What Electrical Wholesalers Need to Know About Breaker Longevity

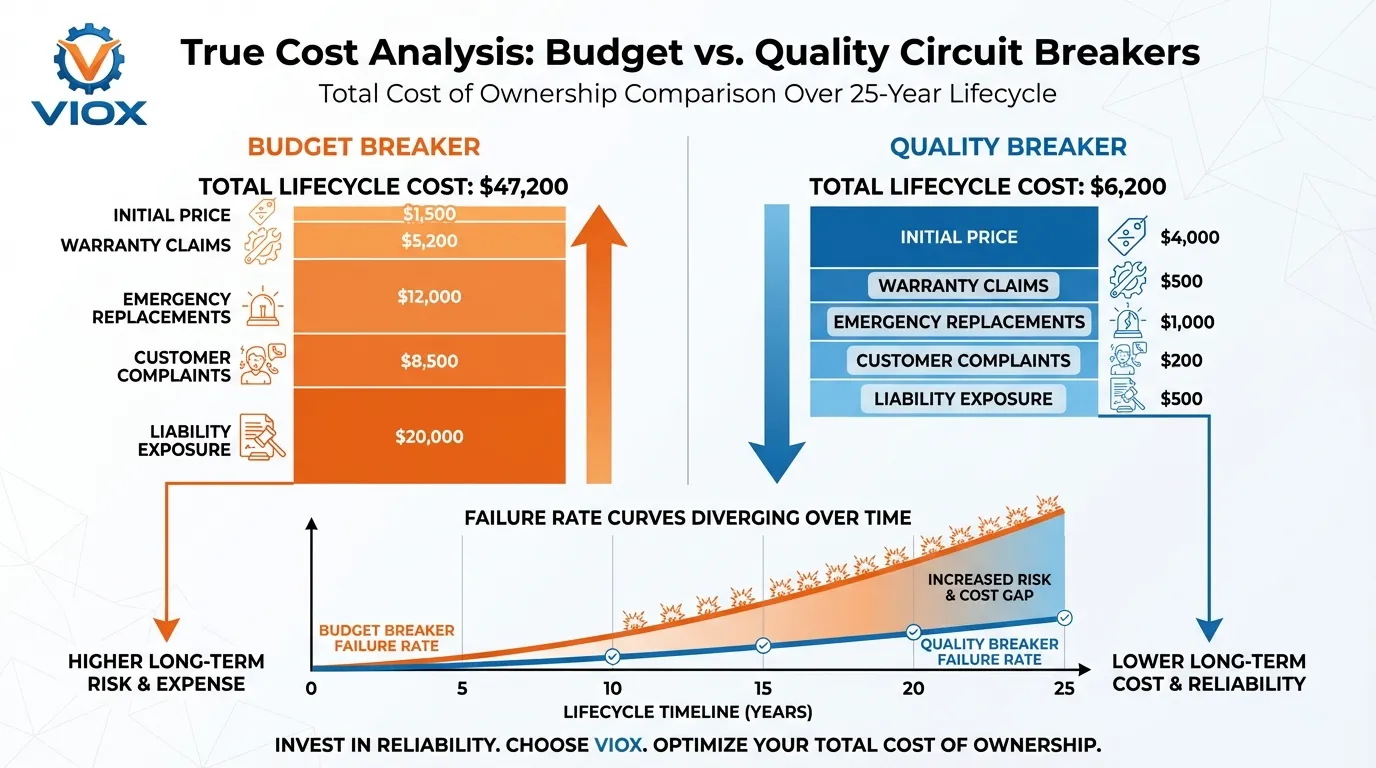

Premature circuit breaker failure costs electrical wholesalers far more than the replacement unit price. When low-quality MCBs and MCCBs fail early, the true financial impact includes warranty claims, emergency replacements, damaged customer relationships, and liability exposure. Industry data reveals that inferior breaker components can reduce service life by 40-60%, while quality breakers from certified manufacturers deliver 25-30 years of reliable operation with proper maintenance.

For B2B buyers sourcing electrical protection equipment, understanding the relationship between component quality and total cost of ownership isn’t optional—it’s a competitive necessity that directly impacts your bottom line and market reputation.

The Real Economics of Breaker Component Quality

Understanding Total Cost of Ownership vs. Purchase Price

Most procurement decisions focus heavily on unit cost, but this narrow view obscures the true financial picture. A $12 MCB that fails after 5 years costs significantly more than a $18 unit that operates reliably for 25 years when you factor in replacement labor, downtime, and potential liability.

The cost structure for quality circuit breakers breaks down into several key components that directly correlate with longevity:

| Cost Component | Budget Breakers | Quality Breakers | Impact on Lifespan |

|---|---|---|---|

| Contact Material | Copper alloy (lower silver content) | Silver-copper composite (8-12% Ag) | 3-5x longer arc resistance |

| Thermal Calibration | ±10% tolerance | ±5% tolerance | Reduces nuisance trips by 60% |

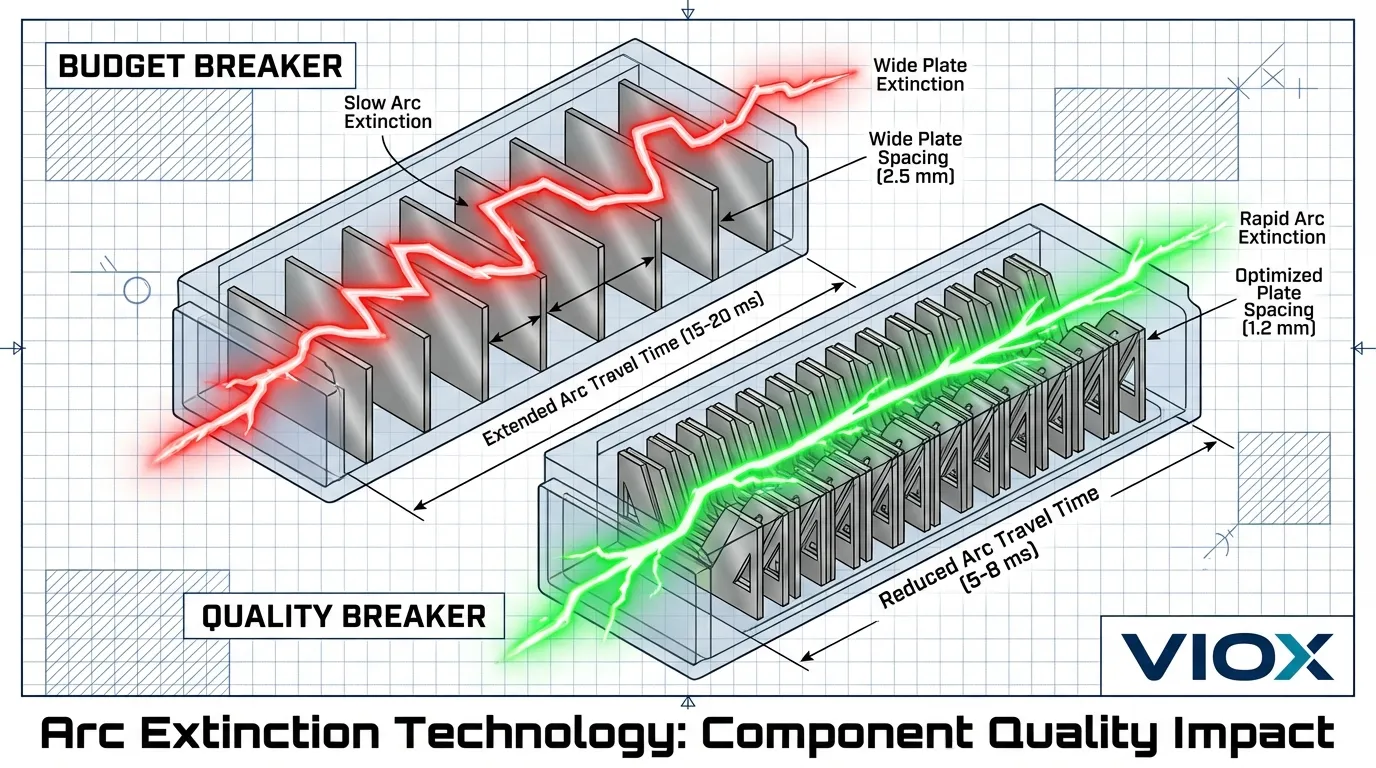

| Arc Chute Design | 5-7 plates, basic geometry | 9-13 plates, optimized spacing | 40% faster arc extinction |

| Housing Material | Recycled thermoplastic | Virgin flame-retardant polymer (UL94 V-0) | 2x better thermal stability |

| Testing Protocol | 200-300% rated current | 135% rated current (full standard) | Ensures accurate trip performance |

MCCBs typically carry a 25-50% cost premium over equivalent MCBs, but this investment delivers adjustable trip settings, higher interrupting capacity, and significantly longer mechanical life—critical factors for industrial applications where downtime costs can exceed $5,000 per hour.

How Component Degradation Accelerates Failure

The Physics of Breaker Wear

Circuit breakers don’t fail suddenly—they degrade gradually through predictable mechanisms that quality components are specifically engineered to resist. Understanding these failure modes explains why component quality matters so dramatically.

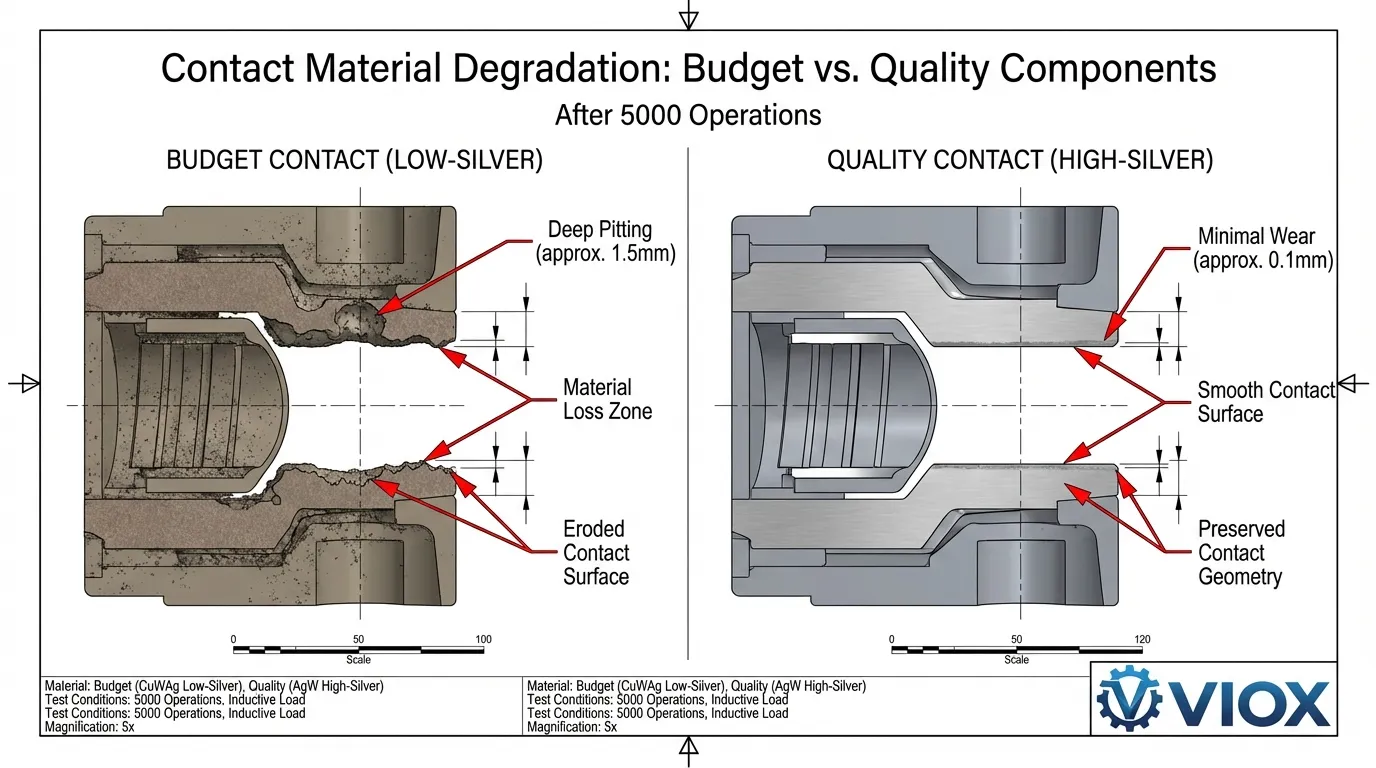

Contact Erosion and Arcing Damage

Every time a breaker interrupts current, an electrical arc forms between the separating contacts. This arc—reaching temperatures of 3,000-20,000°C—vaporizes microscopic amounts of contact material. Low-quality contacts using minimal silver content erode 3-5 times faster than properly engineered silver-copper composites.

The arc chute assembly plays an equally critical role. Quality breakers use 9-13 precisely spaced steel plates to divide and cool the arc, while budget units may use only 5-7 plates with suboptimal geometry. This difference translates directly to arc extinction speed and contact preservation.

Thermal Stress and Calibration Drift

The bimetallic strip that provides overload protection is extraordinarily sensitive to thermal cycling. Each heating and cooling cycle causes microscopic changes in the metal’s crystalline structure. Over thousands of cycles, inferior materials lose calibration accuracy, leading to either nuisance tripping or—far more dangerous—failure to trip when needed.

Research on circuit breaker failures reveals that some manufacturers test at 200-300% of rated current for faster production throughput, rather than the 135% standard that ensures accurate trip performance at normal overload conditions. This shortcut creates breakers that pass factory testing but fail in real-world applications.

Environmental Degradation Factors

Temperature extremes, humidity, corrosive atmospheres, and vibration all accelerate component degradation. Quality breakers specify virgin flame-retardant polymers rated to UL94 V-0 standards, which maintain dimensional stability and insulation properties across temperature ranges of -25°C to +70°C. Budget alternatives using recycled thermoplastics may become brittle or deform under thermal stress, compromising both mechanical operation and electrical isolation.

The Hidden Costs That Destroy Profit Margins

Beyond the Replacement Unit Price

When electrical wholesalers stock low-quality breakers, the financial consequences extend far beyond the initial cost savings. Here’s what the spreadsheet doesn’t show:

Warranty and Return Processing

A 2-5% failure rate within warranty periods might seem acceptable until you calculate the actual cost per incident:

- Administrative processing: $25-50 per claim

- Reverse logistics and shipping: $15-30

- Replacement unit cost: $12-80

- Customer service time: $20-40

- Total cost per warranty claim: $72-200

For a distributor moving 10,000 breaker units annually, a 3% failure rate means 300 warranty claims costing $21,600-60,000 in direct expenses—completely erasing the margin gained from buying cheaper units.

Emergency Replacement and Expedited Shipping

When a breaker fails in a commercial or industrial setting, customers don’t wait for standard shipping. They demand immediate replacement, often requiring:

- Same-day or next-day shipping: $50-150 premium

- Rush order processing: $25-50

- Potential stock-out of premium units: Lost sale opportunity

- Customer relationship damage: Immeasurable but real

Liability Exposure and Insurance Implications

Circuit breaker failure that results in equipment damage, fire, or injury creates liability exposure that can dwarf all other costs. While rare, catastrophic failures of substandard breakers have resulted in:

- Property damage claims: $50,000-500,000+

- Litigation costs: $100,000-1,000,000+

- Insurance premium increases: 15-40% annually

- Reputational damage: Lost contracts and market share

Quality manufacturers maintain comprehensive product liability insurance and rigorous quality control specifically to mitigate these risks. When you source from certified suppliers, you’re not just buying a breaker—you’re buying risk transfer.

Component Quality Indicators for B2B Buyers

What to Verify Before Placing Orders

Savvy electrical wholesalers don’t rely on supplier claims alone. Here are the specific quality indicators that separate reliable manufacturers from those cutting corners:

| Quality Indicator | What to Verify | Red Flags |

|---|---|---|

| Certifications | IEC 60947-2, UL 489, CE marking with notified body number | Generic “CE” without number, missing test reports |

| Contact Material Specs | Silver content 8-12%, documented composition | “Silver alloy” without percentage, no material certificate |

| Trip Curve Accuracy | ±5% thermal tolerance, published curves | ±10% tolerance, no curves provided |

| Breaking Capacity | Tested at rated Icu/Ics, third-party verification | Only Icu listed, no independent test data |

| Temperature Rise Limits | Meets IEC 60947-2 Table 1 (terminal: 70K, housing: 55K) | No temperature data, “meets standards” claims |

| Mechanical Life | 10,000-20,000 operations documented | No specification, “long life” marketing claims |

| Factory Audit Trail | ISO 9001:2015, documented QC procedures | No quality certifications, limited documentation |

The Testing Protocol Difference

Quality manufacturers test every production batch at 135% of rated current to verify accurate trip performance—the actual overload condition breakers will face in service. Budget manufacturers may test at 200-300% for faster throughput, creating units that pass factory testing but fail to protect properly at real-world overload levels.

When evaluating suppliers, request:

- Type test reports from accredited laboratories (not just certificates)

- Routine test procedures showing what’s tested on every production batch

- Material certificates for critical components (contacts, arc chutes, housing)

- Thermal imaging data showing temperature rise under rated load

- Endurance test results documenting mechanical and electrical life

Quality Comparison: Budget vs. Premium Breakers

Real-World Performance Data

Independent testing and field performance data reveal stark differences between quality tiers. Here’s what 25 years of operation looks like:

Budget Breaker Lifecycle (Typical)

- Years 0-5: Normal operation with 2-3% annual failure rate

- Years 5-10: Calibration drift begins, nuisance trips increase 40%

- Years 10-15: Contact erosion accelerates, 8-12% annual failure rate

- Years 15+: Unsafe to continue operation, replacement required

- Total lifecycle cost: Initial price + 15-25% replacements + warranty processing + customer complaints

Quality Breaker Lifecycle (Certified Manufacturer)

- Years 0-10: Normal operation with <0.5% annual failure rate

- Years 10-20: Minimal degradation, maintained calibration accuracy

- Years 20-30: Gradual performance decline, still within specifications

- Years 30+: Replacement recommended for safety, not failure

- Total lifecycle cost: Initial price + 2-5% replacements + minimal warranty claims + strong customer relationships

The difference becomes dramatic when you calculate cost per year of service:

- Budget breaker: $12 ÷ 12 years = $1.00/year (plus hidden costs)

- Quality breaker: $18 ÷ 28 years = $0.64/year (minimal hidden costs)

The quality breaker delivers 36% lower annual cost while eliminating the warranty processing, emergency replacements, and customer relationship damage that budget units generate.

Manufacturing Quality Control: What Separates Leaders from Followers

The Factory Audit Perspective

Having visited dozens of breaker manufacturing facilities across Asia and Europe, the quality differences are immediately visible to trained observers. Here’s what distinguishes top-tier manufacturers:

Incoming Material Inspection

Quality manufacturers maintain dedicated laboratories that test every batch of critical materials before production:

- Silver content verification via X-ray fluorescence spectroscopy

- Polymer flame resistance testing to UL94 standards

- Dimensional inspection of stamped components (±0.02mm tolerance)

- Bimetallic strip calibration verification before assembly

Budget facilities often accept supplier certifications without independent verification, creating vulnerability to material substitution.

Production Line Quality Gates

Top manufacturers implement multiple inspection points:

- Pre-assembly: Component dimensional checks and visual inspection

- Mid-assembly: Contact alignment verification, spring tension measurement

- Post-assembly: Trip current testing at 135% rated current

- Final inspection: Dielectric strength test, mechanical operation test, visual inspection

Each breaker receives a unique serial number enabling full traceability to production batch, material lot, and test results.

Statistical Process Control

Leading manufacturers don’t just test samples—they monitor production trends to detect quality drift before it produces defective units. When trip current measurements start trending toward specification limits, they halt production and adjust tooling rather than shipping units that technically pass but sit at the edge of acceptable performance.

Strategic Sourcing Recommendations for Electrical Wholesalers

Building a Quality-First Supply Chain

For electrical wholesalers competing in markets where reputation matters, here’s a practical framework for breaker procurement:

Tier Your Product Offering

Not every application demands premium breakers, but every application deserves appropriate quality:

- Tier 1 (Premium): Critical infrastructure, industrial plants, commercial buildings—specify certified manufacturers with documented quality systems

- Tier 2 (Standard): Light commercial, residential main panels—verified compliance with IEC/UL standards, factory audits required

- Tier 3 (Economy): Temporary installations, non-critical circuits—basic certification acceptable, but never compromise on safety standards

Supplier Qualification Process

Before adding a new breaker supplier to your approved list:

- Request and verify third-party test reports (not just certificates)

- Conduct factory audit or review recent audit reports from qualified inspectors

- Order sample batch for independent testing at accredited laboratory

- Implement pilot program with limited SKUs before full-line adoption

- Monitor field performance for 12-24 months before expanding commitment

Cost-Benefit Analysis Framework

When evaluating supplier proposals, calculate true cost including:

- Unit price × expected volume

- Warranty claim processing (historical rate × cost per claim)

- Emergency replacement frequency (historical rate × expedited shipping premium)

- Customer relationship impact (complaint rate × customer lifetime value)

- Liability exposure (failure rate × average claim cost × probability)

This comprehensive analysis typically reveals that a 30-50% premium for quality breakers delivers 15-25% lower total cost of ownership while protecting market reputation.

The VIOX Quality Difference

Engineering Excellence in Every Component

At VIOX Electric, we engineer circuit breakers with a singular focus: delivering reliable protection that electrical professionals can specify with confidence. Our approach to component quality reflects decades of electrical engineering expertise:

Contact System Engineering

Our MCB and MCCB lines use silver-copper contacts with 10-12% silver content, optimized for both conductivity and arc resistance. Each contact undergoes surface treatment that creates a micro-textured finish, reducing contact resistance while improving arc mobility during interruption.

Thermal Calibration Precision

VIOX breakers maintain ±5% thermal trip tolerance across the full operating temperature range (-25°C to +70°C). We achieve this through:

- Bimetallic strips manufactured to aerospace-grade specifications

- Individual calibration of each thermal element during assembly

- Temperature-compensated trip mechanism design

- 100% production testing at 135% rated current (not 200-300% shortcuts)

Arc Extinction Optimization

Our arc chute assemblies use 11-13 precisely spaced steel plates with optimized geometry derived from finite element analysis. This design delivers arc extinction in 8-12 milliseconds—40% faster than minimum standards require—directly translating to reduced contact erosion and extended service life.

Quality Assurance Protocol

Every VIOX breaker undergoes:

- Dielectric strength testing at 2,500V AC for 1 minute

- Mechanical endurance testing (sample basis: 10,000 operations)

- Trip current verification at 1.13×, 1.45×, and 2.55× rated current

- Temperature rise measurement under continuous rated load

- Final visual inspection and electrical continuity verification

For electrical wholesalers seeking to differentiate on reliability rather than compete solely on price, VIOX delivers the documented quality that protects both your customers and your reputation.

Key Takeaways

- Lifecycle cost matters more than purchase price: Quality breakers cost 36% less per year of service despite higher initial investment

- Component quality directly determines lifespan: Inferior contacts, thermal elements, and housing materials reduce service life by 40-60%

- Hidden costs destroy margins: Warranty claims, emergency replacements, and liability exposure from budget breakers can cost $72-200 per incident

- Testing protocols reveal quality: Manufacturers testing at 135% rated current deliver accurate trip performance; those using 200-300% shortcuts create field failures

- Certification verification is essential: Demand third-party test reports, not just certificates, and conduct factory audits before committing to new suppliers

- Strategic tiering optimizes value: Match breaker quality to application criticality while never compromising on safety standards

- Total cost of ownership analysis changes decisions: When warranty processing, emergency shipping, and liability exposure are factored in, quality breakers deliver 15-25% lower total cost

Frequently Asked Questions

Q: How can I tell if a circuit breaker is using quality components without laboratory testing?

A: Request material certificates for contacts (should specify 8-12% silver content), examine the arc chute through the housing (quality units have 9+ visible plates), verify the housing material is marked UL94 V-0, and check that thermal trip tolerance is specified as ±5% or better. Also demand third-party test reports, not just certificates—quality manufacturers provide detailed documentation.

Q: What’s the real-world failure rate difference between budget and quality breakers?

A: Field data shows budget breakers typically experience 2-3% annual failure rates in the first 5 years, increasing to 8-12% annually after year 10. Quality breakers from certified manufacturers maintain <0.5% annual failure rates through 20+ years of service. This 4-6× difference in reliability directly impacts warranty costs and customer satisfaction.

Q: Are MCCBs always better than MCBs for commercial applications?

A: Not necessarily. MCCBs offer adjustable trip settings and higher interrupting capacity, making them ideal for main distribution and motor protection. However, MCBs are more cost-effective for branch circuits under 100A where adjustment isn’t needed. The key is matching breaker type and quality to application requirements—both can be excellent or poor depending on component quality and proper specification.

Q: How often should circuit breakers be replaced in commercial installations?

A: Quality breakers properly applied typically last 25-30 years before replacement is recommended. However, breakers in harsh environments (high temperature, humidity, vibration) or high-cycle applications may need replacement every 15-20 years. Budget breakers often require replacement every 10-15 years. Regular testing per NFPA 70B guidelines helps identify breakers approaching end-of-life before failure occurs.

Q: What documentation should I require from breaker suppliers to verify quality?

A: Demand: (1) Type test reports from accredited labs showing compliance with IEC 60947-2 or UL 489, (2) Material certificates for contacts specifying silver content, (3) ISO 9001:2015 certification for the manufacturing facility, (4) Routine test procedures showing what’s tested on every production batch, and (5) Temperature rise test data. Quality manufacturers provide this documentation readily; those who can’t or won’t are revealing their quality level.

For electrical wholesalers seeking to build competitive advantage through quality rather than competing solely on price, VIOX Electric delivers the component excellence, testing rigor, and documentation transparency that protects both your customers and your market reputation. Contact our B2B team to discuss how our certified MCB and MCCB solutions can strengthen your product portfolio.