VOPV1000-3/1 Solar Combiner Box

Streamline your solar installation with the VIOX VOPV1000-3/1, a high-performance 3-String Solar Combiner Box. This DC1000V unit efficiently combines three independent solar strings into a single output, perfect for complex roof layouts and multi-orientation arrays.

- Configuration: 3 Inputs / 1 Output (3-in-1-out)

- Max Voltage: DC1000V

- Total Current: 45A Output (15A per string)

- String Protection: 6x Integrated 15A gPV Fuses (2 per string)

- Surge Protection: Type 2 DC SPD (20kA/40kA)

- Isolation: 45A DC Switch Disconnector

- Enclosure: IP65 Waterproof ABS (296 x 230 x 120mm)

The ideal PV combiner box for 10-15kW systems, offering superior wire management and cost savings.

Send your requirements, we will quote for you within 12 hours

- TEL:+8618066396588

- Whatsapp:+8618066396588

- Email:[email protected]

Product Overview

VIOX Electric is a leading manufacturer of renewable energy electrical equipment, specializing in high-quality solar photovoltaic solutions for the global market. Our VOPV1000-3/1 Solar Combiner Box represents an advanced multi-string solution designed specifically for medium to large-scale DC1000V solar systems that require flexible design and efficient power consolidation.

The VOPV1000-3/1 is a professional-grade DC combiner box engineered for high-voltage solar PV systems operating at DC1000V. This versatile 3-input, 1-output configuration enables efficient consolidation of three independent solar strings into a single output feed, making it ideal for complex roof layouts, multi-orientation installations, and phased solar projects. With its 45A current rating and comprehensive protection for each string, this combiner box delivers optimal performance for 10-15kW solar installations.

Key Features & Benefits

- Triple-String Capability: 3 independent input strings combined into 1 output for streamlined system architecture

- DC1000V High Voltage Rating: Optimized for next-generation solar systems with high-efficiency modules

- 45A Output Current: Sufficient capacity for high-power multi-string configurations

- Individual String Protection: Dedicated fuse protection for each string (6 fuses total) enables precise fault isolation

- Design Flexibility: Perfect for complex roof layouts with multiple orientations (east-west, split arrays)

- Centralized Protection: Single surge protection device and switch disconnector after combining reduces component costs

- Cost-Effective Architecture: Reduces wiring complexity to inverter with single consolidated output

- Robust Construction: IP65-rated ABS enclosure (VOAT-13) withstands harsh environmental conditions

- Phased Installation Ready: Allows gradual system expansion by activating strings sequentially

- Simplified Inverter Connection: Single output feed reduces installation time and material costs

- Easy Troubleshooting: Individual fusing per string simplifies fault diagnosis

- Certified Quality: Complies with EN50539 Type 2 standards for high-voltage photovoltaic applications

Technical Specifications

General Data

| Parameter | Specification |

|---|---|

| Model | VOPV1000-3/1 |

| Rated Voltage | DC1000V |

| Maximum Output Current | 45A |

| Configuration | 3 Inputs / 1 Output |

| Maximum String Current | 15A per string |

| Degree of Protection | IP65 |

| Operating Temperature | -25°C to +60°C |

| Maximum Altitude | 2000m (standard), >2000m on request |

| Standard Compliance | EN50539 Type 2 |

| Insulation Voltage | DC1500V |

| Recommended System Size | 10-15kW |

Enclosure Specifications

| Parameter | Value |

|---|---|

| Model | VOAT-13 |

| Material | ABS (Acrylonitrile Butadiene Styrene) |

| Protection Rating | IP65 |

| Dimensions (H x W x D) | 296mm x 230mm x 120mm |

| Mounting Type | Wall-mounted |

| Color | Light Gray (RAL 7035) |

| Fire Rating | Self-extinguishing, UL94 V0 flame-retardant material |

| UV Resistance | UV-stabilized for outdoor applications |

| Cable Entry Points | Multiple M16/M20/M25 knockouts |

| Weight | Approximately 3.5kg (with components) |

| Internal Layout | Optimized for 3-string configuration with clear labeling |

PV Switch Disconnector

| Parameter | Specification |

|---|---|

| Model | VOD1-63/4B |

| Type | DC Load Break Switch |

| Rated Voltage | DC1000V |

| Rated Current | 45A |

| Number of Poles | 2-pole (positive and negative) |

| Breaking Capacity | According to EN50539 |

| Operation | Manual rotary operation with clear ON/OFF indication |

| Mounting | DIN rail compatible (35mm) |

| Handle Type | Red/Green rotary handle with padlock facility |

| Contact Material | Silver alloy optimized for DC switching |

| Position | After string combining point (common disconnection) |

| Electrical Life | >10,000 operations at rated current |

| Mechanical Life | >100,000 operations |

DC Surge Arrester (SPD)

| Parameter | Specification |

|---|---|

| Model | VO-PV1000 |

| Type | Type 2 DC Surge Protection Device |

| Maximum Continuous Operating Voltage (Uc) | DC1000V |

| Nominal Discharge Current (In) | 20kA (8/20μs) |

| Maximum Discharge Current (Imax) | 40kA (8/20μs) |

| Voltage Protection Level (Up) | ≤3.5kV |

| Number of Poles | 2-pole + PE |

| Quantity | 1 unit (common protection after combining) |

| Response Time | <25ns |

| Status Indication | Visual indicator window (green = OK, red = replace) |

| Standard | EN50539 Type 2, IEC 61643-31 |

| Mounting | DIN rail compatible |

| Follow Current Extinction | Self-extinguishing design |

| Thermal Disconnector | Integrated for end-of-life protection |

DC Fuse Holder & Fuse

| Parameter | Specification |

|---|---|

| Model | VOPV-32 |

| Fuse Type | gPV (Photovoltaic fuse) |

| Rated Voltage | DC1000V |

| Rated Current | 15A |

| Breaking Capacity | 30kA @ DC1000V |

| Fuse Size | 10 x 38mm |

| Configuration | 6 fuse holders (2 per string: positive and negative) |

| Fuse Links Included | 6 pieces (15A DC gPV fuse) |

| Protection Scheme | Individual protection for each string |

| Mounting | DIN rail compatible |

| Standard | IEC 60269-6 |

| Indicator | Visual fuse status indicator per holder |

| Contact Material | Copper, tin-plated |

| Operating Temperature | -40°C to +85°C |

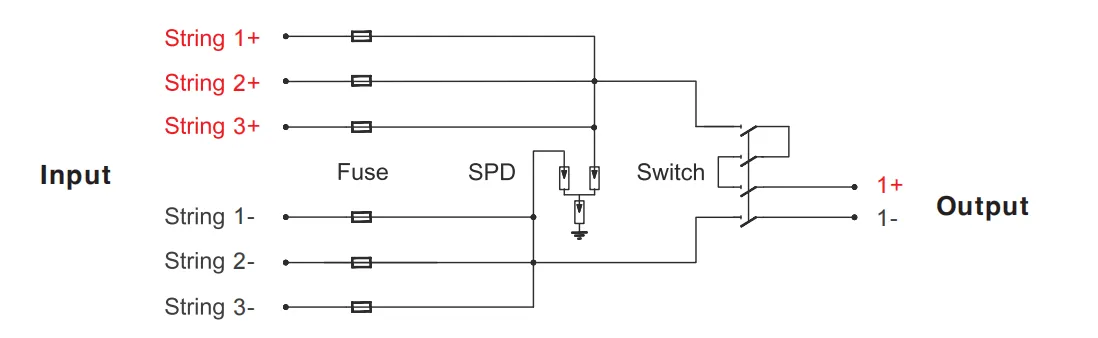

Electrical Configuration

The VOPV1000-3/1 features a sophisticated multi-string electrical design optimized for DC1000V systems with enhanced flexibility and safety:

VOPV1000-3/1 Solar Combiner Box Diagram

Input Configuration:

- Three independent string inputs (String 1, String 2, String 3)

- Each string has dedicated positive (+) and negative (-) terminals

- Individual dual-pole fuse protection for each string (6 fuses total)

- Terminal blocks rated for 4-6mm² cable per string

- Clear identification labels for each string input

- Supports different string configurations and module orientations

String-Level Protection:

- Primary Protection: DC fuses (15A gPV type, 30kA breaking capacity) on both poles of each string

- Individual Fault Isolation: Each string can be isolated independently without affecting others

- Overcurrent Protection: Prevents damage from string-level faults or module failures

Combining Point:

- Internal busbar combines three strings after individual fuse protection

- Parallel connection of all three strings to single output feed

- Optimized busbar design minimizes voltage drop and heating

Common Protection (After Combining):

- Secondary Protection: Type 2 DC surge arrester (VO-PV1000, 20kA nominal discharge)

- Isolation: 2-pole DC switch disconnector (45A rated) for complete system disconnection

- Single Point Control: One switch controls all three strings simultaneously

Output Configuration:

- Single consolidated output to inverter with clear polarity marking

- Terminal blocks rated for 6-16mm² cable (larger to accommodate combined current)

- PE (Protective Earth) connection provided with dedicated terminal

- Output labeled for connection to inverter DC input

Circuit Architecture Benefits:

- Independent string monitoring capability

- Simplified troubleshooting with per-string fusing

- Reduced component count (single SPD and switch for all strings)

- Lower installation cost to inverter (single cable run)

- Enhanced system reliability through fault isolation

Bill of Materials

| Item No. | Component | Model/Specification | Quantity |

|---|---|---|---|

| 1 | ABS Enclosure | VOAT-13, 296x230x120mm, IP65 | 1 |

| 2 | DC Switch Disconnector | VOD1-63/4B, 2P, 45A, DC1000V | 1 |

| 3 | DC Surge Arrester | VO-PV1000, Type 2, 20kA, DC1000V | 1 |

| 4 | DC Fuse Holder | VOPV-32, 10x38mm, DC1000V | 6 |

| 5 | DC Fuse Link (gPV) | 15A, DC1000V, 10x38mm, 30kA | 6 |

| 6 | Input Terminal Block | 4-6mm², Red/Black, 1000V rated | 6 |

| 7 | Output Terminal Block | 6-16mm², Red/Black, 1000V rated | 2 |

| 8 | PE Terminal Block | 6-16mm², Yellow/Green | 1 |

| 9 | DIN Rail | 35mm standard, zinc-plated | 2 |

| 10 | Busbar | Copper, tin-plated, 1000V rated, combining | 1 set |

| 11 | Cable Glands | M16/M20/M25, IP65 rated, 1000V | 8 |

| 12 | Mounting Brackets | Stainless steel 304 | 2 |

| 13 | String Labels | String 1/2/3 identification labels | 1 set |

| 14 | Warning Labels | DC1000V safety labels, multilingual | 1 set |

| 15 | Installation Manual | English/Multi-language, 3/1 configuration guide | 1 |

Applications

The VOPV1000-3/1 Solar Combiner Box is specifically designed for multi-string high-voltage photovoltaic applications:

Residential Solar Systems

- Large residential installations (10-15kW systems)

- Homes with complex roof layouts requiring multiple orientations

- Split-array configurations (east-west, north-south combinations)

- Properties with multiple roof sections or buildings

- Premium residential projects with high-efficiency 500W+ modules

Commercial Installations

- Small to medium commercial rooftop arrays (15-25kW)

- Building-integrated photovoltaic (BIPV) systems with multiple zones

- Industrial facility solar installations with varied roof orientations

- Multi-tenant buildings with consolidated metering

- Carport and canopy solar structures

Complex Roof Scenarios

- Multiple roof pitches requiring separate string configurations

- East-west facing arrays optimizing morning and evening generation

- Partial shading management with string-level optimization

- Historic buildings with architectural constraints

- Mixed tilt angles for optimal year-round performance

Multi-Orientation Benefits

- East-West Systems: Combine east-facing and west-facing strings for extended generation profile

- Split Arrays: Connect strings from different roof sections efficiently

- Azimuth Optimization: Independent strings maximize energy capture from various orientations

- Tilt Variation: Accommodate different mounting angles in single system

Phased Installation Projects

- Stage 1: Install and connect first string, reserve capacity for expansion

- Stage 2: Add second string when budget allows or demand increases

- Stage 3: Complete system with third string for full capacity

- Flexibility: Allows customers to start small and grow over time

System Architecture Applications

- Connection point for three strings to single-input inverter

- Distribution hub for multi-MPPT inverter systems

- Centralized protection and isolation for string-level maintenance

- Simplified wiring to inverter reduces installation complexity

- Ideal for systems requiring string-level monitoring integration

Benefits of 3-to-1 Configuration

Design Flexibility

Complex Roof Layouts

- Accommodates up to three different roof sections or orientations

- Eliminates need for multiple combiner boxes in distributed arrays

- Simplifies system design for challenging installation sites

- Enables creative solutions for architectural constraints

Multi-Orientation Systems

- Optimize energy production across different sun exposure patterns

- Balance morning, midday, and evening generation profiles

- Compensate for shading at different times of day

- Maximize annual energy yield in suboptimal conditions

Cost Efficiency

Installation Savings

- Single output cable to inverter reduces material costs by 50-70%

- Simplified conduit runs and cable management

- Reduced labor time for inverter connection

- Single entry point at inverter simplifies termination

Component Optimization

- One surge protection device instead of three (cost reduction)

- Single switch disconnector for all strings (simplified operation)

- Fewer components reduce failure points and maintenance needs

- Consolidated protection reduces overall system cost

Cable Cost Reduction

- Lower current per string (15A max) allows smaller input cables

- Single larger output cable more economical than three separate runs

- Reduced DC cable losses through optimized architecture

- Less copper required overall compared to separate string runs

Operational Advantages

Simplified Maintenance

- Single access point for all protection devices

- One switch controls entire system for maintenance

- Individual fusing allows string-level troubleshooting

- Clear labeling simplifies fault diagnosis

Enhanced Safety

- Centralized disconnection point reduces arc flash risk

- Single lockout/tagout location for maintenance procedures

- Lower voltage at combining point compared to series connection

- Individual overcurrent protection prevents cascading failures

System Monitoring Integration

- Compatible with string-level monitoring systems

- Individual fuse status enables fault detection

- Simplified data collection point for performance analysis

- Easier integration with smart home or building management systems

Scalability Benefits

Future Expansion Ready

- Start with one or two strings, add third later

- No need to replace combiner box when expanding

- Maintains warranty and certification with expansion

- Protects initial investment while allowing growth

Flexible Capacity Management

- Disconnect individual strings for partial maintenance

- Continue operation with reduced capacity during repairs

- Test new strings before full integration

- Optimize system performance incrementally

Quality & Compliance

Certifications & Standards:

- EN50539 Type 2 – Photovoltaic (PV) systems – DC connectors for 1000V applications

- IEC 60269-6 – Low-voltage fuses for photovoltaic applications (1000V)

- IEC 61643-31 – Surge protective devices for photovoltaic installations (1000V)

- IEC 60947-3 – Low-voltage switchgear – Switches, disconnectors (1000V DC)

- IP65 – Ingress Protection (dust-tight and water jet protected)

- RoHS Compliant – Restriction of Hazardous Substances

- REACH Compliant – EU chemicals regulation

- CE Marking – European conformity

Quality Assurance Testing:

- 100% factory testing before shipment

- High-voltage withstand testing (DC1500V for 1 minute)

- Insulation resistance verification (>200MΩ @ DC1000V)

- High-temperature aging tests (96 hours at 70°C)

- Thermal cycling tests (-40°C to +85°C, 100 cycles)

- Mechanical stress testing (vibration and impact per IEC standards)

- Contact resistance measurement on all terminals (<30μΩ)

- Surge protection device testing per IEC 61643-31

- UV aging test for enclosure materials (1000 hours)

- String balancing test to verify current distribution

Manufacturing Excellence:

- ISO 9001:2015 certified manufacturing facility

- ISO 14001:2015 environmental management system

- Strict quality control procedures at each production stage

- Premium component selection from certified suppliers (UL, TÜV listed)

- Automated busbar assembly for consistent quality

- Manual inspection of all electrical connections

- Comprehensive final inspection and functional testing

- Complete traceability system for all components and assemblies

- Continuous improvement programs based on field performance data

Installation & Maintenance

Installation Guidelines:

Site Selection:

- Mount in a well-ventilated location accessible for maintenance

- Ensure protection from direct sunlight, rain, and water accumulation

- Minimum clearance of 150mm on all sides for ventilation

- Consider cable entry paths from three different string locations

- Position for easy access to switch and visual inspection of SPD indicator

Mounting Procedure:

- Use appropriate mounting hardware rated for enclosure weight (3.5kg + cables)

- Ensure level installation using spirit level

- Verify enclosure is securely fastened (minimum 4 fixing points)

- Maintain IP65 protection rating after installation

- Consider future expansion access when positioning

String Connection Sequence:

- Label all three strings clearly before connection (String 1, 2, 3)

- Connect strings in numerical order for systematic installation

- Verify correct polarity for each string before termination

- Use cables rated for DC1000V with appropriate temperature rating (typically 4-6mm²)

- Apply proper torque to all terminals (1.2-1.5 Nm as specified)

- Ensure proper cable entry sealing with appropriate glands

Electrical Connection Best Practices:

- Follow color-coded terminals: Red (+), Black (-), Yellow/Green (PE)

- Maintain consistent color coding across all three strings

- Use ferrules on stranded conductors for reliable connection

- Verify cable cross-section matches expected current (15A max per string)

- Double-check polarity before energization

- Keep string cables separated to prevent cross-connection errors

Pre-Commissioning Checks:

- Perform insulation resistance test on each string (minimum 200MΩ @ DC1000V)

- Verify continuity of PE connection

- Check all mechanical connections for tightness

- Confirm SPD indicator shows green (operational status)

- Test switch disconnector operation under no-load conditions

- Verify all cable glands are properly sealed

- Measure open-circuit voltage of each string to confirm correct connection

- Verify string voltages are balanced (within 5% of each other)

Safety Precautions:

DC1000V Multi-String Safety:

- Higher complexity requires enhanced safety procedures

- Qualified personnel only – specialized multi-string training required

- Always use appropriate PPE: insulated gloves (Class 2), safety glasses, arc-rated clothing

- Be aware that capacitive charge may remain in cables for several minutes after disconnection

- Use CAT III 1000V rated test equipment only

Multi-String Specific Hazards:

- Even with one string disconnected, voltage remains from other strings

- Never assume system is de-energized until all strings are verified dead

- Use multi-point voltage testing on all three strings

- Implement proper lockout/tagout procedures with multiple locks if needed

Operational Safety:

- Always open the switch disconnector before accessing internal components

- Wait minimum 5 minutes after disconnection before opening enclosure

- Use voltage detector to verify absence of voltage on all strings

- Test each string individually before proceeding with maintenance

- Never exceed the rated voltage (DC1000V) and current specifications

- Do not operate the switch disconnector under load

- Keep the area around the combiner box clear of flammable materials

- Ensure proper grounding of the system PE terminal

Maintenance Recommendations:

Regular Inspection (Every 6 Months):

- Visual inspection for signs of damage, discoloration, or overheating

- Check surge arrester indicator status (green = OK, red = replace immediately)

- Inspect enclosure for cracks, damage, or compromised seals

- Verify cable glands maintain proper seal integrity

- Check for any signs of moisture ingress

- Inspect each string’s fuse status visually

- Look for any unusual patterns (e.g., one string repeatedly blowing fuses)

Annual Maintenance:

- Verify all connections remain tight (retorque check: 1.2-1.5 Nm)

- Test switch disconnector operation under no-load conditions

- Perform insulation resistance test on each string (should be >200MΩ)

- Clean enclosure exterior with damp cloth

- Inspect internal components for signs of aging or degradation

- Check and clean ventilation openings if present

- Verify string voltage balance (all within 5% of each other)

- Inspect busbar connections for signs of heating

Component Replacement:

- Replace fuses only with identical specifications (15A gPV, DC1000V, 10x38mm, 30kA)

- Always replace fuses in pairs (both positive and negative) for same string

- SPD replacement: only use VO-PV1000 or equivalent approved model

- Maintain detailed maintenance log for warranty and safety records

- Record which strings have had fuse replacements for trend analysis

String Balancing and Troubleshooting:

| Symptom | Possible Cause | Solution |

|---|---|---|

| One string no output | Fuse blown in that string | Check and replace both fuses for affected string, investigate cause |

| String disconnected | Verify connections at string input | |

| Unbalanced string voltages | Module mismatch | Verify all modules in string are identical |

| Partial shading | Check for new obstructions on specific string | |

| Module degradation | Investigate module performance in affected string | |

| Frequent fuse failure (one string) | Short circuit in string | Inspect string for damaged cables or modules |

| Overcurrent condition | Verify string design current < 15A | |

| All strings affected | Switch in OFF position | Turn switch to ON position |

| SPD failure | Check SPD indicator, replace if red | |

| Inverter issue | Check inverter DC input status | |

| Overheating at terminals | Loose connection | Retorque terminals to specification |

| Undersized cable | Verify cable sizing, upgrade if necessary | |

| High ambient temperature | Improve ventilation or consider shading | |

| SPD indicator red | SPD end-of-life | Replace SPD immediately, do not operate until replaced |

| Output current imbalance | Different string configurations | Verify all strings have same number and type of modules |

| Module degradation | Investigate performance of specific string |

Technical Comparison: VOPV1000 Series

| Feature | VOPV1000-3/1 | VOPV1000-1/1 |

|---|---|---|

| String Inputs | 3 | 1 |

| String Outputs | 1 (combined) | 1 |

| Enclosure Size | 296x230x120mm | 218x200x100mm |

| Maximum Output Current | 45A | 45A |

| Fuse Holders | 6 (2 per string) | 2 (1 string) |

| Fuse Links | 6 pieces | 2 pieces |

| SPD Units | 1 (after combining) | 1 |

| Weight | ~3.5kg | ~2.2kg |

| Ideal System Size | 10-15kW | 5-8kW |

| Best Application | Multi-orientation, complex roofs | Simple single-string systems |

| String Flexibility | High (3 orientations) | Low (1 orientation) |

| Expansion Capability | Yes (up to 3 strings) | No |

| Cost per String | Lower (shared components) | Higher (dedicated components) |

Why Choose VIOX VOPV1000-3/1?

Multi-String Versatility

- Handles up to three different roof orientations or sections efficiently

- Ideal solution for complex architectural scenarios

- Enables creative system designs that maximize available space

- Perfect for properties with challenging roof layouts

Superior System Economics

- Lower overall cost compared to three separate 1/1 combiner boxes

- Reduced installation labor through single output connection

- Optimized cable costs with consolidated output feed

- Shared protection components reduce BOS (Balance of System) costs

Design Intelligence

- Individual string protection enables precise fault isolation

- Centralized control simplifies operation and maintenance

- Scalable architecture supports phased installation approach

- Future-proof design accommodates system expansion

Professional Engineering

- Purpose-built components rated specifically for DC1000V applications

- Optimized busbar design for efficient string combining

- Enhanced insulation coordination for long-term reliability

- Comprehensive testing ensures multi-string operation reliability

Installation Excellence

- Clear string identification prevents connection errors

- Systematic layout simplifies complex wiring

- Single output point reduces inverter termination complexity

- Professional documentation includes multi-string configuration guide

Technical Support

- Expert engineering support for complex system design

- String configuration optimization assistance

- Comprehensive installation and commissioning guidance

- Responsive after-sales technical assistance for troubleshooting

Get in Touch

Ready to optimize your multi-string solar installation with the VOPV1000-3/1 Solar Combiner Box? Contact VIOX Electric today for:

- Detailed technical specifications and CAD drawings

- Multi-string system design consultation and optimization

- String configuration calculations and recommendations

- Competitive pricing and MOQ (Minimum Order Quantity) information

- Custom configuration options for specific project requirements

- Technical guidance on complex roof layout solutions

- Sample orders for testing and evaluation

- Bulk order quotations with volume discounts

- Delivery timeline and international logistics support

- Installation training specific to 3/1 configuration

- Product certifications and compliance documentation

- String-level monitoring integration support