Výrobce proudového chrániče (RCCB)

Společnost VIOX Electric se specializuje na výrobu proudových chráničů (RCCB), které jsou nezbytné pro prevenci úrazů elektrickým proudem a požárů díky detekci unikajících proudů. S více než desetiletými zkušenostmi se společnost VIOX Electric zavázala dodávat inovativní a vysoce kvalitní elektrická řešení pro různá odvětví, včetně obytných, komerčních a průmyslových aplikací.

Certifikováno

Proudový chránič VIOX (RCCB)

Řada VKL11B

- Konfigurace: 2P / 4P

- Jmenovitý proud: 16–100 A

- Citlivost: 30 mA, 100 mA, 300 mA, 500 mA

- Frekvence: až 1 kHz

- Normy: IEC 62423, IEC 61008-1

Řada VML01B

- Konfigurace: 2P / 4P

- Jmenovitý proud: 16–100 A

- Citlivost: 30 mA, 100 mA, 300 mA

- Frekvence: až 20 kHz

- Normy: IEC 62423, IEC 61008-1

Řada VKL11F

- Konfigurace: 2P / 4P

- Jmenovitý proud: 16–100 A

- Citlivost: 30 mA, 100 mA, 300 mA

- Nabíjení EV: ✓ Ano (OVE E8601)

- Normy: IEC 62423, IEC 61008-1

Řada VML01F

- Konfigurace: 2P / 4P

- Jmenovitý proud: 16–100 A

- Citlivost: 30 mA, 100 mA, 300 mA

- Zvláštní vlastnost: Zpožděné/typ G vypínání

- Normy: IEC 62423, IEC 61008-1

Řada VKL11 TypeA

- Konfigurace: 2P / 4P

- Jmenovitý proud: 16–100 A

- Citlivost: 30 mA, 100 mA, 300 mA, 500 mA

- Použití: Elektronické zátěže, LED osvětlení

- Normy: IEC 62423, IEC 61008-1

Řada VKL11

- Konfigurace: 2P / 4P

- Jmenovitý proud: 16–100 A

- Citlivost: 30 mA, 100 mA, 300 mA

- Nabíjení EV: ✓ Ano (OVE E8601)

- Normy: IEC 62423, IEC 61008-1

Stručná vlastní nominace: Proč si vybrat VIOX Electric?

VIOX Electric provozuje Certifikát ISO 9001:2025 zařízení, kde každý RCCB prochází 17stupňové ověřování kvality, včetně vysokonapěťových obloukových zkoušek a cyklů mechanické odolnosti přesahující 20 000 operací.

- Špičkové testování v oboru: Každý RCCB VIOX prochází přísným testováním 100% podle mezinárodních bezpečnostních norem.

- Špičková kvalita materiálů: Prémiové komponenty zajišťují delší životnost a spolehlivý výkon.

- Inovace v inženýrství: Náš výzkumný a vývojový tým neustále zdokonaluje technologii RCCB pro lepší ochranu.

- Globální certifikace: IEC, CE, UL a regionální bezpečnostní certifikáty pro celou naši řadu RCCB.

- Komplexní podpora: Od poradenství při výběru až po školení k instalaci a poprodejní servis

Porovnání typů RCCB: Který potřebujete?

| Funkce | Typ AC | Typ A | Typ F | Typ B/B+ |

|---|---|---|---|---|

| Detekuje střídavý zbytkový proud | ✓ | ✓ | ✓ | ✓ |

| Detekuje pulzující stejnosměrný proud | ✗ | ✓ | ✓ | ✓ |

| Detekuje hladký stejnosměrný proud | ✗ | ✗ | Částečně (≤10 mA) | ✗ |

| Rozsah frekvence | 50/60Hz | 50/60Hz | Až 1 kHz | Až 1 kHz (B) / 20 kHz (B+) |

| Nabíjení EV | ✗ | ✗ | ✓ Doporučeno | ✓ Pokročilé |

| Aplikace s VFD/měniči | ✗ | Omezené | ✓ Ano | ✓ Optimální |

| Fotovoltaické systémy | ✗ | ✗ | ✓ Ano | ✓ Ano |

| Standardní bytové | Starší | ✓ Standardní | ✓ Budoucně bezpečné | ✓ Prémiové |

Scénáře použití

Nabíjecí stanice pro elektromobily

Modely typu A EV a typu F EV poskytují nezbytnou ochranu proti stejnosměrným poruchám pro infrastrukturu nabíjení elektrických vozidel a zajišťují bezpečný provoz nabíjení s citlivostí 6 mA na stejnosměrný proud.

- Ochrana nabíječek úrovně 2 a 3

- Detekce stejnosměrné poruchy (hladký stejnosměrný proud 6 mA)

- Ochrana proti smíšenému střídavému/stejnosměrnému zbytkovému proudu

Průmyslová zařízení

Varianty typu B a B+ zvládají složité průmyslové zátěže včetně VFD, pohonů motorů a výkonové elektroniky s ochranou proti vysokofrekvenčnímu zbytkovému proudu až do 20 kHz.

- Ochrana nabíječek úrovně 2 a 3

- Aplikace v rozváděčích motorů

- Zvládání vysokofrekvenční zátěže

Komerční budovy

Standardní RCCB typu A poskytuje spolehlivou ochranu pro kancelářské budovy, prodejní prostory a hotely s citlivou detekcí svodového proudu.

- Ochrana rozváděče

- Bezpečnost vedení

- Ochrana osob (30 mA)

Solární fotovoltaické systémy

RCCB typu B je nezbytné pro fotovoltaické instalace, poskytuje detekci stejnosměrného zbytkového proudu pro měniče a systémy bateriového uložení energie.

- Ochrana fotovoltaického měniče

- Bezpečnost systému bateriového uložení

- Detekce stejnosměrného poruchového proudu

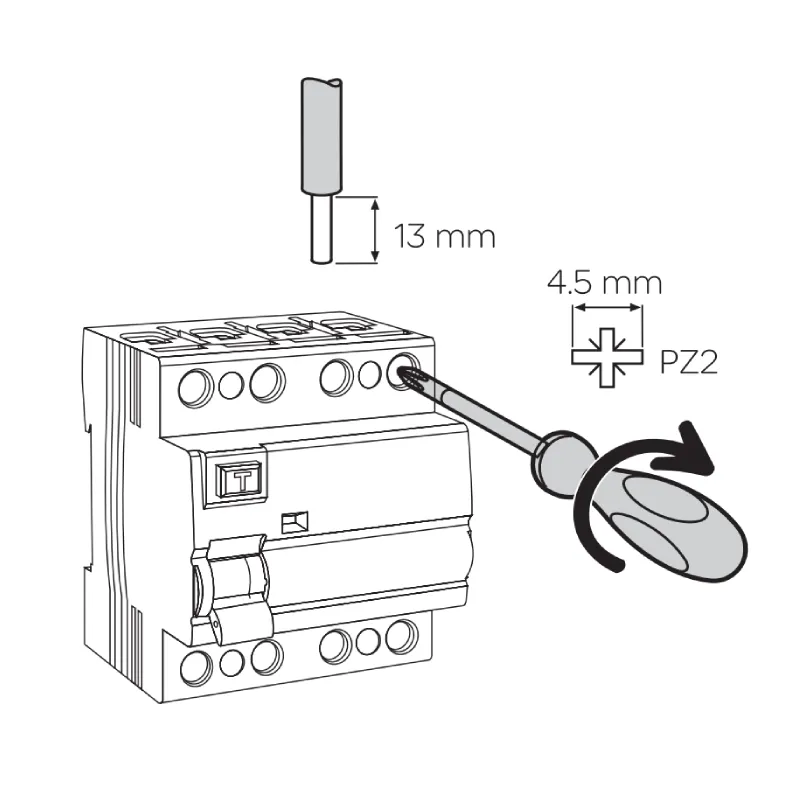

Příručka pro instalaci VIOX RCCB

Instalace RCCB je jednoduchá a vyžaduje pouze lištu DIN (35 mm), šroubovák a vhodné měděné kabely. Proces zahrnuje tři klíčové kroky:

01

02

03

04

05

06

Pro dosažení optimálního výkonu zajistěte správné použití krouticího momentu a použijte doporučené velikosti kabelů. Tento jednoduchý postup instalace v kombinaci s precizní konstrukcí společnosti VIOX zaručuje spolehlivý provoz v různých elektrických řídicích aplikacích.

Získejte svůj Vzorek zdarma!

Vzorky poskytujeme zdarma, stačí nám říct, co potřebujete.

Více než jen výrobce RCCB

Ve společnosti VIOX nabízíme nejen výrobu proudových chráničů (RCCB), ale i soubor služeb s přidanou hodnotou, které jsou přizpůsobeny potřebám vašeho projektu. Náš závazek k dokonalosti zajišťuje, že každý zákazník dostane individuální pozornost, odborné vedení a bezproblémovou podporu po celou dobu spolupráce s námi.

Servisní konzultace

Ať už jsou vaše požadavky na RCCB jednoduché nebo složité, náš tým vám poskytne odborné poradenství a technické konzultace. U složitějších projektů nabízíme hloubkovou inženýrskou podporu, která zajistí optimální výběr a použití výrobku a zaručí bezpečnost a účinnost vašich elektrických systémů.

Doporučení produktů

Nejste si jisti, který RCCB je vhodný pro váš systém? Naši specialisté vám zdarma poskytnou doporučení na míru na základě vašich specifických provozních a environmentálních požadavků, čímž vám zajistí dokonalé přizpůsobení vašim potřebám elektrické ochrany.

Logistická podpora

Pokud nemáte spolehlivého dopravce, můžeme vám zajistit přepravu z naší továrny na místo projektu bez příplatku. Náš logistický tým zajišťuje včasné a bezpečné dodání, aby váš projekt probíhal podle plánu a minimalizoval prostoje a zpoždění.

Podpora při instalaci

Potřebujete pomoci s instalací? Náš technický tým je připraven zodpovědět vaše dotazy nebo poskytnout praktickou podporu. U větších projektů můžeme na místo vyslat i technika, který vám pomůže přímo na místě a zajistí, že vaše RCCB budou správně nainstalovány a budou bez problémů fungovat v rámci vaší elektrické sítě.

Často Kladené Otázky

Připravili jsme pro vás několik častých otázek našich klientů. Pokud zde váš dotaz není uveden, náš zákaznický servis je vám vždy k dispozici. Rádi si s vámi popovídáme.

Jak mohu získat nabídku na RCCB

Chcete-li získat cenovou nabídku na náš systém RCCB, kontaktujte náš zákaznický servis. Jsme vám k dispozici 24 hodin denně, 7 dní v týdnu. Stačí uvést specifika vaší objednávky, jako je typ, velikost a množství. Provedeme vás celým procesem objednávky.

Jaké je vaše MOQ pro objednávku?

Máme nízké MOQ neboli minimální objednací množství. Můžete si objednat pouze jednu jednotku a my vám dodáme zboží podle vašich požadavků.

Jaká je doba vyřízení mé objednávky?

Standardní doba zpracování našich RCCB je 7 až 10 pracovních dnů. Dodací lhůta se může prodloužit až o 15 pracovních dnů z důvodu přepravy. V případě zakázkových nebo hromadných objednávek můžeme dobu realizace projednat před dokončením objednávky.

Mohu před objednáním získat vzorek?

Ano, poskytujeme vzorky k posouzení a schválení. Vytvoření vzorků obvykle trvá 3 až 7 pracovních dnů.

Lze vyrobit RCCB na míru?

Ano, nabízíme RCCB na míru. Sdělte nám své požadavky a náš odborný tým zákaznického servisu s vámi bude spolupracovat při návrhu.

Jaká je vaše záruka na RCCB?

Na všechny námi vyrobené RCCB poskytujeme tříletou záruku. To zaručuje, že dodáváme vysoce kvalitní výrobky. Každý výrobek je před dodáním důkladně testován.

ZNALOSTI O RCCB

Co je RCCB?

Proudový chránič (RCCB) je důležité elektrické bezpečnostní zařízení určené k ochraně před úrazem elektrickým proudem a nebezpečím požáru.. Funguje tak, že nepřetržitě sleduje rovnováhu mezi živým a nulovým proudem v elektrickém obvodu.. Když RCCB zjistí nerovnováhu, která indikuje únik proudu do nechtěné cesty (například přes tělo člověka), rychle odpojí obvod, obvykle do 30 milisekund..

Časová osa vývoje RCCB

Historie proudových chráničů (RCCB) sahá až do poloviny 20. století a vyvinula se z prvních snah o ochranu před elektrickým nebezpečím. V roce 1957 podal Dr. Gottfried Biegelmeier, rakouský fyzik, patent na první RCCB.. Tato inovace navázala na dřívější práci Henriho Rubina v Jižní Africe, který v roce 1955 vyvinul vysoce citlivý systém ochrany proti zemním svodům..

Mezi hlavní milníky vývoje RCCB patří:

1955: Henri Rubin vytváří systém se studenou katodou s citlivostí 250 mA.

1956: Rubin vyvíjí prototyp magnetické jádrové váhy typu zesilovače s citlivostí 12,5-17,5 mA.

1957: Dr. Biegelmeier patentuje první RCCB

1961: Charles Dalziel vyvíjí ve Spojených státech přerušovač zemního spojení (GFCI).

1970s: V Severní Americe se rozšířily jističe typu GFCI.

1980s: Zásuvkové spínače GFCI se stávají populárními, což snižuje počet falešných vypnutí

Tyto pokroky vedly k širokému rozšíření RCCB a významně zvýšily elektrickou bezpečnost v obytných, komerčních a průmyslových zařízeních po celém světě.

RCCB vs. RCBO vs. MCB

- RCCB: Poskytuje ochranu pouze před reziduálním proudem (zemním svodem).

- MCB: Chrání pouze proti nadproudu a zkratu.

- RCBO: Spojuje funkce RCCB a MCB v jednom zařízení.

Jak RCCB fungují

Základním principem fungování RCCB je Kirchhoffův proudový zákon - ve zdravém elektrickém obvodu se proud tekoucí ve vodiči vedení rovná proudu vracejícímu se nulovým vodičem. RCCB tuto rovnováhu nepřetržitě sleduje:

- Mechanismus detekce: Citlivý transformátor proudu porovnává vstupní a výstupní proudy.

- Reakce na nerovnováhu: Pokud rozdíl (zbytkový proud) překročí nastavenou mez, což indikuje únik proudu.

- Rychlé odpojení: RCCB sepne během milisekund a odpojí napájení před nebezpečným ozářením.

Klíčové technické parametry

- Jmenovitý proud (In): Maximální trvalý proud, který může RCCB přenášet (např. 16A, 25A, 40A).

- Citlivost (IΔn): Prahová hodnota zbytkového proudu, která vyvolá odpojení (obvykle 10 mA, 30 mA, 100 mA, 300 mA).

- Přerušovací kapacita: Maximální poruchový proud, který může RCCB bezpečně přerušit.

- Čas na výlet: Doba mezi detekcí a odpojením (obvykle <30 ms)

Průvodce výběrem RCCB

Při výběru správného RCCB pro vaši domácnost nebo zařízení zvažte tyto klíčové faktory:

Aktuální hodnocení: Zvolte RCCB s proudovou hodnotou, která odpovídá zatížení vašeho obvodu. Pro většinu domácností postačí 30A až 63A, zatímco větší instalace mohou vyžadovat vyšší jmenovitý proud..

Citlivost: Pro použití v domácnostech jsou standardem 30mA RCCB, které poskytují ochranu před úrazem elektrickým proudem. Vyšší citlivost (100mA nebo 300mA) může být vhodná pro venkovní obvody nebo oblasti s vyšším rizikem úniku proudu..

Typ: Zvolte typ AC pro základní bytové aplikace, typ A pro obvody s elektronickými zařízeními nebo typ B pro systémy s pohony a měniči..

Počet pólů: Pro jednofázové systémy použijte jednopólové RCCB, pro třífázové obvody dvoupólové nebo třípólové..

Značka a certifikace: Vyberte si RCCB od renomovaných výrobců, které splňují mezinárodní bezpečnostní normy..

Vždy se poraďte s kvalifikovaným elektrikářem, abyste se ujistili, že RCCB splňuje specifické požadavky na elektrický systém a místní předpisy.

Detekce poruchy RCCB

Chcete-li zjistit, kdy RCCB nepracuje správně, postupujte podle následujících kroků:

Použijte tlačítko test: Stiskněte měsíční testovací tlačítko na RCCB. Pokud se nespustí okamžitě, může být zařízení vadné..

Zkontrolujte, zda nedochází k častému vypínání: Pokud se RCCB opakovaně vypíná bez zjevné příčiny, může to znamenat vnitřní problémy..

Sledujte chování při resetování: RCCB, který nelze resetovat nebo zůstává ve vypnuté poloze, může mít poruchu..

Sledujte unikající proud: Neobvykle vysoký unikající proud může signalizovat vadný RCCB, což představuje riziko požáru nebo úrazu elektrickým proudem..

Zkontrolujte, zda nedošlo k fyzickému poškození: Hledejte známky opotřebení, spálení nebo poškození na samotném RCCB.

Pokud máte podezření, že vaše RCCB nefunguje správně, obraťte se na kvalifikovaného elektrikáře, který provede důkladnou kontrolu a případnou výměnu, aby byla zajištěna trvalá elektrická bezpečnost..

Průvodce výměnou RCCB

Chcete-li vyměnit proudový chránič (RCCB), postupujte podle následujících pokynů:

Pro zajištění bezpečnosti během procesu výměny vypněte hlavní zdroj napájení..

Odstraňte kryt panelu pomocí izolovaného šroubováku, abyste získali přístup k vnitřním součástem..

Odpojte vodiče od starého RCCB uvolněním šroubů svorek..

Odpojte starý RCCB od panelu uvolněním všech upevňovacích svorek nebo výstupků..

Nainstalujte novou jednotku RCCB tak, že ji zarovnáte do příslušných drážek v panelu..

Znovu připojte vodiče k novému RCCB a zajistěte správné připojení ke svorkám vedení a zátěže..

Zajistěte kryt panelu a obnovte napájení, abyste otestovali funkčnost nového RCCB..

Pokud si nejste jisti jakýmkoli krokem v procesu výměny, vždy se poraďte s kvalifikovaným elektrikářem.3. Nezapomeňte vybrat RCCB se správnými specifikacemi pro váš elektrický systém..

Základy údržby RCCB

Chcete-li zajistit optimální výkon a dlouhou životnost zařízení RCCB, dodržujte tyto hlavní zásady:

Provádějte měsíční testy pomocí vestavěného testovacího tlačítka, abyste ověřili správnou funkci..

Provádějte vizuální kontroly, zda nejsou patrné známky opotřebení, poškození nebo uvolněných spojů..

Každoročně naplánujte odborné kontroly, včetně testování impedance zemní smyčky..

Udržujte RCCB a jeho okolí v čistotě a bez prachu a nečistot.

Výměna RCCB každých 10-25 let, v závislosti na doporučení výrobce a podmínkách používání..

Pravidelná údržba zajišťuje nejen bezpečnost, ale také prodlužuje životnost vašeho elektrického systému. Pokud při testování nebo kontrole zjistíte jakékoli problémy, okamžitě se obraťte na kvalifikovaného elektrikáře, který je posoudí a případně vymění..

Oblasti použití RCCB

RCCB nacházejí široké uplatnění v různých odvětvích a zvyšují elektrickou bezpečnost v různých prostředích:

Obytné budovy: Běžně se instalují v domácnostech, zejména v rizikových oblastech, jako jsou kuchyně a koupelny, aby chránily před úrazem elektrickým proudem a zabránily požárům..

Komerční: Používá se v kancelářích, obchodech a hotelech k ochraně zaměstnanců, zákazníků a cenného vybavení před elektrickými poruchami..

Průmyslové: Nezbytné v továrnách a průmyslových zařízeních pro ochranu těžkých strojů a složitých elektrických systémů..

Staveniště: Rozhodující pro dočasné elektrické instalace, kde je zvýšené riziko elektrického nebezpečí..

Zdravotnická zařízení: V nemocnicích se používají specializované RCCB s vysokou citlivostí (např. 10 mA), aby byla zajištěna bezpečnost pacientů..

Obnovitelná energie: RCCB typu B se používají v systémech výroby solární energie pro zpracování střídavého i stejnosměrného proudu..

Nabíjecí stanice pro elektromobily: RCCB typu B se stále častěji používají k prevenci možných elektrických poruch v infrastruktuře pro nabíjení elektromobilů..

Všestrannost RCCB je činí nepostradatelnými v moderních elektrických systémech, kde poskytují kritickou vrstvu ochrany proti úrazu elektrickým proudem, požárům a poškození zařízení v různých aplikacích..

Yueqing: Výrobní centrum RCCB

Yueqing, okresní město v čínské provincii Zhejiang, je považováno za největší světové centrum výroby proudových chráničů (RCCB). Toto město v regionu Wen-čou, známé jako "hlavní město elektrotechniky v Číně", získalo na významu díky rozsáhlé síti výrobců elektrotechnických součástek a vyspělým výrobním kapacitám.

Dominantní postavení města v oblasti výroby RCCB je dáno vysokou koncentrací specializovaných továren, jako je například VIOX Electric, které se zaměřují na výrobu vysoce kvalitních elektrických bezpečnostních zařízení. Yueqing se může pochlubit nejmodernějšími výrobními zařízeními s automatizovanými výrobními linkami a přísnými opatřeními pro kontrolu kvality. Blízkost hlavních dopravních uzlů, jako jsou přístavy Wenzhou, Ningbo a Šanghaj, zajišťuje efektivní globální distribuci. Kromě toho klade důraz na výzkum a vývoj a nabízí řešení OEM/ODM na míru při dodržování mezinárodních norem, jako jsou certifikace CE, RoHS a ISO9001. Tato kombinace faktorů upevnila pozici společnosti Yueqing jako světového lídra ve výrobě RCCB.

Žádost o nabídku OEM RCCB

Společnost VIOX Electric je připravena vám pomoci s vašimi potřebami v oblasti RCCB OEM. Nabízíme vysoce kvalitní a cenově výhodná řešení.