VIOX Electric is a leading manufacturer of renewable energy electrical equipment, specializing in high-quality solar photovoltaic solutions for the global market. Our VOPV1000-3/3 Solar Combiner Box represents a premium multi-circuit solution designed specifically for advanced DC1000V solar systems requiring complete circuit independence, multi-inverter capability, and maximum operational flexibility.The VOPV1000-3/3 is a professional-grade DC combiner box engineered for high-voltage solar PV systems operating at DC1000V. This advanced 3-input, 3-output configuration features

three completely independent circuits , each with dedicated protection and control devices. Unlike combined configurations, the 3/3 architecture maintains total isolation between strings, making it ideal for multi-inverter systems, multi-MPPT applications, three-phase installations, and projects requiring maximum safety through circuit independence.

Key Features & Benefits

Three Independent Circuits : Complete electrical isolation between all three strings – each has its own protection and outputMulti-Inverter Ready : Perfect for systems with multiple inverters or multi-MPPT input invertersMaximum Circuit Independence : Each string operates completely independently with dedicated switch, SPD, and fusesDC1000V High Voltage Rating : Optimized for next-generation solar systems with high-efficiency modulesTriple Protection Systems : Three complete protection sets (3 switches, 3 SPDs, 6 fuses) for ultimate safety45A Per Output : Each of the three outputs rated for 45A, supporting high-power stringsIndividual Control : Operate, maintain, or isolate any string without affecting the othersEnhanced Safety : Complete circuit isolation eliminates cross-circuit faults and simplifies troubleshootingLarge Capacity Enclosure : VOAT-39 (296 x 550 x 130mm) accommodates three full protection circuitsRobust Construction : IP65-rated ABS enclosure withstands harsh environmental conditionsThree-Phase Compatible : Ideal for three-phase inverter systems with separate DC inputsPhased Operation Ready : Activate or deactivate individual circuits for staged commissioningCertified Quality : Complies with EN50539 Type 2 standards for high-voltage photovoltaic applications

Technical Specifications

General Data

Parameter

Specification

Model

VOPV1000-3/3

Rated Voltage

DC1000V

Configuration

3 Independent Inputs / 3 Independent Outputs

Maximum Current Per Output

45A

Maximum String Current

15A per string

Degree of Protection

IP65

Operating Temperature

-25°C to +60°C

Maximum Altitude

2000m (standard), >2000m on request

Standard Compliance

EN50539 Type 2

Insulation Voltage

DC1500V

Circuit Independence

Complete electrical isolation between all three circuits

Recommended System Size

15-25kW (multi-inverter or multi-MPPT)

Enclosure Specifications

Parameter

Value

Model

VOAT-39

Material

ABS (Acrylonitrile Butadiene Styrene)

Protection Rating

IP65

Dimensions (H x W x D)

296mm x 550mm x 130mm

Mounting Type

Wall-mounted

Color

Light Gray (RAL 7035)

Fire Rating

Self-extinguishing, UL94 V0 flame-retardant material

UV Resistance

UV-stabilized for outdoor applications

Cable Entry Points

Multiple M16/M20/M25 knockouts (arranged for 3 circuits)

Weight

Approximately 6.5kg (with all components)

Internal Layout

Three independent circuit sections with clear separation and labeling

PV Switch Disconnector

Parameter

Specification

Model

VOD1-63/4B

Type

DC Load Break Switch

Quantity

3 units (one per circuit)

Rated Voltage

DC1000V

Rated Current

45A per switch

Number of Poles

2-pole (positive and negative) per switch

Breaking Capacity

According to EN50539

Operation

Manual rotary operation with clear ON/OFF indication

Mounting

DIN rail compatible (35mm)

Handle Type

Red/Green rotary handle with padlock facility

Contact Material

Silver alloy optimized for DC switching

Independence

Each switch controls only its corresponding circuit

Electrical Life

>10,000 operations at rated current

Mechanical Life

>100,000 operations

DC Surge Arrester (SPD)

Parameter

Specification

Model

VO-PV1000

Type

Type 2 DC Surge Protection Device

Quantity

3 units (one per circuit)

Maximum Continuous Operating Voltage (Uc)

DC1000V

Nominal Discharge Current (In)

20kA (8/20μs) per unit

Maximum Discharge Current (Imax)

40kA (8/20μs) per unit

Voltage Protection Level (Up)

≤3.5kV

Number of Poles

2-pole + PE per unit

Response Time

<25ns

Status Indication

Visual indicator window (green = OK, red = replace)

Standard

EN50539 Type 2, IEC 61643-31

Mounting

DIN rail compatible

Independence

Each SPD protects only its corresponding circuit

Follow Current Extinction

Self-extinguishing design

Thermal Disconnector

Integrated for end-of-life protection

DC Fuse Holder & Fuse

Parameter

Specification

Model

VOPV-32

Fuse Type

gPV (Photovoltaic fuse)

Rated Voltage

DC1000V

Rated Current

15A

Breaking Capacity

30kA @ DC1000V

Fuse Size

10 x 38mm

Configuration

6 fuse holders total (2 per string: positive and negative)

Fuse Links Included

6 pieces (15A DC gPV fuse)

Protection Scheme

Individual dual-pole protection for each of three strings

Mounting

DIN rail compatible

Standard

IEC 60269-6

Indicator

Visual fuse status indicator per holder

Contact Material

Copper, tin-plated

Operating Temperature

-40°C to +85°C

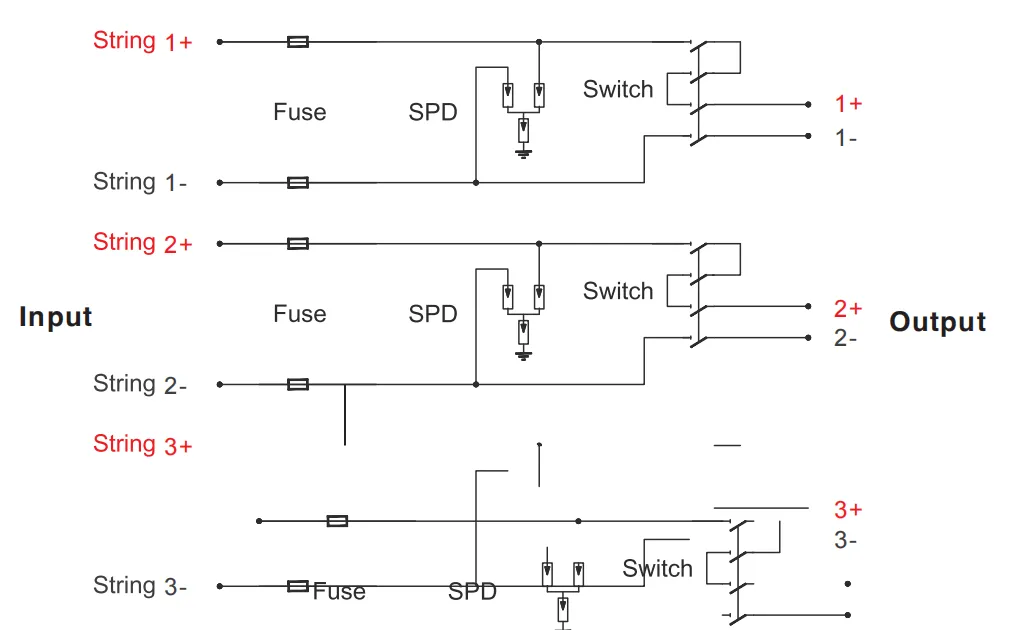

Electrical Configuration

The VOPV1000-3/3 features a unique three-independent-circuit architecture that fundamentally differs from combining configurations:

Three Independent Circuit Paths:

Circuit 1:

String 1 Input (positive + and negative -)

Dual-pole fuse protection (2 fuses)

VO-PV1000 surge protection device

VOD1-63/4B switch disconnector

Output 1 (independent feed to inverter/MPPT input 1)

Circuit 2:

String 2 Input (positive + and negative -)

Dual-pole fuse protection (2 fuses)

VO-PV1000 surge protection device

VOD1-63/4B switch disconnector

Output 2 (independent feed to inverter/MPPT input 2)

Circuit 3:

String 3 Input (positive + and negative -)

Dual-pole fuse protection (2 fuses)

VO-PV1000 surge protection device

VOD1-63/4B switch disconnector

Output 3 (independent feed to inverter/MPPT input 3)

Key Architectural Features:

Complete Isolation:

No electrical connection between the three circuits

Each circuit operates independently

Fault in one circuit does not affect others

Individual voltage and current characteristics maintained

Independent Protection:

Each string has dedicated overcurrent protection (fuses)

Each circuit has dedicated surge protection (SPD)

Each circuit has dedicated isolation switch

Visual status monitoring for each protection device

Independent Control:

Individual ON/OFF control per circuit

Independent lockout/tagout capability

Selective maintenance without system shutdown

Phased commissioning and operation

Terminal Configuration:

6 input terminals (2 per string: +/-)

6 output terminals (2 per circuit: +/-)

1 common PE (Protective Earth) terminal

All terminals rated for DC1000V

Input terminals: 4-6mm² cable capacity

Output terminals: 6-16mm² cable capacity

Bill of Materials

Item No.

Component

Model/Specification

Quantity

1

ABS Enclosure

VOAT-39, 296x550x130mm, IP65

1

2

DC Switch Disconnector

VOD1-63/4B, 2P, 45A, DC1000V

3

3

DC Surge Arrester

VO-PV1000, Type 2, 20kA, DC1000V

3

4

DC Fuse Holder

VOPV-32, 10x38mm, DC1000V

6

5

DC Fuse Link (gPV)

15A, DC1000V, 10x38mm, 30kA

6

6

Input Terminal Block

4-6mm², Red/Black, 1000V rated

6

7

Output Terminal Block

6-16mm², Red/Black, 1000V rated

6

8

PE Terminal Block

6-16mm², Yellow/Green

1

9

DIN Rail

35mm standard, zinc-plated

3

10

Cable Glands

M16/M20/M25, IP65 rated, 1000V

12

11

Mounting Brackets

Stainless steel 304

3

12

Circuit Separation Barriers

Non-conductive dividers

2

13

Circuit Labels

Circuit 1/2/3 identification labels

1 set

14

Warning Labels

DC1000V safety labels, multilingual

1 set

15

Installation Manual

English/Multi-language, 3/3 configuration guide

1

Applications

The VOPV1000-3/3 Solar Combiner Box is specifically designed for advanced solar installations requiring complete circuit independence:

Multi-Inverter Systems

Systems with three separate string inverters

Distributed inverter architectures

Micro-inverter connection hubs

Multiple small inverters for different roof sections

Systems requiring inverter-level isolation for maintenance

Multi-MPPT Inverter Applications

Three-MPPT input inverters (each circuit to separate MPPT)

Optimized power harvest from different orientations

Independent maximum power point tracking per string

Hybrid inverters with multiple DC inputs

High-performance inverters requiring isolated DC inputs

Three-Phase Solar Systems

Three-phase inverter systems with separate DC inputs per phase

Balanced three-phase power generation

Industrial three-phase applications

Grid-tied three-phase commercial installations

Phase-specific power distribution requirements

Complex Multi-Orientation Arrays

East-West-South three-orientation systems

Different roof sections with distinct characteristics

Mixed tilt angles requiring separate optimization

Arrays with different shading patterns

Optimal energy harvest from diverse conditions

Large Residential and Commercial Installations

Premium residential systems (15-25kW) with advanced architecture

Commercial rooftop arrays requiring maximum flexibility

Building-integrated photovoltaic (BIPV) with multiple zones

Industrial facilities with distributed solar generation

Multi-tenant buildings with separate metering per circuit

Phased Installation and Expansion Projects

Stage 1 : Install Circuit 1, operate independentlyStage 2 : Add Circuit 2 without affecting Circuit 1Stage 3 : Complete with Circuit 3 for full system capacityFlexibility : Each phase operates independently throughout process

High-Reliability and Safety-Critical Applications

Systems requiring maximum fault isolation

Critical infrastructure with redundancy requirements

Applications demanding individual circuit control

Projects requiring comprehensive safety documentation

Installations with stringent compliance requirements

Monitoring and Data Acquisition Systems

String-level performance monitoring

Individual circuit data collection

Advanced analytics requiring per-string data

Fault detection and diagnostic systems

Energy management systems with granular control

Benefits of 3/3 Independent Configuration

Complete Circuit Independence

Total Electrical Isolation : Zero electrical connection between the three circuitsFault in one circuit cannot propagate to others

Maximum system reliability through redundancy

Simplified fault diagnosis and troubleshooting

Enhanced safety through isolation

Individual Circuit Control : Operate any circuit independentlyMaintenance on one circuit without system shutdown

Selective activation for commissioning

Independent testing and validation

Flexible operational modes

Multi-Inverter System Advantages

Perfect for Multiple Inverters : Direct connection to three separate invertersDistributed inverter architectures supported

Optimal inverter sizing per circuit

Inverter-level redundancy

Individual inverter maintenance without system downtime

Multi-MPPT Optimization : Each circuit to separate MPPT input for maximum efficiencyIndependent optimization per string orientation

Better performance in complex shading scenarios

Maximized energy harvest from diverse conditions

Advanced power electronics integration

Enhanced Safety and Reliability

Maximum Fault Isolation : Fault in one string does not affect othersContinue operation at 67% capacity if one circuit fails

Reduced risk of cascading failures

Enhanced arc fault containment

Simplified troubleshooting with isolated circuits

Individual Protection Devices : Three complete protection sets eliminate single points of failureIndependent surge protection per circuit

Dedicated switching per circuit for maintenance safety

Individual fusing prevents cross-circuit issues

Redundant protection philosophy

Operational Flexibility

Phased Commissioning : Activate circuits one at a time during commissioningTest each circuit independently

Simplified startup procedures

Reduced commissioning risk

Systematic validation process

Selective Maintenance : Service one circuit while others remain operationalMinimize system downtime

Scheduled maintenance without production loss

Individual component replacement

Simplified lockout/tagout procedures

Mixed System Configurations : Different string configurations per circuit possibleVarying module types or quantities per circuit

Accommodate system changes over time

Flexible for future modifications

Support legacy and new components simultaneously

Performance Advantages

Optimized Power Electronics : Each circuit optimized for its specific conditionsBetter MPPT performance with separate inputs

Reduced losses from string mismatch

Enhanced performance in partial shading

Maximum energy yield from diverse orientations

String-Level Monitoring : Precise performance data per circuitIdentify underperforming strings immediately

Detailed energy production analytics

Predictive maintenance capabilities

Enhanced system optimization

Cost-Benefit Analysis vs. 3/1 Configuration

Higher Initial Investment but Greater Value : Three complete protection sets vs. shared componentsLarger enclosure to accommodate independent circuits

More complex wiring but greater flexibility

Higher component count ensures reliability

Long-Term Operational Savings : Reduced maintenance downtime (maintain one circuit at a time)Better energy yield through optimization

Lower risk of total system failure

Simplified troubleshooting reduces service costs

Extended system lifetime through redundancy

Ideal When:

Using multi-MPPT inverters (maximize their capability)

Multiple inverters in system (direct connection)

Maximum reliability required (critical applications)

Complex orientations (optimize each separately)

Phased installation planned (add circuits over time)

Quality & Compliance

Certifications & Standards:

EN50539 Type 2 – Photovoltaic (PV) systems – DC connectors for 1000V applications

IEC 60269-6 – Low-voltage fuses for photovoltaic applications (1000V)

IEC 61643-31 – Surge protective devices for photovoltaic installations (1000V)

IEC 60947-3 – Low-voltage switchgear – Switches, disconnectors (1000V DC)

IP65 – Ingress Protection (dust-tight and water jet protected)

RoHS Compliant – Restriction of Hazardous Substances

REACH Compliant – EU chemicals regulation

CE Marking – European conformity

Quality Assurance Testing:

100% factory testing of all three independent circuits

High-voltage withstand testing (DC1500V for 1 minute per circuit)

Insulation resistance verification (>200MΩ @ DC1000V per circuit)

Circuit isolation testing (>200MΩ between circuits)

High-temperature aging tests (96 hours at 70°C)

Thermal cycling tests (-40°C to +85°C, 100 cycles)

Mechanical stress testing (vibration and impact per IEC standards)

Contact resistance measurement on all terminals (<30μΩ)

All three surge protection devices tested per IEC 61643-31

UV aging test for enclosure materials (1000 hours)

Independent operation verification for all three circuits

Manufacturing Excellence:

ISO 9001:2015 certified manufacturing facility

ISO 14001:2015 environmental management system

Strict quality control procedures for multi-circuit assemblies

Premium component selection from certified suppliers (UL, TÜV listed)

Specialized assembly process for independent circuit architecture

Manual inspection of all electrical connections and isolation barriers

Comprehensive final inspection and functional testing per circuit

Complete traceability system for all components and assemblies

Continuous improvement programs based on field performance data

Installation & Maintenance

Installation Guidelines

Site Selection for Multi-Circuit Installation:

Mount in a well-ventilated location with easy access for maintenance

Ensure protection from direct sunlight, rain, and water accumulation

Minimum clearance of 200mm on all sides for ventilation and access

Consider cable entry paths from three different string locations

Position for easy visual inspection of all three SPD indicators

Ensure sufficient space for future service access to individual circuits

Mounting Procedure:

Use appropriate mounting hardware rated for enclosure weight (6.5kg + cables)

Ensure level installation using spirit level (critical for larger enclosure)

Verify enclosure is securely fastened (minimum 6 fixing points due to size)

Maintain IP65 protection rating after installation

Consider load distribution on mounting surface due to weight

Circuit Connection Sequence:

Label all three circuits clearly before connection (Circuit 1, 2, 3)

Connect circuits in numerical order for systematic installation

Critical : Maintain complete separation between circuits during wiringVerify correct polarity for each circuit before termination

Use cables rated for DC1000V with appropriate temperature rating

Input cables: 4-6mm² (15A max per string)

Output cables: 6-16mm² (to accommodate 45A capacity)

Independent Circuit Wiring:

Route Circuit 1, 2, and 3 cables separately to avoid confusion

Use consistent color coding within each circuit (Red +, Black -)

Maintain physical separation between circuit cables where possible

Label all cables clearly with circuit number

Apply proper torque to all terminals (1.2-1.5 Nm as specified)

Ensure proper cable entry sealing with appropriate glands

Pre-Commissioning Checks (Per Circuit):

Perform insulation resistance test on each circuit (minimum 200MΩ @ DC1000V)

Verify insulation between circuits (minimum 200MΩ between any two circuits)

Verify continuity of PE connection (common to all circuits)

Check all mechanical connections for tightness in each circuit

Confirm all three SPD indicators show green (operational status)

Test each switch disconnector operation individually under no-load

Verify all cable glands are properly sealed

Measure open-circuit voltage of each string independently

Critical : Verify no electrical connection exists between circuits

Phased Commissioning Procedure:

Commission Circuit 1 first, verify operation

Commission Circuit 2, ensure Circuit 1 unaffected

Commission Circuit 3, verify all three operate independently

Confirm isolation: disconnect each circuit individually while others operate

Safety Precautions

Multi-Circuit Safety Considerations:

Critical : Even with one circuit disconnected, other circuits remain energizedNever assume entire system is de-energized until ALL THREE circuits verified

Use multi-point voltage testing on all three circuits independently

Implement lockout/tagout procedures with THREE SEPARATE LOCKS if working on all circuits

DC1000V Multi-Circuit Safety:

Qualified personnel only – specialized multi-circuit training required

Always use appropriate PPE: insulated gloves (Class 2), safety glasses, arc-rated clothing

Use CAT III 1000V rated test equipment only

Be aware that capacitive charge may remain in cables after disconnection

Operational Safety:

Always open the specific switch disconnector before accessing that circuit’s components

Wait minimum 5 minutes after disconnection before opening enclosure

Use voltage detector to verify absence of voltage on the specific circuit

Test adjacent circuits to ensure they remain isolated

Never exceed rated voltage (DC1000V) and current specifications

Do not operate switch disconnectors under load

Maintain clear identification of which circuit is being serviced

Maintenance Recommendations

Regular Inspection (Every 6 Months):

Visual inspection of all three circuits for signs of damage or overheating

Check all three SPD indicators (green = OK, red = replace immediately)

Inspect enclosure for cracks, damage, or compromised seals

Verify cable glands maintain proper seal integrity on all circuits

Check for any signs of moisture ingress

Inspect each circuit’s fuse status visually

Verify circuit separation barriers remain intact

Annual Maintenance (Per Circuit):

Verify all connections remain tight in each circuit (retorque: 1.2-1.5 Nm)

Test each switch disconnector operation individually under no-load

Perform insulation resistance test on each circuit (should be >200MΩ)

Test insulation between circuits (should be >200MΩ between any pair)

Clean enclosure exterior with damp cloth

Inspect internal components in each circuit for signs of aging

Verify string voltage on each circuit independently

Component Replacement (Per Circuit):

Replace fuses only with identical specifications (15A gPV, DC1000V, 10x38mm, 30kA)

Always replace fuses in pairs (positive and negative) for same circuit

SPD replacement: only use VO-PV1000 or equivalent approved model

When replacing SPD, only that circuit needs to be de-energized

Maintain detailed maintenance log for each circuit separately

Record component replacements per circuit for trend analysis

Independent Circuit Troubleshooting

Symptom

Possible Cause

Solution

Circuit 1 no output, Circuits 2&3 OK

Circuit 1 fuse blown

Check/replace Circuit 1 fuses only, others unaffected

Circuit 1 switch OFF

Turn Circuit 1 switch to ON

All three circuits no output

Common issue upstream

Check array-level connections

All three switches OFF

Verify all switches in ON position

One circuit overheating

Loose connection in that circuit

Retorque terminals in affected circuit only

Undersized cable

Verify and upgrade cable for that circuit

One SPD indicator red

That circuit’s SPD end-of-life

Replace SPD in affected circuit, others continue operating

Unbalanced output between circuits

Different string configurations

Verify each string design independently

Module degradation in one string

Investigate specific circuit’s performance

Frequent fuse failure (one circuit)

Short circuit in that specific string

Inspect string for that circuit only

Overcurrent condition

Verify that circuit’s string design <15A

Two circuits normal, one intermittent

Faulty component in intermittent circuit

Isolate and diagnose that circuit independently

Technical Comparison: VOPV1000-3/3 vs VOPV1000-3/1

Feature

VOPV1000-3/3

VOPV1000-3/1

Architecture

3 Independent Circuits

3 Inputs Combined to 1 Output

String Inputs

3

3

Outputs

3 Independent

1 Combined

Circuit Isolation

Complete (no connection)

Combined (parallel connection)

Enclosure Size

296x550x130mm (VOAT-39)

296x230x120mm (VOAT-13)

Switch Disconnectors

3 units (one per circuit)

1 unit (after combining)

SPD Units

3 units (one per circuit)

1 unit (after combining)

Fuse Holders

6 (2 per string)

6 (2 per string)

Weight

~6.5kg

~3.5kg

Ideal Application

Multi-inverter, multi-MPPT

Single inverter, combined feed

Circuit Control

Individual per circuit

All circuits together

Fault Isolation

Complete (one circuit fails, others OK)

Partial (fault may affect combined output)

Maintenance Downtime

Minimal (service one, others run)

Full system (must disconnect all)

Multi-Inverter Support

Excellent (direct connection)

Not applicable

Multi-MPPT Support

Excellent (separate MPPT per circuit)

Limited (combined input)

System Size

15-25kW

10-15kW

Cost

Higher (triple protection)

Lower (shared protection)

Flexibility

Maximum

Moderate

Best For

Complex systems, maximum reliability

Simple systems, cost optimization

Why Choose VIOX VOPV1000-3/3?

Unmatched Circuit Independence : Three completely isolated circuits eliminate cross-circuit interference, maximizing system reliability and allowing operation even if one circuit issues occur.Multi-Inverter System Excellence : Direct connection to three separate string inverters, ideal for distributed architectures and advanced multi-MPPT systems.Superior Safety Architecture : Triple protection systems eliminate single points of failure, with individual circuit control for safer maintenance and simplified lockout/tagout.Maximum Operational Flexibility : Supports phased commissioning, selective maintenance, and mixed configurations to adapt to changing system requirements.Professional Engineering : Large VOAT-39 enclosure with optimized internal layout, premium DC1000V components, and enhanced insulation coordination.Advanced System Capabilities : Supports string-level monitoring, smart solar installations, and sophisticated energy management systems.Long-Term Value : Higher reliability reduces total cost of ownership, minimizes maintenance downtime, and extends system lifetime through redundancy.

Get in Touch

Ready to implement the ultimate multi-circuit solution with the VOPV1000-3/3 Solar Combiner Box? Contact VIOX Electric today for:

Detailed technical specifications and CAD drawings

Multi-inverter and multi-MPPT system design consultation

Independent circuit configuration optimization

Competitive pricing and MOQ (Minimum Order Quantity) information

Custom configuration options for specific project requirements

Technical guidance on complex multi-circuit installations

Sample orders for testing and evaluation

Bulk order quotations with volume discounts

Delivery timeline and international logistics support

Specialized installation training for 3/3 independent configuration

Product certifications and compliance documentation

Integration support for multi-inverter systems

String-level monitoring system recommendations