In any industrial setting, managing hazardous energy is not just a matter of compliance—it’s a matter of life and death. Among the most common and critical sources of this energy is electricity, controlled and distributed through countless components. While large machinery often gets the spotlight in safety discussions, the humble Miniature Circuit Breaker (MCB) is a frequent point of interaction for maintenance personnel and a critical link in the safety chain. Failure to properly control the energy flowing through an MCB can lead to catastrophic accidents, including electric shock, arc flashes, and severe burns.

This is where a robust Lockout/Tagout (LOTO) procedure specifically for the MCB becomes indispensable. A proper MCB lockout program ensures that a circuit is not only turned off but is physically locked in a de-energized state, preventing accidental reactivation during service or maintenance. This guide from VIOX Electric will provide a comprehensive overview of MCB Lockout Tagout procedures, from understanding the components to implementing a compliant and effective safety program that protects your most valuable asset: your people.

The Critical Role of the MCB in Electrical Safety

To implement a safe LOTO procedure, one must first understand the device being isolated. The Miniature Circuit Breaker (MCB) is a foundational component of modern electrical systems, but its simplicity can sometimes lead to a dangerous underestimation of its potential hazard.

What is a Miniature Circuit Breaker (MCB)?

A Miniature Circuit Breaker, or MCB, is an automatic electromechanical switch designed to protect an electrical circuit from damage caused by overcurrent. It serves as a reusable, more precise alternative to traditional fuses. When an MCB detects an overload (too much current draw) or a short circuit (a direct path between conductors), it automatically “trips,” interrupting the flow of electricity to prevent wire damage and reduce fire risk.

These essential safety devices are ubiquitous in industrial and commercial settings, found in electrical distribution panels, control cabinets for machinery, and lighting systems. Every MCB is a gateway to a potentially hazardous electrical circuit.

The ‘Why’ Behind MCB Lockout Tagout

Simply flipping an MCB to the “OFF” position is not a safe work practice. This action alone provides no protection against another worker, unaware of the ongoing maintenance, flipping it back on. Accidental re-energization is a leading cause of electrical injuries and fatalities in the workplace.

The Occupational Safety and Health Administration (OSHA) identifies “contact with electric current” as one of the “Fatal Four” causes of death in the construction industry. Many of these incidents could be prevented by following proper LOTO procedures. An MCB lockout physically prevents the toggle from being moved back to the “ON” position. Paired with a tag, it communicates that the circuit is under maintenance and must not be energized. This dual-layer of protection is the cornerstone of a safe work condition when dealing with any MCB-controlled circuit.

A Closer Look at MCB Lockout Devices

Because Miniature Circuit Breakers come in various shapes, sizes, and designs from numerous manufacturers, a one-size-fits-all lockout device is often not feasible or safe. Specialized MCB lockout devices are engineered to fit the unique characteristics of these breakers, ensuring a secure and reliable isolation point. Using the correct type of MCB lockout is as crucial as the procedure itself.

Types of MCB Lockout Devices

There are several common designs, each suited for different types of MCB toggles:

- Pin-Type Lockouts: These are among the most common. They are designed for MCB toggles that have a small hole. The device’s pin is inserted through the hole, and a padlock is used to secure it. They come in several variations:

- Pin-In (PIN): The pin faces inward toward the breaker.

- Pin-Out (PO): The pin faces outward from the breaker.

- Pin-Out Wide (POW): Similar to Pin-Out but designed for wider breaker toggles.

- Clamp-On or Tie-Bar Lockouts: These versatile devices use a thumbscrew mechanism to clamp down securely on the MCB switch tongue. A “tie bar” may be included to lock out multi-pole breakers that are connected. Their advantage is the ability to fit many MCB models that lack a built-in lockout hole.

- Universal MCB Lockouts: As the name suggests, these are engineered to work with a broad spectrum of single and multi-pole MCB models. They often use a simple screw mechanism that presses against the breaker body, locking the toggle in the OFF position without the need for any tools. This flexibility makes them an excellent choice for facilities with diverse equipment.

Key Features to Look For

When selecting an MCB lockout device, prioritize materials and design. Look for devices made from durable, non-conductive materials like reinforced polymer, nylon, or powder-coated steel to prevent electrical conductivity and withstand harsh industrial environments. The device should be easy to apply and remove by an authorized user but impossible to bypass without the key to the padlock. A quality MCB lockout device is a small investment that pays huge dividends in safety and compliance.

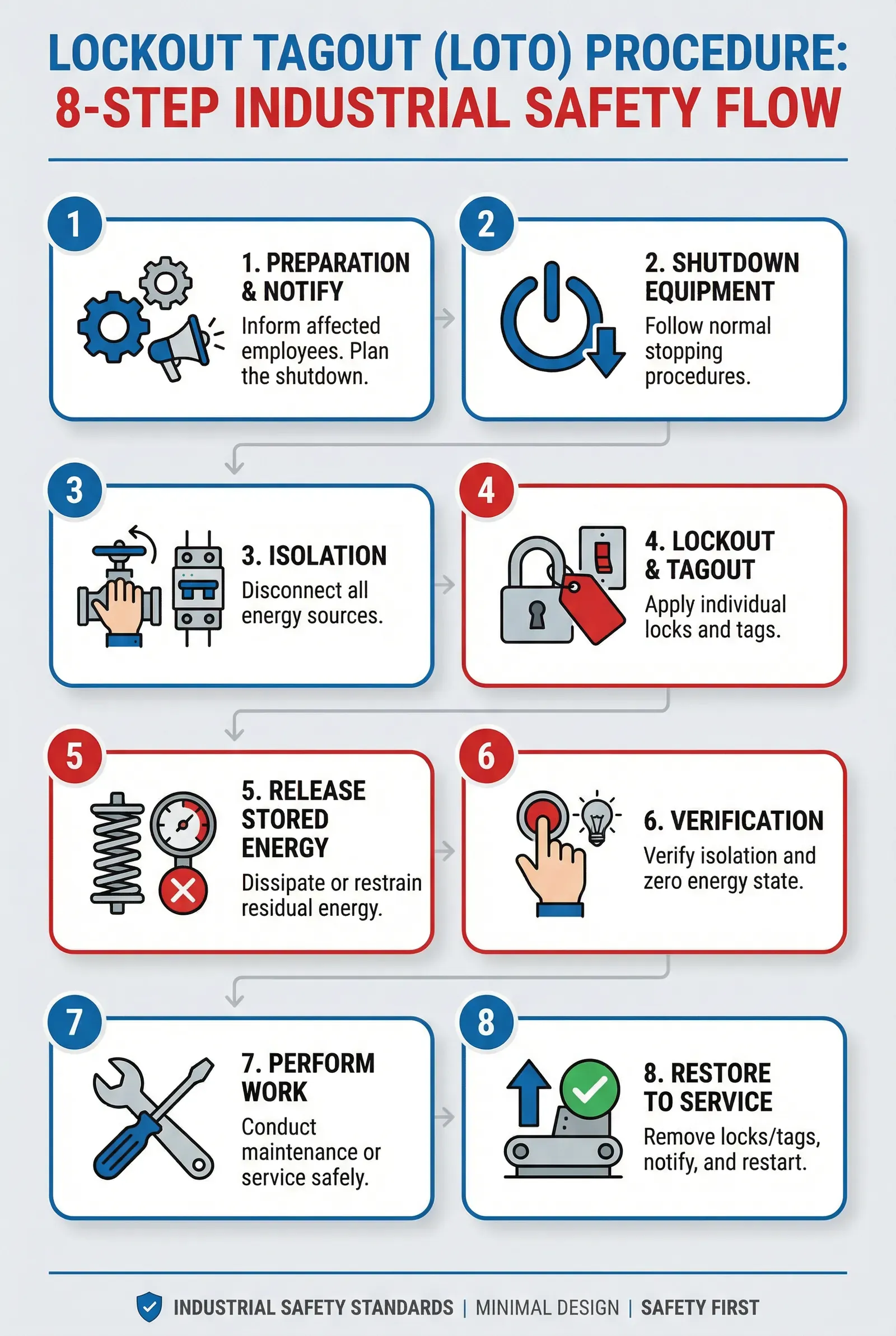

The 8 Steps to a Safe MCB Lockout Tagout

A successful and compliant MCB lockout procedure is systematic and must be followed in the correct order every time. While OSHA outlines the general requirements, this 8-step process details the practical application for isolating a Miniature Circuit Breaker.

- Preparation: Before any work begins, the authorized employee must identify the specific energy source. This involves consulting equipment diagrams or panel schedules to locate the exact MCB that controls the machine to be serviced. Review the machine-specific LOTO procedure to understand all energy sources, not just electrical.

- Notification: Inform all affected employees—those who work with or in the area of the equipment—that a LOTO procedure is about to commence and the equipment will be shut down. Clear communication prevents confusion and mistaken attempts to restart the machine.

- Shutdown: Turn off the machine or equipment using its normal operating controls (e.g., stop button, control switch). Following the standard shutdown sequence helps avoid unexpected hazards from an abrupt stop.

- Isolation: Locate the pre-identified MCB in the electrical panel. Firmly move the MCB toggle to the “OFF” position. This action physically interrupts the electrical circuit, isolating the equipment from its power source.

- Lockout/Tagout Application: This is the core physical step. Secure the appropriate MCB lockout device onto the breaker toggle, ensuring it cannot be moved to the “ON” position. Affix your personal safety padlock through the hole in the lockout device. Finally, attach a durable, legible tag that clearly identifies the authorized employee performing the lockout, the date, and a brief description of the work.

- Verification of Isolation: This is arguably the most critical step. Attempt to restart the equipment using its normal operating controls to confirm it will not turn on. This is known as the “try-out.” For absolute certainty, a qualified person should use a properly rated voltage tester to verify that the circuit is de-energized. Always assume a circuit is live until you have proven it is dead.

- Perform the Work: With the MCB securely locked out and the absence of energy verified, the authorized employee can now safely perform the required maintenance or service.

- Release from LOTO: Once the work is complete, the authorized employee must inspect the area to ensure all tools have been removed and machine guards are back in place. They then notify the affected employees that the LOTO is being removed. Only the individual who applied the lock has the authority to remove their personal padlock, tag, and the MCB lockout device. After removal, the MCB can be switched back “ON” and the equipment returned to service.

Navigating the Regulatory Landscape for MCB Safety

Implementing MCB lockout tagout procedures is not merely a suggestion; it is a strict legal requirement enforced by regulatory bodies to prevent workplace injuries and fatalities. Understanding these standards is essential for any facility manager or safety professional.

OSHA Standard 1910.147 – The Control of Hazardous Energy

In the United States, the primary regulation governing these procedures is OSHA 29 CFR 1910.147, “The Control of Hazardous Energy (Lockout/Tagout).” This standard mandates that employers establish a comprehensive energy control program, document equipment-specific LOTO procedures, and provide thorough training for all employees. [Source]

Isolating an MCB falls directly under the scope of this standard. The regulation requires that any energy-isolating device, including an MCB, be physically locked or tagged to prevent unexpected energization. Non-compliance can result in severe fines, and more importantly, exposes employees to unacceptable risks.

The Role of NFPA 70E

The National Fire Protection Association’s NFPA 70E, “Standard for Electrical Safety in the Workplace®,” provides crucial guidance that complements OSHA’s regulations. While OSHA dictates what must be done, NFPA 70E often details how to do it safely.

A central principle of NFPA 70E is establishing an “electrically safe work condition” before any work is performed on or near exposed conductors. The very first step listed for achieving this state is to “identify all sources of power” and then “properly interrupt the load current,” followed by “open the disconnecting device(s) for each source.” An MCB serves as this disconnecting device. The standard reinforces that a lockout/tagout device must then be applied in accordance with documented procedures. Adhering to NFPA 70E is considered a best practice for demonstrating compliance with OSHA’s more general requirements.

From Procedure to Culture: Best Practices for MCB LOTO

A written procedure is only effective if it’s consistently and correctly applied. This requires building a strong safety culture where every employee understands the importance of LOTO and is empowered to follow the rules without exception.

Key Elements of a Successful Program

- Comprehensive Training: All employees must receive training appropriate to their role. “Authorized” employees (those who apply locks) need in-depth training on the procedures, while “affected” employees (those who work near the equipment) must be taught to recognize LOTO devices and understand their purpose.

- Equipment-Specific Procedures: A generic LOTO procedure is insufficient. Your program must include documented, step-by-step instructions for locking out each piece of equipment, clearly identifying the location and type of the specific MCB involved.

- Annual Audits: OSHA requires at least an annual inspection of your energy control procedures. This involves observing an authorized employee performing a LOTO to ensure they are following the procedure correctly and that the procedure itself remains effective.

Common Mistakes to Avoid

- “Trust Me, It’s Off”: Never proceed with work based on a verbal assurance. Always follow the full LOTO procedure, especially the verification step.

- Wrong Device for the Job: Using tape, zip ties, or a poorly fitting lockout device on an MCB is a recipe for failure. Always use a device specifically designed for the MCB in question.

- Ignoring Stored Energy: An MCB only cuts off electrical energy. Be aware of other potential energy sources like pneumatic, hydraulic, or gravitational energy that may also need to be controlled.

- Group Lockout Errors: For jobs with multiple workers, a group lockout box and procedure must be used to ensure the last person out is the one who enables re-energization.

Selecting Your MCB Lockout Toolkit with VIOX Electric

An effective MCB lockout program is only as strong as its weakest link, and that often comes down to the quality and suitability of the hardware. Choosing the right equipment is a critical step in building a reliable safety system.

Criteria for Selection

- Compatibility: The first and most important criterion is ensuring the device will fit your specific types of MCB. Audit your panels and breakers to determine if you need pin-type, clamp-on, or a mix of universal devices.

- Durability: Industrial environments are demanding. Select MCB lockout devices made from robust, impact-resistant, and non-conductive materials that can withstand daily use and exposure to chemicals or temperature extremes.

- Compliance: Ensure the products you purchase are designed to help you meet OSHA 1910.147 standards. They must be substantial enough to prevent removal without a key and be easily identifiable as safety devices.

At VIOX Electric, we understand that effective LOTO starts with reliable hardware. Our range of MCB lockout devices is engineered for durability and broad compatibility, ensuring your team has the right tools to safely isolate any miniature circuit breaker. From versatile universal lockouts to specialized pin-type and clamp-on solutions, VIOX Electric provides the compliant and high-quality equipment needed to build a world-class MCB safety program.

Prioritizing Safety with Every Flip of a Switch

The safety of your workforce is non-negotiable. While a Miniature Circuit Breaker is designed to protect equipment, a proper MCB Lockout Tagout procedure is designed to protect people. By understanding the critical role of the MCB, implementing the 8-step LOTO process, and using high-quality, purpose-built lockout devices, you transform a point of potential danger into a fortress of safety. It’s a commitment that ensures every employee who services your equipment can do so with the confidence that they will return home safely at the end of their shift.

Ready to enhance your electrical safety program? Explore VIOX Electric‘s full line of MCB lockout tagout solutions or contact our safety experts today to discuss your specific needs and ensure your facility is both compliant and safe.