In the electrical equipment industry, safety is paramount. Whether you’re specifying test instruments, designing electrical systems, or managing industrial facilities, understanding CAT ratings (Category ratings) is critical for protecting personnel and equipment from electrical hazards. These safety classifications, defined by the International Electrotechnical Commission (IEC), determine which environments electrical test and measurement equipment can safely operate in.

At VIOX Electric, we manufacture electrical equipment engineered to meet rigorous safety standards, including proper CAT rating specifications. This comprehensive guide explains what CAT ratings mean, why they matter, and how to select the appropriate rating for your applications.

What Are CAT Ratings?

CAT ratings are overvoltage categories established under IEC 61010-1, the international safety standard for electrical equipment used in measurement, control, and laboratory applications. The term “CAT” stands for “Category,” and these ratings classify electrical test equipment based on its ability to withstand transient overvoltages—sudden voltage spikes that occur in electrical systems.

The Purpose of CAT Ratings

CAT ratings serve several critical functions:

- Protect users from electric shock and arc flash incidents

- Prevent equipment failure caused by voltage transients

- Standardize safety requirements across the electrical industry

- Guide proper equipment selection for specific electrical environments

- Ensure compliance with workplace safety regulations (NFPA 70E, OSHA)

It’s essential to understand that CAT ratings are not simply voltage measurement ranges. A multimeter might measure up to 1000V, but its CAT rating determines how much transient energy it can safely withstand without catastrophic failure.

The Science Behind Transient Overvoltages

Electrical systems experience transient overvoltages—brief but powerful voltage spikes that can reach several thousand volts. These transients originate from:

- Lightning strikes coupled onto power lines

- Switching of large industrial loads (motors, transformers)

- Short circuit events

- Capacitor switching operations

- Utility power grid fluctuations

While these spikes last only microseconds (typically 50 µsec), they carry sufficient energy to cause equipment to arc, explode, or fail catastrophically. The closer you are to the power source, the higher the available fault current and the more powerful the transients become.

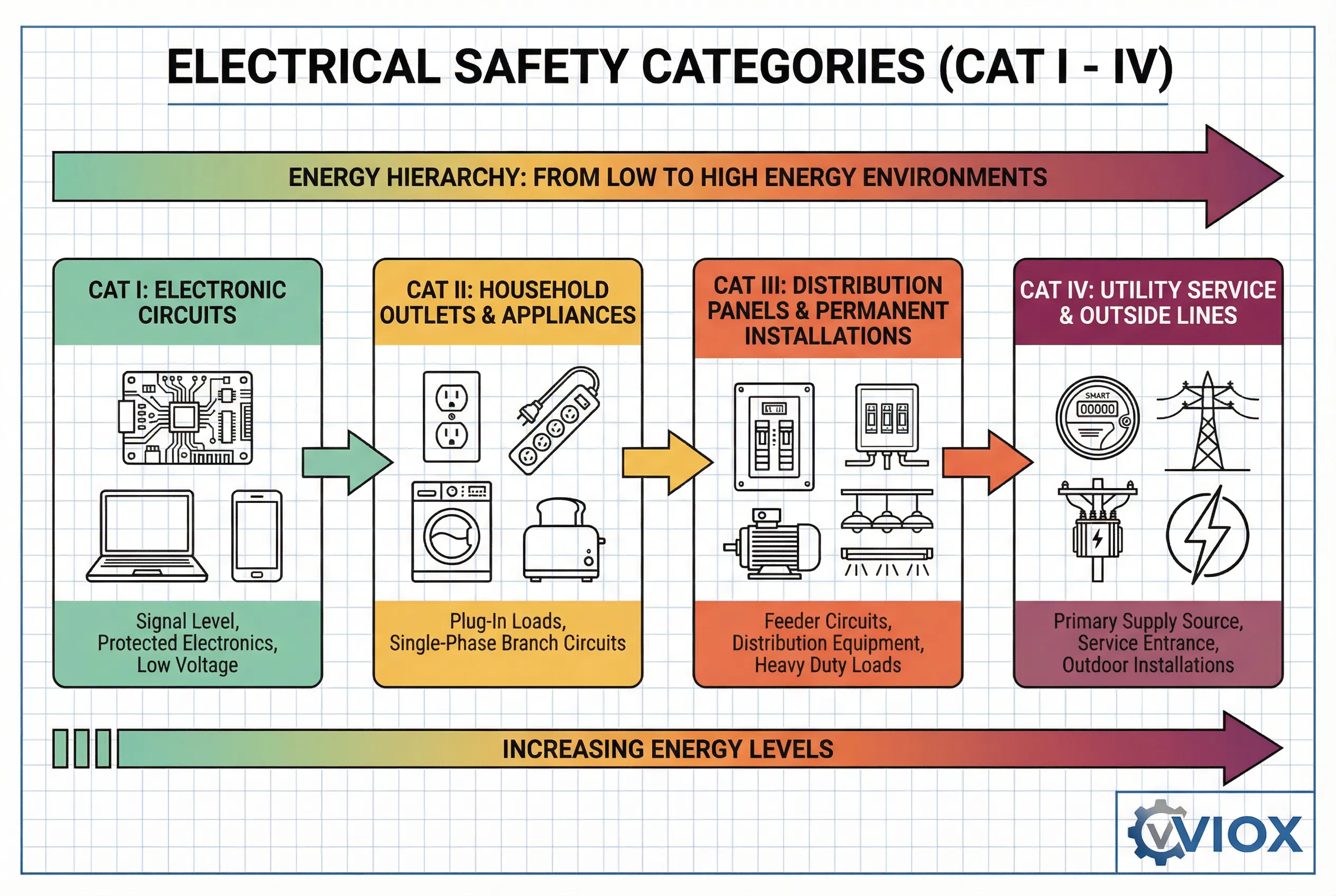

The Four CAT Rating Categories Explained

The IEC 61010-1 standard defines four measurement categories, each corresponding to different locations within an electrical distribution system:

CAT I: Protected Electronic Circuits

CAT I applies to measurements on circuits not directly connected to mains power or specially protected secondary circuits.

Typical Applications:

- Electronic circuits powered by regulated DC supplies

- Battery-operated devices

- Signal-level measurements

- Telecommunications equipment

- Protected low-voltage sensor circuits

- Laboratory bench equipment

Transient Protection Level: Up to 800V (at 150V working voltage)

Key Characteristic: Minimal risk of high-energy transients due to isolation from mains power.

CAT II: Single-Phase Receptacle Circuits

CAT II covers measurements on circuits connected to standard electrical outlets and plug-in loads.

Typical Applications:

- Household appliances (washing machines, refrigerators)

- Portable power tools

- Desktop computers and office equipment

- Residential wiring and outlet testing

- Point-of-use electrical devices

Transient Protection Level: Up to 4,000V (at 600V working voltage)

Key Characteristic: Suitable for end-user equipment and portable devices plugged into standard outlets.

CAT III: Fixed Building Installation Circuits

CAT III applies to measurements on permanently installed electrical distribution systems within buildings.

Typical Applications:

- Distribution panels and circuit breakers

- Three-phase distribution systems

- Bus bars and feeders

- Commercial lighting systems

- Fixed motors and HVAC equipment

- Switchgear and polyphase motors

- Photovoltaic (solar) installations

Transient Protection Level: Up to 6,000V (at 600V working voltage), 8,000V (at 1000V)

Key Characteristic: Higher energy environment with more powerful transients due to proximity to distribution equipment.

CAT IV: Utility Service and Primary Supply

CAT IV represents the highest level of protection for measurements at or near the power source.

Typical Applications:

- Utility electricity meters

- Primary overcurrent protection devices

- Service entrance equipment

- Outdoor power lines (overhead or underground)

- Underground utility vaults

- Service drop from pole to building

- Main service disconnects

Transient Protection Level: Up to 12,000V (at 1000V working voltage)

Key Characteristic: Maximum protection against the most severe transient overvoltages encountered at the utility level.

CAT Rating Comparison Table

| Category | Location in System | Transient Level (600V) | Transient Level (1000V) | Energy Level | Typical Applications |

|---|---|---|---|---|---|

| CAT I | Protected circuits | 800V | N/A | Lowest | Electronics, batteries, signals |

| CAT II | Outlet level | 4,000V | 2,500V | Low | Appliances, portable tools |

| CAT III | Distribution level | 6,000V | 8,000V | High | Panels, fixed equipment, solar |

| CAT IV | Utility service | 8,000V | 12,000V | Highest | Meters, service entrance, utility |

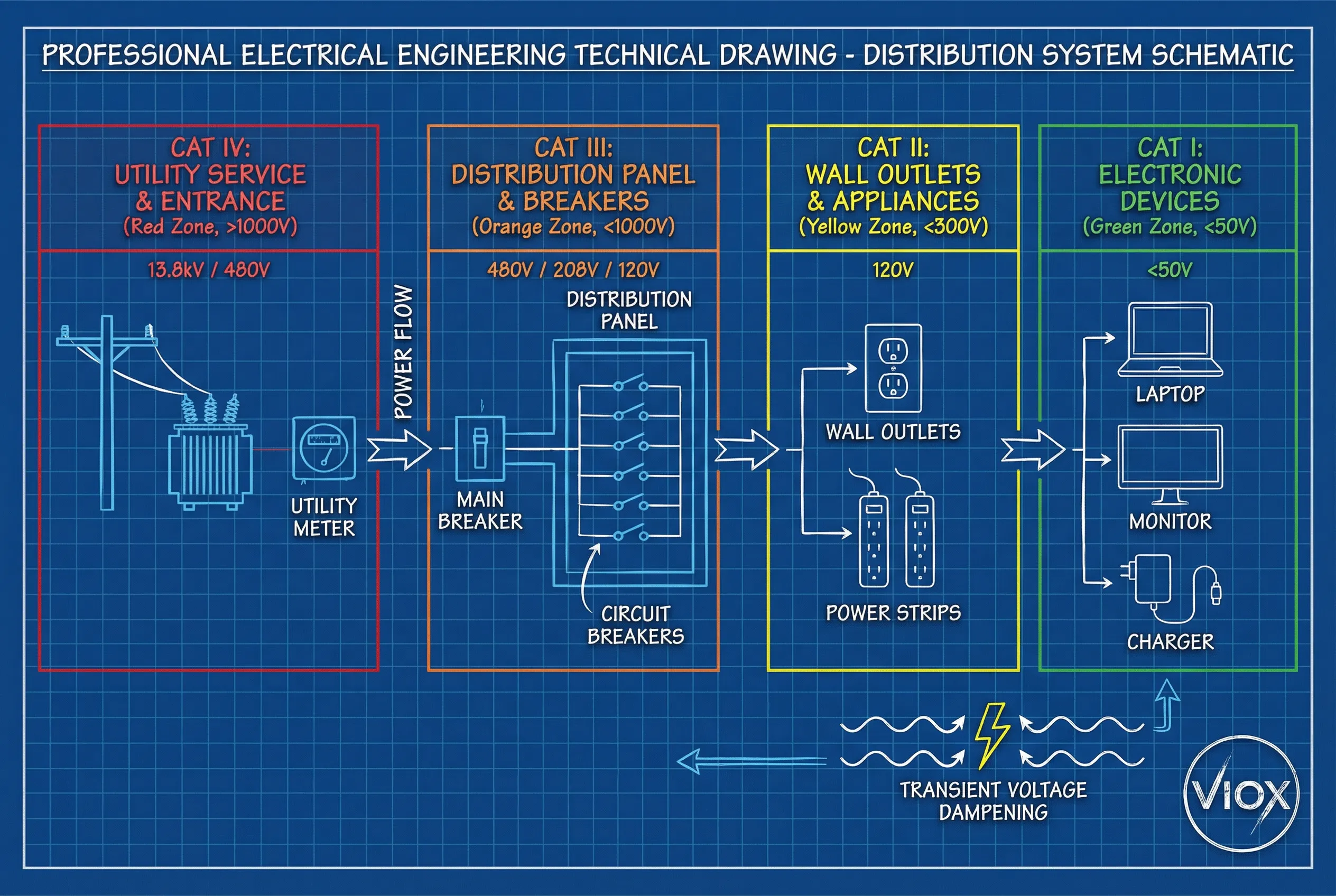

Understanding Voltage Ratings with CAT Categories

A complete CAT rating includes both a category and voltage level, such as “CAT III 600V” or “CAT IV 1000V.” This dual specification is crucial for proper equipment selection.

Important Principle: Category Trumps Voltage

A higher category at lower voltage provides more protection than a lower category at higher voltage.

Example:

- CAT IV 600V > CAT III 1000V > CAT II 1000V

Even though CAT II 1000V has a higher working voltage rating than CAT IV 600V, the CAT IV instrument provides superior transient protection due to its more robust internal design, greater creepage and clearance distances, and higher energy-withstanding capability.

Impulse Withstand Voltage (Uimp) Standards

| Working Voltage | CAT I | CAT II | CAT III | CAT IV |

|---|---|---|---|---|

| 50V | 500V | 500V | 800V | 1,500V |

| 150V | 800V | 2,500V | 4,000V | 6,000V |

| 300V | 1,500V | 4,000V | 6,000V | 8,000V |

| 600V | 2,500V | 4,000V | 6,000V | 8,000V |

| 1000V | 4,000V | 6,000V | 8,000V | 12,000V |

Why CAT Ratings Are Critical for Safety

The Consequences of Using Incorrect CAT Ratings

Forensic investigations of electrical accidents have revealed that using test equipment without proper CAT ratings—or with ratings insufficient for the task—can result in:

- Arc Flash Explosions: When transients exceed the equipment’s capability, internal components can fail, creating a plasma arc that propagates to the test leads

- Electric Shock: Insulation breakdown exposes users to dangerous voltages

- Equipment Destruction: Internal circuitry is destroyed instantly

- Fire Hazards: Failed equipment can ignite surrounding materials

- Severe Injuries or Fatalities: Burns, cardiac arrest, or explosive trauma to operators

According to the U.S. Bureau of Labor Statistics, hundreds of electrical workers are injured or killed annually due to arc flash and electrical shock incidents. Many of these accidents are preventable through proper equipment selection.

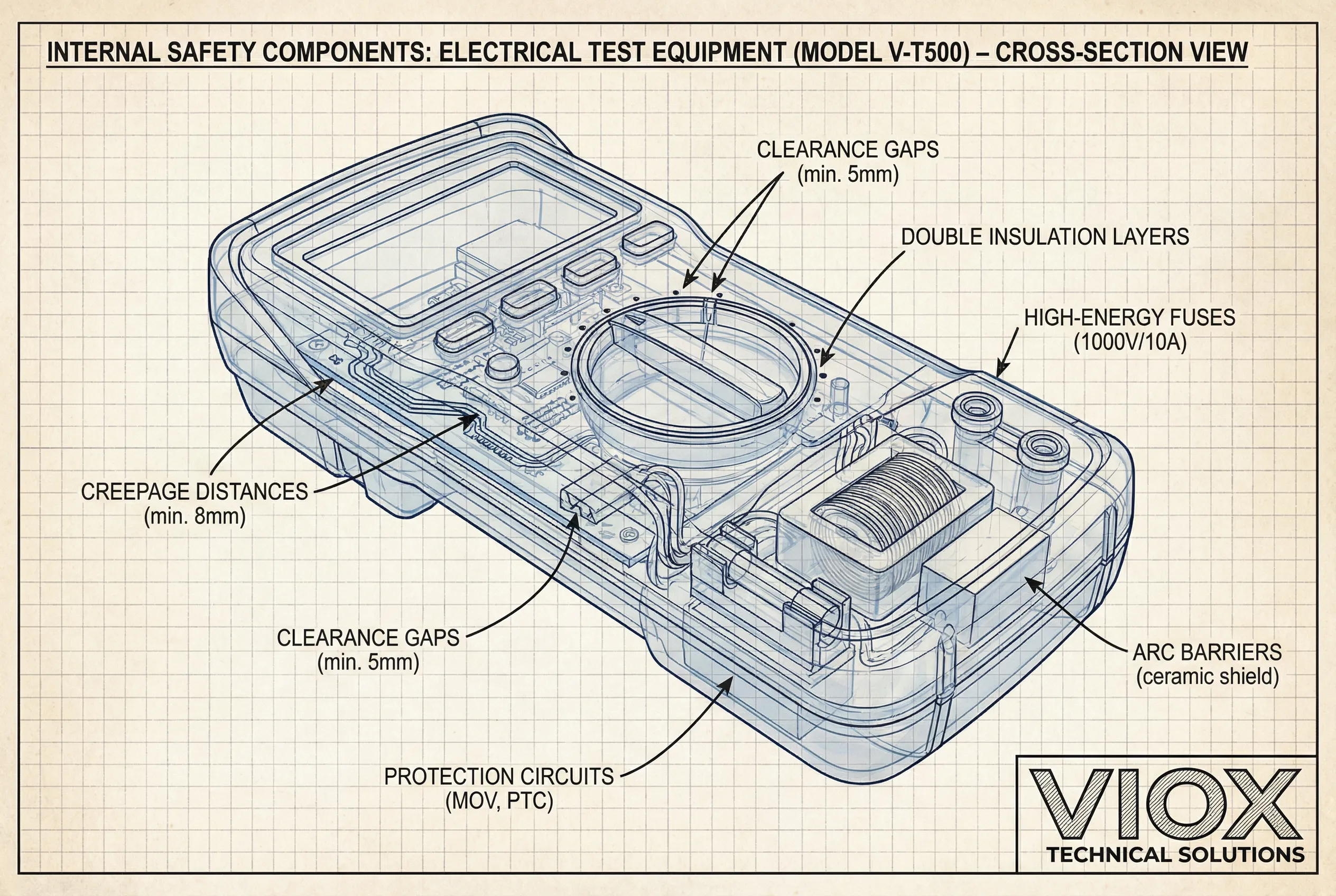

Design Features That Enable CAT Ratings

Test equipment certified for higher CAT ratings incorporates enhanced safety features:

- Increased Creepage and Clearance Distances: Greater physical separation between conductive parts

- Double Insulation Design: Multiple layers of insulation to prevent shock hazards

- High-Energy Fuses: Specially designed fuses rated to safely interrupt high fault currents

- Robust Internal Components: Materials and construction capable of withstanding transient energy

- Arc Barriers: Physical barriers that contain internal arcing

- Voltage Limiting Circuits: Protection systems that divert excess energy

How to Choose the Right CAT Rating

Step 1: Identify Your Work Environment

Determine where measurements will be performed:

- Electronics bench work → CAT I

- Residential outlets and appliances → CAT II

- Commercial distribution panels → CAT III

- Utility service equipment → CAT IV

Step 2: Select the Appropriate Category

Always choose equipment rated for the highest category you might encounter. You can safely use higher-rated equipment in lower-category environments, but never the reverse.

Step 3: Verify Voltage Rating

Ensure the voltage rating meets or exceeds the maximum voltage in your application:

- Residential/light commercial (120-240V) → 300V or 600V rating

- Industrial (277-480V) → 600V rating

- High-voltage industrial (up to 1000V) → 1000V rating

Step 4: Check Test Leads and Accessories

Critical: Test leads, probes, and accessories must have the same or higher CAT rating as the instrument. A high-rated meter with low-rated leads creates a dangerous mismatch.

Selection Guide by Application

| Application Type | Recommended CAT Rating | Voltage Rating |

|---|---|---|

| Electronic repair/development | CAT I | 300V |

| Residential HVAC service | CAT II | 600V |

| Commercial electrical maintenance | CAT III | 600V |

| Industrial facility management | CAT III | 1000V |

| Solar PV installation/testing | CAT III | 1500V |

| Utility meter reading | CAT IV | 600V |

| Service entrance work | CAT IV | 1000V |

Real-World Applications by Industry

Industrial Manufacturing

Manufacturing facilities require CAT III equipment for:

- Motor control center testing

- Distribution panel troubleshooting

- Production equipment maintenance

- Three-phase power monitoring

Commercial Construction

Electrical contractors need CAT III/IV equipment for:

- New installation verification

- Service entrance commissioning

- Load center testing

- Code compliance verification

Renewable Energy

Solar installers must use CAT III 1500V equipment for:

- Photovoltaic array testing (IEC 61730-1 classifies PV modules as CAT III)

- Inverter commissioning

- String voltage measurements

- System performance verification

Utilities and Power Distribution

Utility workers require CAT IV equipment for:

- Meter installation and reading

- Primary protection equipment testing

- Transformer maintenance

- Service drop verification

Compliance and Standards

Key Standards and Regulations

- IEC 61010-1: International safety standard for measurement equipment

- UL 61010B-1: North American version of IEC 61010-1

- CSA 22.2-1010.1: Canadian safety standard

- NFPA 70E: Standard for Electrical Safety in the Workplace

- OSHA 1910 Subpart S: Electrical safety regulations

- IEC 60664: Insulation coordination for low-voltage systems

Third-Party Certification

Reputable equipment should be certified by independent testing laboratories:

- UL (Underwriters Laboratories)

- TÜV (Technischer Überwachungsverein)

- CSA (Canadian Standards Association)

- CE marking (European Conformity)

Warning: Equipment without proper certification or with ambiguous markings like “CAT rated” (without specific category and voltage) should not be trusted for safety-critical applications.

VIOX Electric’s Commitment to Safety

At VIOX Electric, we design and manufacture electrical equipment with safety as our foremost priority. Our products undergo rigorous testing to meet and exceed IEC 61010-1 requirements, ensuring that every instrument provides the protection level indicated by its CAT rating.

Our Quality Assurance Process

- Design Validation: CAD modeling and simulation verify creepage/clearance distances

- Prototype Testing: Physical prototypes undergo impulse withstand testing

- Third-Party Certification: Independent laboratories verify compliance

- Production Quality Control: Every unit is tested before shipment

- Continuous Improvement: Field feedback drives ongoing design refinement

Frequently Asked Questions

Q1: Can I use a CAT II meter for CAT III applications?

No. Using equipment rated for a lower category than your work environment is extremely dangerous. The equipment may not withstand the transient voltages present, potentially causing arc flash explosions or electric shock. Always match or exceed the required category.

Q2: Why does my CAT III 600V meter cost more than a CAT II 1000V meter?

CAT III equipment requires more robust internal construction, greater creepage and clearance distances, high-energy fuses, and enhanced insulation systems. These design features increase manufacturing costs but provide superior protection against higher-energy transients, even though the working voltage may be lower.

Q3: Do I need to match CAT ratings for all accessories?

Yes. Test leads, probes, clamps, and all accessories must have CAT ratings equal to or exceeding your instrument’s rating. A CAT IV meter with CAT II leads creates a dangerous mismatch.

Q4: What’s the difference between working voltage and transient voltage?

Working voltage is the maximum continuous voltage the equipment can measure. Transient voltage is the brief spike the equipment can survive without damage or creating a shock hazard. CAT ratings primarily address transient protection, not measurement range.

Q5: Can CAT IV equipment be used for CAT I, II, or III applications?

Yes. You can always use higher-category equipment in lower-category environments. Using CAT IV equipment for CAT II work provides additional safety margin, though it may be more expensive than necessary.

Q6: How often should CAT-rated equipment be tested or recertified?

Follow manufacturer recommendations and workplace safety protocols (typically annual inspection). Visually inspect equipment before each use for damage to insulation, test leads, or probe tips. Any damaged equipment should be removed from service immediately, as damage can compromise CAT rating protection.

Conclusion: Prioritizing Safety Through Proper CAT Rating Selection

Understanding CAT ratings is not merely a technical specification—it’s a critical safety requirement that can prevent serious injury or death. By selecting test and measurement equipment with appropriate CAT ratings for your work environment, you protect yourself, your team, and your equipment from the invisible hazards of transient overvoltages.

Key Takeaways:

- CAT ratings indicate transient overvoltage protection, not just measurement range

- Higher category numbers provide greater protection against more powerful transients

- Always match equipment category to your work environment (or higher)

- Voltage rating and category rating work together—both must be appropriate

- Test leads and accessories must match the instrument’s CAT rating

- Only use certified equipment from reputable manufacturers

- Never compromise on safety to save costs

At VIOX Electric, we’re committed to providing electrical equipment that meets the highest safety standards. Whether you need CAT II instruments for residential work or CAT IV equipment for utility applications, our products deliver the protection and reliability your work demands.

For more information about VIOX Electric’s CAT-rated equipment and safety solutions, contact our technical team or visit viox.com.

About VIOX Electric: VIOX Electric is a leading B2B manufacturer of electrical equipment, specializing in test instruments, measurement devices, and power distribution solutions engineered to meet international safety standards. With decades of industry experience, VIOX Electric serves electrical contractors, industrial facilities, utilities, and renewable energy professionals worldwide.