Cable tie cutter is specialized tools designed for efficiently and safely cutting zip ties, offering various types from manual to pneumatic options to suit different needs and applications in cable management.

Types of Cable Tie Cutter

Cable tie cutter comes in various types, each designed for specific applications and user preferences:

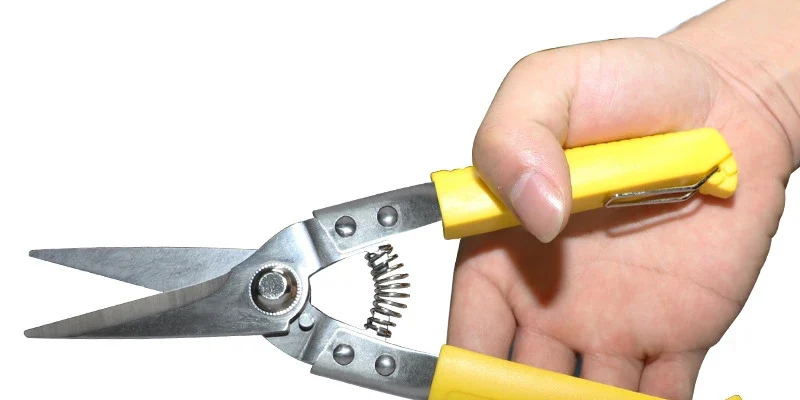

- Manual Cutter: These handheld tools are the most common and versatile option for general use. They feature ergonomic handles and precise cutting blades, making them ideal for smaller projects or occasional use. Manual cutters like the Xuron Model 2275 offer clean cuts without burrs, suitable for cable ties up to 7 mm wide.

- Pneumatic Cutter: Powered by compressed air, pneumatic cutters are ideal for high-volume industrial applications. They offer faster operation and reduced hand fatigue compared to manual tools. Many pneumatic models allow for one-handed operation, enabling users to tension, secure, lock, and cut ties in just two steps.

- Automatic Cutter: These advanced tools combine the benefits of pneumatic power with automated features. They’re designed for maximum efficiency in large-scale operations, often featuring adjustable tension settings and the ability to cut ties of various sizes.

- Flush-Cut Plier: Specialized tools like the Knipex cable tie pliers are designed for flush cutting, allowing users to accurately cut off the protruding end of a cable tie after tightening. This ensures a smooth finish and prevents sharp edges that could cause injury or damage to nearby components.

- Multi-functional Cutter: Some cable tie cutters offer additional functionality, such as the ability to cut soft plastics or thin wires. These versatile tools can be particularly useful in environments where various materials need to be managed.

When selecting a cable tie cutter, consider factors such as the volume of work, the size and material of the cable ties you’ll be working with, and any specific requirements of your project or industry. For instance, industries with stringent safety standards may require tools that ensure flush cuts to eliminate sharp edges.

Key Features to Consider

When selecting a cable tie cutter, several key features should be considered to ensure optimal performance and user satisfaction:

- Cutting Capacity: Choose a cutter that can handle the width and thickness of the cable ties you commonly use. For instance, the Xuron Model 2275 can cut plastic and nylon cable ties up to 7 mm wide, making it suitable for a wide range of applications.

- Blade Quality: Look for high-quality, durable blades that provide clean cuts without leaving burrs or sharp edges. The Xuron Model 2275 utilizes Micro-Shear technology to achieve smooth, flat ends on cut cable ties.

- Ergonomics: Comfort is crucial, especially for frequent use. Seek out cutters with ergonomic handles that reduce hand fatigue during extended periods of use.

- Cutting Mechanism: Some cutters, like the Xuron Model 2275, offer full cutting access along the entire length of their blades, providing unrestricted cutting surfaces for faster operation.

- Safety Features: Consider cutters with built-in safety mechanisms to prevent accidental cuts or injuries during use.

- Versatility: Multi-functional cutters that can handle various materials or cable tie sizes may be beneficial in diverse work environments.

- Power Source: For high-volume applications, pneumatic or automatic cutters may be more efficient. These tools often allow for one-handed operation, enabling users to tension, secure, lock, and cut ties in just two steps.

- Precision: Flush-cut capabilities, like those offered by the Knipex cable tie pliers, allow for accurate cutting of protruding ends after tightening cable ties.

- Durability: Consider the overall construction and materials used in the cutter to ensure it can withstand frequent use in your specific work environment.

- Maintenance Requirements: Some cutters may require more frequent maintenance or blade replacements. Factor in the long-term care needs when making your selection.

By carefully evaluating these features, you can choose a cable tie cutter that best suits your specific needs, whether for occasional home use or intensive industrial applications.

Best Practices for Use

When using cable tie cutters, position the tool close to the tie head to avoid leaving sharp spikes that could cause injury or damage nearby components. Regularly inspect your cutter for wear and tear, as dull blades can lead to uneven cuts and increased effort during use. For large projects or industrial applications, consider using powered tools like pneumatic or battery-operated cutters to save time and reduce physical strain. Always select a cutter that matches the width and material of the cable ties you’re working with to ensure optimal performance and longevity of both the tool and the ties.

Maintenance and Care of Cable Tie Cutter

Innovative Uses for Cable Tie Cutter

Cable tie cutter has found innovative applications beyond their primary use in cable management:

- Gardening: Precise pruning of small plant stems and removal of plant ties without damaging surrounding foliage.

- Crafting: Clean cuts for plastic crafting materials, allowing for intricate designs in model-making and jewelry creation.

- Automotive: Removal of temporary fasteners and trim clips during vehicle repairs or modifications.

- Medical: In some emergency situations, specialized medical cable tie cutters are used to safely remove patient restraints or tight clothing.

- 3D Printing: Trimming excess filament and support structures from 3D printed objects for a cleaner finish.

These diverse applications showcase the versatility of cable tie cutters across various industries and hobbies, demonstrating their utility beyond traditional cable management tasks.