I. Introduction

A. Definition of Motor Protection Circuit Breakers (MPCBs)

Electric motors are protected by Motor Protection Circuit Breakers (MPCBs), which are specialist devices made to guard against overloads and short circuits among other electrical problems. They offer complete safety for motor-driven systems by combining the features of a thermal overload relay and a circuit breaker. MPCBs are essential for preserving the motors’ operational integrity because they guard against damage from high currents or abrupt voltage swings.

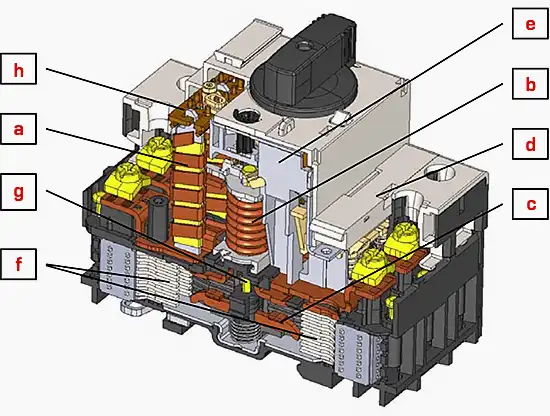

This is what A MPCB looks like:

B. Importance in electrical systems

MPCBs are essential components of electrical systems used in a wide range of applications, such as home appliances, commercial structures, and industrial gear. They improve the safety and effectiveness of motor operations while reducing downtime and maintenance costs by offering dependable protection against electrical faults. Their capacity to recognize and react to anomalous circumstances guarantees that motors function within safe bounds, so extending their longevity and averting disastrous malfunctions.

C. Brief overview of the guide’s content

We will explore MPCB types, uses, and functions in this guide. It will examine the various technologies used in these apparatuses, including electronic, magnetic, and thermal mechanisms, as well as their unique functions in motor protection. We will also go over the several industries that use MPCBs and emphasize their importance in both home and industrial settings. Lastly, we will offer advice on selecting premium MPCBs from reliable suppliers.

II. Understanding Motor Protection Circuit Breakers

A. How MPCBs work

MPCBs work by continuously observing the current flowing through the motor. Through a thermal mechanism, they offer overload protection. When a bimetallic strip bends from the excess heat produced by a high current, the circuit trips. They use a magnetic system for short circuit protection that swiftly disconnects the motor from the power source in response to abrupt surges in current.

B. Key components of an MPCB

The main components of an MPCB include:

- a. Thermal Overload Release: Protects against prolonged overloads.

- b.Magnetic Trip: Responds to short circuits.

- c. Main Contacts: Facilitate the flow of current.

- d. Auxiliary Switches: Indicate the status of the MPCB.

- e. Switch latch

- f. Arcing chamber

- g. Plunger armature

- h. Differential trip slide

C. Differences between MPCBs and standard circuit breakers

MPCBs offer specific protection for motors by combining both overload relay functions and circuit breaker capabilities, in contrast to normal circuit breakers, which are primarily designed to prevent overloads and short circuits. Because of their dual purpose, MPCBs can protect against additional problems that are important for motor applications, like phase loss and overheating.

III. Types of Motor Protection Circuit Breakers

A. Thermal-magnetic MPCBs

Thermal protection against overloads and magnetic protection against short circuits are combined in thermal-magnetic MPCBs. The thermal component trips the circuit when it becomes too hot from continuous overload circumstances since it uses a bimetallic strip. By applying electromagnetic principles, the magnetic component responds instantly to short circuits, rapidly cutting the motor off from the power supply. This kind is frequently utilized in a variety of industries because of its dependability and efficiency in shielding motors against common problems.

B. Electronic MPCBs

Microprocessor technology is used by electronic MPCBs to precisely monitor motor parameters including temperature and current. Phase loss detection and imbalance monitoring, as well as more precise protection settings, are made possible by their improved diagnostic capabilities. This kind of MPCB is especially useful for applications that need for in-depth monitoring and control, which makes it appropriate for contemporary industrial settings where accurate motor management is crucial.

C. Intelligent MPCBs

With cutting-edge capabilities like programmable settings, communication interfaces, and real-time data monitoring, intelligent MPCBs are the newest development in motor protection technology. These devices offer thorough diagnostics that may be linked into larger automation systems, and they can modify their protective measures in response to operational situations. Intelligent MPCBs provide specialized protection solutions for intricate motor-driven applications, which improves operational efficiency and safety.

IV. Key Features and Functions of MPCBs

A. Overload protection

MPCBs keep an eye on the motor’s current flow continually. The MPCB trips the circuit to protect the motor from damage if the current consistently exceeds a preset limit, suggesting a possible overheating situation. This safeguard is essential for avoiding problems like excessive beginning cycles or rotor jamming, which can cause overheating.

B. Short-circuit protection

MPCBs offer quick disconnection in the event of a short circuit, which results in an abrupt spike in current. The MPCB’s magnetic system responds to strong currents almost instantly, protecting the motor and its windings from potentially disastrous damage.

C. Phase loss protection

MPCBs are intended to identify phase imbalance or loss in three-phase systems. They keep an eye on phase voltages and currents all the time, and if they see any irregularities, like one phase being unplugged, the MPCB trips to keep the motor from running in dangerous circumstances, which may cause it to overheat or fail.

D. Ground fault protection

By cutting the circuit when a ground fault is detected, these advanced MPCBs assist ensure safety and prevent electrical risks. Some modern MPCBs offer ground fault protection, which detects leakage currents that may occur when there is an insulation failure or other ground-related difficulties.

E. Adjustable trip settings

Adjustable trip settings are a common feature of MPCBs, enabling users to tailor the protection levels to particular motor requirements and operating situations. This feature increases adaptability and makes it possible to calibrate for various motor types and applications.

V. Selecting the Right MPCB for Your Application

Selecting the right Motor Protection Circuit Breaker (MPCB) is essential to guaranteeing the effectiveness and safety of electric motors. The following are crucial factors and recommendations for choosing the appropriate MPCB:

A. Factors to consider (motor size, voltage, environment)

- Motor Size: The motor’s rated voltage and current are the main determinants. To avoid annoying tripping and still offer reliable protection against overloads and short circuits, the MPCB should be rated somewhat higher than the motor’s full load current.

- Voltage: Verify that the voltage rating on the MPCB equals or surpasses the nameplate voltage of the motor. For safe functioning and adherence to electrical standards, this is necessary.

- Environment: Take into account elements including humidity, temperature, and exposure to chemicals or dust. These factors may impact the MPCB’s longevity and performance, so choose one with the right ratings for your particular setting.

B. Sizing guidelines

Here are some guidelines to follow while building an MPCB:

- The MPCB current rating ought to be somewhat higher than the motor’s full load current.

- Depending on the needs of the application and the kind of motor, adjust the trip settings for overload protection. Higher magnetic trip settings are necessary to enable prompt disconnection in the event of short circuits, while simultaneously making sure that overload settings give enough time for regular operation.

C. Coordination with other protective devices

Coordination between the MPCB and other system protection components, like fuses or upstream circuit breakers, is crucial. Through coordination, all devices are guaranteed to function as a unit to safeguard against a variety of problem scenarios without resulting in unneeded downtime. In order to minimize interference with other processes, effective coordination can also aid in selecting tripping only the impacted circuit.

VI. Installation and Wiring of MPCBs

Proper installation and wiring of Motor Protection Circuit Breakers (MPCBs) are vital for assuring their effectiveness and the safety of motor operations. The following are important installation considerations:

A. Proper mounting techniques

- Location: To decrease cable length and lower voltage drop and potential electrical noise interference, install the MPCB as close to the motor as possible. This is especially crucial for applications where variable frequency drives (VFDs) are used.

- Mounting Orientation: Unless the manufacturer specifies differently, make sure the MPCB is positioned vertically. This orientation guarantees dependable functioning and facilitates appropriate heat dissipation.

- Secure Fastening: To minimize vibrations that could eventually cause loose connections, firmly fasten the MPCB to a stable surface using the proper screws or mounting brackets.

B. Wiring best practices

- Cable Sizing: Choose conductors that are safe to use with the MPCB’s rated current. To avoid overheating, conductors should have a minimum of one-third the branch circuit conductors’ ampacity.

- Connection Quality: To reduce resistance and the possibility of arcing, use high-quality connectors and make sure all connections are tight and secure. Check connections often for corrosion or wear.

- Brief Wire Paths: Keep wiring lines as short as possible, especially between the MPCB and motor, to decrease inductance and potential voltage spikes. Observe the manufacturer’s recommendations for the longest possible cables.

C. Safety considerations during installation

- Power Off: In order to avoid electrical shock or damage, make sure that the power is off before starting any installation or maintenance work on the MPCB.

- PPE, or personal protective equipment: To protect yourself from electrical risks during installation, wear the proper PPE, such as gloves and safety eyewear.

- Standards Compliance: To guarantee compliance and safety during installation, adhere to local electrical codes and regulations. This involves utilizing equipment that complies with applicable international standards or is UL listed.

Video check:

VII. Setting Up and Configuring MPCBs

A. Adjusting trip settings

- Ascertain Motor Specifications: To start, find the motor’s nameplate rated voltage and current. Using this information will help you choose the right trip settings on the MPCB to meet the operational needs of the motor.

- Set Overload Trip: Take into account the motor’s full load current when adjusting the overload trip setting. Setting this just a little bit above the full load current will avoid annoying tripping while maintaining sufficient protection.

- Set Up Short-Circuit Protection: Make sure the magnetic trip setting is set up to respond rapidly to short circuits, reducing the possibility of the motor being damaged.

B. Calibration procedures

- Initial Calibration: Upon installation, run a motor under a known load and watch the MPCB’s reaction to determine the initial calibration. This makes it possible to guarantee that the parameters are appropriately modified for the given application.

- Conduct Routine Calibration Checks: If there are variations in the motor load or operating conditions, conduct routine checks to ensure that the trip settings stay accurate over time. This could entail changing parameters or recalculating using performance data.

C. Testing and verification

- Functional Testing: Make that the MPCB trips as intended by conducting functional tests that simulate overload and short-circuit situations. Test instruments made specifically for this purpose can be used to accomplish this securely.

- Verification of Settings: After testing, ensure that all settings are correctly configured according to manufacturer specifications and operational needs. For future use, note any modifications made during testing.

- Monitoring Performance: Keep an eye out for any indications of malfunction or failure to trip under fault situations while you continuously monitor the MPCB’s performance during normal operation. Frequent inspections can assist in spotting possible problems before they cause harm to the vehicle.

VIII. Maintenance and Troubleshooting

To guarantee their dependable performance and the safety of electric motors, Motor Protection Circuit Breakers (MPCBs) require routine maintenance and efficient troubleshooting. Here’s a thorough guide:

A. Regular maintenance tasks

- Visual Inspections: Conduct routine visual examinations for evidence of wear, discoloration, or damage to the MPCB case and components. Seek out any signs of overheating, such as burned connections or melted components.

- Cleaning: Remove any dust or dirt from the MPCB and its surroundings. To clean the gadget, use compressed air because collected particles can cause interference with its functionality.

- Connection Checks: Verify the tightness and corrosion of every electrical connection. Overheating and failure might result from loose or corroded connections.

- Functional Testing: To make sure the MPCB trips as intended, simulate overload and short-circuit situations on a regular basis. This assists in verifying that the defense systems are operating as intended.

B. Common issues and their solutions

- Unexpected Tripping: Look for overloaded circuits or improper trip settings if the MPCB trips for no apparent reason. As needed, adjust the settings, and make sure the linked loads are within the allowed limits.

- Failure to Trip: Check for internal damage or wear in parts such as the magnetic coil or thermal bimetallic strip if the MPCB does not trip under a fault situation. If they break, these might have to be replaced.

- Moisture Ingress: The presence of moisture may suggest that enclosure sealing needs to be improved. Make sure the installation space is dry, and in humid places, think about utilizing models that can withstand moisture.

C. When to replace an MPCB

- Physical Damage: To avoid more problems, it is advised to replace the MPCB right once if there are obvious indications of damage, such as casing cracks or melted components.

- Repeated Tripping: When an MPCB trips frequently during regular operation, it can be an indication that it is malfunctioning. In certain situations, replacement is advised since it might no longer offer sufficient protection.

- Aging Components: Electrical stress and temperature cycling can cause internal components to deteriorate over time. If maintenance attempts are made but performance problems persist, you should think about replacing the MPCB to guarantee dependable motor protection.

IX. Advanced Features of Modern MPCBs

Contemporary Motor Protection Circuit Breakers (MPCBs) are equipped with sophisticated features that improve their performance and ease of integration in electrical systems. The following are some of the key upgraded features:

A. Remote monitoring capabilities

A large number of modern MPCBs have remote monitoring features that enable real-time data transmission about motor performance and operating status. With the help of this capability, operators can keep an eye on things from a distance and identify possible problems like overloads or phase imbalances early on. Remote access to this data improves operational effectiveness and safety by lowering the requirement for on-site inspections and facilitating prompt problem-solving.

B. Integration with motor management systems

Supervisory control and data acquisition (SCADA) and motor management systems can be easily integrated with modern MPCBs. This integration enables for centralized control and monitoring of many motors, boosting the overall management of electrical systems. MPCBs can share vital data with other devices via communication interfaces like Modbus or Ethernet, facilitating coordinated fault responses and improved resource management.

C. Energy monitoring and efficiency features

Advanced MPCBs frequently have energy monitoring features that allow users to see how much energy associated motors are using. Facility managers can use this function to evaluate performance indicators, spot inefficiencies, and put energy-saving plans into action. Through monitoring characteristics such as power factor and current draw, these MPCBs assist in optimizing motor performance, resulting in lower energy expenses and increased overall efficiency.

X. Case Studies: MPCBs in Action

Electric motor protection is a critical function of Motor Protection Circuit Breakers (MPCBs), which are indispensable in many applications. The following case studies demonstrate their efficacy in commercial and industrial environments:

A. Industrial applications

MPCBs are widely utilized in manufacturing facilities to safeguard the motors that power pumps and conveyor systems. For example, MPCBs were placed in a big automotive assembly factory to protect the motors that drive conveyor belts. The repeated starts and pauses of these motors can cause them to overheat. In order to prevent damage and minimize downtime, the MPCBs’ overload protection feature made sure that the motors would trip and disconnect under overload conditions. MPCB installation led to a 30% decrease in motor failures and a notable decrease in maintenance expenses.

B. Commercial building scenarios

MPCBs are essential for safeguarding elevator and HVAC motors in business facilities. To improve safety and dependability, a high-rise office building, for instance, incorporated MPCBs into its elevator systems. Phase loss and short circuit protection, which are essential for preserving elevator functionality, was provided by the MPCBs. The building reported a 40% reduction in elevator service interruptions caused by motor failures after MPCBs were installed, which increased tenant satisfaction and operational effectiveness.

C. Success stories and lessons learned

One noteworthy success story was a chemical processing facility that frequently had motor failures brought on by phase imbalances and overloads. Real-time motor performance tracking was made possible by the plant’s installation of sophisticated electronic MPCBs equipped with remote monitoring capabilities. By taking a proactive stance, maintenance crews were able to resolve problems before they became major ones. Consequently, the facility had a 50% decrease in unscheduled downtime and experienced substantial cost savings due to a decrease in maintenance interventions.

XI. Manufacturers of MPCBs

- VIOX: Provides a range of MPCBs with dependable overload and short-circuit protection for AC circuits up to 660V in China. Their goods are appropriate for a variety of industrial uses, such as HVAC systems and manufacturing facilities.

- Schneider Electric: Offering a variety of MPCBs, including thermal magnetic and electronic versions, Schneider Electric is renowned for their quality and endurance. Their products are appropriate for a range of motor protection demands and are made to comply with international safety standards.

- ABB: ABB is a well-known multinational technology business that provides cutting-edge MPCBs that smoothly interface with other electrical systems, guaranteeing strong motor protection in a variety of applications.

- Allen-Bradley: An arm of Rockwell Automation, Allen-Bradley offers a wide range of MPCBs for motor control and industrial automation applications.

- Havells: Their MPCBs are made to be highly functional and resistant to phase failures, overloads, and short circuits. They are appropriate for a variety of industries, such as the pharmaceutical and chemical sectors.

- Danfoss: Provides MPCBs that are perfect for industrial settings since they emphasize dependability and energy economy in motor applications.

- Andeli Group Company: Offers affordable options with a range of MPCB models customized to meet various operational needs.

XII. Conclusion

Modern electrical systems are not complete without Motor Protection Circuit Breakers (MPCBs), which provide full protection for electric motors against a variety of failures. Their capacity to combine several defense features into one unit improves operational effectiveness and system dependability. MPCBs are evolving along with technology, adding capabilities like energy management and remote monitoring. Engineers and facility managers may increase motor longevity, minimize downtime, and optimize energy consumption by having a thorough understanding of the types, functions, and appropriate application of MPCBs. For motor-driven systems in a variety of sectors to operate safely and effectively, MPCB selection, installation, and maintenance must be done correctly.

XIII. FAQs

A. Can Conventional Motor Starters Be Replaced with MPCBs?

In many cases, MPCBs can indeed take the place of conventional motor starters. They do away with the necessity for separate overload relays and contactors by performing both motor protection and control tasks. Because MPCBs are built to withstand overloads, short circuits, and phase failures, they can be used for direct motor control and yet provide complete protection.

B. When Should MPCBs Be Put Through Testing?

Regular testing of MPCBs is necessary as part of a preventative maintenance program. Functional testing should be carried out at least once a year, or more frequently if the motors are used in demanding applications or hostile environments. Testing on a regular basis can help ensure that the safety features are operating as intended and help avoid unplanned malfunctions.

C. Can MPCBs Be Used with Any Kind of Motor?

MPCBs can be used with a variety of motors, such as synchronous and induction motors. But there are certain things to keep in mind, like the motor’s operating frequency and current ratings. While they can handle most applications, it’s vital to check compatibility with certain motor types and configurations, especially when employing variable frequency drives (VFDs).

D. What Distinguishes a Thermal Overload Relay from an MPCB?

An MPCB and a thermal overload relay are primarily distinguished by their functional differences. An MPCB is a more adaptable device for motor protection since it integrates phase failure detection, overload protection, and short-circuit protection into one unit. A thermal overload relay, on the other hand, does not offer phase loss detection or short-circuit protection; instead, it primarily provides overload protection based on thermal principles. Because of this, MPCBs provide a more complete motor safety solution.

Reference:

https://literature.rockwellautomation.com/

https://www.tutorialspoint.com/motor-protection-circuit-breaker-mpcb-how-it-works

https://electrical-engineering-portal.com/the-design-basics-of-motor-protection-circuit-breaker