What Makes Industrial Enclosure Manufacturing Different?

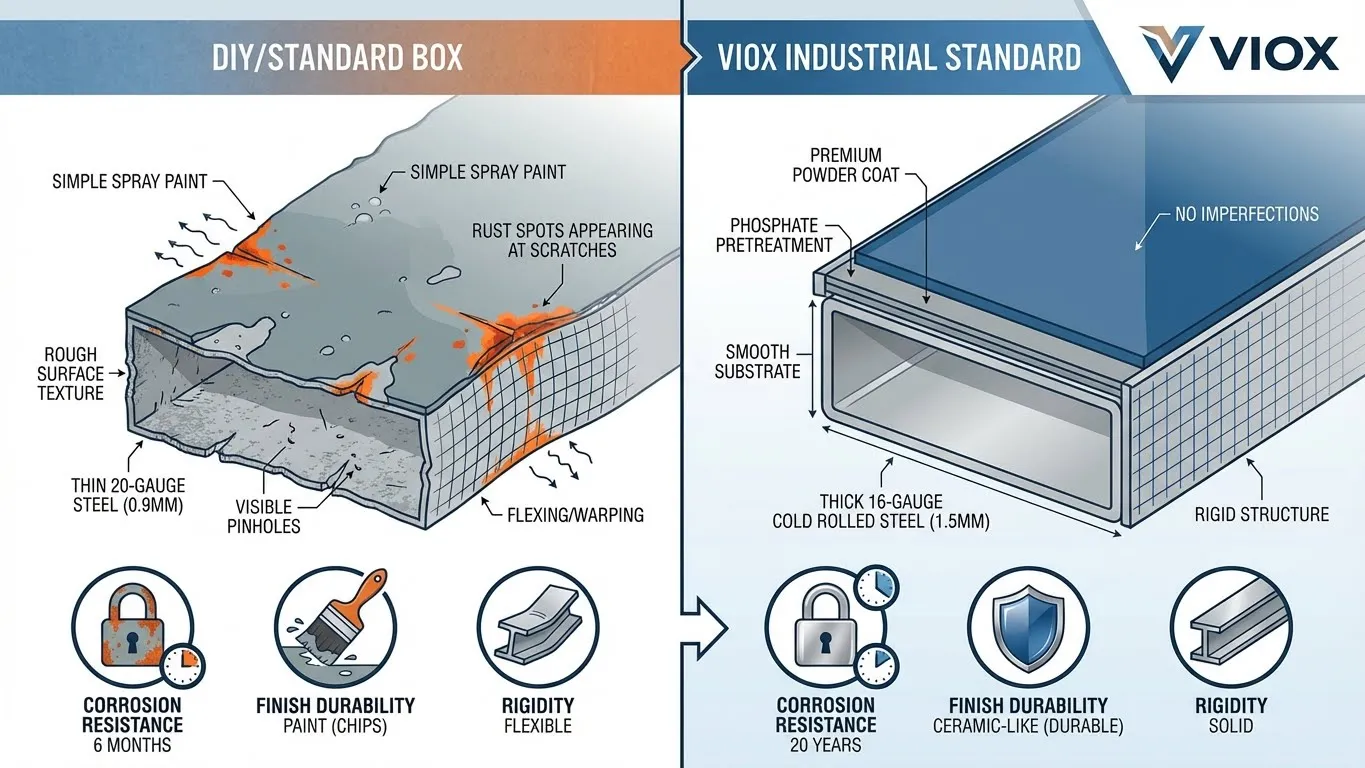

Run your fingernail across a hardware store junction box. It feels like painted metal and clangs when tapped. Now touch a premium industrial enclosure from manufacturers like VIOX, Rittal, or Hoffman. The surface feels ceramic-smooth, and tapping produces a solid, dampened thud. This tangible difference reveals a fundamental truth: industrial enclosure manufacturing isn’t about bending metal and applying paint—it’s engineering a complete corrosion defense system designed to protect critical electrical equipment for decades.

Quality enclosure manufacturing determines whether your electrical infrastructure lasts 20 years or fails within months. The difference lies in three critical manufacturing stages: substrate selection, chemical pretreatment, and thermal coating application. Understanding these processes helps engineers, facility managers, and procurement professionals specify enclosures that deliver genuine long-term value rather than false economy.

The Foundation: Steel Substrate Selection in Enclosure Manufacturing

Cold Rolled Steel vs. Hot Rolled Steel

The steel substrate forms the foundation of any electrical enclosure. Not all steel provides equal performance, and choosing the wrong material guarantees premature failure regardless of subsequent processing.

| Property | Cold Rolled Steel (CRS) | Hot Rolled Steel (HRS) |

|---|---|---|

| Surface Finish | Smooth, uniform, scale-free | Rough with mill scale (iron oxide) |

| Dimensional Tolerance | ±0.001″ (tight tolerance) | ±0.015″ (loose tolerance) |

| Mill Scale | None (processed at room temp) | Present (requires removal) |

| Paint Adhesion | Excellent (clean surface) | Poor (scale creates weak bond) |

| Relative Cost | 15-25% higher | Lower baseline cost |

| Typical Applications | Industrial enclosures, precision parts | Structural steel, construction |

| Density | Higher (compressed structure) | Lower (less processing) |

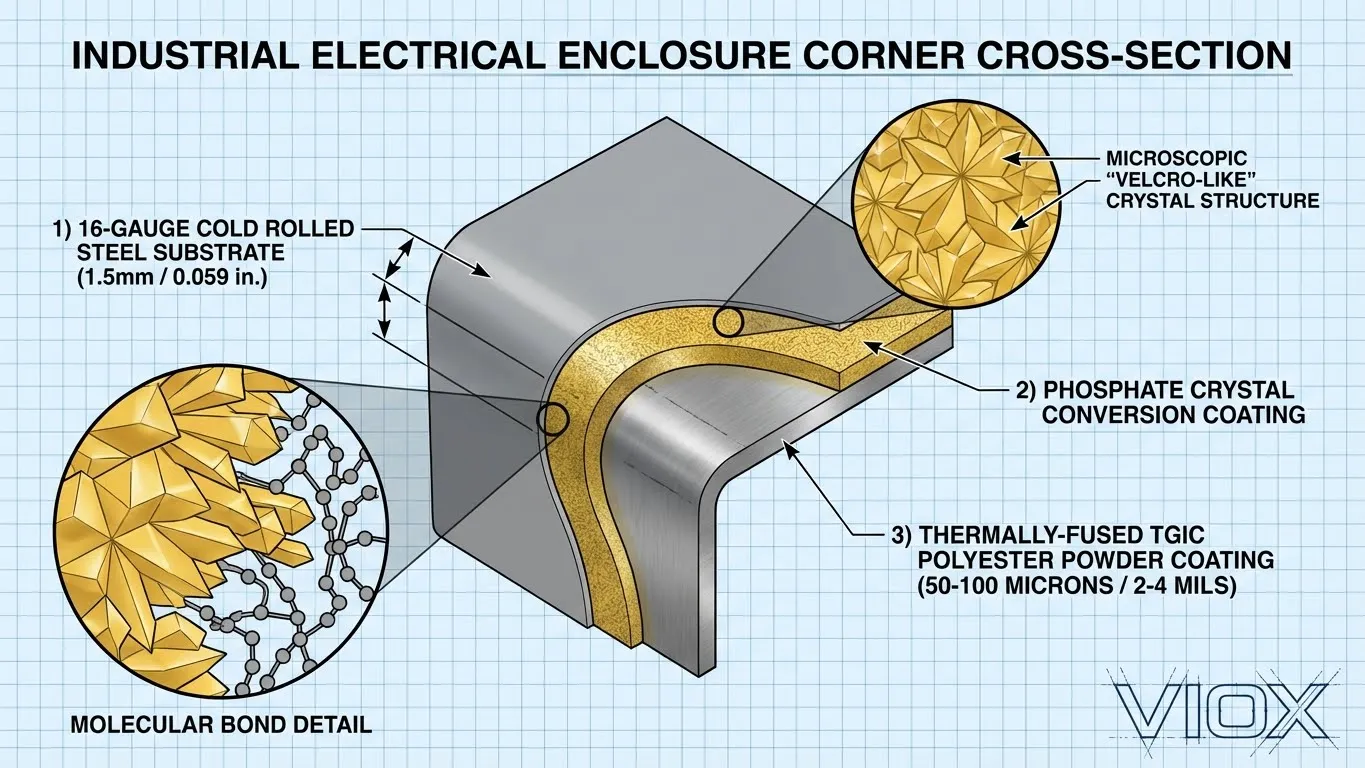

Cold rolled steel undergoes compression at room temperature, creating a denser molecular structure with superior dimensional stability. This process eliminates the iron oxide scale that forms during hot rolling at temperatures exceeding 1,700°F. The scale-free surface provides optimal adhesion for chemical pretreatment and powder coating—the key to long-term corrosion resistance.

Steel Gauge: Understanding Thickness Standards

Steel gauge directly impacts enclosure rigidity, mounting capacity, and overall durability. Thinner gauges flex under load, causing door misalignment and gasket seal failure.

| Gauge | Thickness (mm) | Thickness (inches) | Weight (lb/ft²) | Rigidity Rating | Typical Applications | NEMA Suitability |

|---|---|---|---|---|---|---|

| 20 Gauge | 0.91 mm | 0.036″ | 1.50 | Low | Residential junction boxes, light-duty | NEMA 1 only |

| 16 Gauge | 1.52 mm | 0.060″ | 2.50 | Medium-High | Industrial wall-mount, control panels | NEMA 1, 3R, 4, 12 |

| 14 Gauge | 1.90 mm | 0.075″ | 3.13 | High | Floor-standing cabinets, heavy equipment | All NEMA types |

| 12 Gauge | 2.66 mm | 0.105″ | 4.38 | Very High | Industrial control centers, outdoor | NEMA 3R, 4X |

The VIOX standard specifies 16-gauge cold rolled steel for wall-mount enclosures and 14-gauge for floor-standing units. This ensures sufficient rigidity to prevent panel flexing when mounting heavy DIN rails, transformers, or motor controllers. A 20-gauge enclosure sounds like a cheap baking sheet when struck; 16-gauge produces the solid thud of a car door—an audible quality indicator.

Chemical Phosphatizing: The Hidden Quality Step

Phosphatizing represents the most critical yet least visible step in enclosure manufacturing. This chemical conversion process determines whether powder coating adheres permanently or peels away in sheets within months.

How Phosphate Conversion Coating Works

Phosphatizing involves immersing cleaned steel in a dilute phosphoric acid solution containing metal ions (iron, zinc, or manganese). The acid etches the steel surface while simultaneously depositing a crystalline phosphate layer through a controlled chemical reaction.

The process occurs in multiple stages:

- Alkaline Cleaning: Removes oils, greases, and contaminants

- Acid Activation: Prepares the surface for phosphate deposition

- Phosphate Conversion: Forms crystalline coating (typically 5-20 minutes)

- Post-Rinse: Removes residual chemicals

- Seal Application: Optional seal to enhance corrosion resistance

Types of Phosphate Coatings

| Type | Coating Weight | Primary Use | Corrosion Resistance | Relative Cost | Crystal Structure |

|---|---|---|---|---|---|

| Iron Phosphate | 50-150 mg/ft² | Paint base, powder coat prep | Good | Low | Amorphous (non-crystalline) |

| Zinc Phosphate | 100-3,000 mg/ft² | Corrosion protection, paint base | Excellent | Medium | Crystalline (needles) |

| Manganese Phosphate | 1,000-4,000 mg/ft² | Wear resistance, anti-galling | Very Good | High | Crystalline (dense) |

Iron phosphate serves as the industry standard for enclosure manufacturing pretreatment because it works effectively on steel, galvanized surfaces, and aluminum while generating minimal hazardous waste. The coating weight of 50-150 mg/ft² provides sufficient “tooth” for powder coating adhesion without excessive buildup.

The phosphate crystals create a microscopic “Velcro effect”—millions of crystalline hooks that mechanically bond with the powder coating. More importantly, phosphate coating prevents rust undercutting. When powder coating gets scratched to bare metal, non-phosphated steel allows rust to creep beneath surrounding paint. Phosphate coating stops this lateral corrosion spread, containing damage to the scratch itself.

Powder Coating: Thermal Fusion Technology

Industrial enclosures don’t use paint—they employ electrostatic powder coating, a fundamentally different technology that creates a chemically cross-linked polymer shell.

The Electrostatic Powder Coating Process

- Powder Application: Electrostatically charged polymer particles (50-100 microns) spray onto grounded metal. Opposite charges create magnetic attraction, coating even complex geometries.

- Thermal Cure: The coated enclosure enters a convection oven at 160-200°C (320-392°F) for 10-20 minutes.

- Molecular Cross-Linking: Heat melts the powder into liquid, which flows across the surface before chemically reacting (cross-linking) to form a single continuous polymer film—not dried paint, but thermally-fused plastic.

This process eliminates pinholes, solvents, and volatile organic compounds (VOCs) while creating coating thickness uniformity impossible with liquid paint. The result feels ceramic-smooth because it is essentially a plastic armor bonded to steel at the molecular level.

Powder Coating Chemistry Comparison

| Property | Epoxy | TGIC Polyester | Urethane Polyester |

|---|---|---|---|

| UV Resistance | Poor (chalks outdoors) | Excellent (3-5 years+) | Excellent (5-10 years) |

| Chemical Resistance | Excellent | Good | Very Good |

| Mechanical Hardness | Very High | High | Medium-High |

| Flexibility | Medium | Excellent | Excellent |

| Cure Temperature | 160-180°C | 180-200°C | 180-200°C |

| Overbake Tolerance | Low (yellows) | High | Medium |

| Typical Applications | Indoor equipment, primers | Outdoor enclosures, architectural | Automotive, premium outdoor |

| Cost (relative) | Low | Medium | High |

VIOX standardizes on TGIC (triglycidyl isocyanurate) polyester for outdoor-rated enclosures because it delivers superior UV stability without chalking or color fade. TGIC chemistry provides excellent overbake resistance—the coating maintains color and gloss even if cure temperature varies slightly, improving production consistency.

Epoxy powder coating excels for indoor control panels and automation equipment where chemical exposure occurs but UV light doesn’t. The exceptional hardness and chemical resistance justify the UV limitation. Urethane polyesters offer premium outdoor durability (5-10 years vs. 3-5 years for TGIC) but cost 25-40% more and require precise cure profiles.

Industry Standards: NEMA and UL Ratings

Enclosure manufacturing quality is formally defined by NEMA (National Electrical Manufacturers Association) and UL (Underwriters Laboratories) standards. These ratings specify environmental protection levels rather than construction methods, but meeting higher ratings demands superior manufacturing.

Key NEMA Ratings for Industrial Enclosures

- NEMA Type 1: Indoor use, protection against falling dirt. Basic construction acceptable—commonly 20-gauge steel with simple enamel finish.

- NEMA Type 3R: Outdoor use, rain protection. Requires gasketed construction, corrosion-resistant finish, typically 16-gauge minimum with drainage provisions.

- NEMA Type 4/4X: Indoor/outdoor, water-tight including hose-directed water. Demands continuous weld construction, high-quality gaskets, and corrosion-resistant materials (4X specifies stainless steel or equivalent corrosion resistance).

- NEMA Type 12: Industrial indoor use, protection against dust, lint, fibers, oil/coolant seepage. Requires gasketed dust-tight construction, typically 16-gauge steel, often specified for manufacturing automation.

UL 50/50E provides parallel standards with independent third-party testing requirements. While NEMA allows manufacturer self-certification, UL mandates independent laboratory testing and ongoing factory inspections. Many industrial specifications require both NEMA rating and UL listing.

The manufacturing implications are significant: a NEMA 12 enclosure requires dust-tight construction without knockouts, continuous weld seams, and a proven gasket system. This drives minimum gauge requirements and eliminates cost-cutting manufacturing shortcuts. A NEMA 4X rating effectively mandates premium materials—either 304/316 stainless steel or carbon steel with proven long-term corrosion resistance through TGIC polyester powder coating over phosphate pretreatment.

The VIOX Manufacturing Standard

VIOX Electric implements a three-pillar quality system for enclosure manufacturing that exceeds minimum NEMA requirements:

1. Material Specification

- Wall-Mount Enclosures: 16-gauge (1.52mm) cold rolled steel minimum

- Floor-Standing Cabinets: 14-gauge (1.90mm) cold rolled steel minimum

- Outdoor Applications: Optional 304 or 316 stainless steel for extreme corrosion environments

- Quality Control: All steel certified to ASTM A1008 standards with mill test reports

2. Surface Preparation

- Multi-Stage Cleaning: Alkaline wash removes manufacturing oils and contaminants

- Iron Phosphate Conversion: Full immersion phosphatizing creates 75-125 mg/ft² coating weight

- Quality Testing: Daily phosphate weight verification and adhesion testing per ASTM D3359

3. Finish Application

- TGIC Polyester Powder: Outdoor-grade formulation meeting AAMA 2604 specifications

- Coating Thickness: 2.0-3.0 mils (50-75 microns) for optimal durability without brittleness

- Cure Profile: 180°C for 12 minutes minimum ensures complete cross-linking

- Salt Spray Testing: Random samples tested per ASTM B117 (minimum 1,000 hours to 5% surface rust)

This systematic approach delivers enclosures that protect electrical equipment in industrial environments for 15-25 years rather than the 3-7 years typical of economy alternatives. The incremental cost of premium manufacturing—typically 15-20% higher than economy options—translates to lifecycle value through eliminated replacement costs, reduced downtime, and maintained equipment protection.

Frequently Asked Questions

What is the difference between powder coating and paint on electrical enclosures?

Powder coating involves electrostatically applying dry polymer particles that thermally fuse into a cross-linked plastic shell at 160-200°C. Paint uses liquid solvents that evaporate, leaving a coating prone to pinholes and weaker adhesion. Powder coating provides 2-3x the durability, better chemical resistance, and eliminates VOC emissions.

Why does steel gauge matter for enclosure performance?

Steel gauge determines rigidity and mounting capacity. Thin 20-gauge steel (0.9mm) flexes under load, causing door misalignment and gasket failure. Industrial 16-gauge steel (1.5mm) provides sufficient rigidity to maintain dimensional stability when mounting heavy components like transformers or motor controllers, ensuring long-term seal integrity.

How long should an industrial enclosure last?

Premium enclosures with 16-gauge cold rolled steel, phosphate pretreatment, and TGIC polyester powder coating typically last 15-25 years in industrial indoor environments and 10-15 years outdoors. Economy enclosures with thin steel and simple paint often fail within 3-7 years due to corrosion and structural degradation.

What NEMA rating do I need for my application?

NEMA Type 1 suffices for clean indoor environments. NEMA Type 12 is standard for manufacturing facilities with dust, coolant, and oil exposure. NEMA Type 3R or 4 is required for outdoor installations. NEMA Type 4X specifies corrosion-resistant construction (stainless steel or equivalent coating system) for marine or chemical environments.

Is phosphate coating really necessary before powder coating?

Yes. Phosphate conversion coating creates microscopic crystalline structures that mechanically bond with powder coating and prevent rust undercutting at scratches. Without phosphatizing, powder coating may initially appear acceptable but will peel in sheets within 6-18 months as corrosion spreads beneath the coating layer.

Specify Quality in Your Next Enclosure Project

Enclosure manufacturing quality directly impacts electrical system reliability, maintenance costs, and total ownership expense. The differences between economy and premium manufacturing—cold rolled steel substrate, phosphate pretreatment, and TGIC polyester powder coating—determine whether your investment protects equipment for decades or requires replacement within years.

VIOX Electric engineers and manufactures industrial enclosures to specifications that exceed NEMA requirements and deliver proven long-term performance. Our technical team assists with enclosure selection, custom configuration, and application-specific material recommendations including stainless steel options for harsh environments.

Contact VIOX Electric today for engineering consultation on your next electrical enclosure project. Our application engineers provide detailed specifications, NEMA/UL rating guidance, and custom solutions for demanding industrial applications.