Introduction

Metal components in electrical systems are under siege. Humidity creeps in. Salt spray corrodes. Industrial atmospheres accelerate degradation. Without proper protection, corrosion transforms reliable equipment into costly failures. This is where ISO 12944 enters—the global standard that translates environmental severity into actionable design decisions for protective coating systems.

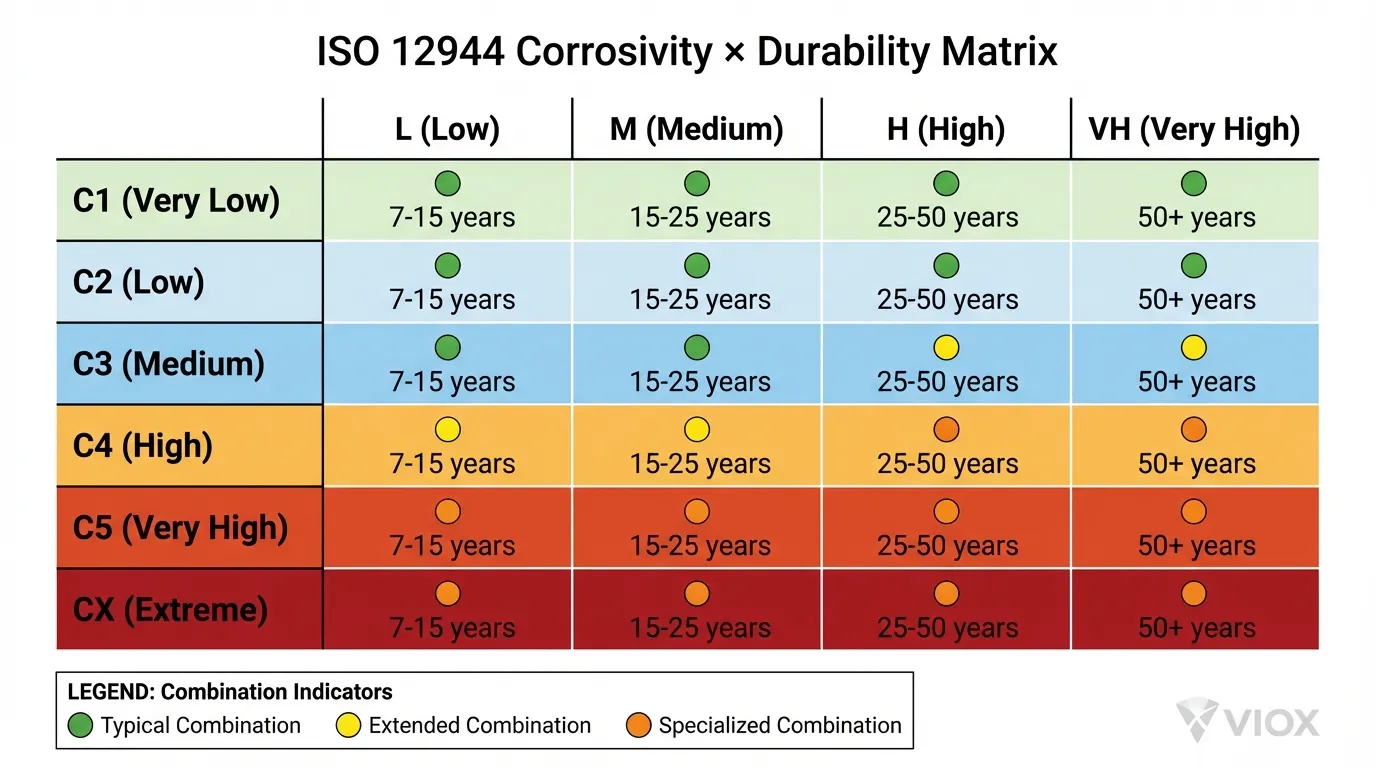

ISO 12944 operates on two axes. The first defines how aggressive your environment truly is—ranging from climate-controlled offices (C1) to extreme offshore platforms (CX). The second sets your maintenance timeline: from inexpensive touch-ups every 7 years to robust systems lasting 25+ years. Understanding this framework is essential for engineers specifying steel structures, electrical enclosure bodies, and structural support systems. It directly shapes procurement, maintenance budgets, and equipment lifespan.

This guide decodes ISO 12944 into practical language and connects the standard to real industrial applications.

What Is ISO 12944?

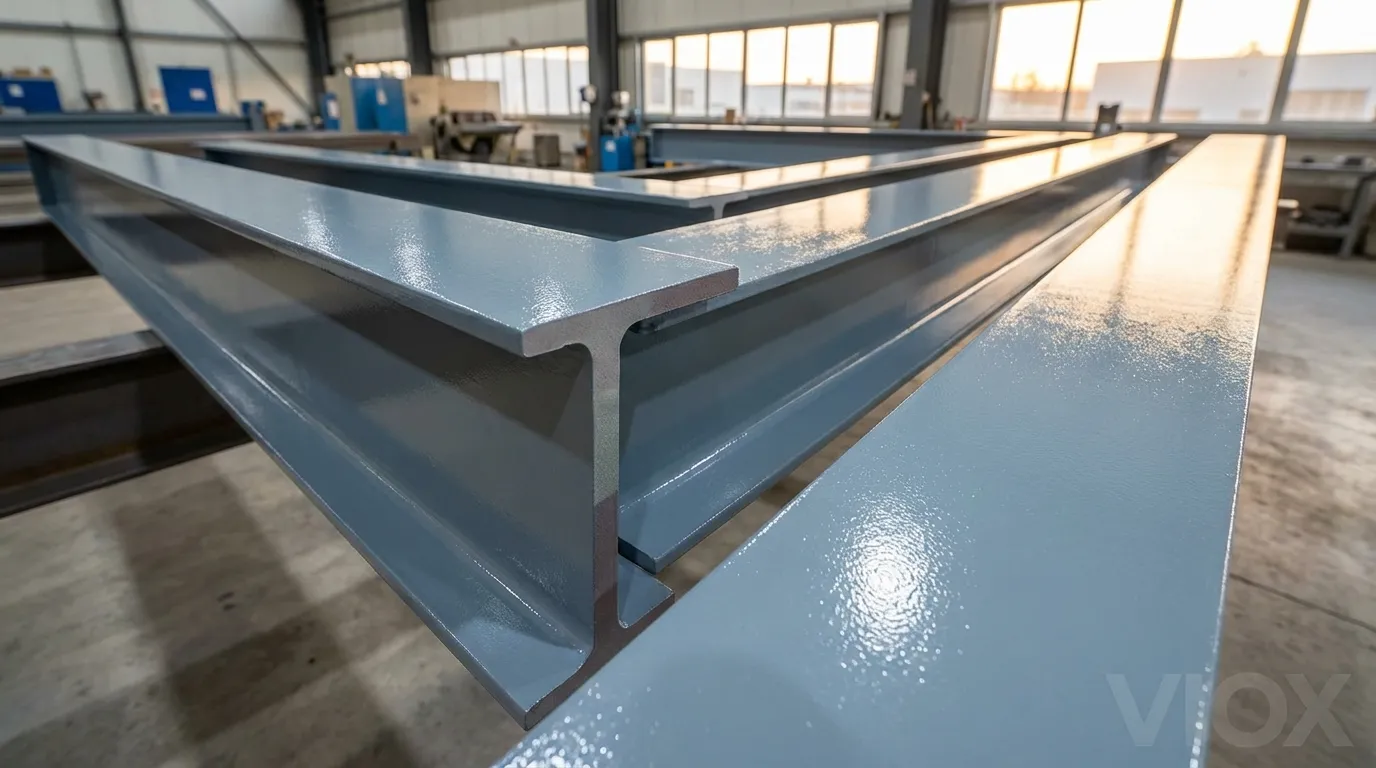

ISO 12944 is the international standard for corrosion protection of steel structures by protective paint systems. It applies specifically to structural steel components and steel electrical enclosure bodies exposed to atmospheric environments. First released in 1998, it has evolved into the globally recognized benchmark for specifying coating systems. The 2018 revision—the current standard—introduced the CX (extreme) category and expanded durability options to address modern industrial challenges like offshore wind, coastal solar installations, and aggressive tropical environments.

Important Scope Clarification: ISO 12944 is NOT applied to individual electrical components inside enclosures—such as terminal blocks, MCBs, contactors, or other conductive parts. These components require separate corrosion protection strategies (see “Application Boundaries” section below). The standard focuses exclusively on the painted/coated steel surfaces of structures and enclosure bodies.

The standard’s power lies in its simplicity: no guesswork. Instead of arguing over vague requirements like “good paint” or “marine grade,” ISO 12944 provides precise specifications—surface preparation grades, primer types, dry film thickness (DFT), number of coats, and laboratory test procedures. This objectivity makes it the foundation for tenders, procurement contracts, and quality verification worldwide.

Corrosivity Categories: C1 Through CX

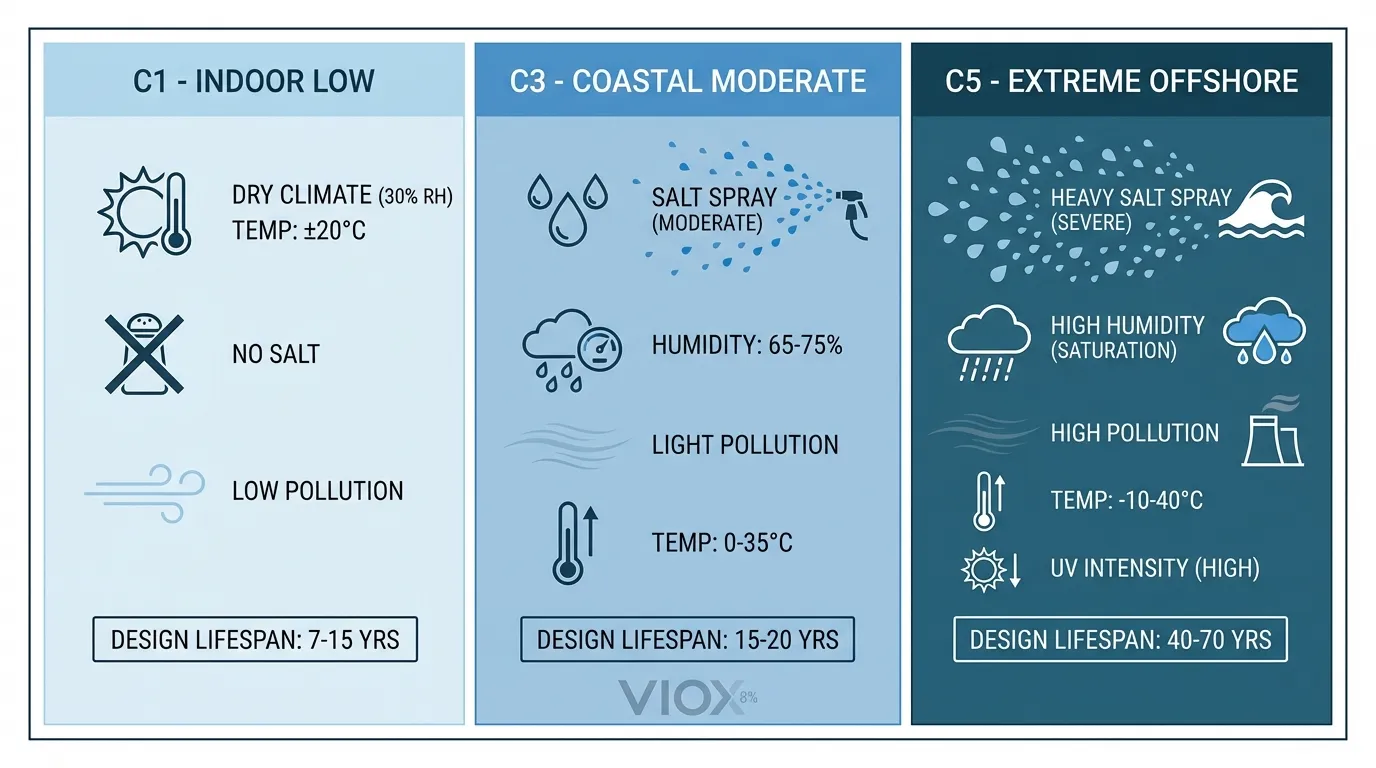

ISO 12944-2 classifies environments into six corrosivity categories. Each category is defined by measurable factors: humidity levels, result from condensation, atmospheric pollutants (SO₂), and salt deposition in coastal areas. The standard quantifies corrosivity by measuring mass loss and thickness loss of standard steel and zinc specimens exposed for one year.

C1: Very Low Corrosivity

Typical Environment: Heated, air-conditioned buildings with clean air

Examples: Office buildings, schools, hotels, shopping malls

Interior Focus: Yes (exterior C1 is rare)

Steel Loss (Year 1): ≤1.3 µm

Zinc Loss (Year 1): ≤0.1 µm

Typical Maintenance Interval: 10–15 years minimum

C1 is essentially corrosion immunity. In controlled indoor environments, even uncoated aluminum can last indefinitely. Coating systems here are minimal—a single coat of acrylic or alkyd, total DFT around 60–100 µm.

C2: Low Corrosivity

Typical Environment: Rural areas, temperate zones, minimal pollution; unheated buildings with condensation risk

Examples: Rural warehouses, agricultural facilities, sports halls

Steel Loss (Year 1): >1.3 to 25 µm

Zinc Loss (Year 1): >0.1 to 0.7 µm

Typical Maintenance Interval: 7–10 years

C2 applies to clean outdoor environments or unheated indoor spaces. Salt air is absent. SO₂ pollution is minimal. Coating systems step up modestly: a primer + single topcoat, DFT 100–150 µm.

C3: Medium Corrosivity

Typical Environment: Urban and industrial atmospheres; moderate SO₂ pollution; low-salinity coastal areas

Examples: City factories, food processing plants, breweries, laundries, low-salinity coastal installations

Interior Examples: High-humidity production rooms with some pollution

Steel Loss (Year 1): >25 to 50 µm

Zinc Loss (Year 1): >0.7 to 2.1 µm

Typical Maintenance Interval: 5–7 years (first major maintenance)

C3 is where many industrial facilities land. Humidity is elevated; condensation occurs regularly. The air carries industrial dust and mild SO₂. Coatings now include zinc-rich epoxy primers and polyurethane topcoats for UV resistance. Total DFT: 120–200 µm. C3 environments are typical for structural steel, equipment frames, and electrical enclosure bodies in urban factories and food processing plants. Interior components like terminal blocks, MCBs, and contactors inside C3-protected cabinets use their own protection strategies (electroplating, stainless materials) as described in the “Application Boundaries” section.

C4: High Corrosivity

Typical Environment: Industrial areas with moderate salinity; coastal regions with seasonal salt spray

Examples: Chemical plants, swimming pool facilities, moderate-salinity shipyards, coastal industrial zones

Steel Loss (Year 1): >50 to 80 µm

Zinc Loss (Year 1): >2.1 to 4.2 µm

Typical Maintenance Interval: 4–5 years (first major maintenance)

C4 introduces serious corrosion risk. Salt spray is now a factor. Humidity stays high. A bare steel panel exposed to C4 will show visible rust within months. Coatings require 2–3 layers: zinc-rich epoxy primer (100–150 µm), epoxy intermediate (100–150 µm), polyurethane topcoat (80–100 µm). Total DFT: 200–250 µm. This applies to structural steel and enclosure/cabinet bodies. VIOX cable glands and waterproof connectors used as cable entries through C4-painted enclosure walls are rated per IEC 60068-2-11 and IP ratings (see “Application Boundaries” section).

C5: Very High Corrosivity

Typical Environment: High-humidity industrial areas with aggressive atmospheres; high-salinity coastal regions

Examples: Offshore support bases, chemical processing plants in humid regions, high-salinity marine installations, tropical industrial sites

Steel Loss (Year 1): >80 to 200 µm

Zinc Loss (Year 1): >4.2 to 8.4 µm

Typical Maintenance Interval: 3–4 years (first major maintenance)

C5 is extreme. Corrosion accelerates relentlessly. A bare steel beam will show deep pitting and significant mass loss in one year. Coating systems become heavy-duty: zinc-rich epoxy primer (100–150 µm), high-build epoxy intermediate (150–250 µm), polyurethane topcoat (100–150 µm). Total DFT often exceeds 300–320 µm. Multiple coats are mandatory. Surface preparation must reach Sa3 (near-white blast cleaning) to ensure adhesion. This is the standard for structural offshore platforms, marine vessels, and critical industrial infrastructure. Components mounted within these structures (from VIOX or others) follow electrical standards, not ISO 12944.

CX: Extreme Corrosivity

Typical Environment: Offshore high-salinity zones; extreme humidity + aggressive industrial atmosphere; tropical/subtropical climates with persistent moisture

Examples: Offshore oil & gas platforms, extreme tropical coastal installations, subsea equipment support structures

Steel Loss (Year 1): >200 to 700 µm

Zinc Loss (Year 1): >8.4 to 25 µm

Typical Maintenance Interval: 2–3 years (first major maintenance)

CX is the frontier. The standard introduced this category in 2018 to address modern energy transitions (offshore wind farms, floating solar). Corrosion rates are phenomenal. Bare steel degrades visibly within weeks. Coating systems often exceed 350–450 µm DFT, combining zinc-rich epoxy primers, multiple high-build intermediates, and specialized polysiloxane or aliphatic polyurethane topcoats. These systems are governed by ISO 12944-9 (formerly NORSOK M-501 for offshore), and testing is rigorous and prolonged.

Application Boundaries: What ISO 12944 Does and Doesn’t Cover

One critical distinction engineers must understand: ISO 12944 applies to structural steel and enclosure bodies—not to internal electrical components.

What ISO 12944 DOES Cover:

- Steel structural frameworks (bridges, towers, industrial buildings)

- Steel electrical enclosure/cabinet bodies

- Steel mounting plates, cable trays, and supports

- Outdoor steel equipment housings

What ISO 12944 DOES NOT Cover:

- Terminal blocks, connectors, and conductors inside enclosures – These use electrical plating (tin, silver, gold) or material selection (stainless steel 316L, nickel-plated copper, PA66 plastic) per IEC 60068-2-11 salt-fog testing or NEMA/IP ratings

- Circuit breakers (MCBs, MCCBs) – Protected by internal plating + material science, not paint

- Contactors and relays – Rely on plating specifications (electroplated tin or silver on copper) + sealed housing (IP54/IP55)

- Any conductive component – Applying hundreds of micrometers of epoxy paint to a current-carrying terminal would cause insulation breakdown or contact resistance failure

Why this distinction matters: Specifying “ISO 12944 C5 coating” for terminal blocks or MCBs is technically incorrect and impractical. These components follow different standards:

- IEC 60068-2-11 – Salt-fog testing (96 or 1000 hours)

- NEMA Type ratings – Enclosure environmental protection

- IP ratings – Ingress protection (dust/moisture)

- Component-level plating specs – Layer thickness, adhesion, hardness per IEC 60068-2-50

In real procurement: An electrical cabinet enclosure body might be specified “ISO 12944 C4-M” (coastal industrial, medium durability). The components inside that enclosure (terminal blocks, MCBs, contactors from VIOX or competitors) are specified separately by their plating thickness, material grade, and IP rating—not by ISO 12944.

Durability Lifespan Tiers: Planning Maintenance Cycles

Durability, in ISO 12944 language, is not a warranty. It is the expected time until the first major maintenance painting is required. Think of it as a maintenance-planning parameter, not a guarantee. When a coating reaches Ri3 on the European scale (roughly 5–10% surface rusting visible to the naked eye), major maintenance is triggered.

Low (L): Up to 7 Years

Best for: Indoor C1 applications, sheltered low-corrosivity environments, or temporary structures

Typical System: Single-coat acrylic or alkyd (60–100 µm DFT)

Total Cost of Ownership: Lowest upfront; frequent recoating

Medium (M): 7–15 Years

Best for: Rural C2 and urban C3 facilities with moderate maintenance budgets

Typical System: Epoxy primer + acrylic topcoat (120–180 µm DFT)

Application: Many industrial plants balance cost and longevity here.

High (H): 15–25 Years

Best for: C4 coastal industrial sites, harsh-environment electrical enclosures, equipment difficult to access

Typical System: Zinc-rich epoxy + high-build epoxy + polyurethane (200–280 µm DFT)

Application: VIOX electrical components in challenging environments often specify High durability.

Very High (VH): More than 25 Years

Best for: C5–CX extreme environments, critical infrastructure, offshore structures

Typical System: Advanced multi-coat systems; zinc-rich epoxy, multiple epoxy intermediates, specialized topcoat (300–450 µm DFT)

Application: Offshore wind platforms, critical chemical facilities, subsea infrastructure

Laboratory Testing: From Lab to Real World

ISO 12944-6 defines how coating systems are validated. Tests simulate environmental stressors—salt spray, humidity cycling, UV, temperature swings—to predict real-world performance.

Atmospheric Test Program (C2 Through C5)

For C2–C5 categories, testing includes:

| Test Method | C2 Low | C3 Medium | C4 High | C5 V.High | Purpose |

| Humidity Condensation (ISO 6270-1) | 48–120 h | 120–480 h | 120–720 h | 480–1200 h | Simulates morning dew, indoor condensation, salt creep |

| Neutral Salt Spray (ISO 9227) | Minimal | 240 h | 480–720 h | 720–1440 h | Simulates coastal salt-air attack |

| Water Immersion (ISO 2812-2) | Minimal | Minimal | Minimal | Minimal | Identifies osmotic blistering risk |

| Cyclic Aging (Appendix B) | None | None | None | 1680–2400 h | Combines UV, humidity, salt spray, temperature cycling |

A C5 Very High durability system must endure 480 hours of condensation, 1440 hours of salt spray, and 1680 hours of cyclic aging—totaling over 3600 cumulative test hours. This is the reason very high durability systems cost 2–3× more than medium durability systems.

Immersion Test Program (Im1–Im3 for Buried or Wet Components)

For cable glands and components in submersed or wet service:

| Immersion Category | Water Type | High Durability | V. High Durability | Application |

| Im1 | Fresh water (rivers) | 3000 h immersion + 1440 h condensation | 4000 h + 2160 h | Hydroelectric, dam facilities |

| Im2 | Seawater (no cathodic protection) | 3000 h immersion + 1440 h salt spray | 4000 h + 2160 h | Submerged marine structures |

| Im3 | Soil (buried pipelines) | 3000 h immersion + 1440 h salt spray | 4000 h + 2160 h | Underground electrical ducts |

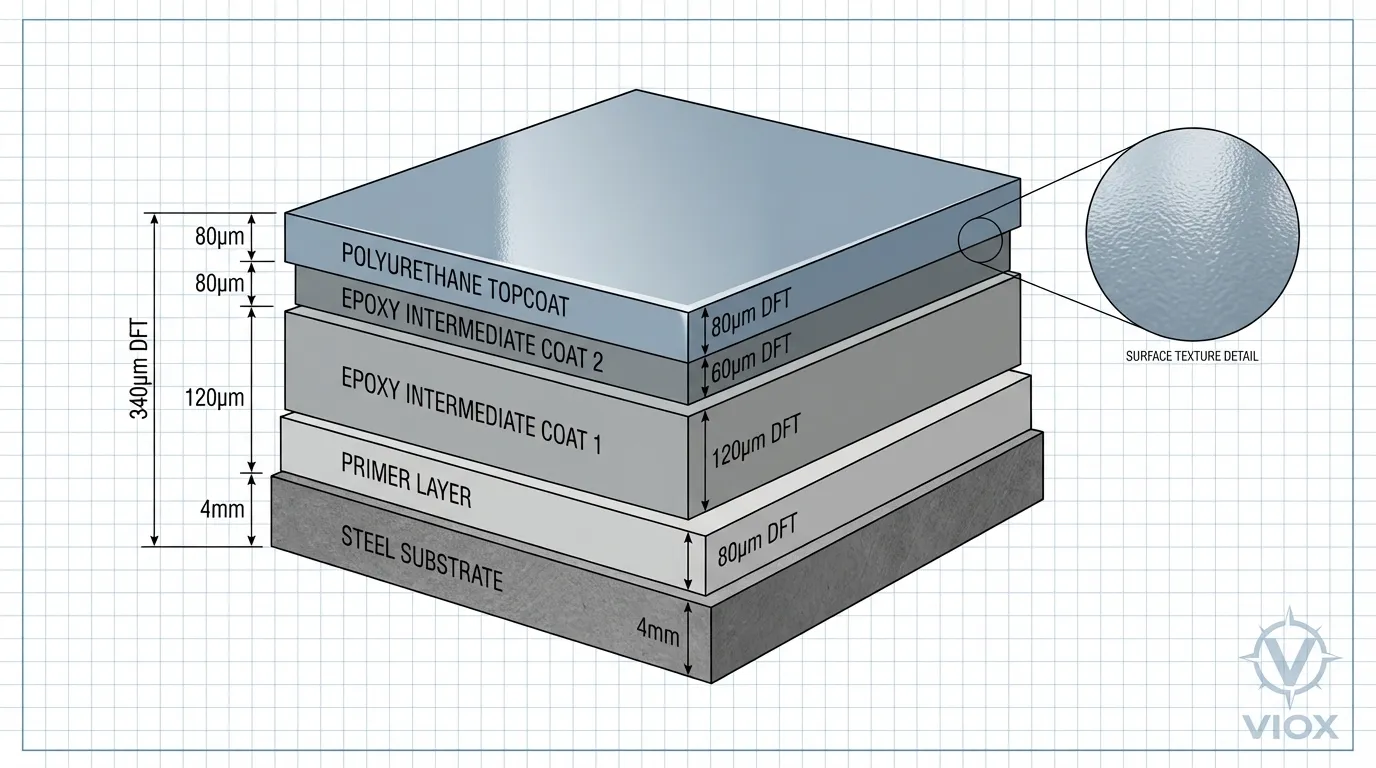

Paint Systems and Dry Film Thickness (DFT)

ISO 12944-5 prescribes the coating systems for each corrosivity and durability combination. Dry Film Thickness (DFT) is critical: it is the dried coating thickness measured in micrometers (µm). Thicker is not always better—adhesion matters—but DFT is the primary lever for durability.

Typical Multi-Coat Systems

C1 Low:

- System: Single-coat acrylic

- Primer: None

- Topcoat: Acrylic (80 µm)

- Coats: 1

- Total DFT: 80 µm

C3 Medium (Industrial Standard):

- System: Zinc epoxy + polyurethane

- Primer: Zinc-rich epoxy (100 µm)

- Intermediate: Epoxy (80 µm)

- Topcoat: Polyurethane UV-resistant (80 µm)

- Coats: 3

- Total DFT: 260 µm

C5 Very High (Harsh Industrial):

- System: Heavy-duty epoxy + polysiloxane

- Primer: Zinc-rich epoxy (120 µm)

- Intermediate 1: High-build epoxy (120 µm)

- Intermediate 2: High-build epoxy (100 µm)

- Topcoat: Aliphatic polyurethane or polysiloxane (80–100 µm)

- Coats: 4–5

- Total DFT: 420–440 µm

Each layer serves a function: the zinc-rich primer sacrifices itself to protect the steel (galvanic protection), intermediates build thickness and UV resistance, and the topcoat provides gloss, weather resistance, and a sacrificial surface.

Real-World Applications

Electrical Enclosure in Coastal Industrial Zone (C4)

A steel electrical control cabinet mounted on a dock near a moderate-salinity harbor faces salt spray year-round. The cabinet body (structural steel frame and side panels) is exposed to C4 corrosivity. The specifier chooses C4-M (Medium durability, 5–7 years) for the enclosure body.

Cabinet Body Specification (ISO 12944): Zinc-rich epoxy primer (80 µm) + epoxy intermediate (100 µm) + polyurethane topcoat (80 µm) = 260 µm total DFT. Testing includes 480 hours salt spray, 240 hours humidity condensation. Maintenance schedule: inspect annually, repaint major surfaces every 5–7 years.

Internal Components (NOT ISO 12944): Inside this cabinet, VIOX terminal blocks, MCB circuit breakers, DIN rail, and contactors are specified separately by:

- Terminal blocks: Tin-plated copper terminals per IEC 60068-2-11 (96h salt-fog minimum)

- MCBs: Electroplated silver or tin contacts, sealed housing IP54

- DIN rail: Galvanized steel with nickel plating for contact areas

- Contactors: Nickel-plated copper contacts, sealed coil per NEMA Type 3R

The cabinet body protects components inside; components use plating/material science, not thick paint coatings.

Offshore Substructure: Painted Steel (C5–CX)

A support frame for an offshore wind platform consists of structural steel exposed to constant high-salinity spray, extreme humidity, and UV. Corrosion category: CX (Extreme). Design life requirement: 25+ years.

Structural Steel Specification (ISO 12944): C5-VH or CX-VH system. Zinc-rich epoxy (120 µm) + two high-build epoxy intermediates (100 µm each) + polysiloxane topcoat (100 µm) = 420 µm total DFT. Testing includes 1440 hours salt spray, 480 hours humidity condensation, and 1680 hours cyclic aging. This specification drives procurement: all structural welds, fasteners, and surfaces must meet this rigorous coating standard.

Cable and Connector Entries (NOT ISO 12944): Electrical connections at the structure interface—cable glands, waterproof connectors, junction boxes—are specified by:

- Cable glands: Stainless steel 316L body, electroplated brass threads, silicone or EPDM seals

- Waterproof connectors: Silver-plated contacts, stainless steel housings, IP67/IP68 rating

- Junction boxes: Stainless steel or powder-coated steel body (C5 exterior) with nickel-plated interior terminals

The painted steel structure (ISO 12944) and the sealed, plated electrical components (IEC standards) work together as a system.

Food Processing Facility: Indoor High-Humidity Environment (C3)

Inside a food processing plant, interior humidity is very high; water/condensation regularly coats equipment. Ambient SO₂ from nearby traffic is low. Classification: C3 (Medium corrosivity).

Structural/Mounting Steel Specification (ISO 12944): Equipment frames, supports, and exposed steel surfaces are painted to C3-M (7–15 years durability). Specification: Zinc-rich epoxy primer (100 µm) + epoxy intermediate (80 µm) + polyurethane topcoat (80 µm) = 260 µm total. Testing includes 240 hours salt spray (simulating hygroscopic salts from food handling), 120 hours humidity condensation.

Electrical Components (NOT ISO 12944): Control equipment inside this environment (from VIOX or other manufacturers) includes modular contactors, terminal blocks, and sensors. These are protected by:

- Stainless steel or nickel-plated copper terminals (food-grade materials)

- Sealed coil enclosures (IP54 minimum) with epoxy-sealed windings (NOT painted)

- Plastic (PA66 or POM) insulation components, inherently corrosion-resistant

The painted steel framework maintains the dry environment inside electrical enclosures; internal components use material science and sealed housing.

Frequently Asked Questions

Q1: Is durability the same as a warranty?

No. Durability is a technical planning parameter—the time until first major maintenance is needed. A 15-year durability system may have a 10-year warranty because warranty involves risk transfer and liability. Durability helps you schedule maintenance; warranty is a legal/commercial guarantee.

Q2: How do I know if my environment is C3 or C4?

C3 indicators: Urban/industrial atmosphere, occasional condensation indoors, mild SO₂ smell, low salinity or no sea access.

C4 indicators: Coastal location, frequent salt spray, constant humidity, visible corrosion on unprotected steel within 1–2 months.

Consult local corrosivity maps (many national standards bodies publish them) or contact a coating supplier with regional expertise. VIOX can advise based on your facility location and profile.

Q3: Can I use a C3 system in a C5 environment and save money?

Technically, yes. Practically, no. A C3 system (260 µm DFT, 3 coats) will show heavy rust and require maintenance within 1–2 years in a C5 environment (where 5+ years is the baseline expectation). The apparent savings vanish in recoating labor and operational downtime. Specify the correct category upfront.

Q4: What is DFT, and why is it critical?

Dry Film Thickness (DFT) is the coating thickness after drying, measured in micrometers. It is the primary durability lever. Thicker films provide longer protection against rust penetration. DFT is verified during application via wet film thickness gauges and confirmed post-cure with dry film thickness gauges. Non-destructive testing ensures compliance.

Q5: How often should I inspect coated equipment?

C1 environments: Every 3–5 years.

C2–C3 environments: Every 1–2 years.

C4–CX environments: Annually or bi-annually.

Early detection of micro-crazing, adhesion loss, or rust bloom allows for spot repairs before major maintenance is triggered. Regular inspections extend coating life and reduce total cost of ownership.

Key Takeaways

ISO 12944 is a two-axis framework: corrosivity category (C1–CX) defines environmental severity; durability tier (L, M, H, VH) defines maintenance interval.

Know your environment: Misclassifying a coastal C4 facility as C3 results in premature failure and costly emergency repainting. Use regional corrosivity maps and local expertise.

DFT is the durability lever: Thicker coatings last longer. Specify correct DFT upfront; do not compromise during application. Verify via testing before acceptance.

Multi-coat systems are engineered: Each layer—primer, intermediate, topcoat—serves a specific function. Do not substitute; integrity depends on the complete system.

Durability is a planning tool: Use it to set maintenance windows and budgets, not as a warranty promise. Maintenance frequency depends on accurate categorization.

Scope clarity—ISO 12944 applies to structural steel and enclosure bodies, NOT internal electrical components: The standard specifies paint systems for steel structures and cabinet exteriors. Individual electrical components inside enclosures (terminal blocks, MCBs, contactors) rely on electroplating (tin, silver, gold), material selection (stainless steel, PA66), and sealed housing (IP ratings), following standards like IEC 60068-2-11 and NEMA Type ratings. Confusing these two protection strategies is a common specification error that experienced electrical engineers will immediately flag.

Cabinet design is a two-tier system: The enclosure body follows ISO 12944 (paint/coating), creating a protective barrier. The components inside follow electrical standards (plating/material/sealing), protecting actual current-carrying elements. Both must be correctly specified, but they are entirely different systems.

VIOX products and ISO 12944: VIOX cable glands and waterproof connectors are often used at the boundary—mounting through ISO 12944-painted cabinet walls. In that context, these entry components are specified per IEC 60068-2-11 (salt-fog testing) and IP ratings. VIOX terminal blocks, MCBs, contactors, and DIN rail inside the cabinet follow their own standards (component-level plating, contact material, sealed housing)—not ISO 12944.

Conclusion

Corrosion does not announce itself. By the time visible rust appears, damage is already underway. ISO 12944 transforms guesswork into precision, giving you a repeatable framework for specifying coatings that match your environment and budget.

Whether you are protecting a modest C2 rural warehouse or a C5 offshore platform, the standard provides a clear path: measure your environment, choose your durability tier, specify the coating system, conduct the appropriate tests, and verify DFT at application. The result: equipment that survives—and thrives—for its intended design life.

Need guidance specifying corrosion protection for your electrical systems? VIOX engineers can help align your requirements with ISO 12944 categories and recommend terminal blocks, cable solutions, and control components suited to your environment. Contact us for a technical consultation.