6:15 AM. Your phone rings.

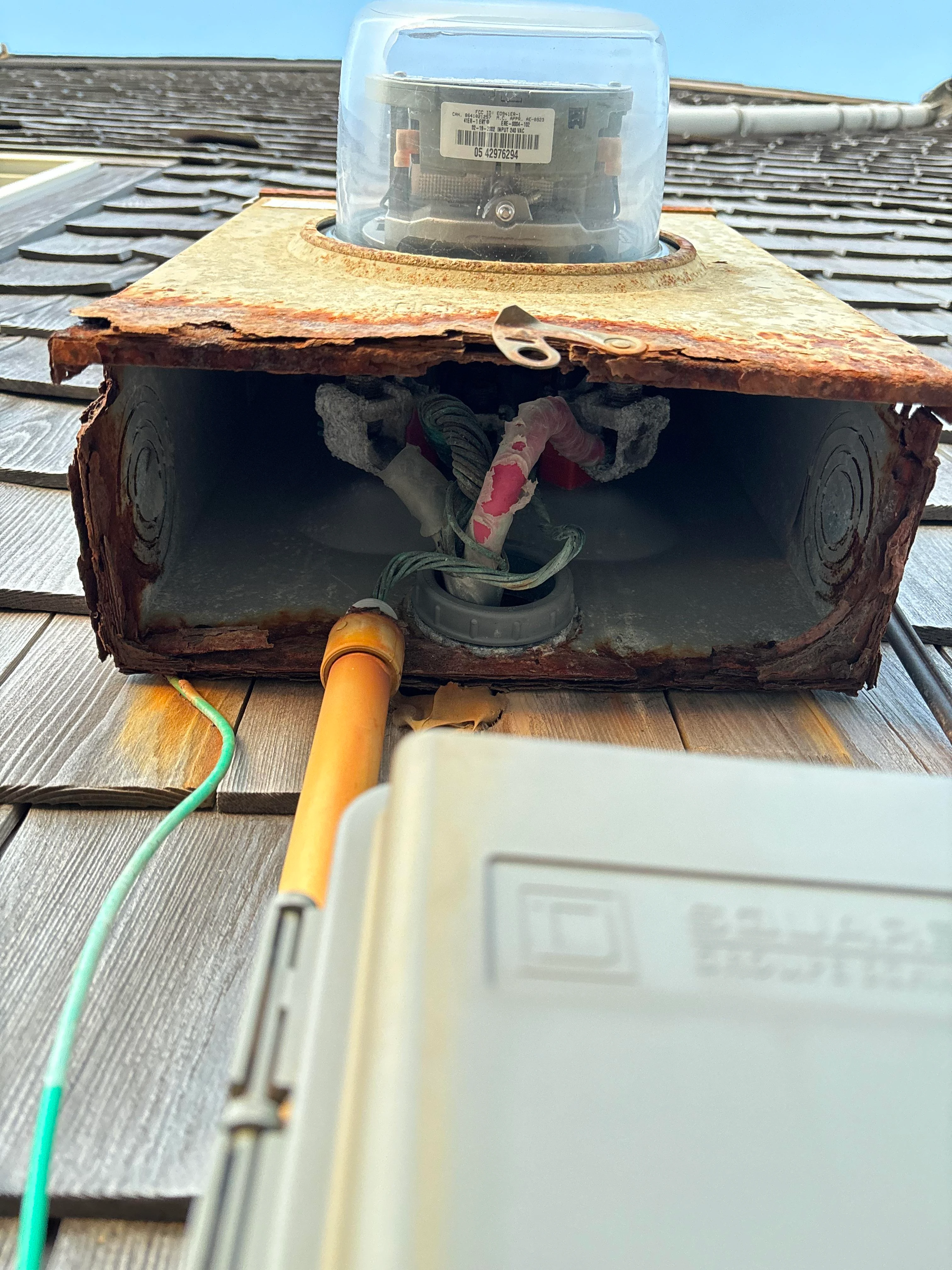

It’s the facilities manager at the marina you wired six months ago. The outdoor lighting panel is dead. When the electrician opens the junction box mounted on the building exterior, salt-crusted terminals and corroded wire ends tell the whole story. Water got in. Corrosion spread. The circuit failed.

The callback costs $2,800 in labor and materials—replacing corroded components, rewiring, and upgrading to proper weatherproof enclosures. The original standard junction box cost $12. The IP65 weatherproof box you should have specified? $35.

So what actually separates a weatherproof junction box from a standard one—and how do you choose the right protection level so this never happens to you?

Quick Answer: Weatherproof vs Standard Junction Boxes

The core difference comes down to tested environmental protection. Standard junction boxes (typically NEMA Type 1 or indoor-rated) provide basic protection against dust and incidental contact in dry, controlled indoor environments. They use simple snap-on or screw-on covers with no gasket seals, cable entries are often knockout holes with basic connectors, and materials like painted steel or basic ABS plastic offer minimal corrosion resistance.

Weatherproof junction boxes are engineered enclosures with validated protection against environmental ingress. They’re rated under IP (Ingress Protection) standards like IP65, IP66, IP67, or IP68, or NEMA standards like Type 3R, 4, 4X, 6, and 6P. These boxes feature continuous gasket seals on covers, threaded cable glands with compression fittings, and corrosion-resistant materials like UV-stabilized polycarbonate, die-cast aluminum, or stainless steel.

This isn’t just a price difference—it’s The Protection Divide. IP and NEMA ratings represent validated test protocols that predict real-world durability. Choose the wrong side of that divide, and you’re not just risking equipment—you’re guaranteeing a failure mode.

Here’s how they compare across critical specifications:

| Specification | Standard Junction Box | Weatherproof Junction Box |

| Primary Function | Protect wire splices in dry indoor environments | Protect wire splices in wet, outdoor, or harsh environments |

| Typical Ratings | NEMA Type 1 (indoor, basic protection) | IP65–IP68; NEMA 3R, 4, 4X, 6, 6P (outdoor, wet, submersible) |

| Dust Protection | Limited (small particle ingress possible) | IP5X (dust protected) to IP6X (dust-tight, zero ingress) |

| Water Protection | None (not rated for wet exposure) | IPX5 (water jets) to IPX8 (continuous submersion) |

| Seal Construction | No gasket; simple snap-on or screw cover | Continuous gasket seal (EPDM, silicone, polyurethane) |

| Cable Entry | Knockouts with basic connectors; no sealing | Threaded cable glands with compression seals; IP-rated entries |

| Materials | Painted steel, basic ABS plastic | UV-stabilized polycarbonate, die-cast aluminum, 304 stainless steel |

| Temperature Range | −17°C to 80°C typical (ABS); limited outdoor exposure | −40°C to 120°C (polycarbonate); designed for extreme temps and UV exposure |

| Corrosion Resistance | Minimal (painted steel rusts; ABS degrades in UV) | High (polycarbonate UV-stabilized; aluminum/stainless naturally resistant) |

| NEC Wet Location | ❌ Not listed for wet locations (fails NEC 314.15) | ✅ Listed for wet locations per NEC 314.15 |

| Best Use Cases | Indoor electrical rooms, dry basements, protected utility spaces | Outdoor walls, parking lots, rooftops, coastal areas, underground vaults |

| Typical Cost Range | $5–$20 per box | $25–$50 (polycarbonate IP65); $160–$340 (stainless IP66/IP68) |

| Expected Lifespan | 5–10 years indoors; < 2 years outdoors (corrosion/UV degradation) | 15–25+ years outdoors (UV-stable materials, sealed construction) |

Notice the stark divide in protection capability and durability? That $2,800 callback from the opening happens when you treat a $10 cost difference as negotiable instead of recognizing it as the price of validated environmental protection.

What “Weatherproof” Actually Means: IP Ratings and NEMA Standards

“Weatherproof” isn’t a vague marketing term—it’s shorthand for tested, validated protection levels defined by international and North American standards. When you see an IP65 rating or NEMA Type 4X marking, you’re looking at the results of specific test protocols that simulate real-world environmental exposure.

Two standards govern weatherproof junction boxes:

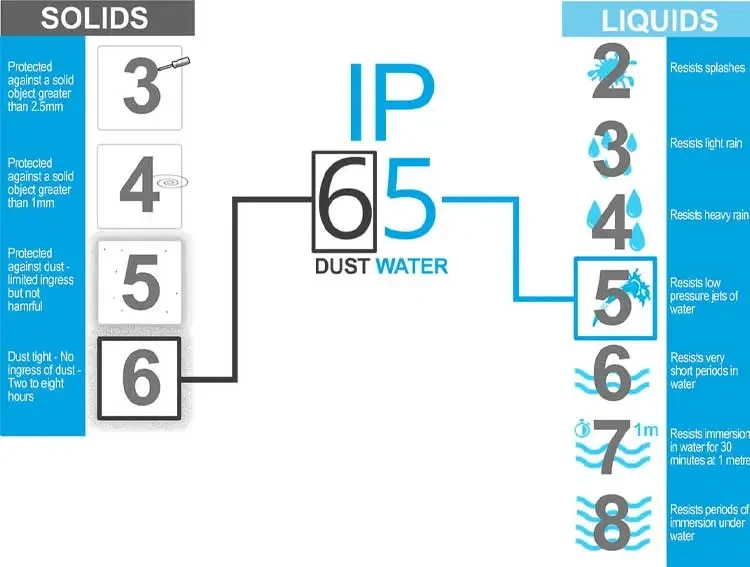

IEC 60529 (IP Code): The international standard defining Ingress Protection ratings. Published by the International Electrotechnical Commission and maintained by IEC Technical Committee 70, the current consolidated edition (1989+A1:1999+A2:2013) applies to electrical and electronic equipment enclosures up to 72.5 kV. The IP Code uses a two-digit format—IPXX—where the first digit rates solid particle protection (0–6) and the second digit rates liquid ingress protection (0–9). As of December 2025, IEC 60529 remains the global reference for IP ratings.

NEMA 250 (Enclosures for Electrical Equipment): The North American standard published by the National Electrical Manufacturers Association. NEMA 250 defines enclosure types for specific environmental conditions—indoor, outdoor, corrosive, hazardous—and includes tests that go beyond IP ratings. Where IEC 60529 focuses solely on dust and water ingress, NEMA 250 adds requirements for corrosion resistance (salt spray testing), ice loading (Type 3S), and functionality in hazardous locations. NEMA types are not directly equivalent to IP ratings, though NEMA 250’s Annex A provides a rough conversion table.

Pro-tip: In North American installations, specify NEMA types to ensure NEC compliance and AHJ (Authority Having Jurisdiction) approval. For international projects or when targeting specific dust/water exposure scenarios, specify IP ratings. Don’t assume they’re interchangeable—NEMA tests cover conditions (like corrosion and icing) that IP ratings don’t address.

The IP Rating System: Decoding the Numbers

The IP Code breaks down environmental protection into two independent dimensions: solid particle ingress (first digit) and liquid ingress (second digit). Understanding what each number actually tests—not just the label—tells you whether a box will survive your specific environment.

First Digit: Dust and Solid Particle Protection (IPXX)

For junction boxes, only two ratings matter in practice:

IP5X – Dust Protected

Limited dust ingress is permitted, but not in amounts that would interfere with safe operation or accumulate to hazardous levels. The test exposes the enclosure to airborne dust (talcum powder or similar) in a sealed chamber for 8 hours while the enclosure is under negative pressure (to simulate worst-case ingress). After the test, internal inspection confirms no harmful dust accumulation.

Practical reality: IP5X is adequate for most outdoor applications where occasional fine dust is expected but won’t accumulate to damaging levels—think building exteriors in urban/suburban areas, parking lot lighting, HVAC equipment pads.

IP6X – Dust-Tight

Zero dust ingress. Complete protection against contact with internal parts. The test uses the same dust chamber protocol as IP5X, but the pass criterion is stricter: absolutely no visible dust inside the enclosure after 8 hours of negative-pressure exposure.

Practical reality: IP6X is required for harsh industrial environments (cement plants, mining operations, grain handling), desert installations, and anywhere dust accumulation would cause electrical failures or create combustible dust hazards.

Pro-tip: The Dust Divide. IP5X vs IP6X is the difference between “dust won’t hurt it” and “dust can’t get in.” For most commercial outdoor installations (parking lots, building exteriors), IP5X is sufficient and costs less. For industrial environments where dust is abrasive or conductive, pay the premium for IP6X.

Second Digit: Water and Liquid Ingress Protection (IPXX)

This is where weatherproof ratings get specific—and where many specifiers make costly mistakes.

IPX5 – Water Jets

Protection against water jets from any direction. The test uses a 6.3 mm nozzle delivering 12.5 liters per minute at 30 kPa (4.4 psi) from a distance of 3 meters, spraying the enclosure from all angles for 3 minutes per square meter of surface area. The pass criterion: no water ingress that would interfere with safe operation.

Practical reality: IPX5 handles heavy rain, splashing from nearby equipment, and occasional hose-down cleaning (low-pressure garden hose). It’s the minimum for outdoor junction boxes exposed to driving rain.

IPX6 – Powerful Water Jets

Protection against powerful water jets. The test escalates to a 12.5 mm nozzle delivering 100 liters per minute at 100 kPa (14.5 psi) from a distance of 3 meters. Duration and pass criteria match IPX5.

Practical reality: IPX6 is required where high-pressure washdown is expected—food processing facilities, chemical plants, marine deck installations, car wash equipment areas. If someone might clean it with a pressure washer (intentionally or accidentally), you need IPX6 minimum.

IPX7 – Temporary Immersion

Protection against temporary immersion up to 1 meter depth for 30 minutes. The test submerges the enclosure with its lowest point 1 meter below the water surface and its highest point 0.15 meters below the surface (or fully submerged for small enclosures). After 30 minutes, internal inspection confirms no water ingress causing harmful effects.

Practical reality: IPX7 is necessary for junction boxes subject to temporary flooding—outdoor ground-level installations in flood-prone areas, underground vaults with occasional water intrusion, landscape lighting subjected to sprinkler overspray.

IPX8 – Continuous Immersion

Protection against continuous immersion at depths and durations specified by the manufacturer (typically 1.5 to 3 meters for extended periods). The test conditions are manufacturer-declared and validated during certification—there’s no single “IPX8 test” like there is for IPX7.

Practical reality: IPX8 is mandatory for permanently submerged applications—underwater lighting, sump pump connections, below-grade utility vaults subject to standing water. Always confirm the manufacturer’s declared test depth and duration match your application.

The Immersion Trap: IPX7/IPX8 ≠ IPX5/IPX6

Here’s the critical mistake that catches many specifiers: water protection ratings are not cumulative. An IPX7-rated enclosure has passed temporary immersion testing, but it has not necessarily passed jet testing (IPX5 or IPX6). The IEC 60529 standard explicitly states that immersion tests (IPX7/IPX8) and jet tests (IPX5/IPX6) validate different protection mechanisms, and passing one does not imply passing the other.

Why this matters: A junction box rated IP67 (dust-tight, temporary immersion) might fail catastrophically when hit with a pressure washer. The gasket and cable gland seals designed to keep out standing water may not withstand directional water pressure. If your application involves both potential immersion and jet exposure (like an outdoor installation that floods occasionally but also gets cleaned with a hose), you need a box with dual certification—marked IP65/IP67 or IP66/IP68, indicating it passed both test regimes.

Pro-tip: Always check for dual IP markings when both water jets and immersion are possible. A box marked “IP67” alone tells you it handles flooding but says nothing about jet resistance. A box marked “IP65/IP67” has passed both tests and handles both exposures.

NEMA Ratings for North America: Types 3R, 4, 4X, 6, 6P

While IP ratings dominate international specifications, North American installations typically reference NEMA 250 enclosure types. NEMA ratings aren’t just rebranded IP numbers—they add environmental and functional requirements (corrosion resistance, ice loading, hazardous area provisions) that go beyond dust and water ingress.

Here are the NEMA types relevant to weatherproof junction boxes:

Type 3R – Outdoor Rain, Sleet, and Snow

Designed for outdoor use where protection against rain, sleet, snow, and external ice formation is required. Type 3R provides no protection against dust, windblown dust, or hose-directed water—it’s strictly for vertical precipitation. The enclosure must prevent rain and sleet from entering when falling at any angle up to 15 degrees from vertical.

Practical reality: Type 3R is the minimum for general outdoor installations where rain is the primary concern—outdoor junction boxes on building walls, pole-mounted equipment, rooftop installations. It’s cost-effective but inadequate for dusty environments or locations subject to washing.

NEMA-to-IP rough equivalent: Approximately IP24 (protected against solid objects > 12 mm and water splashing from any direction). Note this equivalence is directional guidance, not certification.

Type 4 – Outdoor Watertight

Provides protection against rain, snow, windblown dust, splashing water, and hose-directed water. Type 4 must remain watertight when subjected to a water stream (not as severe as a pressure washer, but more aggressive than rain).

Practical reality: Type 4 is necessary for installations subject to water beyond simple rain—equipment subject to spray from nearby processes, locations near loading docks or wash areas, or anywhere hose-down cleaning might occur. It protects against windblown dust, making it suitable for dusty outdoor environments.

NEMA-to-IP rough equivalent: Approximately IP66 (dust-tight, powerful water jets). Again, this is guidance, not equivalence—NEMA Type 4 testing includes specific water stream tests different from IPX6 protocols.

Type 4X – Outdoor Watertight, Corrosion-Resistant

All the protection of Type 4, plus enhanced corrosion resistance. Type 4X enclosures are constructed from stainless steel, fiberglass-reinforced polyester, polycarbonate, or other materials that pass 200+ hours of salt spray testing per ASTM B117.

Practical reality: Type 4X is mandatory for coastal installations (within 10 miles of salt water), chemical processing environments, food/beverage facilities (frequent chemical washdown), and anywhere corrosive contaminants are present. The cost premium over Type 4 (typically 20-40%) pays for materials that won’t corrode under salt spray or chemical exposure.

Pro-tip: The Corrosion Tax. If you’re within sight or smell of the ocean, or if the facility uses corrosive cleaning agents, spec Type 4X from the start. Replacing corroded Type 4 boxes in year 3 costs far more than the initial 4X premium.

Type 6 – Submersible, Temporary Immersion

Provides all the protection of Type 4, plus resistance to temporary submersion at a limited depth (typically 6 feet for 30 minutes, per manufacturer declaration). Type 6 must be watertight under static water pressure and pass water ingress tests after submersion.

Practical reality: Type 6 is required for ground-level outdoor installations subject to flooding—underground vaults with occasional water intrusion, low-lying areas prone to storm water accumulation, or installations near bodies of water with seasonal high water.

NEMA-to-IP rough equivalent: Approximately IP67 (dust-tight, temporary immersion up to 1 meter).

Type 6P – Submersible, Prolonged Immersion

Provides all Type 6 protection plus resistance to prolonged submersion at greater depths (manufacturer-specified, typically 20+ feet for extended duration). Type 6P enclosures must remain watertight under higher static pressure and often feature reinforced construction and enhanced seal designs.

Practical reality: Type 6P is necessary for below-grade utility vaults with standing water, pump stations, sewer lift stations, and any permanently submerged or frequently flooded application. This is the highest NEMA water protection available.

NEMA-to-IP rough equivalent: Approximately IP68 (dust-tight, continuous immersion per manufacturer specs).

NEMA vs IP: Why You Can’t Just Convert

NEMA 250 Annex A includes a conversion table mapping NEMA types to approximate IP ratings, but this creates dangerous overconfidence. NEMA and IP test different things:

- NEMA includes corrosion testing: Salt spray tests (ASTM B117) for Type 3X, 4X, and 6P. IP ratings don’t address corrosion at all.

- NEMA includes ice loading tests: Type 3S requires the enclosure to remain operable when covered with ice. IP has no equivalent.

- NEMA specifies construction features: Latches, hinges, mounting provisions. IP only tests ingress, not mechanical functionality.

- NEMA addresses hazardous locations: Some NEMA types (12, 12K) target specific industrial environments. IP doesn’t classify hazardous areas.

When you’re working under NEC jurisdiction or need AHJ approval in North America, specify NEMA types. The building inspector won’t accept “it’s IP66, which is like NEMA 4” as compliance. For international projects or when you need precise dust/water ingress specifications, use IP ratings.

Construction Differences: How Weatherproof Boxes Seal Out Water

The protection level ratings—IP65, NEMA 4X, etc.—aren’t achieved through magic. They’re the result of specific construction techniques that create barriers against environmental ingress. Understanding how weatherproof boxes are built tells you what to inspect during receiving, installation, and maintenance.

Gasket Seal Systems

The primary defense against water ingress is the gasket seal between the box body and cover. Standard indoor junction boxes use metal-to-metal or plastic-to-plastic contact with no resilient seal material. Water, dust, and air pass freely through the gaps. Weatherproof boxes employ continuous gasket seals that compress when the cover is secured, creating a barrier.

Gasket materials and applications:

- EPDM (Ethylene Propylene Diene Monomer): Excellent resistance to UV, ozone, and weathering. Temperature range −40°C to +120°C. Widely used in outdoor IP65/IP66 boxes. Degrades in contact with oils and petroleum products.

- Silicone: Superior temperature range (−55°C to +200°C), excellent UV and weathering resistance. More expensive than EPDM. Used in high-temperature environments and where extreme weather cycling occurs.

- Polyurethane foam (FIPFG – Formed-In-Place Foam Gasketing): A continuous bead of expanding polyurethane foam is applied to the box mating surface during manufacturing, creating a custom-fit gasket profile. Common in polycarbonate enclosures. Good sealing performance but less durable than EPDM for repeated open/close cycles.

- Neoprene: Good general-purpose gasket material with moderate oil resistance. Temperature range −30°C to +100°C. Less common than EPDM in modern weatherproof boxes.

Gasket profiles:

- Flat compression gasket: A flat strip of gasket material sits in a groove on one mating surface. Simple, low-cost, effective for IP65 when properly compressed.

- O-ring seal: A round-profile gasket seated in a groove provides superior sealing performance under high compression. Common in IP67/IP68 submersible boxes.

- Tongue-and-groove with gasket: The box and cover feature interlocking profiles with a gasket seated in the groove. Provides alignment and consistent compression. Often used in NEMA 4X and IP66 designs.

Pro-tip: The Gasket Gamble. Gasket seals degrade over time, especially in UV exposure and thermal cycling. When inspecting weatherproof boxes during maintenance, check the gasket for cracking, compression set (permanent deformation), or hardening. A degraded gasket turns your IP65 box into an IP20 failure waiting to happen. Replace gaskets every 5–7 years in harsh outdoor environments.

Cable Entry Sealing

A perfect gasket seal on the cover is worthless if water pours in through unsealed cable entries. Weatherproof junction boxes use threaded cable glands (also called cord grips or cable connectors) that create compression seals around incoming cables.

Cable gland construction:

- Threaded body: NPT (National Pipe Thread) or metric threads screw into threaded knockouts or pre-formed holes in the box. The threads create a mechanical seal against the box wall.

- Compression insert: Inside the gland, a rubber or elastomer insert compresses around the cable jacket when the gland’s compression nut is tightened. This creates a water-tight seal on the cable.

- IP rating: Quality cable glands carry their own IP ratings (often IP68) and must be properly sized to the cable diameter to achieve rated performance.

Installation critical point: Cable glands must be tightened to the manufacturer’s specified torque. Under-tightened glands leak. Over-tightened glands can crush cable insulation. Use a torque wrench or calibrated installer when IP67/IP68 protection is required.

For unused cable entry points, weatherproof boxes include threaded plugs or blanking plates that seal the holes. Never leave an unused knockout open on a weatherproof box—it’s a direct water entry path that bypasses all other sealing.

Material Corrosion Resistance

Seals prevent water from entering, but material selection determines what happens when water eventually gets in (gasket failure, condensation, or incidental exposure during maintenance).

Polycarbonate (UV-stabilized):

A thermoplastic polymer with high impact resistance, excellent weathering properties, and broad temperature range (−40°C to +120°C). UV stabilizers prevent yellowing and embrittlement from sunlight exposure. Naturally corrosion-resistant because it’s non-metallic. Clear polycarbonate versions allow visual inspection without opening the box.

Best for: General outdoor installations, rooftop equipment, parking lot lighting, commercial building exteriors. Cost-effective weatherproof solution for most applications.

Limitations: Not suitable for high-RF environments (no shielding), can be scratched or gouged more easily than metal, limited chemical resistance (some solvents and cleaners attack polycarbonate).

Die-cast aluminum:

Lightweight metal with natural corrosion resistance from surface oxide layer. Provides electromagnetic shielding (important for sensitive electronics). Easier to machine than stainless steel for custom modifications. Dissipates heat better than plastic.

Best for: Industrial control panels, RF/EMI-sensitive applications, locations requiring metal enclosures for grounding/shielding, moderate corrosive environments.

Limitations: Aluminum can corrode in highly corrosive environments (coastal salt spray, chemical exposure). More prone to denting from impact than polycarbonate or stainless. Thermal expansion/contraction can stress gaskets in extreme temperature cycling.

304 Stainless Steel:

Iron-chromium-nickel alloy (typically 18% chromium, 8% nickel) with exceptional corrosion resistance. The chromium forms a passive oxide layer that self-heals when scratched. Highly resistant to pitting, crevice corrosion, and stress corrosion cracking. Superior scratch and impact resistance.

Best for: Coastal installations (marine environments, offshore platforms), chemical processing facilities, food/beverage processing (frequent washdown with harsh cleaners), high-vandalism areas, applications demanding 25+ year service life.

Limitations: Highest cost (2–4× polycarbonate). Heavier (complicates mounting). Difficult to machine for field modifications. Can still corrode in extreme environments (e.g., concentrated chlorides, high-temperature acid exposure).

316 Stainless Steel (optional upgrade):

Adds molybdenum (2–3%) to 304’s composition, providing superior resistance to chlorides and marine environments. Specify 316 SS for permanent offshore installations or chemical plants with chlorinated process streams. Cost premium over 304: typically 30–50%.

When Standard Boxes Fail: Real-World Failure Modes

Protection ratings aren’t abstract numbers—they predict specific failure modes that occur when environmental exposure exceeds the enclosure’s tested capability. Here’s what happens when you use a standard junction box in conditions that demand weatherproof protection.

Failure Mode 1: Direct Water Ingress and Conductor Corrosion

Rain or spray enters through unsealed cover gaps and cable entries. Water accumulates on the bottom of the box, submerging the lowest conductors and wire nut connections. Copper conductors oxidize (green corrosion), connection resistance increases, heat builds up at corroded joints, and insulation eventually fails or conductors open-circuit.

Time to failure: 6–18 months in moderate outdoor exposure (building exterior, covered but exposed to wind-blown rain). 2–6 months in aggressive exposure (direct rain, coastal salt spray).

Cost: $800–$3,000 per failed box (labor to diagnose, replace corroded conductors, install proper weatherproof enclosure, plus downtime costs).

Failure Mode 2: Internal Condensation in Sealed Boxes

This is the sneaky one. A standard box is installed “under a soffit” or “in a protected location” where it won’t see direct rain. Temperature cycling (hot day, cool night) causes air inside the box to expand and contract, drawing moisture-laden air in through unsealed gaps. When the box cools at night, water vapor condenses on internal surfaces and conductors. Over hundreds of thermal cycles, corrosion builds up even though the box never sees a drop of rain.

Time to failure: 12–36 months depending on daily temperature swing and humidity. Coastal installations accelerate this (salt in the air deposits with each condensation cycle).

Cost: Similar to Mode 1, but harder to diagnose (“it’s under cover, how did water get in?”), leading to repeat failures if the root cause (condensation) isn’t recognized.

Pro-tip: The Condensation Trap. “Protected location” doesn’t mean “no moisture.” Any outdoor installation with daily temperature swings above 15°C creates condensation risk. Use weatherproof boxes with sealed cable entries even in covered locations to prevent moisture-laden air cycling.

Failure Mode 3: UV Degradation of Non-Stabilized Plastics

Basic ABS plastic junction boxes turn brittle after 12–24 months of direct sunlight exposure. UV radiation breaks down the polymer chains. The box becomes fragile—a moderate impact (maintenance activity, hail, windborne debris) cracks the enclosure. Once cracked, water ingress follows, leading to Mode 1 failure.

Time to failure: 12–24 months for embrittlement, plus 6–12 months from crack to electrical failure.

Cost: $500–$1,500 (enclosure replacement, labor, typically discovered during routine maintenance or after weather event).

Failure Mode 4: Fastener and Hinge Corrosion

Standard junction boxes use uncoated steel screws, hinges, and latches. In outdoor exposure, these corrode first (preferential galvanic corrosion at dissimilar metal junctions). Corroded screws seize (can’t remove cover for maintenance). Corroded hinges fail (cover detaches). Corroded latches fail to secure the cover (wind blows it open, water ingress follows).

Time to failure: 6–12 months in coastal environments, 12–24 months inland.

Cost: $300–$800 (might be repairable with stainless fastener replacement, but often requires full enclosure replacement once corrosion spreads to box body).

Failure Mode 5: Dust Accumulation and Tracking

In dusty industrial or desert environments, fine dust enters through unsealed gaps. Over time, dust accumulates on bus bars, terminals, and conductors. Moisture (humidity, condensation) combines with conductive dust to create tracking paths—gradual electrical breakdown across insulation. The result: intermittent short circuits, arcing, and eventual catastrophic failure (fire risk).

Time to failure: Highly variable (6 months to 5+ years) depending on dust conductivity and moisture levels.

Cost: $1,000–$5,000+ (includes fire damage potential, equipment replacement, investigation costs, possible insurance involvement).

Application Decision Guide: Matching Protection to Environment

Choosing between standard and weatherproof junction boxes—and selecting the right weatherproof rating—comes down to systematically evaluating your installation environment against protection test criteria. Here’s the decision framework:

Step 1: Determine Location Category

Indoor, Climate-Controlled (no special protection required)

Environment: Interior electrical rooms, office spaces, residential interiors, conditioned server rooms.

Exposure: Stable temperature, low humidity, no dust beyond normal building levels, no water exposure.

Recommended: Standard NEMA Type 1 junction box. No need to pay for weatherproof protection.

Indoor, Non-Climate-Controlled (dust protection may be needed)

Environment: Warehouses, unheated storage, mechanical rooms, garages.

Exposure: Temperature cycling, moderate humidity, dust from ventilation or activities, occasional moisture (leaks, condensation).

Recommended: Standard NEMA 1 for clean warehouses. Consider NEMA 12 (industrial, dust-tight) for dusty manufacturing areas. Consider NEMA 4 for mechanical rooms with washdown or high humidity.

Outdoor, Protected from Direct Precipitation

Environment: Under roof overhangs, soffits, inside weatherproof cabinets or shelters.

Exposure: Temperature cycling, humidity (condensation risk), wind-blown dust, indirect moisture, UV exposure.

Recommended: Minimum IP54 or NEMA 3R. Better: IP65 or NEMA 4 to prevent condensation-driven failures. Use UV-stabilized polycarbonate even in “protected” locations if box is visible from outdoors (indirect UV still degrades non-stabilized plastic).

Outdoor, Direct Precipitation Exposure

Environment: Building exterior walls, rooftops, pole-mounted equipment, parking lot lighting.

Exposure: Rain, snow, sleet, UV, temperature cycling, wind, humidity.

Recommended: Minimum NEMA 3R or IP65. For dusty environments (industrial sites, construction areas), upgrade to NEMA 4 or IP66 for dust-tight protection.

Outdoor, Hose-Down or High-Pressure Wash Areas

Environment: Food processing exteriors, chemical plants, car wash facilities, loading docks, marine deck equipment.

Exposure: High-pressure water jets, chemicals, temperature cycling, UV.

Recommended: Minimum NEMA 4 or IP66. If corrosive chemicals are present (salt water, cleaning agents), specify NEMA 4X with stainless steel or chemical-resistant polycarbonate.

Flood-Prone or Temporary Submersion Risk

Environment: Ground-level installations in flood zones, low-lying areas, near storm drains, landscape lighting.

Exposure: Temporary submersion (hours to days), standing water, silt/debris.

Recommended: Minimum NEMA 6 or IP67. Ensure all cable entries are sealed with IP68-rated cable glands. Mount boxes above expected flood level when possible.

Permanent Submersion or Below-Grade Vaults

Environment: Utility vaults with standing water, sump locations, underwater lighting, pump stations.

Exposure: Continuous or frequent submersion, hydrostatic pressure, silt, potential contaminants.

Recommended: NEMA 6P or IP68. Confirm manufacturer’s declared test depth and duration exceed your application. Use 316 stainless steel if corrosive water is present.

Step 2: Evaluate Corrosive Environment

Coastal (within 10 miles of salt water):

Salt spray accelerates corrosion dramatically. Standard painted steel boxes fail in 12–18 months. Specify NEMA 4X minimum. Material: stainless steel (304 SS for most coastal; 316 SS for direct surf zone or offshore). Alternative: heavy-duty UV-stabilized polycarbonate with stainless hardware.

Chemical Processing or Washdown Facilities:

Chemical exposure and frequent high-pressure cleaning. Specify NEMA 4X. Material: 316 stainless steel if halogenated cleaners or acids are used. Polycarbonate suitable for mild alkaline cleaners only (check chemical compatibility charts).

Industrial Corrosive (paper mills, waste treatment, petrochemical):

Airborne corrosive contaminants. Specify NEMA 4X. Material selection depends on specific contaminants—consult compatibility charts. Stainless steel (304 or 316) generally best choice.

Non-Corrosive (standard outdoor, no salt or chemicals):

NEMA 4 or IP66 adequate. Material: polycarbonate cost-effective for most applications. Aluminum acceptable if RF shielding needed.

Step 3: Consider Temperature Extremes

Standard Range (−10°C to +50°C):

Most materials and gaskets perform well. Standard EPDM or polyurethane gaskets acceptable.

Cold Extremes (below −20°C):

Some gasket materials become brittle. Specify silicone gaskets (rated to −55°C). Polycarbonate remains ductile to −40°C. Avoid ABS (becomes brittle below −17°C).

Hot Extremes (above +60°C ambient):

Direct sun on dark enclosures can push internal temperatures to +80°C or higher. Specify silicone gaskets. Polycarbonate handles +120°C. Consider aluminum or stainless steel enclosures for superior heat dissipation if internal components are heat-sensitive.

Step 4: Decision Matrix

| Application Environment | Minimum Rating | Recommended Material | Estimated Cost Premium vs Standard |

| Indoor, climate-controlled | NEMA 1 / IP20 | Painted steel, basic ABS | Baseline ($5–$20) |

| Outdoor, protected, no corrosion | NEMA 3R / IP54 | UV-stabilized polycarbonate | +60–100% ($15–$35) |

| Outdoor, rain, no corrosion | NEMA 4 / IP65 | UV-stabilized polycarbonate | +100–150% ($25–$50) |

| Outdoor, dusty industrial | NEMA 4 / IP66 | Polycarbonate or die-cast aluminum | +120–180% ($30–$60) |

| Outdoor, coastal (within 10 mi of ocean) | NEMA 4X / IP66 | 304 stainless steel | +400–600% ($160–$240) |

| High-pressure washdown, corrosive | NEMA 4X / IP66 | 316 stainless steel | +500–700% ($200–$340) |

| Temporary submersion, flood-prone | NEMA 6 / IP67 | Polycarbonate or aluminum | +150–200% ($40–$70) |

| Permanent submersion, corrosive water | NEMA 6P / IP68 | 316 stainless steel | +600–800% ($240–$400+) |

Pro-tip: When in doubt, spec one protection level higher than your initial assessment. The cost difference between IP65 and IP66, or between NEMA 4 and 4X, is typically $10–$30 per box. That’s noise compared to a single callback. Overprotection is cheap insurance.

Cost Analysis: The $25 Upfront vs $2,800 Callback

The weatherproof vs standard decision often gets framed as “cost control.”—procurement sees a $12 standard box and a $35 weatherproof box and asks “why pay 3× more?” Here’s the real math:

Total Cost of Ownership Formula:

TCO = (Material Cost) + (Installation Labor) + (Failure Rate × Callback Cost) + (Downtime Cost)

Scenario: Outdoor Lighting Control, 20 Junction Boxes

Option A: Standard NEMA 1 Boxes

- Material: 20 boxes × $12 = $240

- Installation: 20 boxes × 0.5 hr × $85/hr = $850

- Expected failures over 5 years: 12 boxes (60% failure rate in outdoor exposure)

- Callback cost per box: $320 material + $240 labor (1.5 hr removal/replacement of corroded box and conductors) + $180 downtime (3 hr lost production) = $740

- Total callbacks: 12 × $740 = $8,880

- 5-year TCO: $9,970

Option B: Weatherproof IP65 Polycarbonate Boxes

- Material: 20 boxes × $35 = $700

- Installation: 20 boxes × 0.6 hr × $85/hr = $1,020 (slightly longer due to cable gland installation)

- Expected failures over 5 years: 1 box (5% failure rate, typically from gasket degradation or installation error)

- Callback cost: 1 × $740 = $740

- 5-year TCO: $2,460

Cost savings with weatherproof: $9,970 – $2,460 = $7,510 over 5 years (75% reduction)

The “expensive” weatherproof boxes save $7,510 across 20 units—an average of $375 per box in avoided callbacks and downtime.

Break-even point: After approximately 1.2 failed standard boxes, the cumulative callback costs exceed the entire upfront premium for weatherproof boxes across the project. In most outdoor installations, you hit break-even within 18–24 months.

When Standard Boxes Make Financial Sense

Indoor, dry, climate-controlled locations where environmental exposure is genuinely zero. If the box is in a finished office, conditioned electrical room, or dry residential basement, the failure rate of standard boxes approaches zero. Spending $35 for IP65 protection you’ll never need is waste.

Temporary installations (under 12 months). If the electrical system is temporary (construction power, event setup, short-term project), and it won’t outlast the typical failure window (12–18 months for outdoor standard boxes), use standard boxes and budget for maintenance.

Protected indoor industrial where dust is manageable. Clean warehouses, light assembly areas, finished manufacturing spaces. NEMA 1 performs adequately. Save the weatherproof budget for outdoor and harsh indoor locations.

NEC Wet Location Requirements: Article 314.15 Compliance

The National Electrical Code (NEC) addresses junction box environmental protection in Article 314.15: Wet Locations. This section isn’t optional guidance—it’s enforceable code adopted by virtually all U.S. jurisdictions. Understanding 314.15 tells you when weatherproof boxes are legally mandatory, not just best practice.

NEC 314.15(A): Boxes in Damp or Wet Locations

“In damp or wet locations, boxes, conduit bodies, and fittings shall be placed or equipped so as to prevent moisture from entering or accumulating within the box, conduit body, or fitting. Boxes, conduit bodies, and fittings installed in wet locations shall be listed for use in wet locations.”

Three critical requirements:

- Prevent moisture entry: The enclosure must be constructed to keep water out (gasket seals, sealed cable entries).

- Prevent moisture accumulation: Even if some moisture enters, it must not accumulate (drainage provisions, sealed construction).

- Listed for wet locations: The box must carry a certification mark (UL, ETL, CSA) specifically stating “suitable for wet locations” or equivalent language.

Wet Location Definition (NEC Article 100):

Installations underground or in concrete slabs or masonry in direct contact with the earth; locations subject to saturation with water or other liquids; and unprotected locations exposed to weather.

Practical interpretation: Any outdoor installation exposed to rain is a wet location. Any below-grade installation is a wet location. Any location where water accumulation is possible (near drains, sprinklers, washdown areas) is a wet location.

Damp Location Definition (NEC Article 100):

Partially protected locations under canopies, marquees, roofed open porches, and interior locations subject to moderate degrees of moisture (basements, barns, cold-storage warehouses).

Practical interpretation: “Protected” outdoor locations (under soffits, inside weatherproof cabinets) are damp locations minimum. Depending on exposure, they may still qualify as wet locations (e.g., under a soffit but exposed to wind-driven rain).

Compliance = Listed Weatherproof Box

A standard indoor NEMA 1 junction box is not listed for wet locations. Installing one outdoors or in wet/damp locations violates NEC 314.15. It will fail inspection, create liability if a failure occurs, and void equipment warranties.

To comply, specify a junction box with certification marking that includes “suitable for wet locations” or “wet location rated” language. This requires:

- IP65 or higher rating (for international-market boxes)

- NEMA 3R, 4, 4X, 6, or 6P rating (for North American-market boxes)

- Sealed cable entries (threaded glands or listed sealing fittings)

- Gasket-sealed cover

The certification mark (UL, ETL, CSA, etc.) on the box label confirms it passed wet-location testing per applicable standards (UL 50, UL 50E, CSA C22.2 No. 94.2). No certification mark = not listed = NEC violation.

Pro-tip: When the AHJ (building inspector, electrical inspector) questions your box selection, point to the certification mark and the “wet location” listing statement on the label. That’s code compliance documented. “It’s IP65” without a listing mark is not compliant in NEC jurisdiction.

Conclusion: Protection Level Selection Checklist

Weatherproof vs standard junction box selection isn’t about product categories—it’s about matching tested protection levels to environmental exposure. Choose wrong, and you’ve locked in a predictable failure mode. Choose right, and you’ve bought 15–25 years of maintenance-free service for an extra $10–$30 per box.

Use this checklist before specifying or purchasing:

✅ Environment Assessment:

☐ Is this installation indoors in climate-controlled space? → Standard NEMA 1 acceptable.

☐ Is this outdoor or damp location? → Weatherproof required minimum NEMA 3R or IP54.

☐ Is direct rain, snow, or spray exposure possible? → Minimum NEMA 4 or IP65.

☐ Is high-pressure washdown expected? → Minimum NEMA 4 or IP66.

☐ Is temporary flooding or submersion possible? → Minimum NEMA 6 or IP67.

☐ Is permanent submersion or below-grade standing water present? → Minimum NEMA 6P or IP68.

✅ Corrosion Risk:

☐ Is installation within 10 miles of salt water? → NEMA 4X, 304 or 316 stainless steel.

☐ Are corrosive chemicals or aggressive cleaners present? → NEMA 4X, verify material compatibility.

☐ Standard outdoor, no special corrosive exposure? → Polycarbonate or aluminum acceptable.

✅ Dust Environment:

☐ Clean outdoor/indoor? → IP5X (dust protected) adequate.

☐ Dusty industrial, abrasive or conductive dust? → IP6X (dust-tight) required.

✅ Temperature Range:

☐ Standard range (−10°C to +50°C)? → All materials suitable.

☐ Cold extremes (below −20°C)? → Silicone gaskets, polycarbonate or metal.

☐ Hot extremes (above +60°C ambient)? → Silicone gaskets, metal enclosures for heat dissipation.

✅ Code Compliance:

☐ NEC 314.15 applies (U.S. installation)? → Box must be listed for wet/damp locations.

☐ Certification mark present (UL, ETL, CSA)? → Verify “wet location” or equivalent on label.

☐ All cable entries sealed with listed glands or fittings? → IP68 cable glands for submersion.

✅ Material Selection:

☐ Cost-sensitive, general outdoor, non-corrosive? → UV-stabilized polycarbonate.

☐ Coastal, chemical, or high-corrosion environment? → 304 or 316 stainless steel.

☐ Need RF shielding or heat dissipation? → Die-cast aluminum or stainless steel.

☐ Need visual inspection without opening? → Clear polycarbonate.

✅ Long-Term Cost:

☐ Calculate 5-year TCO including expected failure rate and callback costs.

☐ For outdoor installations, weatherproof boxes break even after ~1.2 failures.

☐ When in doubt, spec one protection level higher—cost difference is minimal compared to callback risk.

That $2,800 callback from the marina installation in the opening? It came down to a $23 decision: standard box at $12 or weatherproof IP65 at $35. The salt air didn’t care about the budget pressure. It corroded the terminals, failed the circuit, and turned a $23 savings into a $2,800 loss.

Environmental protection isn’t negotiable. It’s physics. Match your protection level to your exposure, verify compliance, and lock in decades of reliable service.

Standards & Sources Referenced

- IEC 60529:1989+A1:1999+A2:2013 (Degrees of protection provided by enclosures – IP Code)

- NEMA 250-2020 (Enclosures for Electrical Equipment, 1000 Volts Maximum)

- NEC 2023 Article 314.15 (Damp or Wet Locations)

- ASTM B117 (Standard Practice for Operating Salt Spray Apparatus)

- UL 50 (Enclosures for Electrical Equipment, Non-Environmental Considerations)

- UL 50E (Enclosures for Electrical Equipment, Environmental Considerations)

Timeliness Statement

All protection ratings, standards editions, and material specifications accurate as of December 2025. IEC 60529 consolidated edition remains current. NEMA 250-2020 edition in effect. NEC references based on 2023 edition.

Article prepared for VIOX Electric Co., Ltd. – December 4, 2025