Önemli Çıkarımlar

- Ayarlanabilir devre kesiciler önceden ayarlanmış değerlere sahip sabit açma devre kesicilerinin aksine, kullanıcıların belirli yük gereksinimlerini karşılamak için açma ayarlarını (akım ve zaman parametreleri) değiştirmesine olanak tanır

- Üç ana ayar türü: Uzun süreli (termal aşırı yük), kısa süreli (geçici aşırı akım) ve anlık (kısa devre) koruma ayarları

- Birincil uygulamalar: Endüstriyel motor kontrolü, değişken yük ortamları, HVAC sistemleri, güneş enerjisi kurulumları ve dalgalı güç talepleri olan ekipmanlar

- Maliyet - esneklik dengesi: Ayarlanabilir kesiciler, sabit tiplere göre -50 daha pahalıdır, ancak birden fazla kesici envanterine duyulan ihtiyacı ortadan kaldırır

- A Tipi - B Tipi tanımı: A Tipi kesiciler sınırsız saha ayarlamasına izin verir; B Tipi kesiciler yalnızca maksimum değerlerinden aşağı doğru ayarlanabilir

- Elektronik gezi üniteleri termal-manyetik tiplere (± tolerans) kıyasla en hassas ayar özelliklerini (±%5 doğruluk) sunar

Ayarlanabilir bir devre kesici, kullanıcıların korunan devrenin veya ekipmanın elektriksel özellikleriyle tam olarak eşleşmesi için akım eşikleri ve zaman gecikmeleri dahil olmak üzere açma ayarlarını değiştirmesine olanak tanıyan bir koruma cihazıdır. Fabrikadan önceden belirlenmiş ayarlarla gelen sabit açma devre kesicilerinin aksine, ayarlanabilir kesiciler sahada koruma parametrelerini ince ayar yapma esnekliği sağlar ve bu da onları yük koşullarının değiştiği veya diğer koruma cihazlarıyla hassas koordinasyonun gerekli olduğu uygulamalar için vazgeçilmez kılar.

Endüstriyel ve ticari elektrik sistemlerinde, tek bir boyut nadiren herkese uyar. Ayarlanabilir bir devre kesici, yüksek ani akıma sahip bir motoru koruyor, karmaşık bir dağıtım sisteminde birden fazla kesiciyi koordine ediyor veya ekipmanı değiştirmeden gelecekteki yük değişikliklerini karşılıyor olsanız da, özel ihtiyaçlarınıza uyum sağlayan özelleştirilebilir koruma sunarak bu zorluğun üstesinden gelir.

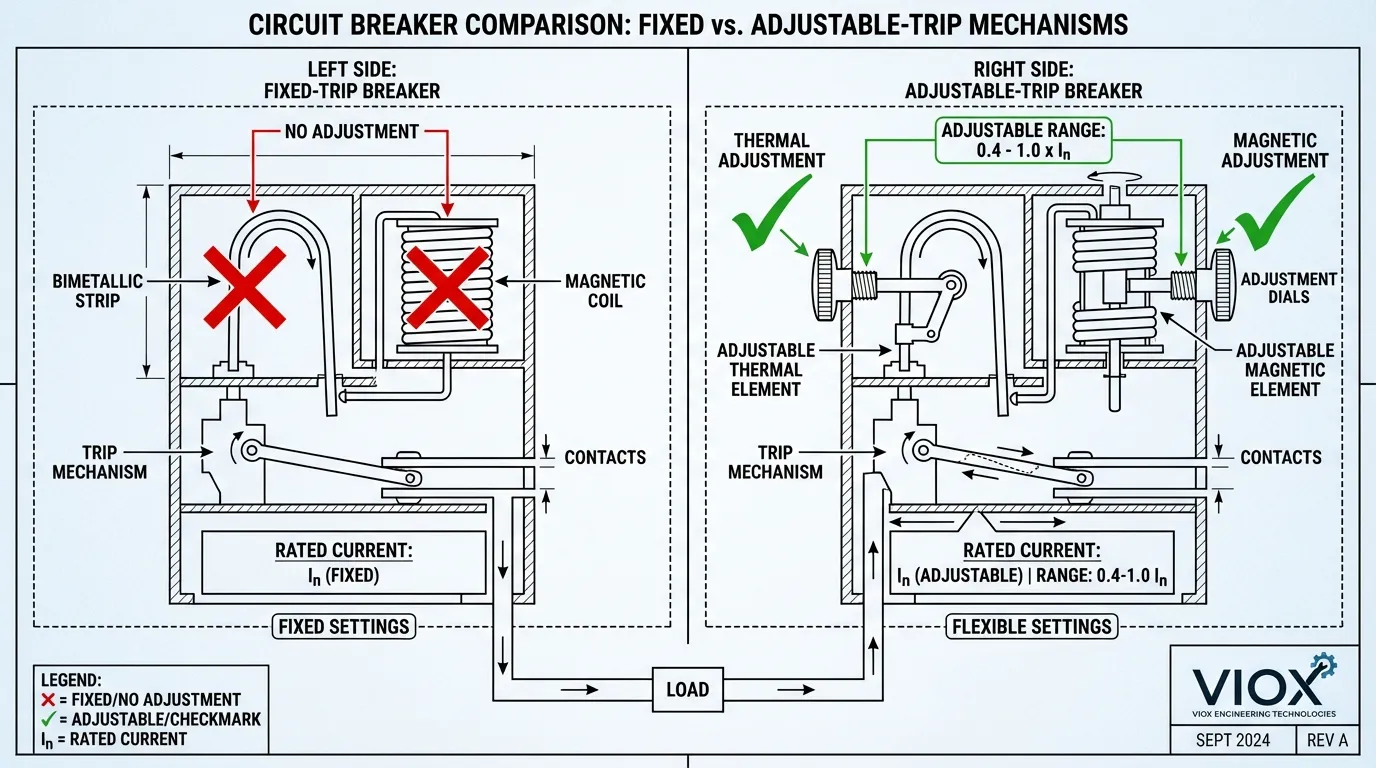

Temel Bilgileri Anlamak: Sabit ve Ayarlanabilir Devre Kesiciler

Bir Devre Kesiciyi “Ayarlanabilir” Yapan Nedir?

“Ayarlanabilir” terimi, bir devre kesicinin kurulumdan sonra bir veya daha fazla açma özelliğini değiştirme yeteneğini ifade eder. Ulusal Elektrik Yasası'nın (NEC) 100. Maddesine göre, ayarlanabilir bir devre kesici, “devre kesicinin önceden belirlenmiş bir aralık içinde çeşitli akım, zaman veya her ikisi değerinde açacak şekilde ayarlanabileceğini gösteren bir niteleme terimi” olarak tanımlanır.”

Sabit açma devre kesicileri koruma parametreleri üretim sırasında kalıcı olarak ayarlanmıştır. Örneğin, standart bir 100A minyatür devre kesici (MCB) aşırı yük koşulları için yaklaşık 100A'da ve kısa devreler için sabit bir katında (tipik olarak nominal akımın 5-10 katı) açacaktır. Bu ayarlar, tüm kesiciyi değiştirmeden değiştirilemez.

Ayarlanabilir açma devre kesicileri, yaygın olarak kalıplanmış kasa devre kesiciler (MCCB'ler) ve hava devre kesicilerinde (ACB'ler) bulunan, açma eşiklerinin ve zamanlama özelliklerinin değiştirilmesine olanak tanıyan mekanizmalara (mekanik kadranlar, elektronik kontroller veya değiştirilebilir değerleme fişleri) sahiptir. Bu esneklik, tek bir kesici çerçeve boyutunun farklı koruma gereksinimlerine sahip birden fazla uygulamaya hizmet etmesini sağlar.

Bir Bakışta Temel Farklılıklar

| Özellik | Sabit Açma Kesici | Ayarlanabilir Açma Kesici |

|---|---|---|

| Gezi Akımı | Fabrika ayarlı, ayarlanamaz | Belirtilen aralıkta ayarlanabilir (örn. 0,4-1,0 × In) |

| Zaman Gecikmesi | Sabit termal eğri | Ayarlanabilir uzun süreli ve kısa süreli gecikmeler |

| Anlık Açma | Nominal değerin 5-10 katı olarak sabitlenmiştir | Modele bağlı olarak 2-40 × nominal değerden ayarlanabilir |

| Tipik Uygulamalar | Konut devreleri, aydınlatma, basit yükler | Motorlar, endüstriyel ekipman, koordinasyon açısından kritik sistemler |

| Maliyet | Daha düşük başlangıç maliyeti | -50 daha yüksek maliyet |

| Esneklik | Farklı ayarlar için değiştirme gerektirir | Tek bir kesici birden fazla uygulamaya hizmet eder |

| Karmaşıklık | Basit kullanım | Doğru ayar için teknik bilgi gerektirir |

| Yaygın Türler | MCB (6-125A) | MCCB (100-2500A), ACB (800-6300A) |

Devre Kesicilerde Ayarlanabilir Ayar Türleri

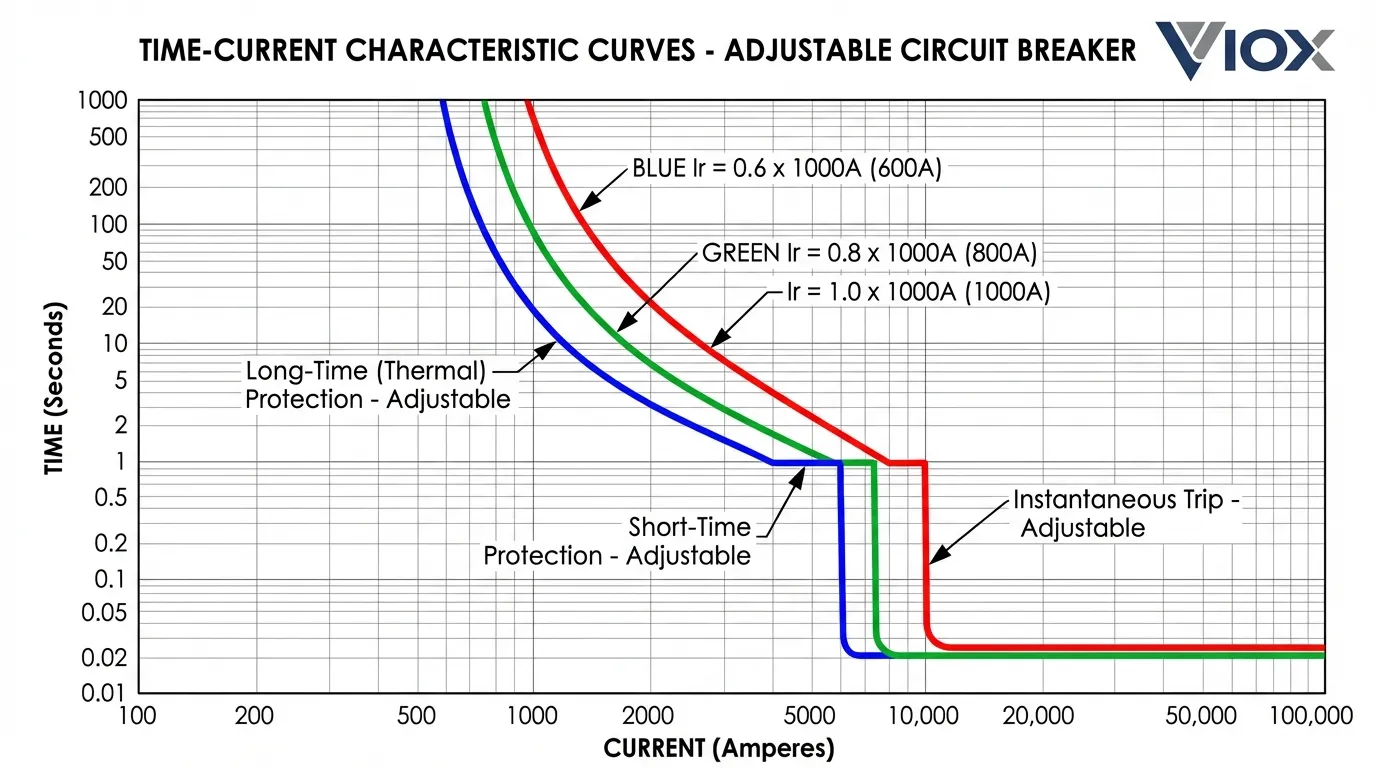

Modern ayarlanabilir devre kesiciler, her biri kendi ayar özelliklerine sahip üç birincil koruma işlevi sunar. Bu ayarları anlamak, doğru uygulama ve sistem koordinasyonu için çok önemlidir.

1. Uzun Süreli (Termal Aşırı Yük) Koruması

Fonksiyon: Aşırı ısınma yoluyla kablolara, bara sistemlerine ve bağlı ekipmanlara zarar verebilecek sürekli aşırı akım koşullarına karşı korur.

Ayar Parametreleri:

- Akım Ayarı (Ir): Tipik olarak kesicinin nominal değerinin (In) 0,4 ila 1,0 katı arasında ayarlanabilir

- Örnek: 1000A'lık bir kesici 400A ile 1000A arasında herhangi bir değere ayarlanabilir

- Kesicinin gerçek yük gereksinimleriyle eşleşmesini sağlar

- Zaman Gecikmesi (tr): 60 ila 600 saniye arasında ayarlanabilir

- Kesicinin açmadan önce aşırı akıma ne kadar süre tolerans göstereceğini belirler

- Ters zaman karakteristiği kullanır: daha yüksek aşırı akım = daha hızlı açma

Pratik Uygulama: Tesisinizde 1000A'lık bir MCCB varsa, ancak gerçek bağlı yük yalnızca 600A ise, Ir'yi 0,6 × 1000A = 600A olarak ayarlayabilirsiniz. Bu, gelecekte daha fazla yük eklerseniz ayarı artırma esnekliğini korurken, gereksiz açmaları önleyerek optimum koruma sağlar.

2. Kısa Süreli (Geçici Aşırı Akım) Koruması

Fonksiyon: Normal çalışma seviyelerini aşan ancak kısa devre büyüklüklerinin altında olan geçici aşırı akım koşullarına karşı koruma sağlar. Bu ayar, seçici koordinasyon için kritik öneme sahiptir.

Ayar Parametreleri:

- Kısa Süreli Alım (Isd): Ir'nin 1,5 ila 10 katı arasında ayarlanabilir

- Örnek: Ir = 600A ile kısa süreli alım 900A ile 6000A arasında değişebilir

- Kısa Süreli Gecikme (tsd): İki mod mevcuttur

- Sabit Süre: 0.05 ila 0.5 saniye

- I²t Rampa: 0.18 ila 0.45 saniye (ters zaman karakteristiği)

Neden Önemli?: Kısa süreli gecikme, alt devre kesicilerinin arızaları ilk önce temizlemesine olanak tanır ve tesisinizin etkilenmeyen kısımlarında gereksiz kesintileri önler. Örneğin, bir branş devresinde bir arıza meydana gelirse, ana devre kesicideki kısa süreli gecikme, branş devre kesicisine açma süresi verir ve diğer devrelere güç sağlamaya devam eder.

3. Anında (Kısa Devre) Koruma

Fonksiyon: Kasıtlı bir gecikme olmaksızın (tipik olarak <50 milisaniye) şiddetli kısa devre akımlarına karşı anında koruma sağlar.

Ayar Parametreleri:

- Anında Alım (Ii): 2 ila 40 kat Ir arasında ayarlanabilir (devre kesici tipine bağlı olarak)

- Bazı devre kesicilerde sabit anlık ayarlar bulunur (daha küçük MCCB'lerde yaygın)

- Elektronik açma ünitelerine sahip daha büyük devre kesiciler daha geniş ayar aralıkları sunar

Kritik Husus: Anında açmayı çok düşük ayarlamak, motor çalıştırmaları veya transformatör ani akımı sırasında istenmeyen açmalara neden olabilir. Çok yüksek ayarlamak korumayı tehlikeye atabilir. Optimum ayar, devre kesici konumundaki mevcut arıza akımına ve yukarı/aşağı akış cihazlarıyla koordinasyon gereksinimlerine bağlıdır.

4. Toprak Kaçağı Koruması (İsteğe Bağlı Özellik)

Fonksiyon: Yangınlara veya ekipman hasarına neden olabilecek toprak kaçağı akımlarını algılar ve kesintiye uğratır.

Ayar Parametreleri:

- Toprak Kaçağı Alımı (Ig): Devre kesici değerinin 'sinden 'ine kadar ayarlanabilir

- Toprak Kaçağı Zaman Gecikmesi: Tipik olarak 0.1s, 0.2s veya 0.4s

Uygulama: Özellikle topraklanmış sistemlerde veya ark parlaması tehlike azaltımının gerekli olduğu durumlarda, toprak arızalarının standart aşırı akım korumasını tetiklemek için yeterli akım üretmeyebileceği sistemler için gereklidir.

Ayarlanabilir Devre Kesiciler Nasıl Çalışır: Açma Ünitesi Teknolojileri

Termal-Manyetik Açma Üniteleri (Geleneksel)

Termal Eleman (Uzun Süreli Koruma):

- Akım akışından ısınan bir bimetalik şerit kullanır

- Akım arttıkça, şerit farklı termal genleşme nedeniyle bükülür

- Aşırı akım devam ettiğinde, şerit açma mekanizmasını serbest bırakacak kadar bükülür

- Ayar tipik olarak mekanik kaldıraç veya yay gerginliğini değiştiren bir kadran aracılığıyla yapılır

- Doğruluk: ± tolerans bandı (termal fiziğe özgü)

Manyetik Eleman (Anında Koruma):

- Elektromanyetik bobin, akımla orantılı manyetik kuvvet üretir

- Akım eşiği aştığında, manyetik kuvvet yay gerginliğinin üstesinden gelir

- Anında açma mekanizmasını serbest bırakır

- Ayar, bobin konumunu, hava boşluğunu veya yay gerginliğini değiştirerek yapılır

- Tepki Süresi: <50 milisaniye

Sınırlamalar:

- Sıcaklığa bağlı (ortam koşulları termal elemanı etkiler)

- Sınırlı ayar hassasiyeti

- Temel modellerde kısa süreli gecikme özelliği yok

- Ölçüm veya iletişim gibi gelişmiş özellikler sağlayamaz

Elektronik Açma Üniteleri (Modern)

Çalışma Prensibi:

- Akım transformatörleri (CT'ler) her fazdaki akımı ölçer

- Mikroişlemci sürekli olarak akım dalga biçimlerini analiz eder

- Ölçülen değerleri programlanmış açma eğrilerine göre karşılaştırır

- Arıza koşulları algılandığında açma mekanizmasını harekete geçirir

- Ayarlar dijital arayüz, DIP anahtarları veya yazılım aracılığıyla yapılandırılır

Avantajlar:

- Yüksek Hassasiyet: Tüm çalışma aralığında ±%5 doğruluk

- Sıcaklık Bağımsızlığı: Dijital işleme termal kaymayı ortadan kaldırır

- Kapsamlı Koruma: L-S-I-G (Uzun, Kısa, Anında, Toprak) fonksiyonları

- Gelişmiş Özellikler: Gerçek RMS algılama, harmonik filtreleme, yük izleme

- İletişim: Modbus, Profibus veya Ethernet bağlantı seçenekleri

- Veri Kaydı: Açma olaylarını, yük profillerini ve güç kalitesi verilerini kaydeder

Ayar Yöntemleri:

- Döner Kadranlar: Dijital kodlamalı fiziksel kadranlar

- DIP Anahtarları: Ayrık ayar değerleri için ikili anahtarlar

- LCD Arayüzü: Menü navigasyonlu yerleşik ekran

- Yazılım Yapılandırması: USB veya ağ bağlantısı üzerinden PC tabanlı programlama

A Tipi ve B Tipi Ayarlanabilir Kesiciler: UL Sınıflandırmalarını Anlamak

UL (Underwriters Laboratories) standardı, saha ayar yeteneklerine göre ayarlanabilir devre kesicilerin iki kategorisini tanımlar. Bu ayrımı anlamak, uyumluluk ve uygun uygulama için kritik öneme sahiptir.

Tip A Ayarlanabilir Kesiciler

Tanım: Tüm değiştirilebilir özellikler için kısıtlama olmaksızın sahada tekrar tekrar ayarlanabilir.

Temel Özellikler:

- Belirtilen aralıkta yukarı veya aşağı sınırsız ayarlama

- Tek bir amper değeri ve ayar aralığı ile işaretlenmiştir (örneğin, “800A” ile “0.5-1.0 × 800A”)

- Genellikle elektronik açma ünitelerine sahip kesicilerde bulunur

- Ayarlama için uygun araçlar ve eğitim gerektirir

- Ayarlanabilir olduğunu belirtmek için işaretlenmelidir

Tipik İşaretleme: “800A AYARLANABİLİR 400-800A”

Kullanım Örnekleri:

- Değişen yük profillerine sahip endüstriyel tesisler

- Sık sık yeniden yapılandırma gerektiren ekipman

- Yük optimizasyonunun devam ettiği uygulamalar

- Gelecekteki genişlemenin beklendiği sistemler

Tip B Ayarlanabilir Kesiciler

Tanım: Belirli bir sürekli akım değerine ayarlandıktan sonra, sahada daha yüksek bir değere ayarlanamaz (yalnızca aşağı doğru ayarlanabilir veya orijinaline sıfırlanabilir).

Temel Özellikler:

- Tek yönlü ayarlama (yalnızca maksimum ayardan aşağı doğru)

- Korumanın yanlışlıkla aşırı derecelendirilmesini önler

- Genellikle mekanik durdurucular veya mandal mekanizmaları kullanır

- Ayarları artırmak için fabrika sıfırlaması gerekebilir

- Termal-manyetik açma ünitelerinde daha yaygın

Güvenlik Gerekçesi: İletken korumasını tehlikeye atabilecek veya elektrik kurallarını ihlal edebilecek açma ayarlarında yetkisiz veya kazara artışı önler.

Önemli Not: UL bu kategorileri tanımlarken, “Tip A” veya “Tip B” tanımının kesicinin kendisinde işaretlenmesi gerekmez - bu, değerlendirme amacıyla kullanılan bir sınıflandırmadır. Ayarlama sınırlamalarını anlamak için daima üreticinin belgelerine başvurun.

Uygulamalar: Ayarlanabilir Devre Kesiciler Ne Zaman Kullanılır?

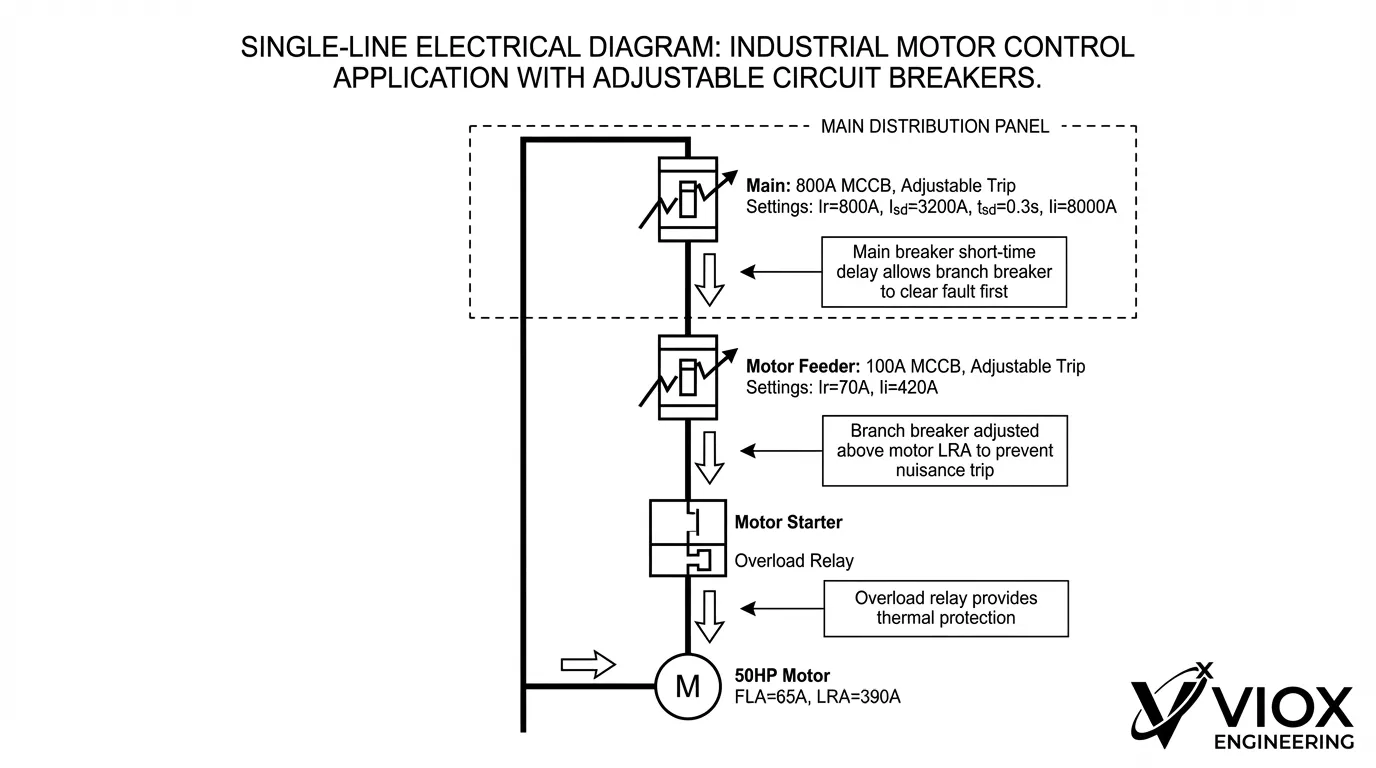

1. Motor Koruması ve Kontrolü

Zorluk: Elektrik motorları, çalıştırma sırasında (ani akım) tam yük akımlarının 5-8 katını çeker ve bu da sabit açma kesicilerinin istenmeyen şekilde açmasına neden olabilir.

Çözüm: Ayarlanabilir kesiciler şunları yapmanızı sağlar:

- Uzun süreli korumayı motor tam yük akımına (FLA) ayarlayın

- Anlık açmayı motor kilitli rotor akımının (LRA) üzerine ayarlayın

- Kapsamlı koruma için motor aşırı yük röleleri ile koordine edin

Örnek Yapılandırma:

- 50 HP motor, 480V, FLA = 65A, LRA = 390A

- Ayarlanabilir açmalı 100A çerçeve MCCB kullanın

- Ir = 0.7 × 100A = 70A (FLA'nın biraz üzerinde) olarak ayarlayın

- Ii = 6 × 70A = 420A (LRA'nın üzerinde, arıza akımının altında) olarak ayarlayın

Bu yapılandırma, motoru ve iletkenleri korurken, istenmeyen açmalar olmadan başarılı başlatmalara olanak tanır. NEC 430.52'ye göre, ayrı aşırı yük koruması ile kullanıldığında, ters zamanlı kesiciler motor FLA'sının 250%'sine kadar boyutlandırılabilir.

2. Dağıtım Sistemlerinde Seçici Koordinasyon

Zorluk: Bir arıza meydana geldiğinde, yalnızca arızaya en yakın kesicinin açmasını, yaygın kesintilere neden olacak yukarı akış kesicilerinin açmasını istemezsiniz.

Çözüm: Ayarlanabilir kısa süreli gecikme ayarları, seçici koordinasyonu sağlar:

- Aşağı akış kesiciler: Yalnızca anlık açma (gecikme yok)

- Orta seviye kesiciler: Kısa süreli gecikme (0.1-0.3 saniye)

- Ana kesiciler: Daha uzun kısa süreli gecikme (0.3-0.5 saniye)

Gerçek Dünya Etkisi: Bir üretim tesisinde, tek bir makine devresindeki bir arıza yalnızca o branş kesicisini açar, dağıtım paneli ana veya bina servis giriş kesicisini açmaz. Üretim diğer tüm ekipmanlarda devam eder, bu da arıza süresini ve gelir kaybını en aza indirir.

3. Solar PV ve Yenilenebilir Enerji Sistemleri

Zorluk: Güneş panelleri, ışınım, sıcaklık ve sistem yapılandırmasına bağlı olarak önemli akım değişiklikleri yaşar. Sabit kesiciler hem normal çalışmayı hem de arıza korumasını en iyi şekilde karşılamayabilir.

Çözüm: Ayarlanabilir DC devre kesiciler şunları sağlar:

- Dizi akımına (NEC 690.8'e göre Isc × 1.56) uyacak şekilde hassas ayar

- Yukarı akış birleştiriciler ve invertörlerle koordinasyon

- Kesici değişimi olmadan sistem genişlemesinin sağlanması

Uygulama: Her biri 9A Isc üreten 8 dizili bir güneş birleştirici kutusu, 9A × 1.56 = 14.04A'da koruma gerektirir. Ayarlanabilir bir DC kesici tam olarak bu değere ayarlanabilirken, sabit kesiciler korumayı tehlikeye atarak bir sonraki standart değere (15A veya 20A) aşırı boyutlandırma gerektirecektir.

4. HVAC ve Bina Sistemleri

Zorluk: Isıtma, havalandırma ve klima sistemleri çeşitli yüklere sahiptir - yüksek ani akımlı kompresörler, sürekli çalışan fanlar ve minimum akımlı kontrol devreleri.

Çözüm: Ayarlanabilir kesiciler şunları sağlar:

- Birden fazla HVAC ekipmanı değeri için tek tip kesici

- Mevsimsel yük değişikliklerinin sağlanması

- Bakım ekipleri için basitleştirilmiş envanter yönetimi

Maliyet Avantajı: Tesisler, 10 farklı sabit açma kesici değeri stoklamak yerine, 3-4 ayarlanabilir kesici çerçeve boyutu envanterini tutabilir ve yedek parça maliyetlerini 40-60% oranında azaltabilir.

5. Endüstriyel Proses Ekipmanları

Zorluk: Üretim ekipmanı genellikle farklı modlarda (başlatma, normal üretim, yüksek hızlı çalışma) değişen akım talepleriyle çalışır.

Çözüm: Ayarlanabilir ayarlar şunlar için optimizasyon sağlar:

- Harmonik içeriğe sahip değişken frekanslı sürücü (VFD) uygulamaları

- Aralıklı yüksek akım darbelerine sahip kaynak ekipmanları

- Döngüsel yük düzenlerine sahip toplu işlemler

Devre Kesici Ayarları Nasıl Yapılır: Adım Adım Kılavuz

Güvenlik Önlemleri (KRİTİK)

⚠️ UYARI: Devre kesici ayarlarının yapılması kalifiye elektrik personeli gerektirir. Yanlış ayarlar şunlara neden olabilir:

- Yangına veya ekipman hasarına yol açan yetersiz koruma

- Operasyonel aksamalara neden olan gereksiz açma

- Elektrik yönetmeliklerinin ve sigorta gereksinimlerinin ihlali

- Enerjili çalışma sırasında ark parlamasından kaynaklanan kişisel yaralanma

Herhangi Bir Ayar Yapmadan Önce:

- Ark parlaması tehlike analizi yapın ve uygun KKD kullanın

- Tesis elektrik mühendisinden veya yetkili makamdan onay alın

- Belirli devre kesici modeli için üreticinin talimat kılavuzunu inceleyin

- Değişiklik yapmadan önce mevcut ayarları belgeleyin

- Üretici gerektiriyorsa devre kesicinin enerjisiz olduğundan emin olun (bazı elektronik üniteler enerjili ayarlamaya izin verir)

Termal-Manyetik Açma Üniteleri için Ayarlama Prosedürü

Adım 1: Ayarlama Mekanizmalarını Tanımlayın

- Uzun süreli ayarlama: Genellikle “Ir” veya “Termal” olarak işaretlenmiş bir kadran veya kaydırıcı”

- Anlık ayarlama: “Ii” veya “Manyetik” olarak işaretlenmiş kadran veya düğmeler”

- Ayarlar genellikle çarpanlar olarak işaretlenir (örn. 0.5, 0.6, 0.7…1.0)

Adım 2: Gerekli Ayarları Hesaplayın

- Uzun süreli (Ir): Beklenen maksimum sürekli yükün 0-125'ine ayarlayın

- Örnek: 480A sürekli yük → Ir = minimum 500A olarak ayarlayın

- Anlık (Ii): Maksimum geçici akımın üzerine ancak minimum arıza akımının altına ayarlayın

- Aşağı akım cihazlarıyla koordine edilmelidir

- Tipik aralık: Çoğu uygulama için 5-10× Ir

Adım 3: Ayarları Yapın

- Uygun aracı kullanın (tornavida, alyan anahtarı veya ayarlama aracı)

- Kadranları istenen ayarlara çevirin

- Tüm üç kutbun aynı şekilde ayarlandığından emin olun (çok kutuplu devre kesiciler için)

- Ayarların açıkça görülebilir ve hesaplamalarla eşleştiğinden emin olun

Adım 4: Belgeleyin ve Etiketleyin

- Ayarları tesis elektrik dokümantasyonuna kaydedin

- Devre kesicinin yakınına dayanıklı bir etiket uygulayın ve şunları gösterin:

- Ayarlama tarihi

- Ayarlar (Ir, tsd, Ii)

- Ayarlamayı yapan kişinin baş harfleri

- Tek hat şemalarını ve koordinasyon çalışmalarını güncelleyin

Elektronik Açma Üniteleri için Ayarlama Prosedürü

Adım 1: Programlama Arayüzüne Erişin

- LCD ekranlı modeller: Ayarlar menüsüne girmek için gezinme düğmelerini kullanın

- DIP anahtarlı modeller: Üreticinin kod tablosuna bakın

- Yazılımla programlanabilir: Dizüstü bilgisayarı USB veya ağ kablosuyla bağlayın

Adım 2: Koruma Fonksiyonlarını Yapılandırın

- Uzun süreli (L): Ir (akım) ve tr (gecikme süresi) ayarlayın

- Kısa süreli (S): Isd (akım) ve tsd (gecikme süresi veya I²t eğrisi) ayarlayın

- Anlık (I): Ii (akım eşiği) ayarlayın

- Toprak hatası (G): Varsa Ig (akım) ve tg (gecikme süresi) ayarlayın

Adım 3: Ayarları Doğrulayın

- Elektronik ünitelerde genellikle bir “gözden geçirme” veya “görüntüleme” modu bulunur

- Doğru değerleri onaylamak için tüm ayarlarda gezinin

- Bazı üniteler yetkisiz değişiklikleri önlemek için parola gerektirir

Adım 4: Test Edin (Gerekirse)

- Birincil enjeksiyon testi, gerçek açma performansını doğrular

- Uzman ekipmana sahip kalifiye bir test şirketi tarafından gerçekleştirilir

- İlk devreye almadan sonra ve her 3-5 yılda bir önerilir

Ayarlanabilir Devre Kesicilerin Avantajları ve Sınırlamaları

Avantajlar

1. Esneklik ve Geleceğe Uygunluk

- Ekipman değiştirmeden yük değişikliklerine uyum sağlama

- Tek bir kesici gövdesi birden fazla uygulamaya hizmet eder

- Sistem değişikliklerine veya genişlemelerine uyum sağlama

- “Ne olur ne olmaz” diye aşırı büyük kesicilere olan ihtiyacı azaltma”

2. Gelişmiş Sistem Koordinasyonu

- Optimum seçicilik için ayarları ince ayar yapma

- Gereksiz açmaları en aza indirme

- Sigortalar, röleler ve diğer kesicilerle koordinasyon

- Uygun koordinasyon yoluyla ark parlaması tehlikesini azaltma

3. Maliyet Verimliliği (Uzun Vadeli)

- Azaltılmış yedek parça envanteri (stokta tutulacak daha az kesici tipi)

- Yükler değiştiğinde daha düşük değiştirme maliyetleri

- Daha iyi eşleşen koruma sayesinde azalan arıza süresi

- Basitleştirilmiş bakım prosedürleri

4. Gelişmiş Koruma

- Gerçek yük özelliklerine hassas eşleşme

- Hassas ekipman için daha iyi koruma

- İletken aşırı ısınma riskinin azaltılması

- Koruma ve kullanılabilirlik arasında optimum denge

5. Gelişmiş Özellikler (Elektronik Tipler)

- Gerçek zamanlı yük izleme ve ölçüm

- Bina yönetim sistemleriyle iletişim

- Veri kaydı yoluyla tahmini bakım

- Uzaktan izleme ve kontrol yetenekleri

Sınırlamalar

1. Daha Yüksek İlk Maliyet

- Ayarlanabilir MCCB'ler, sabit tiplere göre -50 daha pahalıdır

- Elektronik açma üniteleri, kesici maliyetine -100 ekler

- Doğrulama için test ekipmanlarına yatırım gerektirir

2. Karmaşıklık

- Uygun ayarlama için eğitimli personel gerektirir

- Düzgün yapılandırılmazsa yanlış ayar riski

- Daha karmaşık sorun giderme prosedürleri

- Yetkisiz veya kazara değişiklik olasılığı

3. Bakım Gereksinimleri

- Ayarlar periyodik olarak doğrulanmalıdır (her 3-5 yılda bir)

- Elektronik üniteler pil değişimi gerektirebilir

- Termal-manyetik tiplerde kalibrasyon kayması olasılığı

- Belgeler muhafaza edilmeli ve güncellenmelidir

4. Yasal Hususlar

- Bazı yargı bölgeleri saha ayarlarını kısıtlar

- Ayar değişiklikleri için elektrik mühendisi onayı gerekebilir

- Sigorta gereksinimleri belirli ayarları zorunlu kılabilir

- Ayarlamalar sonrasında kod uyumluluğu doğrulanmalıdır

Fayda-Maliyet Analizi Örneği

Senaryo: 30A ila 100A arasında değişen 20 motor devresine sahip endüstriyel tesis

Seçenek 1: Sabit Açma Kesiciler

- Maliyet: 20 kesici × ortalama 150$ = 3.000$

- Envanter: Yedek olarak 5 farklı değerde stok bulundurulmalıdır = 750$

- Gelecekteki değişiklikler: Motor değişirse kesiciyi değiştirin = değişiklik başına 150$

- Toplam 5 Yıllık Maliyet: 3.000$ + 750$ + (tahmini 8 değişiklik × 150$) = 4.950$

Seçenek 2: Ayarlanabilir Açma Kesiciler

- Maliyet: 20 kesici × ortalama 225$ = 4.500$

- Envanter: Yedek olarak 2 gövde boyutu stoklayın = 450$

- Gelecekteki değişiklikler: Yalnızca ayarları yapın = değişiklik başına 0$

- Toplam 5 Yıllık Maliyet: $4,500 + $450 = $4,950

Başabaş Noktası: Yaklaşık 5 yıl içinde 3 yük değişikliği

Ayarlanabilirliğin Ek Faydaları (yukarıda belirtilmemiş):

- Daha iyi koordinasyondan kaynaklanan daha az arıza süresi

- Geliştirilmiş ekipman koruması

- Gelecekteki bilinmeyen değişiklikler için esneklik

Doğru Ayarlanabilir Devre Kesiciyi Seçme

Anahtar Seçim Kriterleri

1. Gerilim Değeri

- Maksimum sistem voltajını aşmalıdır

- Yaygın değerler: 240V, 480V, 600V (AC); 250V, 500V, 1000V (DC)

- Voltaj geçişlerini ve sistem topraklamasını göz önünde bulundurun

2. Akım Değeri (Gövde Boyutu)

- Gövde boyutunu beklenen maksimum yüke göre seçin

- Gelecekteki büyüme için -30'luk bir pay bırakın

- Ortam sıcaklığı düşüşünü göz önünde bulundurun (tipik olarak 40°C referans)

3. Kesme Kapasitesi (Kısa Devre Değeri)

- Kurulum noktasındaki mevcut arıza akımını aşmalıdır

- Yaygın değerler: 10kA, 25kA, 35kA, 50kA, 65kA, 100kA

- Kısa devre çalışması veya şebeke verileri ile doğrulayın

- Daha yüksek değerler daha pahalıdır ancak güvenlik payı sağlar

4. Açma Ünitesi Tipi

- Termal-Manyetik: Daha düşük maliyetli, kanıtlanmış teknoloji, çoğu uygulama için yeterli

- Elektronik: Daha yüksek hassasiyet, gelişmiş özellikler, karmaşık koordinasyon için gerekli

- Gelecekteki ihtiyaçları göz önünde bulundurun: iletişim, ölçüm, kestirimci bakım

5. Ayar Aralığı

- Ayar aralığının öngörülen tüm yük senaryolarını kapsadığından emin olun

- Tipik aralık: uzun süre için 0,4-1,0 × çerçeve değeri

- Daha geniş aralık = daha fazla esneklik ancak ayarları karmaşıklaştırabilir

6. Standartlara Uygunluk

- Kuzey Amerika: UL 489 (MCB/MCCB), UL 1066 (Güç ŞB), CSA C22.2

- Uluslararası: IEC 60947-2 (MCCB), IEC 60947-1 (Genel)

- Kesicinin yargı alanınız için listelendiğini/sertifikalandığını doğrulayın

7. Çevresel Faktörler

- Ortam sıcaklığı aralığı (40°C'nin üzerinde düşüş uygulanabilir)

- Rakım (2000m'nin üzerinde düşüş gerekli)

- Nem, aşındırıcı atmosfer, titreşim

- İç mekan ve dış mekan kurulumu (muhafaza derecesi)

8. Montaj ve Kurulum

- Sabit ve çekmeceli (çıkarılabilir) tip

- Panel alanı gereksinimleri

- Terminal tipi ve boyutu

- Yardımcı kontak ve aksesuar kullanılabilirliği

Karşılaştırma: MCB - MCCB - ACB Ayarlanabilirliği

| Özellik | MCB (Mini Devre Kesici) | MCCB (Kalıplı Kasa) | ACB (Hava Devre Kesici) |

|---|---|---|---|

| Geçerli Aralık | 0,5-125A | 15-2500A | 800-6300A |

| Ayarlanabilirlik | Sadece sabit açma (nadir istisnalar) | Daha büyük boyutlarda ayarlanabilir (>100A) | Her zaman ayarlanabilir |

| Açma Ünitesi Tipi | Termal-manyetik (sabit) | Termal-manyetik veya elektronik | Elektronik (gelişmiş) |

| Ayar Parametreleri | Hiçbiri | Ir, tr, Ii (bazı modeller: Isd, tsd) | Hassas kontrollü tam L-S-I-G |

| Tipik Uygulamalar | Konut, hafif ticari | Ticari, endüstriyel | Ağır sanayi, şebeke, veri merkezleri |

| Maliyet Aralığı | $10-$100 | $100-$2,000 | $2,000-$20,000+ |

| Standartlar | UL 489, IEC 60898 | UL 489, IEC 60947-2 | UL 1066, IEC 60947-2 |

Kaçınılması Gereken Yaygın Hatalar

1. Ayarlanabilir Kesicileri Çok Yükseğe Ayarlama

Sorun: Rahatsız edici açmayı önlemek için açma ayarlarını iletken akım taşıma kapasitesinin üzerine ayarlama.

Sonuç: İletkenler, kesici koruması olmadan aşırı ısınabilir, yangın tehlikesi ve kod ihlali oluşturabilir.

Çözüm: Kesici uygun ayarlarda sık sık açıyorsa, temel nedeni araştırın:

- Gerçek yük için yetersiz boyutlandırılmış iletkenler

- Daha yüksek akıma neden olan aşırı voltaj düşüşü

- Ekipman arızası veya bozulması

- Yanlış yük hesaplamaları

Kod Gereksinimi: NEC 240.4, aşırı akım korumasının iletken akım taşıma kapasitesini aşmamasını gerektirir (belirli istisnalar dışında).

2. Koordinasyon Çalışmalarını Göz Ardı Etme

Sorun: Sistem koordinasyonu üzerindeki etkisini dikkate almadan bir kesiciyi ayarlama.

Sonuç: Seçicilik kaybı—aşağı akım arızaları için yukarı akım kesicileri açar ve yaygın kesintilere neden olur.

Çözüm:

- Zaman-akım eğrisi analizi kullanarak koordinasyon çalışması yapın

- Ayarları aşağı akımdan yukarı akıma doğru sistematik olarak ayarlayın

- Cihazlar arasında yeterli zaman ayrımı sağlayın (tipik olarak 0,2-0,4 saniye)

- Herhangi bir ayar değişikliğinden sonra koordinasyonu doğrulayın

3. Tutarsız Çok Kutuplu Ayarlar

Sorun: Üç fazlı bir kesicinin her kutbunda farklı değerler ayarlama.

Sonuç: Kesici bir fazda açabilirken diğerleri kapalı kalabilir, bu da motorlara ve diğer üç fazlı ekipmanlara zarar veren tek fazlı çalışma durumunu yaratır.

Çözüm: Üretici özellikle izin vermedikçe ve uygulama asimetrik ayarlar gerektirmedikçe (nadir), her zaman tüm kutupları aynı şekilde ayarlayın.

4. Değişiklikleri Belgelememe

Sorun: Belgeleri veya etiketleri güncellemeden ayarları ayarlama.

Sonuç:

- Gelecekteki bakım personelinin standart dışı ayarlardan haberdar olmaması

- Koordinasyon çalışmaları yanlış hale gelir

- Sorun giderme zorlaşır

- Kod uyumluluğu doğrulanamaz

Çözüm: Aşağıdakiler dahil kapsamlı belgeler tutun:

- Kesici ayarlarıyla birlikte yapılmış tek hat şemaları

- Ayar hesaplama çalışma sayfaları

- Her ayar için tarih ve neden

- Değişikliği yapan kişinin baş harfleri

- Ekipman üzerinde dayanıklı etiketler

5. Uygun Eğitim Olmadan Ayarlama

Sorun: Eğitim almamış personelin karmaşık elektronik açma ünitelerini ayarlamaya çalışması.

Sonuç: Yanlış ayarlar korumayı tehlikeye atar, kodları ihlal eder, garantileri geçersiz kılar, güvenlik tehlikeleri yaratır.

Çözüm:

- Ayarları yalnızca kalifiye elektrikçilerin veya mühendislerin ayarladığından emin olun

- Karmaşık elektronik üniteler için üretici eğitimi sağlayın

- Ayar değişiklikleri için yazılı prosedürler oluşturun

- Kritik devreler için mühendislik incelemesi isteyin

6. Ortam Sıcaklığı Etkilerini İhmal Etme

Sorun: Termal-manyetik kesicileri gerçek kurulum sıcaklığını dikkate almadan ayarlama.

Sonuç: Sıcak ortamlardaki (fırınların yakınında, doğrudan güneş ışığında, yetersiz havalandırılan muhafazalarda) kesiciler erken açabilir.

Çözüm:

- Üretici verilerine göre sıcaklık düşürme faktörlerini uygulayın

- Tipik düşürme: 40°C referansın üzerindeki her °C için %1-3

- Yüksek sıcaklık uygulamaları için elektronik açma ünitelerini düşünün (sıcaklığa daha az duyarlı)

- Mümkünse muhafaza havalandırmasını iyileştirin

7. Anlık Açma Ayarını Çok Düşük Ayarlama

Sorun: Anlık açma ayarını motor kalkış akımının veya transformatör mıknatıslanma akımının altına ayarlama.

Sonuç: Normal ekipman başlatma sırasında istenmeyen açmalar.

Çözüm:

- Motor uygulamaları: Ii > 1,5 × kilitli rotor akımı olarak ayarlayın

- Transformatör uygulamaları: Ii > 12 × transformatör nominal akımı olarak ayarlayın

- Mümkünse gerçek kalkış akımı ölçümleriyle doğrulayın

- Daha iyi koordinasyon için anlık yerine kısa süreli gecikme kullanın

Ayarlanabilir Devre Kesicilerin Bakımı ve Testi

Rutin Kontrol (Yıllık)

Görsel Kontroller:

- Ayarların değişmediğini doğrulayın (belgelerle karşılaştırın)

- Fiziksel hasar, korozyon veya aşırı ısınma belirtileri olup olmadığını kontrol edin

- Ayar mekanizmalarının serbestçe hareket ettiğinden emin olun (erişilebilir ise)

- Etiketlerin okunaklı ve doğru olduğunu doğrulayın

- Terminalleri sıkılık ve renk değişikliği açısından inceleyin

Operasyonel Kontroller:

- Düzgün çalışmayı doğrulamak için kesiciyi manuel olarak çalıştırın

- Açma serbest mekanizmasını kontrol edin (tutamak tutulsa bile kesici açmalıdır)

- Varsa yardımcı kontakları ve aksesuarları test edin

- Gösterge ışıklarının veya ekranların doğru şekilde çalıştığını doğrulayın

Periyodik Test (3-5 Yıl)

Birincil Enjeksiyon Testi:

- Açma performansını doğrulamak için kesiciden gerçek akım enjekte eder

- Her koruma fonksiyonunu birden fazla akım seviyesinde test eder

- Açma süresinin üretici spesifikasyonlarına uygun olduğunu doğrular

- Uzman ekipmana sahip kalifiye bir test şirketi tarafından gerçekleştirilir

Tipik Test Noktaları:

- Uzun süreli: Ir ayarının 0, 0, 0'ü

- Kısa süreli: Isd ayarının 0'ü (varsa)

- Anlık: Ii ayarının 0'ü

- Toprak hatası: Ig ayarının 0'ü (varsa)

Kabul Kriterleri:

- Açma süresi üreticinin tolerans bandı içinde (tipik olarak termal-manyetik için ±, elektronik için ±%5)

- Tüm kutuplar aynı anda açar (1 çevrim içinde)

- Test sırasında görünür hasar veya aşırı ısınma yok

İkincil Enjeksiyon Testi (Elektronik Açma Üniteleri):

- Kesiciden yüksek akım geçirmeden açma ünitesi elektroniğini test eder

- Akım trafosu doğruluğunu ve açma ünitesi mantığını doğrular

- Birincil enjeksiyondan daha sık gerçekleştirilebilir

Kalibrasyon ve Ayarlama

Kalibrasyon Ne Zaman Gerekli:

- Test sonuçları tolerans bandının dışında

- Kesici yüksek arıza akımına maruz kalmış

- Termal-manyetik üniteler 10+ yıl hizmetten sonra

- Üretici tavsiyesine göre elektronik üniteler (genellikle 5-10 yıl)

Kalibrasyon Süreci:

- Üretici veya yetkili servis merkezi tarafından yapılmalıdır

- Özel ekipman ve eğitim gerektirir

- Eski kesicileri değiştirmek daha uygun maliyetli olabilir

- Kalibrasyon tarihini ve sonuçlarını belgelendirin

Kayıt Tutma

Şunların Kayıtlarını Tutun:

- İlk devreye alma test sonuçları

- Tarih ve teknisyen ile tüm periyodik test sonuçları

- Gerekçesi ile birlikte herhangi bir ayar değişikliği

- Bakım faaliyetleri (temizlik, sıkma vb.)

- Arıza işlemleri (tarih, tür, kesicinin arızayı giderip gidermediği)

Önerilen Belgeler:

- Seri numaraları ile kesici veri sayfaları

- Ayarlar işaretlenmiş zaman-akım eğrileri

- Nitelikli test şirketinden test raporları

- Her kesici için bakım günlüğü

Sıkça Sorulan Sorular (SSS)

S: Enerji varken bir devre kesiciyi ayarlayabilir miyim?

C: Kesici tipine ve üretici özelliklerine bağlıdır. Birçok elektronik açma ünitesi, ayarın tamamen dijital olması nedeniyle arayüzleri aracılığıyla enerji varken ayar yapılmasına izin verir. Ancak, termal-manyetik kesiciler, ayar mekanik bileşenlerin hareket ettirilmesini içerdiğinden, güvenlik için tipik olarak enerjisizleştirme gerektirir. Her zaman üreticinin talimat kılavuzuna başvurun ve uygun kilitleme/etiketleme prosedürlerini izleyin. Enerjili ekipman üzerinde herhangi bir çalışma için ark parlaması tehlike analizi ve uygun KKD gereklidir.

S: Devre kesicimin ayarlanabilir olup olmadığını nasıl anlarım?

C: Şu göstergelere bakın: (1) Kesici önünde veya açma ünitesinde görülebilen ayar kadranları, düğmeler veya dijital arayüz, (2) Tip plakasında “AYARLANABİLİR” veya “400-800A” gibi bir aralık gibi işaretler, (3) Ayarlanabilir tipi gösteren model numarası (üretici kataloğuna bakın), (4) Elektronik açma ünitesinin varlığı (çoğu ayarlanabilir). Emin değilseniz, belirli model numaranız için üreticinin veri sayfasına bakın. 100A'nın altındaki çoğu MCB'nin (minyatür devre kesiciler) yalnızca sabit açmalı olduğuna dikkat edin.

S: Ayarlanabilir açma ve değiştirilebilir açma arasındaki fark nedir?

A: Ayarlanabilir açma kadranlar, anahtarlar veya programlama kullanarak belirtilen bir aralıkta açma ayarlarını (akım ve zaman değerleri) değiştirebileceğiniz anlamına gelir. Değiştirilebilir açma tüm açma ünitesini fiziksel olarak çıkarıp farklı bir değerle değiştirebileceğiniz anlamına gelir. Değiştirilebilir açma üniteleri daha da fazla esneklik sunar—aynı kesici çerçevesinde 600A'lık bir açma ünitesinden 800A'lık bir açma ünitesine geçebilirsiniz—ancak daha pahalıdırlar ve tipik olarak yalnızca daha büyük güç devre kesicilerinde bulunurlar. Bazı kesiciler her iki özelliği de sunar: ayarlanabilir olan değiştirilebilir açma üniteleri.

S: Devre kesicimi ayarlamak garantiyi veya UL listesini geçersiz kılar mı?

C: Düzgün yapıldığında hayır. Ayarlanabilir devre kesiciler, özellikle belirtilen aralıkta sahada ayarlanacak şekilde tasarlanmış ve UL listesine alınmıştır. UL listesi tüm ayar aralığını kapsar. Ancak, aşağıdaki durumlarda garanti geçersiz olabilir: (1) Ayarlar kalifiye olmayan personel tarafından yapıldığında, (2) Ayarlar belirtilen aralığın dışında yapıldığında, (3) Ayar sırasında fiziksel hasar meydana geldiğinde, (4) Uygun aletler kullanılmadığında. Her zaman üretici talimatlarını izleyin ve ayarlamaların belgelerini saklayın.

S: Ayarlanabilir devre kesici ayarlarını ne sıklıkla doğrulamalı veya yeniden kalibre etmeliyim?

A: Doğrulama (ayarların belgelere uygun olup olmadığını kontrol etme): Rutin denetimler sırasında yıllık olarak. Test (gerçek açma performansını doğrulama): Birincil enjeksiyon testi yoluyla her 3-5 yılda bir veya herhangi bir yüksek arıza akımı işleminden sonra. Yeniden kalibrasyon (doğruluğu geri yüklemek için dahili bileşenleri ayarlama): Yalnızca test sonuçları toleransın dışına düştüğünde, tipik olarak termal-manyetik tipler için 10+ yıl sonra veya elektronik tipler için üretici programına göre. Kritik uygulamalar (hastaneler, veri merkezleri, yaşam güvenliği sistemleri) NFPA 70B veya sigorta gereksinimlerine göre daha sık test gerektirebilir.

S: Ayarlanabilir bir devre kesiciyi bir konut panosunda kullanabilir miyim?

C: Genellikle hayır. Konut panoları (yük merkezleri), neredeyse her zaman 15-125A değerinde sabit açmalı tipler olan takılabilir minyatür devre kesiciler (MCB'ler) için tasarlanmıştır. Ayarlanabilir devre kesiciler tipik olarak ticari ve endüstriyel panolarda kullanılan cıvatalı montajlı kalıplı kasa (MCCB) veya hava devre kesicileridir (ACB). Nadir istisnalar vardır—bazı üst düzey konut uygulamaları küçük ayarlanabilir MCCB'ler kullanır—ancak standart konut panoları bunları barındırmaz. Ek olarak, NEC ve yerel yönetmelikler, kalifiye olmayan kişiler tarafından yanlış ayar olasılığı nedeniyle konut uygulamalarında ayarlanabilir kesicileri kısıtlayabilir.

S: Ayarlanabilir kesiciyi çok düşük ayarlarsam ne olur?

C: Açma akımını çok düşük ayarlamak, normal çalışma sırasında gereksiz açmaya neden olur. Kesici, yük normal çalışma seviyelerine ulaştığında gereksiz yere gücü keserek ekipman kapanmalarına ve operasyonel aksamalara neden olur. Örneğin, bir kesiciyi 50A'ya ayarlarsanız, ancak bağlı yük normal çalışma sırasında düzenli olarak 60A çekerse, kesici tekrar tekrar açacaktır. Çözüm, gerçek yük gereksinimlerine (tipik olarak maksimum sürekli yükün 100-125%'si) göre uygun ayarı yeniden hesaplamak, iletken akım taşıma kapasitesinin yeterli olduğunu doğrulamak ve buna göre ayarlamaktır.

S: Ayarlanabilir devre kesiciler özel kurulum prosedürleri gerektirir mi?

C: Fiziksel kurulum, aynı tipteki sabit açmalı kesicilerle aynıdır—terminaller için uygun montaj, tork özellikleri ve boşluk gereksinimleri. Ancak, ayarlanabilir kesiciler ek adımlar gerektirir: (1) İlk yapılandırma: Ayarlar enerji verilmeden önce hesaplanmalı ve ayarlanmalıdır, (2) DokümantasyonEtiketleme : Ayarlar kaydedilmeli ve etiketlenmelidir, (3)Koordinasyon doğrulaması : Ayarlar sistem koordinasyon çalışmasına göre doğrulanmalıdır, (4)Devreye alma testi.

: Birçok spesifikasyon, doğru çalışmayı doğrulamak için ilk açma testini gerektirir. Bazı yargı bölgeleri, enerji verilmeden önce ayarların elektrik mühendisi tarafından onaylanmasını gerektirir.

S: Ayarlanabilir devre kesiciler ark parlaması tehlikesini azaltmaya yardımcı olabilir mi?.

Sonuç: Uygulamanız için Doğru Seçimi Yapmak

C: Evet, düzgün uygulandığında. Kısa süreli gecikme ayarlarına sahip ayarlanabilir kesiciler, servis çalışması sırasında "bakım modu" için yapılandırılabilir—kısa süreli gecikmeyi geçici olarak sıfıra (yalnızca anlık açma) indirerek ark parlaması olay enerjisini önemli ölçüde azaltır. Bazı elektronik açma ünitelerinde özel bir "bakım modu" anahtarı bulunur. Ek olarak, ayarlanabilir ayarlar kullanılarak uygun koordinasyon, arıza giderme süresini azaltabilir, bu da doğrudan ark parlaması enerjisini azaltır (E = P × t). Ancak, ark parlaması azaltımı kapsamlı analiz gerektirir ve NFPA 70E ve IEEE 1584 yönergelerini izleyen kalifiye mühendisler tarafından yapılmalıdır.

Ayarlanabilir devre kesiciler, elektrik koruma teknolojisinde önemli bir ilerlemeyi temsil eder ve sabit açmalı kesicilerin eşleşemeyeceği esneklik, hassasiyet ve maliyet etkinliği sunar. Ancak, her uygulama için doğru seçim değillerdir.:

- Aşağıdaki durumlarda ayarlanabilir devre kesicileri seçin

- Yük koşulları değişir veya değişmesi beklenir

- Diğer koruyucu cihazlarla hassas koordinasyon gereklidir

- Gelecekte sistemin genişletilmesi bekleniyor

- Motor veya ekipman kalkış akımları sabit kesicilerle gereksiz açmaya neden olur

- Gelişmiş özelliklere (ölçüm, iletişim) ihtiyaç duyulur

Yük sabit ve iyi tanımlanmış olduğunda sabit açma değerli kesicileri tercih edin:

- Yük sabit ve iyi tanımlanmış olduğunda

- Basit konut veya hafif ticari uygulama

- Bütçe kısıtlamaları önemlidir

- Ayarlama için kalifiye personel bulunmadığında

- Yasa veya sigorta gereksinimleri sabit koruma gerektirdiğinde

Ayarlanabilir devre kesicilerin başarılı bir şekilde uygulanmasının anahtarı, doğru seçim, doğru ilk yapılandırma, eksiksiz dokümantasyon ve periyodik doğrulamadır. Bu unsurlar yerinde olduğunda, ayarlanabilir kesiciler üstün koruma, operasyonel esneklik ve uzun vadeli değer sağlar.

At VIOX Elektrik, hem termik-manyetik hem de elektronik açma ünitelerine sahip ayarlanabilir MCCB'ler dahil olmak üzere kapsamlı bir devre koruma cihazları yelpazesi üretiyoruz. Mühendislik ekibimiz, elektrik dağıtım sisteminizin optimum koruma ve güvenilirlik sağlaması için doğru seçim, koordinasyon çalışmaları ve teknik destek konusunda yardımcı olabilir.

Devre kesici seçimi ve uygulaması hakkında daha fazla bilgi için şu ilgili kaynakları inceleyin:

- Kalıplı Kutulu Devre Kesici (MCCB) Nedir?

- Devre Kesici Çeşitleri

- Bir Panele MCCB Nasıl Seçilir

- Şalter Değerleri: ICU, ICS, ICW, ICM

- Devre Kesici Açma Eğrilerini Anlamak

- MCB ve MCCB: Temel Farklılıkları Anlamak

- Devre Koruma Seçim Çerçevesi: 5 Adımlı Bir Kılavuz

- Elektrik Güvenliği için MCCB İsim Plakaları Nasıl Okunur

- Kontaktör ve Motor Yolverici

- Termik Aşırı Yük Röleleri Nelerdir?