Introduction

When reviewing electrical specifications or shopping for panelboards, you’ve likely encountered the acronyms MCB and MLO—and if you’re uncertain about which configuration your project requires, you’re not alone. The choice between Main Circuit Breaker (MCB) and Main Lug Only (MLO) panelboards is one of the most common sources of confusion for electrical contractors, consulting engineers, and facility managers.

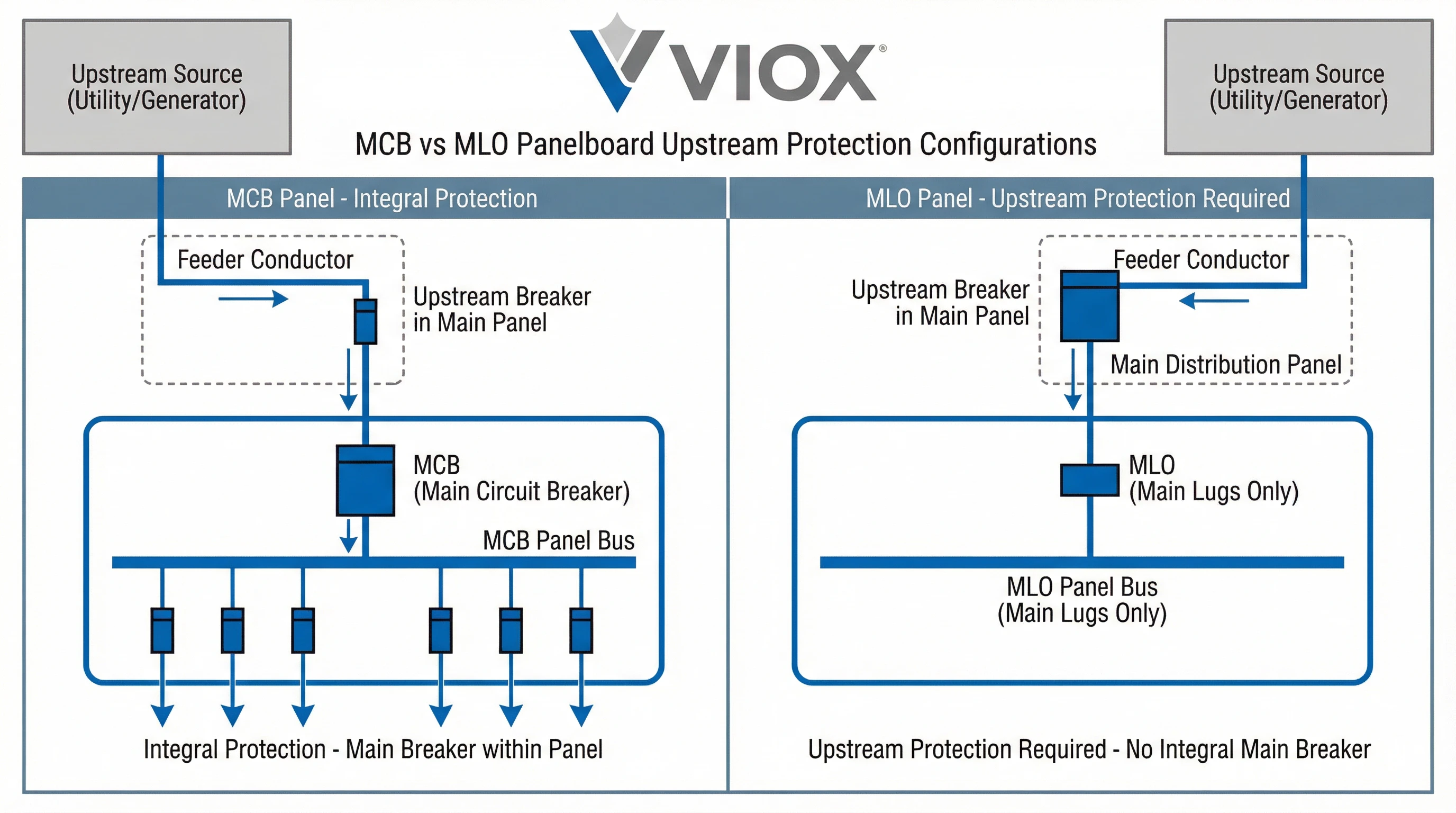

The distinction is fundamental: an MCB panelboard includes an integral main circuit breaker that protects the entire panel, while an MLO panelboard connects directly to incoming feeder lugs and relies on an upstream overcurrent device for protection. According to industry data, MCB panelboards can cost 30–100% more than equivalent MLO units, making the selection decision critical for project budgets—but only if MLO is code-compliant for your application.

This guide provides a comprehensive technical comparison between MCB and MLO panelboards, walking you through NEC Article 408 requirements, practical selection criteria, and real-world application scenarios.

What Is a Panelboard?

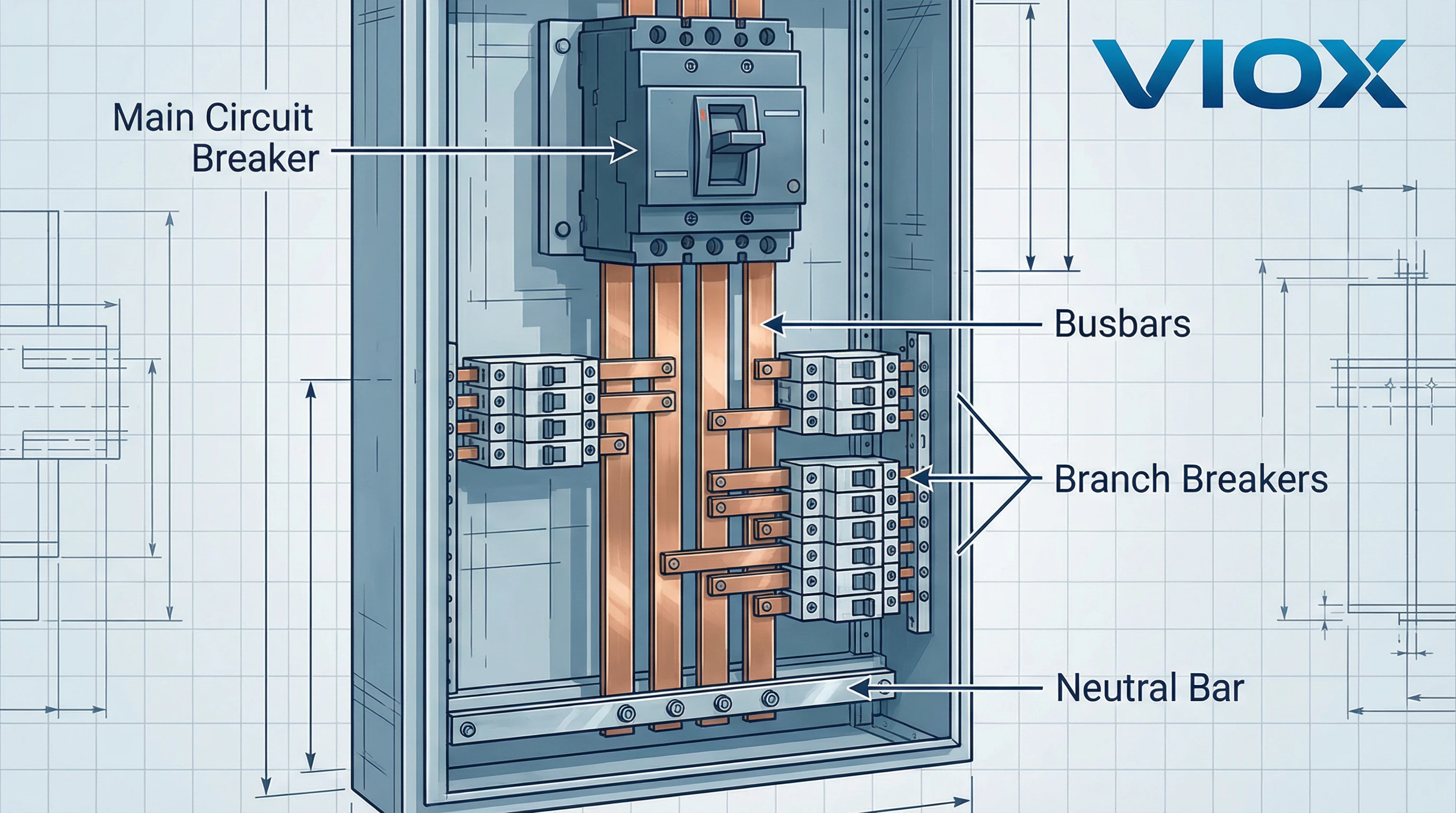

A panelboard is a component of the electrical supply system that divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure. Under NEC Article 408.1, a panelboard is defined as a single panel or group of panel units designed for assembly in the form of a single panel, containing buses and automatic overcurrent devices.

Panelboards serve as distribution hubs—they take incoming power from a larger source (service entrance, transformer, or upstream panel) and distribute it to multiple branch circuits that feed lighting, receptacles, equipment, and other loads throughout a building. Typical facilities employ panelboards arranged hierarchically: a main distribution panel feeds multiple sub-panels located throughout the facility.

Panelboards are rated by their bus ampacity (commonly 100A, 225A, 400A, 600A, or higher), voltage (120/208V, 277/480V, etc.), and number of circuit positions. They must comply with UL 67 (Standard for Panelboards) and meet all applicable NEC requirements for overcurrent protection, grounding, and accessibility.

MCB Panelboards: Main Circuit Breaker Design

An MCB panelboard incorporates a main circuit breaker as part of the panelboard assembly. Incoming feeder conductors land directly on the line-side terminals of this main breaker, which then feeds the panelboard’s internal busbars. Branch circuit breakers connect to these busbars to protect and control individual circuits.

The main breaker serves two critical functions: it provides overcurrent protection for the entire panelboard per NEC 408.36, and it acts as a disconnecting means, allowing the entire panelboard to be de-energized for maintenance or emergency shutdown without accessing an upstream device.

Technical Architecture:

The main circuit breaker is typically a molded-case circuit breaker (MCCB) rated to match or exceed the calculated load per NEC Article 220. For example, a 225A MCB panelboard contains a 225A main breaker protecting a 225A-rated busbar. The breaker must have an interrupting rating sufficient for the available fault current (commonly 10kA, 14kA, 22kA, or higher).

Safety Considerations:

Even when the main breaker is OFF, the line-side terminals remain energized. Working inside an MCB panelboard safely requires proper lockout/tagout (LOTO) procedures at the upstream source.

MLO Panelboards: Main Lug Only Design

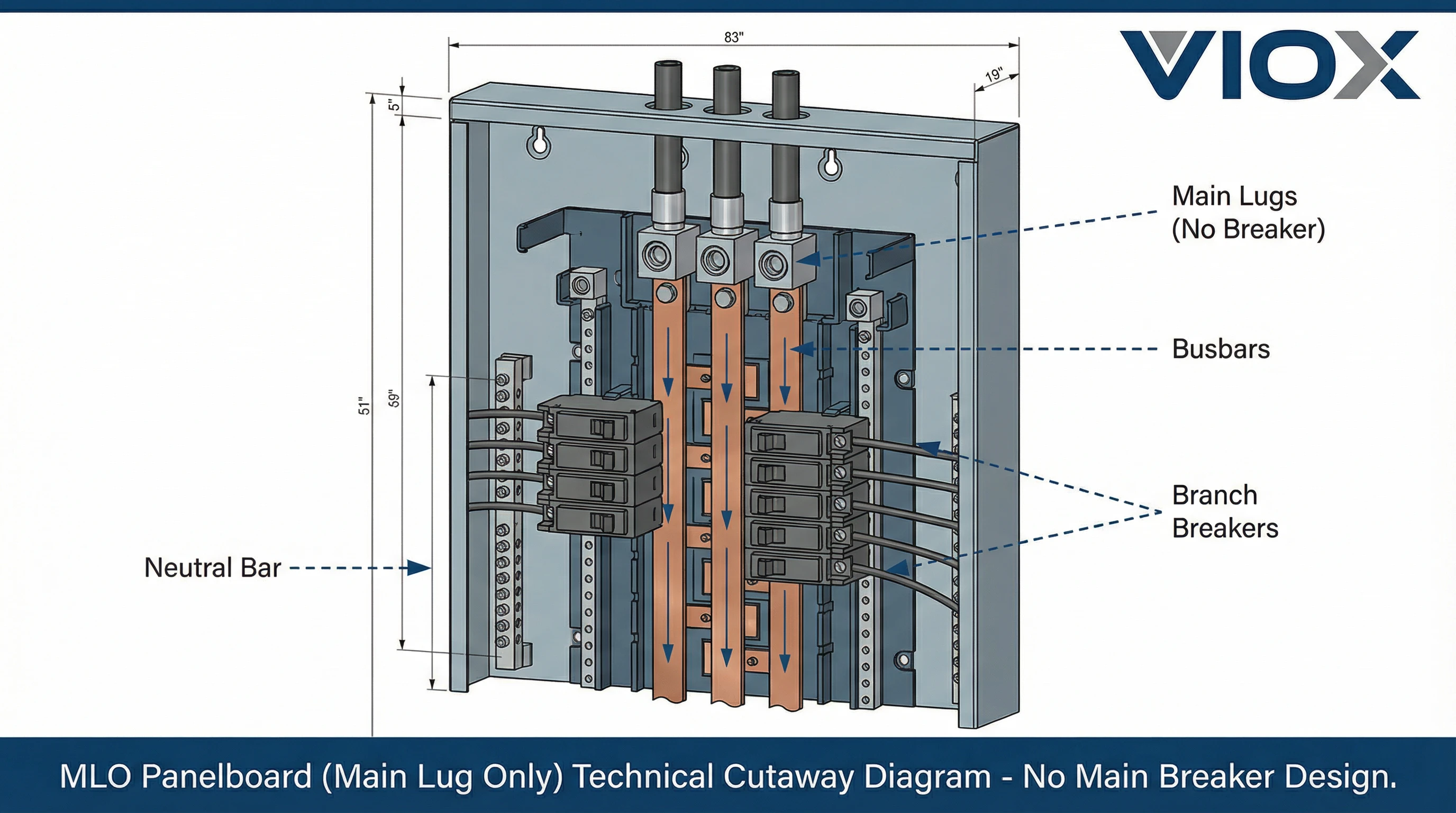

An MLO panelboard does not contain a main circuit breaker. Instead, incoming feeder conductors terminate directly on lugs that connect to the panelboard’s busbars.

Because the MLO panelboard has no integral overcurrent protection, NEC 408.36 requires overcurrent protection on the supply side—meaning upstream from the panel itself. This upstream overcurrent protective device (OCPD) must have a rating that does not exceed the rating of the MLO panelboard. Common upstream protection includes a feeder breaker in another panelboard, a fused disconnect switch, or a circuit breaker in switchboard.

Technical Architecture:

MLO panelboards are mechanically simpler than MCB panels. The main lugs connect the incoming conductors to the internal busbars, and branch circuit breakers connect to these buses. The absence of a main breaker reduces the panel’s physical footprint, weight, and cost.

Operational Implications:

To de-energize an MLO panelboard completely, you must open the upstream OCPD. If the upstream breaker is located far from the MLO panel, maintenance becomes more complex. NEC 240.24(A) emphasizes that overcurrent devices must be “readily accessible.”

Key Differences: MCB vs. MLO Comparison

Understanding the technical and operational differences between MCB and MLO panelboards is essential for specification accuracy and code compliance:

| Feature | MCB Panelboard | MLO Panelboard |

|---|---|---|

| Overcurrent Protection | Integral main circuit breaker within panel | Upstream OCPD (feeder breaker or fused disconnect) |

| Disconnecting Means | Main breaker provides local disconnect | No local disconnect; must use upstream device |

| NEC 408.36 Compliance | Inherently compliant; main breaker protects panel | Requires upstream protection rated ≤ panel rating |

| Typical Application | Main service entrance, transformer secondaries, remote locations | Sub-panels, downstream distribution, cost-sensitive projects |

| Physical Size | Larger; includes main breaker enclosure | Smaller; no main breaker space required |

| Cost | 30–100% more expensive than equivalent MLO | Lower cost; no main breaker expense |

| Maintenance Access | Local disconnect simplifies LOTO procedures | Requires access to upstream OCPD (may be remote) |

| Service Equipment Use | Permitted for service entrance (common application) | Limited use as service equipment under 2020+ NEC |

Short-Circuit Current Rating (SCCR):

Every panelboard must have a short-circuit current rating (SCCR) equal to or greater than the available fault current at its installation point. VIOX Electric conducts rigorous short-circuit testing per UL 67 to ensure our panelboards meet or exceed SCCR requirements for commercial and industrial applications, with ratings from 10kA to 65kA or higher.

When to Choose MCB Panelboards

Certain applications and NEC requirements mandate or strongly favor MCB panelboards:

- 1. Service Entrance Equipment: When a panelboard serves as the main service disconnect for a building, an MCB panelboard is typically required. NEC 230.70 mandates a readily accessible service disconnecting means.

- 2. Transformer Secondary Protection: When the panelboard is fed from a transformer secondary, NEC 408.36(B) and 240.21(C) govern protection. Exceptions exist under the “tap rules” (10-foot and 25-foot rules), but if conductors exceed these limits, an MCB panelboard is required.

- 3. Separate Buildings or Structures: NEC Article 225.31 requires a disconnecting means for feeders supplying separate buildings. An MCB panelboard serves dual purposes: required disconnecting means and distribution panel.

- 4. Remote Locations: In large facilities—manufacturing plants, warehouses, hospitals—installing MCB panels in remote locations provides local disconnecting means for maintenance and emergencies.

- 5. Critical Infrastructure: Hospitals, emergency response facilities, and critical infrastructure use MCB panelboards to ensure clear, immediate shutdown capability.

When to Choose MLO Panelboards

MLO panelboards offer significant advantages in applications where code permits their use:

- 1. Sub-Panel Applications: The most common use for MLO panelboards is as sub-panels fed from a main distribution panel. A feeder breaker in the main panel provides overcurrent protection for both the feeder and the downstream MLO sub-panel—fully NEC-compliant and cost-effective.

- 2. Cost-Sensitive Projects: Where NEC permits MLO panels, the 30–100% cost savings versus MCB units is substantial. On large projects with dozens of sub-panels, choosing MLO for appropriate locations can save $50,000 to $100,000 or more in equipment costs.

- 3. Space-Constrained Installations: MLO panels are physically smaller and lighter than equivalent MCB panels—valuable in retrofit projects or installations with limited wall space.

- 4. Upstream OCPD is Readily Accessible: If the upstream breaker is in sight (visible and within 50 feet) or readily accessible from the panel location, the operational disadvantage of lacking a local disconnect is minimal.

When MLO is NOT Appropriate:

- Service entrance equipment (use MCB unless specific 2020 NEC exceptions apply)

- Fed directly from transformer secondary without qualifying for tap rule exceptions

- Located more than 25 feet from upstream OCPD or where upstream device is not readily accessible

- Local disconnect required by applicable codes or facility safety procedures

Sizing and Selection Guidelines

Selecting the right panelboard requires systematic evaluation:

Step 1: Calculate Load Requirements

Use NEC Article 220 to calculate total connected and demand load. Account for continuous loads (operating 3+ hours) at 125% per NEC 210.20.

Step 2: Determine Mandates

Identify whether the application mandates MCB:

- Service entrance equipment? (MCB typically required)

- Fed from transformer secondary? (Check tap rule compliance)

- Separate building/structure? (MCB required per NEC 225.31–225.32)

- Upstream protection readily accessible and coordinated? (If yes, MLO may be allowed)

Step 3: Evaluate Operational Needs

Consider maintenance access, facility size, future expansion, and critical infrastructure requirements.

Step 4: Assess Cost and Space Constraints

If MLO is code-compliant and operationally acceptable, calculate cost savings (typically 30–100%).

Selection Example Matrix:

| Application | Recommended Type | Key Reason |

|---|---|---|

| Building main service entrance | MCB | NEC 230.70 disconnect requirement |

| Transformer secondary (>10 ft from transformer) | MCB | NEC 240.21(C) secondary protection |

| Sub-panel fed from main distribution panel | MLO | Cost savings; upstream breaker provides protection |

| Separate building feeder | MCB | NEC 225.31 disconnect requirement |

| Floor panel in same closet as main riser | MLO | Upstream accessible; cost effective |

| Remote warehouse panel (200+ ft from main) | MCB | Operational convenience; local disconnect |

| Hospital critical care panel | MCB | Life safety; immediate local disconnect |

| Office tenant improvement sub-panel | MLO | Cost effective; fed from building MCB panel |

VIOX Product Recommendation:

VIOX Electric manufactures both MCB and MLO panelboards for commercial and industrial applications. Our MCB panels feature high-interrupting-rating main breakers (up to 65kA), bus ratings from 100A to 1200A, and 3-phase configurations for 208V, 480V, and 600V systems. MLO panels offer the same robust bus construction and branch circuit flexibility without the main breaker, delivering 35–50% cost savings for appropriate applications. All VIOX panelboards comply with UL 67, meet NEC requirements, and include factory-installed ground and neutral bars, copper buses, and comprehensive circuit directories.

Conclusion

The choice between MCB and MLO panelboards is never arbitrary—it’s a technical decision driven by NEC requirements, application specifics, operational needs, and cost considerations. MCB panelboards provide integral overcurrent protection and local disconnecting means, making them the default choice for service entrance equipment, transformer secondary installations, separate building feeders, and critical infrastructure. MLO panelboards offer significant cost and space savings for sub-panel applications where upstream overcurrent protection is properly coordinated and readily accessible.

VIOX Electric understands that electrical distribution decisions impact safety, code compliance, and project budgets for decades. Our MCB and MLO panelboards are engineered to meet or exceed UL 67 and NEC requirements, featuring high-quality copper bus construction, robust fault current ratings, and comprehensive labeling for simplified installation and inspection. Whether you need a 225A MCB panel for transformer secondary protection, an 800A MLO sub-panel for a warehouse expansion, or a complete coordinated panelboard system for a new facility, VIOX delivers the technical specifications, compliance documentation, and engineering support to ensure your project succeeds.

Ready to specify the right panelboard configuration for your next project? Contact VIOX Electric’s technical team for selection assistance, short-circuit current analysis, custom configurations, and detailed submittal documentation. Let’s build electrical infrastructure that’s code-compliant, cost-effective, and engineered for long-term reliability.