characteristics

The QRR0.01G/S Series is optimized for small, enclosed electrical cabinets up to 0.1 cubic meters in volume. This typically covers:

- Standard electrical distribution boxes

- Single-door control panels up to approximately 50cm × 50cm × 40cm

- Motor control cabinets

- PLC and automation enclosures

- Solar combiner boxes

- Small server racks and telecom cabinets

For larger enclosures, multiple units can be deployed to provide complete coverage. The wide operating temperature range (-50°C to +90°C) ensures reliable performance in extreme environments, from outdoor installations in cold climates to high-temperature industrial settings.

Applications & Use Cases

DIN rail aerosol fire extinguishers excel in applications where space is limited, external power is unreliable, and direct-to-source protection is essential. The VIOX QRR0.01G/S Series is deployed across diverse industries:

Industrial Manufacturing: Motor control centers (MCCs), CNC machine control cabinets, switchgear and distribution panels, PLC and automation systems

Renewable Energy: Solar combiner boxes, energy storage BMS cabinets, inverter enclosures, wind turbine control systems

Data Centers & Telecommunications: Server racks, telecom equipment cabinets, base station equipment, UPS battery enclosures

Transportation: Railway signal cabinets, maritime electrical systems, EV charging stations

Commercial Buildings: Elevator control panels, building management systems, emergency power systems

Application Selection Matrix

| Industry | Equipment Type | Suitability | Key Benefit |

| Manufacturing | Motor controls, PLCs | Excellent | Minimizes production downtime |

| Solar/Renewable | Combiner boxes, inverters | Excellent | Operates without grid power |

| Data Centers | Server racks, network cabinets | Good | Non-conductive agent protects electronics |

| Transportation | Railway, maritime systems | Excellent | Wide temperature range, vibration-resistant |

| Telecom | Base stations, distribution frames | Excellent | Maintenance-free for remote sites |

| Commercial | Elevator controls, BMS | Good | Long service life reduces inspection costs |

The QRR0.01G/S Series is particularly well-suited for unmanned facilities, remote installations, and applications where traditional suppression systems are impractical due to space, power, or maintenance constraints.

Installation & Mounting

Proper installation ensures optimal fire detection and suppression performance. The VIOX QRR0.01G/S Series is designed for straightforward installation by electrical contractors and facility personnel.

DIN Rail Installation Steps

- Select Location: Position the device on the DIN rail near the center of the protected enclosure, ensuring adequate clearance (minimum 10cm) from heat-generating components like transformers or power resistors

- Snap onto Rail: Align the device’s mounting clip with the standard 35mm DIN rail and press firmly until it clicks into place

- Position Thermal Probes: Attach one probe near the top of the cabinet (where heat accumulates) and one near potential ignition sources (circuit breakers, contactors, cable entry points)

- Route Probe Cables: Run the 10cm probe cables to their designated positions. For larger cabinets, request custom cable lengths (up to 50cm) to reach optimal detection points

- Verify Clearance: Ensure the device and probes have unobstructed air flow and are not covered by cable bundles or other obstructions

- Apply Warning Labels: Affix the provided warning labels to the cabinet door indicating automatic fire suppression is installed

Alternative Mounting: 3M Adhesive

For cabinets without DIN rails or when rail space is fully utilized, the optional 3M adhesive backing allows side-wall mounting:

- Clean and degrease the mounting surface

- Remove the adhesive backing and press firmly for 30 seconds

- Allow 24 hours for full adhesive cure before considering the device operational

Thermal Probe Placement Guidelines

| Probe | Recommended Position | Purpose |

| Top Probe | Upper third of cabinet, away from vents | Detects heat accumulation (hot air rises) |

| Bottom Probe | Near potential ignition sources (MCBs, contactors, cable terminations) | Early detection of localized fire events |

Both probes must reach 170°C to trigger activation, providing redundancy and reducing false activations.

Installation Considerations

- Enclosure Sealing: Designed for semi-sealed to fully sealed enclosures

- Multiple Units: For cabinets exceeding 0.1m³, install multiple units distributed evenly

- Temperature Zones: Avoid placing probes directly above components that routinely operate at elevated temperatures

Comparison with Traditional Fire Suppression Systems

When evaluating fire protection for electrical cabinets, buyers typically compare condensed aerosol systems against three established technologies: CO2, FM-200 (clean agent), and water mist. Each has distinct advantages and limitations.

Technology Comparison Table

| Feature | Condensed Aerosol (VIOX QRR0.01G/S) |

CO2 Systems | FM-200 (HFC-227ea) |

Water Mist |

| Extinguishing Mechanism | Chemical chain reaction interruption + heat absorption | Oxygen displacement + cooling | Heat absorption | Cooling + wetting |

| Electrical Safety | Non-conductive, safe for energized equipment | Non-conductive, safe for energized equipment | Non-conductive, safe for energized equipment | Conductive, requires de-energization |

| Space Requirements | Minimal (18mm on DIN rail) | Large (high-pressure cylinders) | Moderate (pressurized cylinders) | Moderate (pump, piping, nozzles) |

| Power Requirements | None (thermal activation) | Electrical for solenoid valve | Electrical for solenoid valve | Electrical for pump and controls |

| Installation Complexity | Simple (snap-on, no piping) | Complex (piping, distribution network) | Complex (piping, distribution network) | Very complex (plumbing, pressure testing) |

| Discharge Time | ≤6 seconds | 30-60 seconds | 10 seconds | 10-30 seconds |

| Residue | Minimal particulate | None | None | Water residue, potential for corrosion |

| Maintenance | None (10-year service life) | Annual inspections, pressure checks | Annual inspections, agent sampling | Quarterly pump tests, nozzle cleaning |

| Environmental Impact | Zero ODP, low GWP | Zero ODP, greenhouse gas | High GWP, being phased out | Environmentally neutral |

| Human Safety | Not suitable for occupied spaces | Lethal at suppression concentrations | Safe in occupied spaces | Safe in occupied spaces |

| Cost | Low (device + installation) | Moderate (equipment + installation) | High (agent + installation + ongoing costs) | High (equipment + installation + water supply) |

| Best Applications | Individual cabinets, remote sites, small enclosures | Unoccupied switchgear rooms | Data centers, control rooms with personnel | Large equipment rooms |

Why Choose Aerosol for Electrical Cabinets?

For individual electrical cabinet protection, the VIOX QRR0.01G/S Series offers compelling advantages:

Direct-to-Source Protection: Aerosol devices install directly within the cabinet, suppressing fires at their source before they spread—faster and more efficient than room-level systems.

Zero External Dependencies: Operates completely independently without electrical power, control panels, or complex infrastructure. Ideal for remote installations, retrofits, and backup protection.

Space Efficiency: At 18mm wide, fits alongside existing DIN rail components. Traditional systems require dedicated equipment rooms and extensive piping.

Total Cost of Ownership: Zero maintenance over 10 years eliminates recurring costs for inspections, pressure testing, and agent refills.

Installation Simplicity: No specialized certifications or hot work permits required. Electrical contractors can complete installation in minutes.

For electrical cabinets specifically, aerosol technology delivers the best balance of performance, cost, and practicality.

Certifications & Standards Compliance

The VIOX QRR0.01G/S Series is designed to meet international fire suppression standards for condensed aerosol systems:

- UL 2775: Standard for Safety for Fixed Condensed Aerosol Extinguishing System Units

- NFPA 2010: Standard for Fixed Aerosol Fire-Extinguishing Systems

- ISO 15779: Requirements for condensed aerosol fire extinguishing systems

- CE Marking: Compliance with EU safety, health, and environmental protection directives

As with all fire protection equipment, verify that the system meets local building codes and insurance requirements for your specific application. VIOX provides technical documentation and certification support to assist with permitting and compliance verification.

Important Safety Classification: Due to the potassium nitrate content in the aerosol compound, this device may be classified as Class 9 Dangerous Goods for international transport. VIOX handles all necessary transport documentation for compliant shipping.

Frequently Asked Questions

Q: Can the QRR0.01G/S Series be used in occupied spaces?

A: No. While the aerosol agent is non-toxic, discharge can cause breathing difficulties and reduced visibility. The device is designed for unmanned electrical cabinets. Evacuate immediately if accidental discharge occurs in an occupied area.

Q: What happens after the device discharges?

A: The device is single-use. After discharge, the unit must be replaced. The aerosol will leave minimal residue; wipe down surfaces before installing a replacement unit. Allow the cabinet to ventilate before re-energizing equipment.

Q: How do I know when the device needs replacement?

A: The QRR0.01G/S Series has a 10-year service life from the manufacturing date (printed on the label). Replace the unit at the end of its service life or immediately after discharge.

Q: Will this work in outdoor cabinets?

A: Yes. The device operates across -50°C to +90°C and tolerates up to 95%RH non-condensing humidity, making it suitable for outdoor enclosures (IP65+ rating) in most climates.

Q: Can I use this with explosive gases or in hazardous locations?

A: No. The device is not suitable for areas with explosive gases or classified hazardous locations. Consult VIOX for explosion-proof alternatives.

Q: How many units do I need for my cabinet?

A: One QRR0.01G/S unit protects up to 0.1m³. Measure your cabinet volume (length × width × depth in meters). For example, a 50cm × 50cm × 40cm cabinet = 0.1m³ (requires 1 unit). A 60cm × 60cm × 60cm cabinet = 0.216m³ (requires 3 units).

Conclusion

Electrical cabinet fires threaten operations across every industry. The VIOX QRR0.01G/S Series DIN Rail Aerosol Fire Extinguisher delivers automated, localized fire suppression exactly where it’s needed—inside the cabinet, before fires spread. With its ultra-compact 18mm footprint, zero maintenance requirements, and 10-year service life, it offers electrical contractors, OEM manufacturers, and facility managers a practical fire protection solution that traditional systems cannot match.

Whether you’re protecting solar combiner boxes, motor control centers, PLC cabinets, or telecommunications equipment, the QRR0.01G/S Series integrates seamlessly with your existing DIN rail infrastructure.

Ready to protect your electrical cabinets? Contact VIOX Electric today for technical specifications, customization options, and distributor information. Our team provides complete support from product selection through installation guidance.

VIOX Electric – Reliable electrical protection solutions for industrial and commercial applications.