Kiedy akcesorium $200 staje się błędem wartym $20 000

Jesteś w trakcie projektowania elektrycznego nowej fabryki. Specyfikacje są jasne: potrzebujesz możliwości awaryjnego wyłączenia zasilania (EPO) w celu zapewnienia zgodności z przepisami bezpieczeństwa oraz solidnego zabezpieczenia nadprądowego, aby zapobiec uszkodzeniu sprzętu. Wysyłasz harmonogram wyłączników do wyceny.

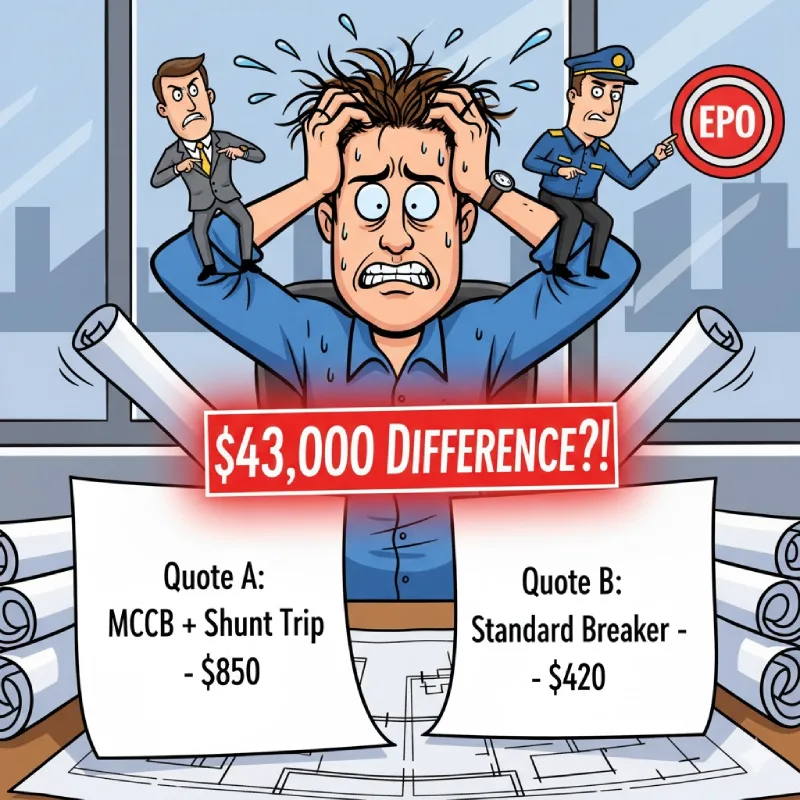

Dwa tygodnie później patrzysz na dwie diametralnie różne propozycje. Dostawca A specyfikuje “MCCB z wyzwalaczem wzrostowym” w cenie $850 za wyłącznik. Dostawca B oferuje “standardowe wyłączniki z wbudowanym zabezpieczeniem wyzwalającym” w cenie $420 za sztukę. Obaj twierdzą, że spełniają wymagania. Kierownik projektu naciska, abyś wyjaśnił różnicę w cenie $43 000 na 100 wyłączników.

Oto problem: nie jesteś do końca pewien, która specyfikacja jest prawidłowa - ani czy faktycznie potrzebujesz obu mechanizmów. Wybierz źle, a czeka Cię albo negatywny wynik kontroli, system wyłączania awaryjnego, który nie działa po uruchomieniu alarmu pożarowego, albo kosztowna modernizacja, która wstrzymuje budowę na dwa tygodnie.

Jaka jest więc prawdziwa różnica między wyzwalaczem wzrostowym a cewką wyzwalającą i jak określić właściwe zabezpieczenie bez nadmiernego projektowania (i przepłacania)?

Dlaczego oba mechanizmy wyglądają tak samo, ale nimi nie są

Pomieszanie jest zrozumiałe. Zarówno wyzwalacze wzrostowe, jak i cewki wyzwalające wykorzystują cewki elektromagnetyczne do fizycznego wyzwolenia wyłącznika. Oba wydają słyszalne “stuknięcie” podczas działania. Oba wyglądają jak małe prostokątne pudełka na obudowie wyłącznika. Ale oto kluczowe rozróżnienie, które determinuje całą architekturę zabezpieczeń:

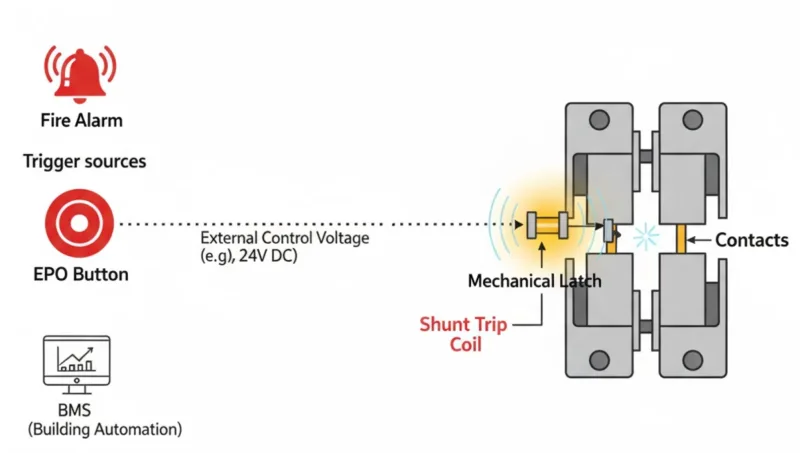

Wyzwalacz wzrostowy to akcesorium, które odbiera polecenia zewnętrzne. Pomyśl o nim jako o “odbiorniku zdalnego sterowania” przykręconym do wyłącznika. Gdy centrala alarmu pożarowego, przycisk zatrzymania awaryjnego lub system zarządzania budynkiem wysyła sygnał, cewka wyzwalacza wzrostowego zostaje zasilona i wymusza otwarcie wyłącznika - niezależnie od tego, czy występuje zwarcie elektryczne.

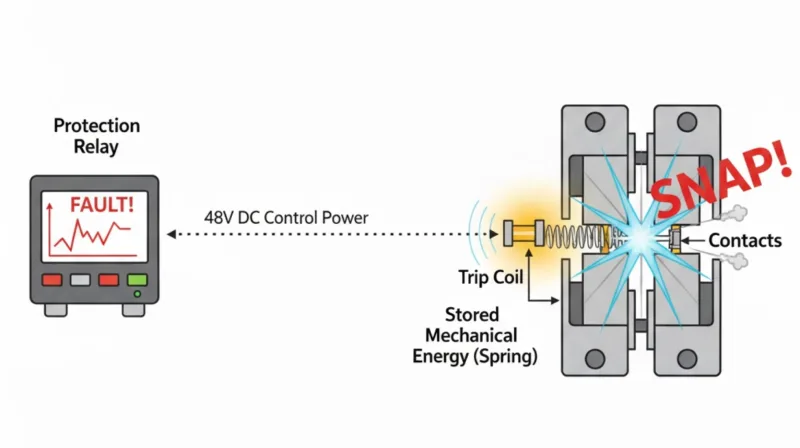

Cewka wyzwalająca to wewnętrzny “automatyczny mechanizm bezpieczeństwa” wyłącznika.” Jest zasilana przez przekaźniki zabezpieczeniowe, które stale monitorują warunki elektryczne (nadprąd, zwarcie doziemne, podnapięcie). Gdy przekaźnik wykryje nieprawidłowy stan, zasila cewkę wyzwalającą, która następnie aktywuje mechanizm wyzwalający wyłącznika. Nie jest wymagany żaden sygnał zewnętrzny - wyłącznik chroni sam siebie i obwód.

Kluczowy wniosek: Wyzwalacze wzrostowe reagują na zewnętrzne systemy bezpieczeństwa; cewki wyzwalające reagują na wewnętrzne zwarcia elektryczne. Nie można ich zastępować i wiele zastosowań wymaga obu.

Odpowiedź, część 1: Zrozumienie, co każdy mechanizm faktycznie robi

Wyzwalacz wzrostowy: Awaryjne sterowanie wyłącznikiem

Wyzwalacz wzrostowy to opcjonalne akcesorium instalowane w wyłączniku, które umożliwia zdalne lub automatyczne wyzwalanie za pomocą zewnętrznego sygnału napięciowego. Gdy to zewnętrzne napięcie sterujące zostanie przyłożone do zacisków wyzwalacza wzrostowego, cewka generuje pole magnetyczne, które mechanicznie zwalnia mechanizm zatrzaskowy wyłącznika, natychmiast otwierając styki i odcinając zasilanie.

Typowe zastosowania:

- Integracja z alarmem pożarowym (NEC 230.85 wymaga awaryjnych odłączeń w niektórych zastosowaniach)

- Przyciski awaryjnego wyłączenia zasilania (EPO) w pomieszczeniach mechanicznych, laboratoriach lub centrach danych

- Systemy automatyki budynkowej, które wyłączają urządzenia poza godzinami pracy

- Systemy blokad bezpieczeństwa, które odłączają zasilanie urządzeń po otwarciu osłon

Kluczowy szczegół specyfikacji: Wyzwalacze wzrostowe wymagają zewnętrznego źródła napięcia, zazwyczaj 120 V AC, 240 V AC lub 24 V DC, w zależności od modelu. Napięcie to musi pochodzić z niezawodnego źródła - często ze styków pomocniczych centrali alarmu pożarowego lub dedykowanego zasilacza sterującego.

Profesjonalna wskazówka nr 1: Największym błędem specyfikacji popełnianym przez inżynierów jest założenie, że standardowy wyzwalacz termomagnetyczny może zastąpić wyzwalacz wzrostowy w integracji z alarmem pożarowym. Nie może - a inspektorzy kodu natychmiast to odrzucą. NEC i lokalne przepisy przeciwpożarowe wyraźnie wymagają możliwości zdalnego wyzwalania w niektórych zastosowaniach, co oznacza, że akcesorium wyzwalacza wzrostowego jest nie do negocjacji.

Cewka wyzwalająca: Wewnętrzny egzekutor zabezpieczeń wyłącznika

Termin “cewka wyzwalająca” odnosi się do cewki elektromagnetycznej wewnątrz wyłącznika, która wykonuje funkcję wyzwalania po zasileniu przez przekaźnik zabezpieczeniowy lub wewnętrzną logikę wyłącznika. W wyłącznikach niskiego napięcia (takich jak typowe MCCB) funkcja “cewki wyzwalającej” jest zwykle zintegrowana z termomagnetycznym lub elektronicznym członem wyzwalającym. W wyłącznikach wysokiego napięcia i przemysłowych wyłącznikach zasilania cewka wyzwalająca jest odrębnym, oddzielnie zasilanym elementem.

Jak to działa: Przekaźniki zabezpieczeniowe stale monitorują prąd, napięcie i inne parametry. Gdy zostanie wykryty nieprawidłowy stan - nadprąd przekraczający ustawienie zadziałania, zwarcie doziemne lub zdarzenie podnapięciowe - przekaźnik zamyka styk, który zasila cewkę wyzwalającą. Zasilana cewka zwalnia zmagazynowaną energię mechaniczną wyłącznika (zwykle naładowaną sprężynę), która szybko otwiera styki.

Typowe zastosowania:

- Zabezpieczenie nadprądowe (zwarcie i przeciążenie)

- Ochrona przed zwarciem na ziemię

- Zabezpieczenie podnapięciowe lub przepięciowe

- Zabezpieczenie różnicowe w obwodach transformatorów lub generatorów

- Schematy zabezpieczeń silnikowych zintegrowane z przekaźnikami zabezpieczeniowymi

Kluczowy szczegół specyfikacji: Cewki wyzwalające w wyłącznikach wysokiego napięcia zazwyczaj wymagają zasilania sterującego DC (125 V DC lub 48 V DC z baterii stacyjnej). Zapewnia to wyzwolenie wyłącznika nawet w przypadku utraty zasilania AC podczas zwarcia. Użycie niewłaściwego napięcia spowoduje albo brak wyzwolenia wyłącznika, albo uszkodzenie cewki.

Profesjonalna wskazówka nr 2: W przypadku systemów wyłączania awaryjnego wyzwalacze wzrostowe muszą być zasilane z oddzielnego, niezawodnego źródła - nie z tego samego obwodu, który chronią. Jeśli pożar uszkodzi główne zasilanie, wyzwalacz wzrostowy musi nadal działać.

Odpowiedź, część 2: Trzyetapowy schemat wyboru

Teraz, gdy rozumiesz podstawowe różnice, oto jak określić właściwy mechanizm zabezpieczający dla Twojego zastosowania.

Krok 1: Dopasuj wymagania dotyczące zabezpieczeń do właściwego mechanizmu

Zacznij od zadania pytania: “Co ma wyzwolić ten wyłącznik i dlaczego?”

Określ wyzwalacz wzrostowy, jeśli potrzebujesz:

- Zdalnego ręcznego wyzwalania (przyciski EPO, stacje wyciągania)

- Integracji z systemami alarmu pożarowego lub systemami bezpieczeństwa życia

- Automatycznego wyłączania w oparciu o warunki inne niż elektryczne (wykrywanie dymu, wyciek gazu, temperatura)

- Sterowania automatyką budynkową (planowane wyłączenia, reakcja na zapotrzebowanie)

Użyj zintegrowanego systemu cewki wyzwalającej/zabezpieczającego, jeśli potrzebujesz:

- Zabezpieczenia nadprądowego (zawsze wymagane)

- Ochrona przed zwarciem na ziemię

- Koordynacji przekaźników zabezpieczeniowych z urządzeniami nadrzędnymi/podrzędnymi

- Schematów zabezpieczeń silnikowych lub transformatorowych

Przykład z życia wzięty: Centrum danych wymaga obu. UPS zasila krytyczne szafy serwerowe przez MCCB 400A. Wyłącznik musi mieć:

- Elektroniczny człon wyzwalający (wewnętrzna funkcja wyzwalania): Zapewnia zabezpieczenie nadprądowe i zwarciowe doziemne z regulowanymi krzywymi czasowo-prądowymi

- Akcesorium wyzwalacza wzrostowego: Podłączone do przycisku EPO przy drzwiach wyjściowych, zgodnie z wymaganiami NFPA 75

Całkowity koszt: $1 240 za wyłącznik. Jeśli pominiesz wyzwalacz wzrostowy i polegasz tylko na zabezpieczeniu nadprądowym, nie przejdziesz kontroli przeciwpożarowej - i zapłacisz za wyłącznik dwa razy.

Krok 2: Zrozum architekturę sterowania i wymagania dotyczące napięcia

Dla wyzwalaczy wzrostowych:

Musisz zaprojektować obwód sterujący, który zasili wyzwalacz wzrostowy. Krytyczne kwestie:

- Dopasowanie napięcia: Napięcie cewki wyzwalacza wzrostowego musi być zgodne z napięciem źródła zasilania sterującego. Typowe opcje to 120 V AC (z centrali pożarowej), 240 V AC (z transformatora sterującego) lub 24 V DC (z bezpiecznego PLC).

- Niezawodność źródła zasilania: W zastosowaniach związanych z bezpieczeństwem życia zasilanie sterujące musi być zasilane z awaryjnego zasilania rezerwowego. Nie zasilaj wyzwalacza wzrostowego alarmu pożarowego z tej samej rozdzielnicy, którą chroni.

- Metoda okablowania: Okablowanie wyzwalacza napięciowego jest często uważane za okablowanie “Klasy 1” zgodnie z NEC, co wymaga określonych metod instalacji.

- Chwilowy kontra trwały: Większość wyzwalaczy napięciowych wymaga jedynie chwilowego impulsu (0,1-1 sekundy) do zadziałania. Utrzymujące się napięcie może spowodować przegrzanie cewki.

Profesjonalna wskazówka nr 3: Zawsze sprawdzaj pobór mocy cewki wyzwalacza napięciowego (zazwyczaj 10-50VA). Jeśli podłączasz 20 wyzwalaczy napięciowych do jednego panelu alarmu pożarowego, upewnij się, że styki przekaźnika pomocniczego panelu są przystosowane do całkowitego prądu rozruchowego. W przeciwnym razie styki przekaźnika zostaną zespawane - a cały system wyłączania awaryjnego zawiedzie.

Dla cewek wyzwalających (aplikacje wysokiego napięcia):

Wyłączniki przemysłowe i wysokonapięciowe z oddzielnymi cewkami wyzwalającymi wymagają:

- Zasilania sterującego DC: Zazwyczaj 125V DC z baterii akumulatorów (bateria stacyjna). Zapewnia to możliwość wyzwolenia nawet podczas całkowitej utraty zasilania AC.

- Nadzoru cewki wyzwalającej: Obwód sterujący powinien monitorować ciągłość cewki wyzwalającej. Przerwany przewód oznacza, że wyłącznik nie zadziała na polecenie - niebezpieczna ukryta awaria.

- Właściwej koordynacji przekaźników: Przekaźniki zabezpieczeniowe muszą być zaprogramowane z prawidłowymi ustawieniami zadziałania, opóźnienia czasowego i charakterystyki, aby zasilić cewkę wyzwalającą we właściwym momencie.

Krok 3: Określ poprawnie i unikaj typowych pułapek

Podczas pisania specyfikacji lub przeglądania rysunków warsztatowych upewnij się, że:

Dla zastosowań z wyzwalaczem napięciowym:

- Wyraźnie określ: “Wyłącznik powinien zawierać fabrycznie zainstalowany wyzwalacz napięciowy, [napięcie], odpowiedni do zdalnego wyzwalania z systemu alarmu pożarowego.”

- Określ napięcie sterujące i sprawdź, czy pasuje do dostępnego zasilania sterującego.

- Jeśli wyłącznik znajduje się w trudnym środowisku, określ klasę środowiskową wyzwalacza napięciowego (standardowe akcesoria mogą nie być odpowiednie do środowisk o wysokich wibracjach lub korozyjnych).

- Dołącz szczegóły okablowania: “Okablowanie sterujące wyzwalacza napięciowego powinno być prowadzone w dedykowanej rurze, oddzielnie od przewodów zasilających.”

Dla zastosowań z cewką wyzwalającą (wyłączniki HV):

- Określ napięcie sterujące DC: “Wyłącznik powinien zawierać cewkę wyzwalającą przystosowaną do baterii stacyjnej 125V DC.”

- Wymagaj obwodów nadzoru cewki wyzwalającej.

- Skoordynuj z ustawieniami przekaźnika zabezpieczeniowego - określ model przekaźnika i potwierdź, że jest kompatybilny z impedancją cewki wyzwalającej wyłącznika.

Profesjonalna wskazówka nr 4: Podczas modernizacji starszych instalacji sprawdź dokładnie napięcie sterujące. Widziałem inżynierów zamawiających wyzwalacze napięciowe 120V AC do paneli, które mają dostępne tylko zasilanie sterujące 240V AC. Rezultat? System wyłączania awaryjnego, który nie działa, odkryty dopiero podczas uruchomienia - po zamknięciu ścian.

Podsumowanie: Wiedz, przed czym się chronisz

Rozumiejąc, że wyzwalacze napięciowe i cewki wyzwalające służą zasadniczo różnym funkcjom ochronnym, możesz teraz z pewnością określić właściwy mechanizm:

- Wyzwalacz napięciowy = Reakcja na polecenie zewnętrzne: Używaj do wyłączania awaryjnego, integracji z alarmem pożarowym i zdalnego sterowania

- Cewka wyzwalająca = Wewnętrzna ochrona przed zwarciem: Używaj do wykrywania przetężenia, zwarcia doziemnego i innych nieprawidłowości elektrycznych

- Wiele zastosowań wymaga obu: Nie zakładaj, że jedno zastępuje drugie

Postępując zgodnie z tym trzystopniowym schematem, będziesz:

- Unikniesz kosztownych błędów specyfikacji i opóźnień w projekcie

- Spełnisz wymagania kodeksu elektrycznego i przeciwpożarowego podczas pierwszej kontroli

- Zaprojektujesz systemy wyłączania awaryjnego, które rzeczywiście działają, gdy są potrzebne

- Prawidłowo przydzielisz budżet na ochronę bez nadmiernego projektowania

Następnym razem, gdy będziesz wpatrywał się w konkurencyjne oferty z różnicą cenową $400 na wyłącznik, będziesz dokładnie wiedział, która specyfikacja jest prawidłowa - i będziesz w stanie obronić swoją decyzję przed kierownikiem projektu, organem posiadającym jurysdykcję i wykonawcą mechanicznym, który zastanawia się, dlaczego “wyłącznik potrzebuje tych wszystkich dodatkowych przewodów”.”

Potrzebujesz określić wyłączniki z wyzwalaczami napięciowymi lub złożonymi schematami ochrony? Zacznij od zmapowania swoich wymagań dotyczących ochrony (Krok 1), a następnie zweryfikuj architekturę napięcia sterującego (Krok 2), przed sfinalizowaniem harmonogramu wyposażenia. I pamiętaj: akcesorium wyzwalacza napięciowego $200 określone poprawnie jest znacznie tańsze niż modernizacja $20 000 po nieudanej kontroli.