To an experienced electrical engineer, a circuit breaker panel is never truly silent. It has a pulse. But to the untrained ear, identifying the difference between the rhythmic hum of a healthy load and the erratic buzz of a failing component is the difference between a routine inspection and an emergency fire hazard.

When a client reports a circuit breaker buzzing, they are providing you with acoustic data. Your job is to decode that data. While many online guides dismiss noise as “just an old breaker,” the reality is often more specific—and potentially dangerous.

This engineering diagnostic guide breaks down the acoustic signatures of breaker failure, the physics behind the noise, and the root causes that require immediate intervention.

For a broader overview of breaker failure symptoms beyond just noise, refer to our guide on How to Know If a Circuit Breaker Is Bad.

Part 1: Acoustic Diagnosis – The Three Sound Signatures

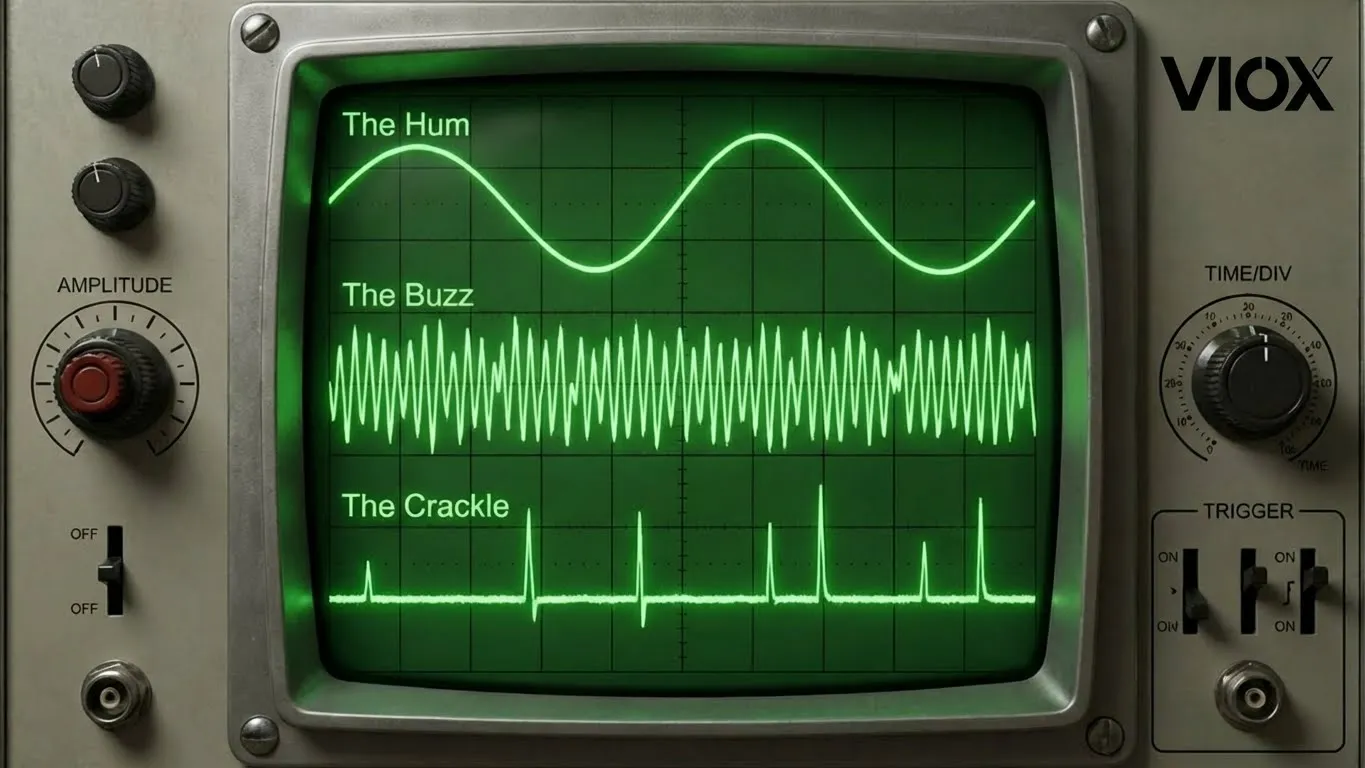

Not all breaker sounds indicate a catastrophe. In VIOX laboratories, we categorize acoustic emissions into three distinct signatures. Distinguishing between them is the first step in troubleshooting.

1. The Hum (Low Frequency, Steady)

- Frequency: ~100Hz or 120Hz (2x grid frequency).

- Character: Monotone, consistent, low volume (<30dB at 1 meter).

- Diagnosis: Often Normal Operation. This is typically caused by magnetostriction (see Physics section below). It is common in heavily loaded circuits or adjacent to transformers.

2. The Buzz (Mid Frequency, Vibrating)

- Character: Rattle, mechanical vibration, fluctuating volume.

- Diagnosis: Warning Sign. This usually indicates a mechanical loose point or a bi-metal strip under extreme thermal stress. It suggests the breaker is operating near its trip threshold or has a compromised mounting connection.

3. The Crackle / Sizzle (High Frequency, Irregular)

- Character: Hissing, popping, frying bacon sound.

- Diagnosis: CRITICAL FAULT. This is the sound of an electrical arc jumping a gap. It indicates ionization of air due to a breakdown in insulation or a severed contact. Immediate isolation is required.

Learn more about the mechanism behind this dangerous sound in our technical analysis: What Is an Arc in a Circuit Breaker?.

Part 2: The Physics of Breaker Noise

Why do static components make noise? There are three primary physical forces at work inside an electrical enclosure.

Magnetostriction

In Alternating Current (AC) systems, magnetic fields expand and collapse 50 or 60 times per second. Ferrous materials inside the breaker—specifically the trip coil and solenoid core—physically expand and contract slightly with these magnetic shifts. This creates a fundamental vibration at double the line frequency (100Hz or 120Hz).

VIOX Advantage: VIOX breakers utilize high-grade ferrous alloys and precision-damped solenoid assemblies to minimize magnetostriction, keeping operational noise significantly below industry averages.

Thermal Expansion Loop

Loose connections create resistance (I²R). Resistance creates heat. Heat causes metal terminals to expand. When the load drops, they cool and contract. This cycle loosens the connection further, allowing components to vibrate physically against the busbar or DIN rail, creating a mechanical “buzz.”

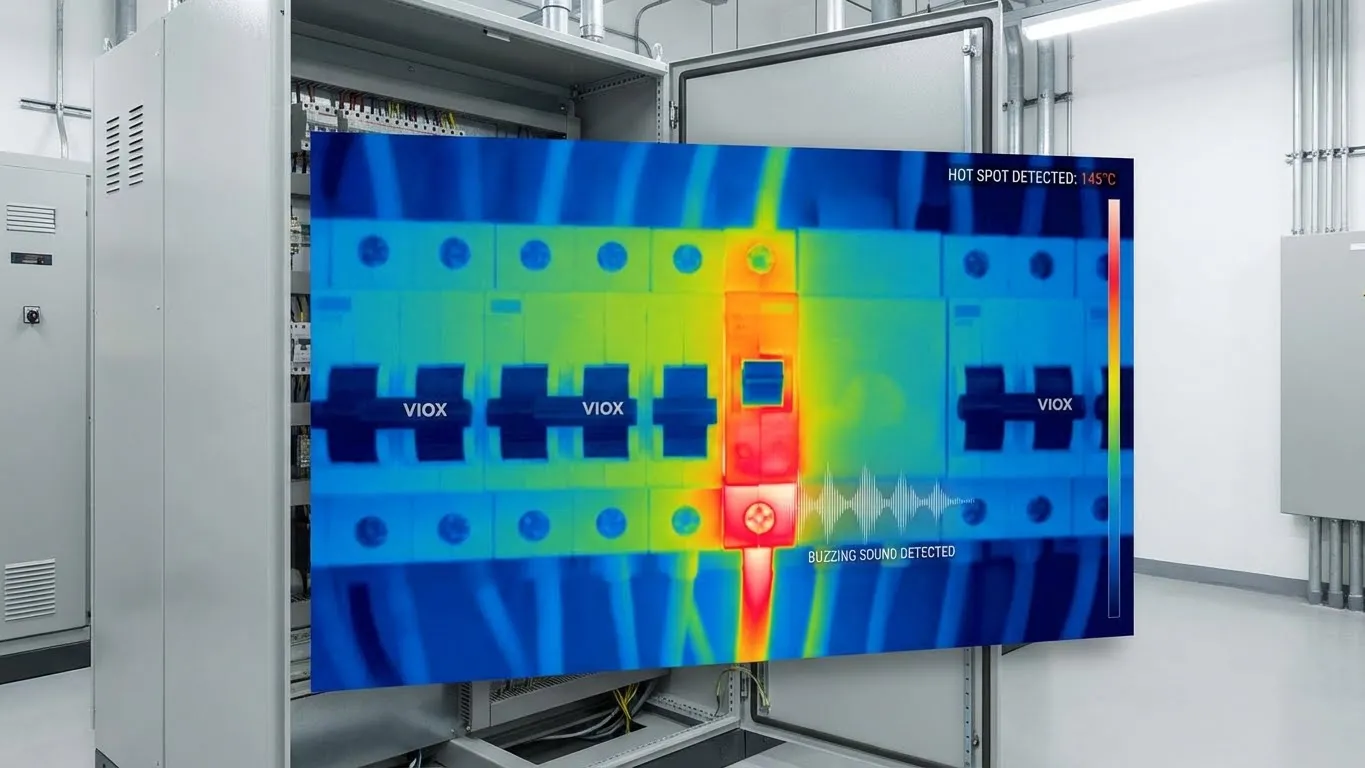

Electrical Arcing

When a contact surface is pitted or a wire is loose, electricity attempts to bridge the air gap. The “sizzle” you hear is the rapid heating and expansion of air molecules as plasma forms. This is not a vibration; it is a series of miniature explosions.

Part 3: Root Cause Analysis

If the sound exceeds the ambient hum threshold (>30dB), one of the following root causes is likely responsible.

1. Loose Terminations (The #1 Cause)

A buzzing breaker is often a symptom of poor installation workmanship. If the terminal screw was not torqued to manufacturer specifications (NEC 110.14), the wire sits loosely.

- The Result: The 50/60Hz current physically vibrates the loose wire against the terminal wall.

- The Fix: Check torque values. Note that simply tightening a charred wire is insufficient; the damaged section must be cut back.

For guidance on proper connection hardware, read How to Choose the Right Terminal Block.

2. Circuit Overload

When a breaker is subjected to a continuous load near its trip rating (e.g., 19A on a 20A breaker), the internal bi-metallic strip heats up and bends. As it hovers right at the mechanical “trip” point, the internal latch mechanism can oscillate or vibrate, producing a loud buzz.

- Diagnostic: Does the buzzing stop immediately if you unplug a major appliance (like an AC unit or space heater)? If yes, it is an overload buzz.

- Reference: What Is Circuit Overload?

3. Contact Pitting (Internal Failure)

Every time a breaker is switched under load, a small arc occurs. Over years, this erodes the contact material, creating a pitted, uneven surface.

- The Issue: Pitted contacts have higher resistance and less surface area. Current is forced through small “peaks” on the contact surface, causing localized sizzling.

- Material Science: Cheap breakers use standard brass contacts. VIOX breakers utilize Silver-Alloy composites which are highly resistant to arc erosion, maintaining a smooth, quiet contact surface over thousands of operations.

Part 4: Professional Troubleshooting Protocol

Safety Warning: Only qualified electricians should open a live electrical panel. PPE (Personal Protective Equipment) is required.

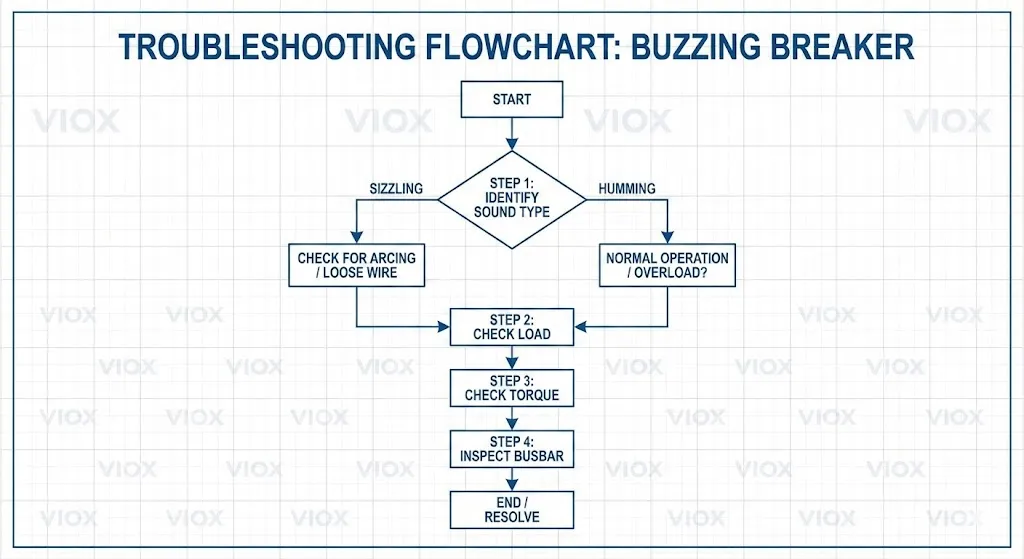

Step 1: Isolate the Sound

Use a mechanic’s stethoscope (or a non-conductive probe) to identify exactly which breaker is vibrating. A general “panel buzz” often originates from a single component resonating through the enclosure.

Step 2: The “Load Drop” Test

Turn off the loads on that circuit.

- Noise stops? The issue is load-related (Overload or Loose Connection under load).

- Noise continues? The issue is likely a bad breaker mechanism or a fault on the busbar connection itself.

Step 3: Torque Inspection

De-energize the panel. Check the torque on the buzzing breaker’s load terminal and the mounting clip (if bolt-on). Do not over-torque. Over-tightening can crush the conductor, reducing contact area and worsening the buzz.

Step 4: Inspection for “Arc Tracks”

Remove the breaker. Inspect the busbar behind it. Are there black burn marks or pitting?

- Yes: The busbar is damaged. Replacing the breaker is not enough; the panel section may need repair.

- No: The fault is internal to the breaker.

Step 5: Replacement

If the connection is tight and the load is normal, the breaker’s internal springs or contacts have failed. Replace it immediately. See our guide: How to Replace a Circuit Breaker.

Diagnostic Comparison Matrix

Use this table to quickly categorize the issue for your customer.

| Sound Type | Decibel Level | Physical Cause | Severity | Action Required |

|---|---|---|---|---|

| Hum | < 30 dB | Magnetostriction (Vibration) | Low | Monitor. Normal for high loads. |

| Buzz | 30 – 50 dB | Loose Wire / Thermal Oscillation | Medium | Check torque. Check amp draw. |

| Buzz | > 50 dB | Mounting Clip Failure | High | Replace breaker. Inspect busbar. |

| Sizzle / Hiss | Variable | Arcing / Ionization | CRITICAL | De-energize immediately. Fire risk. |

Frequently Asked Questions (FAQ)

1. Can a buzzing circuit breaker cause a fire?

Yes, depending on the cause. A “hum” is usually safe. However, a “buzz” caused by a loose connection creates intense heat that can melt insulation and ignite surrounding materials. A “sizzle” is an active fire hazard (arcing). Never ignore a sound that changes in pitch or volume.

2. Is it normal for AFCI/GFCI breakers to hum?

AFCI (Arc Fault) and GFCI (Ground Fault) breakers contain internal electronics and sensing coils that standard breakers do not. They may produce a slightly audible hum due to the continuously active monitoring circuits. However, this should not be heard through a closed panel door.

3. How loud is “too loud”?

A rule of thumb: If you have to place your ear against the panel to hear it, it’s likely magnetostriction (normal). If you can hear it standing 1 meter (3 feet) away, or if the sound is audible over the noise of the appliance it powers, it is a defect.

4. Does the breaker type (MCB vs. MCCB) affect noise?

Yes. Molded Case Circuit Breakers (MCCBs) used in commercial settings handle higher currents and have larger internal solenoids, leading to a naturally louder “hum” (magnetostriction) than residential Miniature Circuit Breakers (MCBs). However, VIOX MCCBs are engineered with dampening cores to minimize this.

5. Why does my breaker buzz only when the AC starts?

Air conditioners have a high “inrush current” (startup surge) that can be 3-5 times their running current. This momentary spike causes a rapid thermal expansion and magnetic pull inside the breaker, causing a brief buzz (1-2 seconds). If the buzz continues after startup, the breaker may be undersized or the connection loose.

6. I tightened the screw, but it still buzzes. Now what?

If the terminal is properly torqued and the sound persists, the failure is internal (contact pitting or weak bimetal strip tension). The breaker cannot be repaired; it must be replaced.

Sound is the first symptom of failure. By listening to your panel, you can prevent thermal damage before it starts. Upgrade to VIOX Circuit Breakers for precision-torqued, silver-alloy performance that is seen—but rarely heard.