A spider box is a portable power distribution unit that converts a single high-amperage electrical feed into multiple protected circuits at the point of use. Also called a temporary power distribution box or portable power center, spider boxes are purpose-built for job sites, events, and temporary installations where crews need safe, weather-resistant power close to the work.

Unlike permanent electrical panels, spider boxes combine rugged outdoor-rated enclosures with ground-fault circuit interrupter (GFCI) protection and circuit breakers in a compact, mobile package. The name “spider” comes from the multiple outlet “legs” extending from a central power source—similar to how a spider’s legs radiate from its body. These units typically accept a 50-amp, 125/250-volt single-phase input via a locking inlet and distribute power through multiple 15-amp or 20-amp GFCI-protected receptacles, plus optional higher-amperage locking outlets for heavy equipment.

For contractors, facility managers, and event professionals, spider boxes solve a critical challenge: delivering compliant temporary power that meets Occupational Safety and Health Administration (OSHA) and National Electrical Code (NEC) requirements without the complexity and cost of installing permanent wiring. VIOX Electric manufactures industrial-grade spider boxes designed for demanding B2B applications where safety, durability, and regulatory compliance are non-negotiable.

How Spider Boxes Work

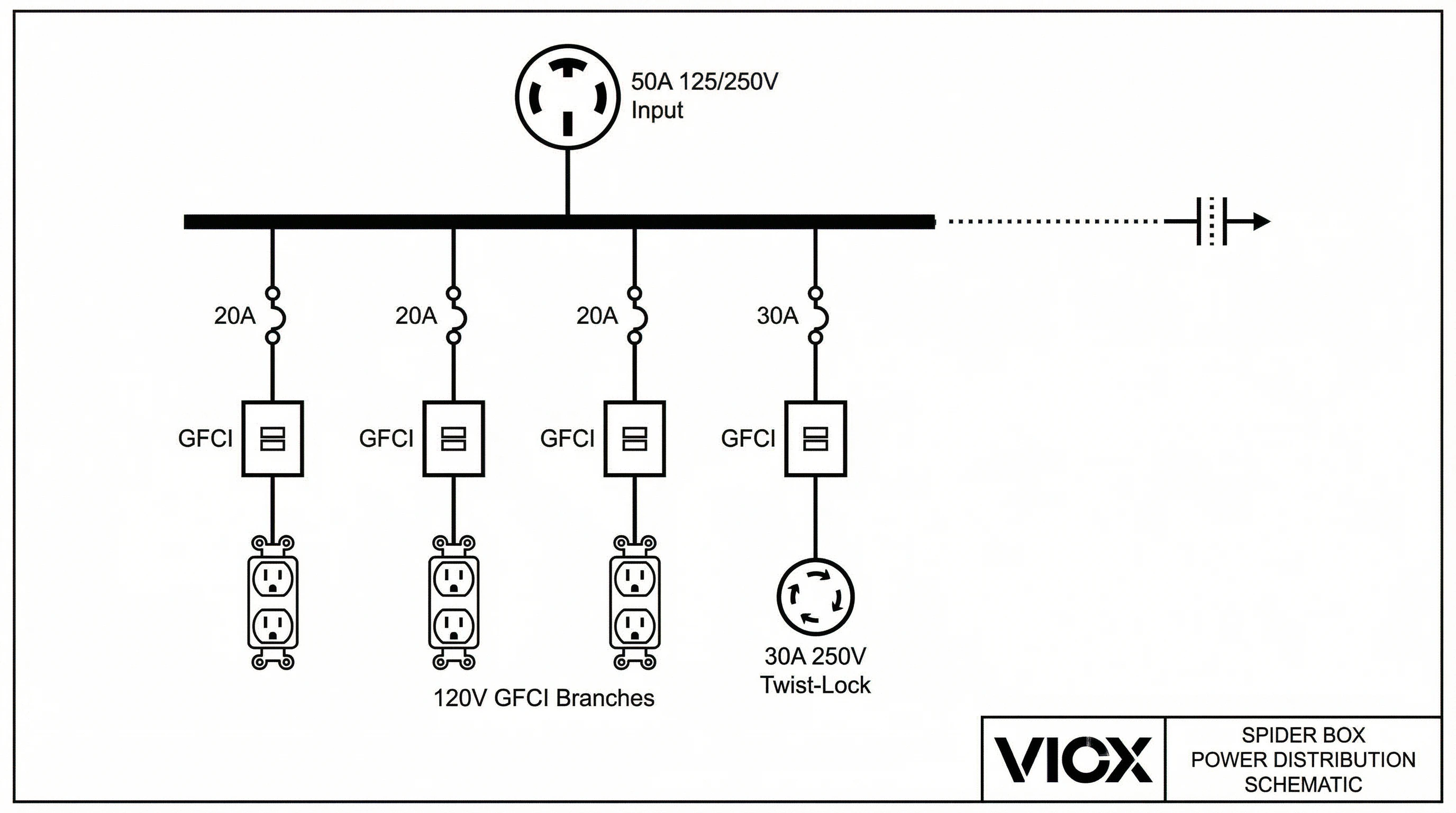

Spider boxes function as mobile sub-distribution panels, stepping down power from a primary source and splitting it into multiple protected branch circuits. The operational workflow follows a straightforward path from input to output:

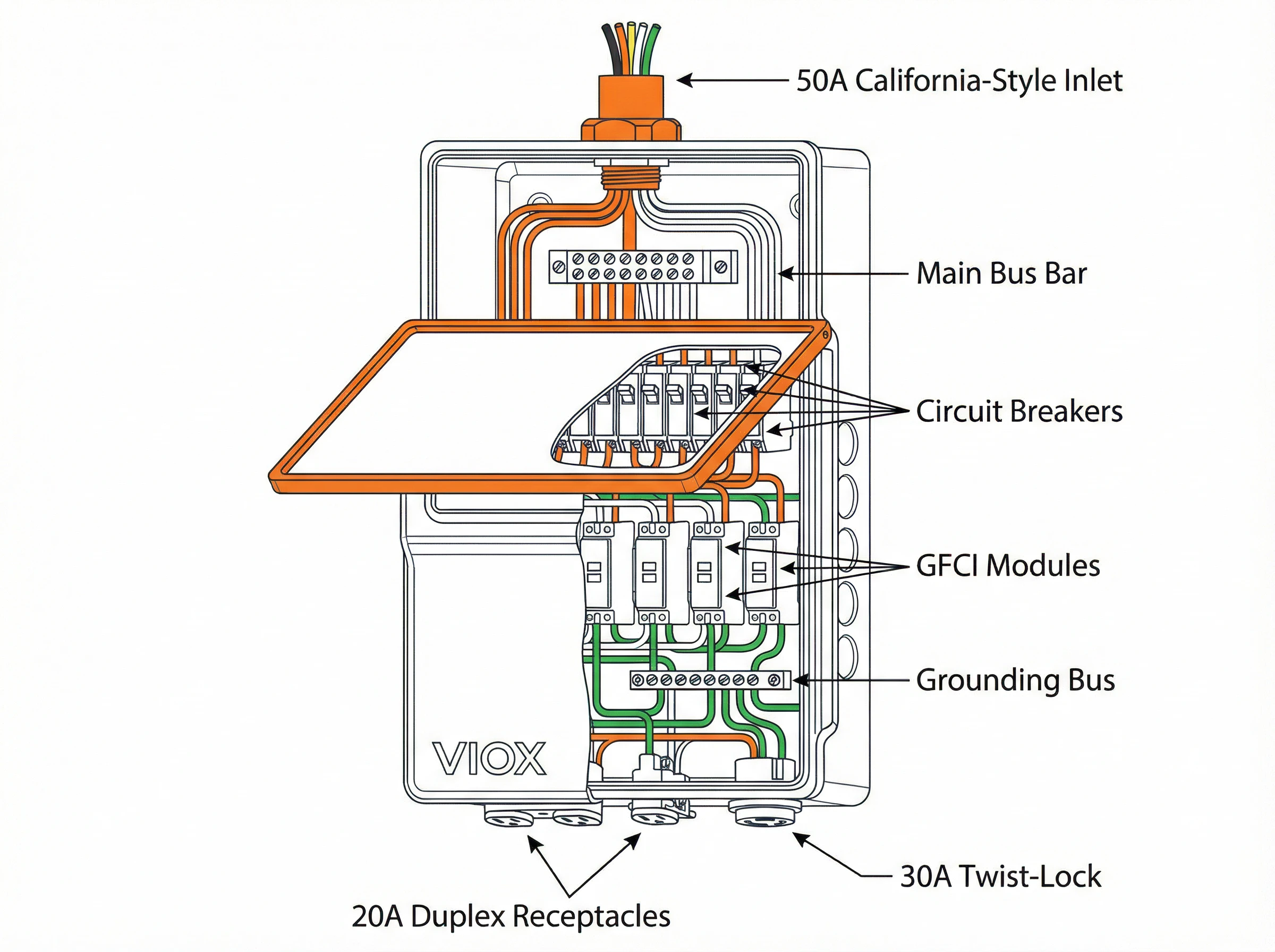

Power Input: A qualified electrician connects the spider box to a generator, temporary service panel, or permanent power source using an appropriate cable assembly and locking connector. Most industrial spider boxes use a 50-amp California-style locking inlet (CS6365C or similar), which provides secure connections that resist accidental disconnection. Many units also feature feed-through outlets on the input side, allowing crews to daisy-chain multiple spider boxes along a single power run—reducing cable requirements and extending distribution reach across large sites.

Internal Distribution: Inside the enclosure, the incoming power feeds a main bus that branches to individual circuit breakers. Each breaker protects a dedicated circuit, typically rated at 15 or 20 amps for general-purpose duplex receptacles. Advanced models incorporate thermal-magnetic circuit breakers that respond to both overload (sustained current above rating) and short-circuit (instantaneous high current) conditions. The breakers mount under a hinged, weather-resistant lid that keeps moisture, dust, and debris away from live terminals while allowing authorized personnel to reset tripped circuits.

GFCI Protection: After passing through the breaker, power flows to GFCI modules that monitor current balance between hot and neutral conductors. If the GFCI detects a ground fault—typically a 5-milliamp imbalance indicating current leakage through a person or damaged equipment—it trips within 25 milliseconds, cutting power before serious injury occurs. Modern spider boxes often use “open-neutral” GFCI technology that reduces nuisance trips caused by multi-wire branch circuits or shared neutrals, a common frustration on construction sites.

Output Receptacles: The final stage delivers power to standard NEMA 5-20R duplex receptacles (the familiar 120-volt outlets) and specialized locking receptacles for higher loads. A typical 50-amp spider box might provide six to eight 20-amp duplex outlets plus one 30-amp L14-30R locking receptacle for equipment like welders, compressors, or large power tools. Weather-resistant covers protect unused outlets from rain, snow, and jobsite contaminants.

Key Components & Specifications

Understanding the major components helps buyers specify the right spider box and troubleshoot issues in the field. Here’s what’s inside a professional-grade unit:

Enclosure: The outer housing determines durability and environmental protection. Industrial spider boxes typically use molded rubber, reinforced thermoplastic, or powder-coated steel construction. National Electrical Manufacturers Association (NEMA) ratings indicate protection level—NEMA 3R is standard for outdoor use, providing resistance to rain, sleet, and ice formation while remaining ventilated to prevent condensation. Heavy-duty models may offer NEMA 4 or 4X ratings for hose-directed water or corrosive environments. Look for elevated mounting legs that keep the enclosure several inches above grade, preventing water ingress from puddles and improving cooling airflow.

Input Connection: The power inlet accepts the incoming feed. Locking connectors—such as California-style (CS6365C), Hubbell (HBL460C9W), or IEC 60309 pin-and-sleeve types—provide mechanical retention superior to standard plugs. Input voltage and current ratings must match or exceed the upstream source; common configurations include 50A at 125/250V single-phase or 60A at 250V. Feed-through capability (a second inlet or output connector on the input side) enables daisy-chaining without splicing or Y-adapters.

Circuit Breakers: These protect branch circuits from overload and short circuits. Thermal-magnetic breakers combine a bimetallic strip (responds to sustained overload by heating and bending) with an electromagnetic coil (responds instantly to short-circuit current). Breaker ratings typically match outlet circuits: 15A or 20A for duplex receptacles, 30A for locking outlets. UL 489 (Molded-Case Circuit Breakers) or UL 1077 (Supplementary Protectors) listings confirm safety testing. Quality spider boxes use trip-free breakers that cannot be held closed against an overload condition.

GFCI Modules: Ground-fault protection is mandatory for most temporary power applications. GFCI devices continuously compare current in the hot and neutral conductors; any difference above the trip threshold (typically 5 mA ± 1 mA) indicates leakage to ground and triggers an immediate disconnect. Class A GFCIs (5 mA trip) protect personnel, while older Class B (20 mA trip) devices are obsolete for new installations. Open-neutral detection prevents the GFCI from operating with a lost neutral, which could create dangerous floating ground conditions. Look for self-test GFCIs (required in some jurisdictions) that automatically verify functionality.

Output Receptacles: Outlets deliver power to connected loads. Standard configurations include NEMA 5-20R duplex receptacles (20A, 125V, common for hand tools and lighting) and locking twist-lock receptacles like L14-30R (30A, 125/250V, for equipment requiring 240V or high 120V current). Weather-resistant (WR) receptacles with spring-loaded covers meet NEC requirements for wet locations. In-use covers allow cords to remain plugged in while maintaining weather protection—essential for continuous operation in rain or snow.

Wiring and Grounding: Internal conductors must meet NEC ampacity and insulation requirements. Copper wire sized per NEC Table 310.16 ensures safe current-carrying capacity; typical spider boxes use 6 AWG for 50A input and 12 AWG for 20A branch circuits. Ground continuity is critical—verify that the enclosure, all receptacles, and the input connector bond to a common grounding bus connected to the equipment grounding conductor in the supply cable.

Types & Configurations

Spider boxes come in various sizes and outlet arrangements to match different applications:

By Input Rating: The input amperage determines total available power. Entry-level 30-amp spider boxes suit small crews or light-duty tasks—think residential remodels or service calls. Standard 50-amp models handle typical commercial construction with multiple trades working simultaneously. Heavy-duty 60-amp or 100-amp units support industrial shutdowns, large events, or high-demand temporary installations. Input voltage may be single-phase 125/250V (most common), 208V three-phase, or 480V three-phase for specialized industrial applications.

By Outlet Configuration: The mix of receptacles defines versatility. Basic models provide four to six 20-amp duplex GFCI outlets—sufficient for hand tools, lighting, and small equipment. Standard configurations add one 30-amp twist-lock (L14-30R) for higher loads like welders or compressors. Premium models include multiple locking receptacles at different voltages (120V, 208V, 240V) to power diverse equipment without adapters. Some spider boxes incorporate built-in voltmeters or hour meters for monitoring and billing.

By Environment: Construction-grade spider boxes use NEMA 3R enclosures—outdoor-rated but not submersible. Marine or offshore models feature NEMA 4X stainless steel construction with gasket seals to resist salt spray and corrosive atmospheres. Hazardous location spider boxes rated for Class I Division 2 or ATEX zones incorporate explosion-proof enclosures and special sealing for petrochemical or mining sites. Entertainment-grade units add cosmetic features like low-profile designs or quiet-close lids for backstage use.

| Configuration Type | Input Rating | Typical Outlets | NEMA Rating | Typical Applications |

|---|---|---|---|---|

| Light-Duty | 30A, 125/250V | 4× 20A duplex GFCI | 3R | Residential remodels, service calls, small crews |

| Standard Construction | 50A, 125/250V | 6× 20A duplex GFCI 1× 30A L14-30R |

3R | Commercial construction, multi-trade jobsites |

| Heavy-Duty Industrial | 60-100A, 125/250V or 208V | 8× 20A duplex GFCI 2× 30A twist-lock 1× 50A receptacle |

3R or 4 | Industrial maintenance, large events, high-demand sites |

| Marine/Offshore | 50A, 125/250V | 6× 20A duplex GFCI 1× 30A twist-lock |

4X (stainless) | Offshore platforms, shipyards, coastal installations |

| Hazardous Location | 30-50A | 4-6× 20A GFCI | Class I Div 2 | Petrochemical, mining, refineries |

| Entertainment/Event | 50A, 125/250V | 6-8× 20A duplex GFCI 1-2× 30A twist-lock |

3R | Concert venues, film production, outdoor festivals |

Safety Standards & Compliance

Regulatory compliance isn’t optional for temporary power—it’s a legal requirement that protects workers and limits liability. Spider boxes must meet multiple overlapping standards:

OSHA 1926.404 (Construction Sites): The Occupational Safety and Health Administration mandates ground-fault protection for all 120-volt, single-phase, 15- and 20-ampere receptacles used on construction sites that are not part of permanent building wiring. Most contractors choose GFCI-equipped spider boxes because they eliminate the administrative burden of maintaining an assured grounding program.

NEC Article 590 (Temporary Installations): The National Electrical Code governs temporary wiring for construction, remodeling, maintenance, repair, demolition, and similar activities. Section 590.6 requires ground-fault protection for personnel on all 125-volt, single-phase, 15-, 20-, and 30-ampere receptacle outlets that are not part of permanent wiring—essentially mirroring OSHA requirements but extending coverage to 30-amp circuits. Spider boxes must also meet NEC requirements for overcurrent protection (Article 240), enclosure ratings for the environment (Article 110.28), and grounding/bonding (Article 250).

UL Listings: Underwriters Laboratories (UL) testing verifies product safety. Look for spider boxes listed to UL 1640 (Portable Power Distribution Equipment). cULus marks indicate compliance with both U.S. and Canadian standards.

NEMA Enclosure Standards: NEMA 250 defines enclosure protection levels. NEMA 3R is the minimum for outdoor temporary power—it protects against rain, sleet, and ice but includes ventilation openings that allow airflow. NEMA 4 adds protection against hose-directed water and splashing, making it suitable for wash-down environments or severe weather. NEMA 4X substitutes corrosion-resistant materials (stainless steel, fiberglass) for coastal or chemical exposure. Indoor-only spider boxes may use NEMA 1, but these are rare in B2B applications where equipment frequently moves between indoor and outdoor locations.

Canadian Standards (CEC): The Canadian Electrical Code includes similar GFCI requirements under Section 26-700 (Temporary Wiring). Products for Canadian markets should carry cUL certification.

Inspection and Testing: GFCI-equipped spider boxes should be tested monthly using the built-in test button—press TEST to trip the device, then RESET to restore power. Any GFCI that fails requires immediate replacement. Document all tests for OSHA compliance and liability protection.

Applications & Use Cases

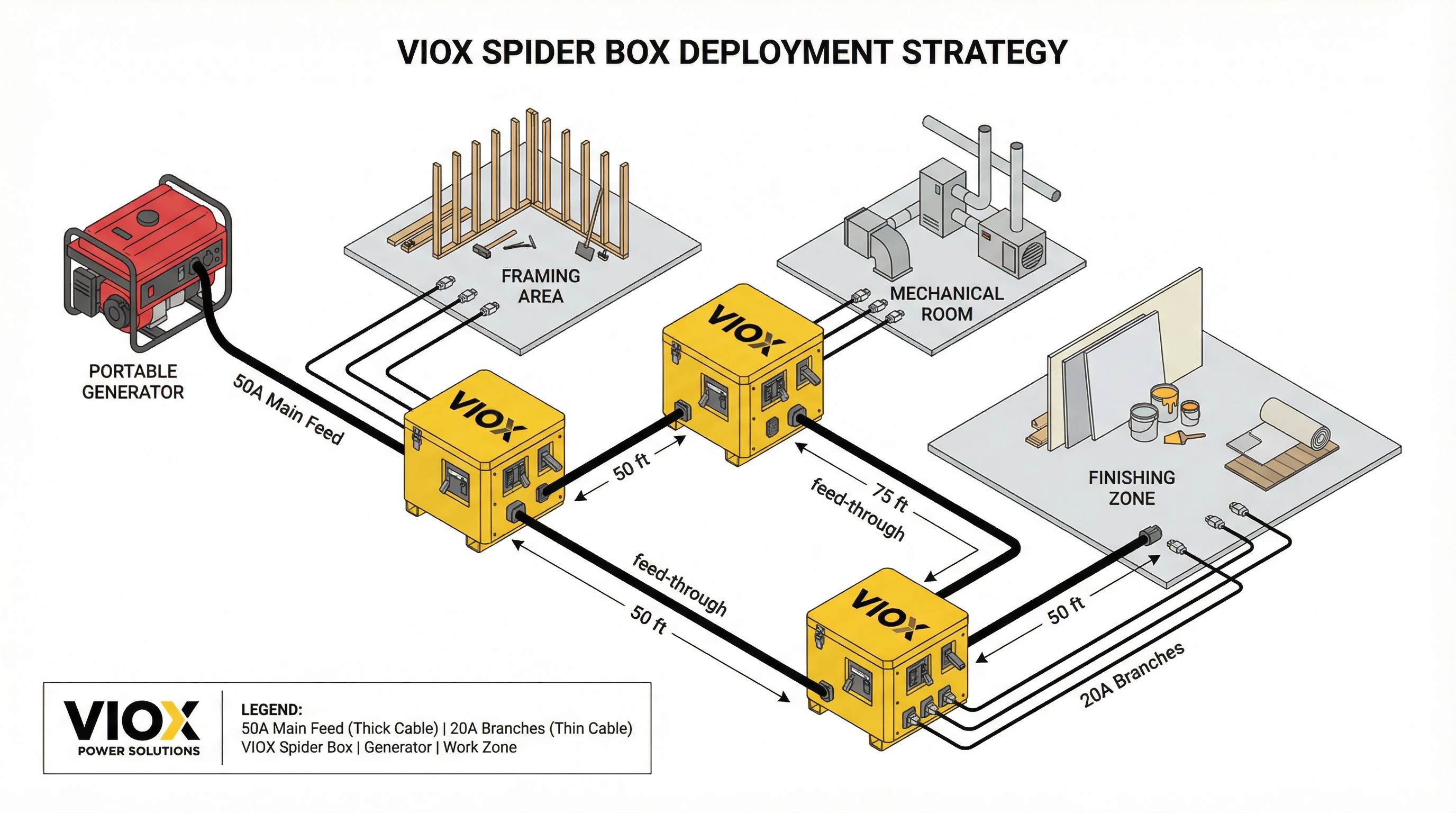

Construction Sites: Spider boxes excel where crews need mobile power that moves with the work. Connect units to a central generator or temporary service panel, then place them in each work zone—framing area, mechanical room, finishing spaces. Feed-through capability lets you daisy-chain boxes along one power run, minimizing cable cost and voltage drop. GFCI protection meets OSHA requirements automatically, passing inspections without additional paperwork.

Industrial Maintenance and Shutdowns: During plant turnarounds or equipment overhauls, spider boxes provide temporary power for welding, grinding, and diagnostic equipment without tapping into production circuits. Portable units deploy in hours rather than days required for temporary panel installation. Locking receptacles prevent accidental disconnection of critical loads.

Events and Entertainment: Concert venues, festivals, and outdoor events use spider boxes to distribute power from generators to lighting, sound systems, concessions, and vendor booths. Weather-resistant construction handles rain and mud. Hour meters (on some models) enable accurate billing when equipment is rented. Feed-through layouts reduce cable clutter and trip hazards in high-traffic areas.

Emergency Response and Disaster Recovery: After storms, floods, or other disruptions, spider boxes pair with portable generators to restore temporary power for lighting, tools, pumps, and communication equipment. Rugged construction survives transport in trucks and trailers. NEMA 3R enclosures function in debris-filled environments where indoor-rated equipment would fail.

Agricultural Operations: Farms and processing facilities use spider boxes during harvest, maintenance, and construction projects. Units power irrigation pumps, grain handling equipment, and temporary structures. Corrosion-resistant models withstand fertilizers, pesticides, and wash-down procedures.

How to Select the Right Spider Box

Choose spider boxes by working backward from your loads. Calculate total connected load (add nameplate wattages), apply a 125% safety factor per NEC, and select an input rating that provides headroom. Match outlet types to your equipment—standard NEMA 5-20R for hand tools and lighting, twist-locks for equipment requiring secure connections. Verify NEMA enclosure rating matches your environment: 3R for typical outdoor use, 4X for corrosive locations.

| Solution | Input | Outputs | GFCI | Portability | Best For |

|---|---|---|---|---|---|

| Spider Box | 30-100A locking inlet | Multiple 15-30A receptacles | Yes, integrated | High (carry handles, compact) | Multi-trade jobsites, distributed loads |

| Portable Generator | Built-in alternator | 2-6 outlets on panel | Optional | Medium (wheels, heavy) | Remote locations, no utility power |

| Temporary Power Panel | Hardwired/cam-lok | Multiple breakers, feeders | At branch level | Low (fixed installation) | Large sites, centralized distribution |

| Extension Cord GFCI | Plug-in | 1-3 outlets | Yes, inline | High (lightweight) | Single tool, short runs |

Frequently Asked Questions

What is a spider box used for?

A spider box distributes temporary electrical power from a single high-amperage source to multiple protected outlets at the point of use. Common applications include construction sites, events, industrial maintenance, and emergency response.

Do spider boxes require GFCI protection?

Yes. OSHA 1926.404 and NEC Article 590 require ground-fault circuit interrupter (GFCI) protection for all 120-volt, 15-, 20-, and 30-amp receptacles used in temporary installations on construction sites. Most spider boxes integrate GFCI protection to meet this requirement automatically.

What does “California-style” mean on a spider box?

California-style refers to the CS6365C (or equivalent) 50-amp, 125/250-volt locking inlet connector widely used in portable power distribution. The term describes the connector type, not a geographic restriction—these spider boxes work nationwide.

Can spider boxes be used outdoors?

Yes, provided they carry an appropriate NEMA rating. NEMA 3R spider boxes are designed for outdoor use and resist rain, sleet, and ice. For harsh environments (salt spray, corrosive chemicals, hose wash-down), specify NEMA 4X models.

How do I daisy-chain multiple spider boxes?

Use models with feed-through capability: an input connector on one end and a matching output connector on the other. Connect the first spider box to your power source, then run a cable from its feed-through outlet to the input of the next box. This extends power distribution along a single run without splicing.