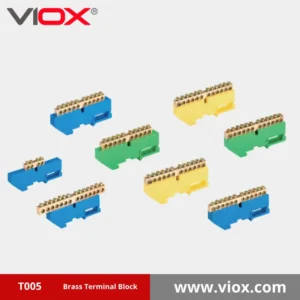

VIOX T002 Brass Terminal Block

VIOX T002 Brass Terminal Blocks: Reliable industrial connections using high-conductivity brass & durable polyamide. DIN rail mount, 4-18 ways. Available in 6×9 (50A, M4) & 8×12 (80A, M5) series. UL/CE/RoHS compliant. Choose blue or yellow.

Send your requirements, we will quote for you within 12 hours

- TEL:+8618066396588

- Whatsapp:+8618066396588

- Email:[email protected]

What Is a Brass Terminal Block?

A brass terminal block is a crucial electrical component designed to securely connect multiple wires in electrical distribution systems. Unlike standard terminal blocks, the T002 brass terminal block series features high-conductivity brass connectors that provide superior electrical performance, enhanced temperature stability, and exceptional corrosion resistance for demanding applications.

The T002 brass terminal block series represents the pinnacle of connection technology, offering reliable power distribution in applications ranging from industrial control panels to high-current electrical systems. These UL-certified components are engineered to provide safe, efficient, and long-lasting electrical connections while meeting stringent industry standards.

Premium Features of the T002 Brass Terminal Block Series

Superior Material Construction

- High-Quality Brass Conductors: Manufactured from premium-grade brass alloy, ensuring excellent electrical conductivity, superior heat dissipation, and remarkable corrosion resistance.

- Durable Insulation Housing: Robust blue polyamide insulation material offering excellent electrical insulation properties, fire resistance, and mechanical strength.

- Precision-Engineered Screws: High-grade steel screws with zinc plating provide secure connections and resistance to loosening under vibration.

Enhanced Design Elements

- Optimized Contact Design: Specialized contact surfaces maximize electrical connection area, reducing contact resistance and minimizing heat generation during operation.

- Advanced Terminal Structure: The unique structure prevents wire damage during installation and ensures reliable long-term performance.

- Versatile Mounting Options: Compatible with standard DIN rails for quick and secure installation in various control panel configurations.

Technical Specifications of the T002 Brass Terminal Block Series

The T002 brass terminal block series is available in multiple configurations to accommodate different connection requirements. Our comprehensive range includes variations in terminal count, dimensions, and screw specifications to meet diverse application needs.

T002-0609 Series (6×9 Specification)

| Article No. | Ways | Spec. | L1 (mm) | L2 Installation Dimension (mm) | Screws | Diameter | Remark |

|---|---|---|---|---|---|---|---|

| T002-0609/4 | 4 | 6×9 | 74 | 63.5 | M4 | 5.2 | T002-0609/4B ■ T002-0609/4Y ■ |

| T002-0609/6 | 6 | 6×9 | 87 | 76.5 | M4 | 5.2 | T002-0609/6B ■ T002-0609/6Y ■ |

| T002-0609/8 | 8 | 6×9 | 100 | 89.5 | M4 | 5.2 | T002-0609/8B ■ T002-0609/8Y ■ |

| T002-0609/10 | 10 | 6×9 | 113 | 102.5 | M4 | 5.2 | T002-0609/10B ■ T002-0609/10Y ■ |

| T002-0609/12 | 12 | 6×9 | 126 | 115.5 | M4 | 5.2 | T002-0609/12B ■ T002-0609/12Y ■ |

| T002-0609/14 | 14 | 6×9 | 139 | 128 | M4 | 5.2 | T002-0609/14B ■ T002-0609/14Y ■ |

| T002-0609/16 | 16 | 6×9 | 152 | 141.5 | M4 | 5.2 | T002-0609/16B ■ T002-0609/16Y ■ |

| T002-0609/18 | 18 | 6×9 | 165 | 154.5 | M4 | 5.2 | T002-0609/18B ■ T002-0609/18Y ■ |

T002-0812 Series (8×12 Specification)

| Article No. | Ways | Spec. | L1 (mm) | L2 Installation Dimension (mm) | Screws | Diameter | Remark |

|---|---|---|---|---|---|---|---|

| T002-0812/4 | 4 | 8×12 | 73 | 60.5 | M5 | 6.0 | T002-0812/4B ■ T002-0812/4Y ■ |

| T002-0812/6 | 6 | 8×12 | 88 | 75.5 | M5 | 6.0 | T002-0812/6B ■ T002-0812/6Y ■ |

| T002-0812/8 | 8 | 8×12 | 103 | 90.5 | M5 | 6.0 | T002-0812/8B ■ T002-0812/8Y ■ |

| T002-0812/10 | 10 | 8×12 | 118 | 105.5 | M5 | 6.0 | T002-0812/10B ■ T002-0812/10Y ■ |

| T002-0812/12 | 12 | 8×12 | 133 | 120.5 | M5 | 6.0 | T002-0812/12B ■ T002-0812/12Y ■ |

| T002-0812/14 | 14 | 8×12 | 148 | 135.5 | M5 | 6.0 | T002-0812/14B ■ T002-0812/14Y ■ |

| T002-0812/16 | 16 | 8×12 | 163 | 150.5 | M5 | 6.0 | T002-0812/16B ■ T002-0812/16Y ■ |

| T002-0812/18 | 18 | 8×12 | 178 | 165.5 | M5 | 6.0 | T002-0812/18B ■ T002-0812/18Y ■ |

Key Technical Parameters

- Material: High-conductivity brass terminals with blue polyamide insulation housing

- Terminal Capacity: Available in 4, 6, 8, 10, 12, 14, 16, and 18 way configurations

- Specifications: 6×9 series and 8×12 series for different current ratings

- Screws: M4 (for 6×9 series) and M5 (for 8×12 series)

- Mounting: Standard DIN rail compatible

- Operating Temperature: -40°C to +130°C

- Voltage Rating: Up to 800V AC/DC (depending on installation conditions)

- Current Rating:

- T002-0609 Series: Up to 50A

- T002-0812 Series: Up to 80A

- Wire Range Compatibility:

- T002-0609 Series: 0.5-10mm²

- T002-0812 Series: 1.0-16mm²

- Color Options: Standard blue insulation housing (B) and yellow insulation housing (Y)

- Certification: UL, CE, RoHS compliant

Applications of T002 Brass Terminal Blocks

The superior quality and robust design of the T002 brass terminal block series make these components ideal for applications where reliability, durability, and high electrical performance are critical requirements.

Industrial Control Systems

In industrial automation and control panels, the T002 brass terminal blocks provide dependable connections for control circuitry, power distribution, and signal transmission. Their high current-carrying capacity and resistance to industrial environments make them perfect for manufacturing facilities, processing plants, and automated production lines.

Power Distribution Panels

The exceptional current-handling capabilities of T002 brass terminal blocks make them ideal for power distribution panels in commercial and industrial settings. Their robust construction ensures safe and reliable electrical connections even under heavy load conditions.

HVAC Systems

In heating, ventilation, and air conditioning installations, T002 brass terminal blocks provide secure connections for control circuits and power distribution. Their resistance to temperature fluctuations and vibration ensures long-term reliability in these critical systems.

Railway and Transportation Systems

The vibration-resistant design and high durability of T002 brass terminal blocks make them suitable for railway signaling systems, transportation control panels, and vehicle electrical systems where reliability under harsh conditions is essential.

Renewable Energy Systems

In solar power installations, wind energy systems, and other renewable energy applications, T002 brass terminal blocks provide reliable connections for power distribution and control circuitry, ensuring efficient energy transfer and system reliability.

Marine and Offshore Applications

The corrosion-resistant properties of brass make T002 terminal blocks particularly valuable in marine environments, shipboard electrical systems, and offshore installations where exposure to moisture and salt air is common.

Installation Guidelines for T002 Brass Terminal Blocks

Proper installation of T002 brass terminal blocks is essential for optimal performance and electrical safety. Follow these professional guidelines to ensure reliable connections:

Mounting Procedure

- Select an appropriate DIN rail that meets industry standards.

- Position the terminal block with the opening facing up for easy wire insertion.

- Snap the terminal block onto the DIN rail by hooking the bottom edge first, then pushing the top until it clicks securely into place.

- Verify that the L2 installation dimension matches the specification in the technical table to ensure proper spacing.

- For multiple terminal blocks, maintain adequate spacing according to electrical code requirements.

Wire Connection Best Practices

- Strip the wire insulation to the appropriate length (typically 8-10mm) to ensure proper conductor exposure.

- For stranded wires, use ferrules or tin the exposed conductors to prevent stray strands.

- Loosen the terminal screw sufficiently to allow easy wire insertion without forcing.

- Insert the wire fully into the terminal cavity until it reaches the stop point.

- Tighten the screw to the recommended torque value:

- M4 screws (T002-0609 series): 1.2-1.5 Nm

- M5 screws (T002-0812 series): 2.0-2.5 Nm

- Verify that no wire strands are visible outside the terminal and that the connection is secure.

- Conduct a gentle pull test to ensure the wire is properly secured.

Advantages of T002 Brass Terminal Blocks Over Alternative Solutions

Compared to Standard Copper Terminal Blocks

- Superior Conductivity: Brass terminal blocks offer better electrical conductivity than standard copper versions, resulting in lower energy losses and reduced heat generation.

- Enhanced Corrosion Resistance: The natural corrosion resistance of brass provides longer service life in challenging environments compared to untreated copper terminals.

- Better Thread Retention: Brass terminal blocks maintain thread integrity even after multiple wire connections and disconnections, unlike copper blocks that may wear more quickly.

Compared to Aluminum Terminal Blocks

- Higher Current Capacity: Brass terminal blocks can handle significantly higher current loads than aluminum versions of the same size.

- Reduced Contact Resistance: Brass provides more stable contact resistance over time, whereas aluminum may develop oxide layers that increase resistance.

- Better Temperature Stability: Brass terminals maintain consistent performance across a wider temperature range than aluminum alternatives.

Maintenance Recommendations for T002 Brass Terminal Blocks

While T002 brass terminal blocks are designed for long-term reliability with minimal maintenance, following these recommended practices will ensure optimal performance throughout their service life:

Regular Inspection

- Conduct visual inspections at least annually, or more frequently in harsh environments.

- Look for signs of overheating, discoloration, or damage to the terminal block or insulation housing.

- Check for loose screws or connections that may have been affected by vibration or thermal cycling.

- Inspect wire entries for proper seating and any evidence of conductor damage.

Connection Maintenance

- Periodically verify screw tightness to the recommended torque values.

- Clean terminal surfaces if there are signs of contamination or oxidation using appropriate electrical contact cleaner.

- When reconnecting wires, ensure fresh conductor material is used by trimming and re-stripping if necessary.

- Apply appropriate contact grease for installations in extremely corrosive or humid environments.

Safety Considerations When Using T002 Brass Terminal Blocks

Ensuring electrical safety is paramount when working with terminal blocks. Observe these safety guidelines when installing and maintaining T002 brass terminal blocks:

- De-energize Before Work: Always disconnect power before installing, removing, or making changes to terminal block connections.

- Proper Insulation: Ensure that all exposed conductors are properly contained within the terminal block cavity.

- Appropriate Wire Sizing: Use wire gauges appropriate for the current load and terminal capacity as specified in the technical tables.

- Temperature Considerations: Account for ambient temperature and load factors when determining the appropriate current rating for your application.

- Segregation of Circuits: Maintain proper separation between different voltage levels and circuit types according to applicable electrical codes.

- Use End Covers: Install end covers on terminal block assemblies to prevent accidental contact with live parts.

- Follow Local Regulations: Always comply with local electrical codes and standards for terminal block installation and use.

Ordering Information for T002 Brass Terminal Blocks

When ordering T002 brass terminal blocks, use the following format to ensure you receive the exact configuration required for your application:

Model Number Format: T002-XXXX/YY[C]

- XXXX: Size specification (0609 or 0812)

- YY: Number of ways (4, 6, 8, 10, 12, 14, 16, or 18)

- C: Color designation (B for blue, Y for yellow)

Example: T002-0812/10B would indicate a T002 brass terminal block with 8×12 specifications, 10 ways, and blue insulation housing.

For custom configurations, volume orders, or special application requirements, please contact our technical support team for personalized assistance.

Conclusion: Why Choose T002 Brass Terminal Blocks

The T002 brass terminal block series represents the highest standard in electrical connection technology. With superior conductivity, exceptional durability, and versatile configuration options, these premium components provide reliable performance in even the most demanding applications.

By choosing T002 brass terminal blocks for your electrical installations, you ensure:

- Enhanced electrical efficiency through superior conductivity

- Reduced maintenance requirements due to robust construction

- Improved safety with reliable connection technology

- Extended service life compared to standard terminal blocks

- Compliance with international safety and quality standards

Trust in the proven performance of T002 brass terminal blocks for your critical electrical connection needs.