December 31, 2020. West Central Agri Services grain loading facility, Adrian, Missouri.

The explosion tore through the main elevator at 9:42 AM. One worker, caught near the bucket elevator system, suffered severe injuries. Investigators found the ignition source: a belt-slip condition in the bucket elevator generated enough friction heat to ignite suspended grain dust. The company had installed standard electrical junction boxes throughout the facility—boxes rated for dry indoor locations, not Class II combustible dust environments.

OSHA’s findings were direct. The facility failed to equip critical dust-handling systems with proper explosion-proof enclosures. Standard junction boxes allowed dust ingress. Dust accumulated on terminals and connections. When arcing occurred during normal switching operations, the dust ignited. Flash fire propagated through the facility’s dust-laden atmosphere.

OSHA fined the company $143,860. The real cost: one worker’s severe injuries, destruction of the main elevator structure, weeks of facility shutdown, and permanent damage to the company’s safety record.

The junction boxes that ignited the disaster? Standard NEMA 1 steel enclosures, $18 each. The explosion-proof Class II, Division 1 boxes specified for grain dust environments? $450 each—a $432 difference that would have prevented an explosion.

So what actually separates an explosion-proof junction box from a standard one—and how do you determine when explosion-proof protection is legally mandated, not just recommended?

Quick Answer: Explosion-Proof vs Standard Junction Boxes

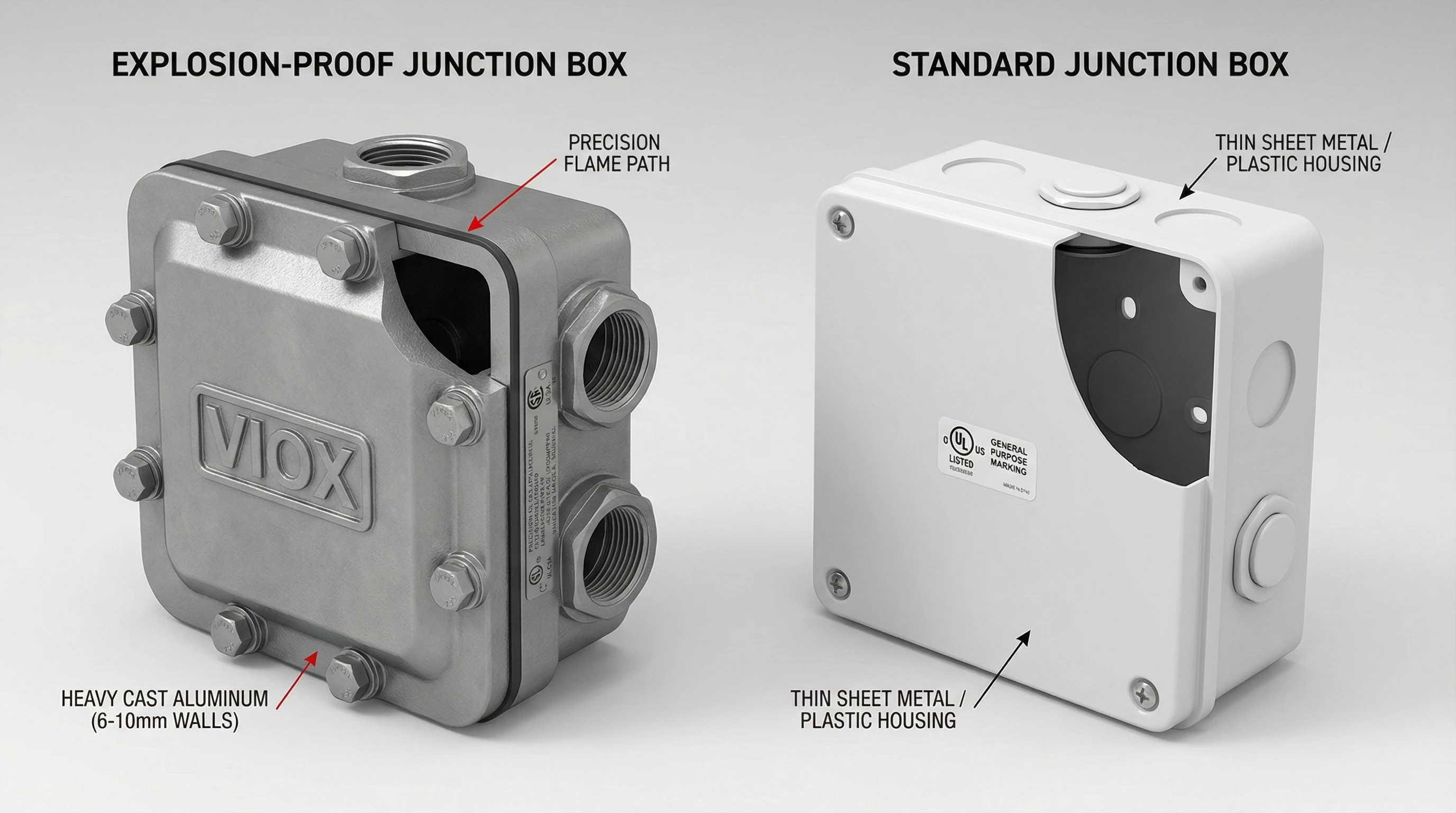

The fundamental difference is ignition containment and prevention. Standard junction boxes are designed for dry, non-hazardous indoor locations. They provide basic protection against incidental contact and dust under normal conditions but have no capability to prevent internal sparks or heat from igniting external flammable atmospheres. Materials are lightweight steel or plastic, construction is simple snap-on or screw covers, and there’s no testing for explosion containment.

Explosion-proof junction boxes are engineered enclosures tested and certified to prevent ignition in hazardous atmospheres containing flammable gases, vapors, or combustible dust. They’re rated under NEC Article 500 (Class I/II/III, Division 1/2) or Article 505 (Zone system), UL 1203/UL 698 standards in North America, and ATEX/IECEx internationally. These boxes use heavy-duty cast aluminum or ductile iron construction, precision-machined flame paths that cool explosion gases below ignition temperature, threaded cable entries with minimum 5-thread engagement, and gasket seals rated for dust-ignition-proof or flameproof service.

This isn’t a cost-performance trade-off—it’s a life-safety mandate. Standard boxes in hazardous locations aren’t just inadequate; they’re code violations that create foreseeable ignition scenarios. Here’s the reality:

| Specification | Standard Junction Box | Explosion-Proof Junction Box |

| Primary Function | Protect wire splices in dry indoor environments | Prevent ignition in flammable gas/vapor/dust atmospheres |

| Typical Ratings | NEMA 1 (indoor, general purpose) | Class I/II Div 1/2; UL 1203/698; ATEX/IECEx Ex d/e; Zone 0/1/2 |

| Hazardous Location Use | ❌ Not rated or listed (NEC violation in Class I/II/III) | ✅ Certified for specific Class, Division, Group, and T-Code |

| Ignition Prevention | None (arcs/sparks/heat can ignite external atmosphere) | Flame path cooling (Ex d), increased safety (Ex e), or other protection methods |

| Construction | Thin sheet steel or plastic; simple covers | Cast aluminum/ductile iron; heavy walls (6-10 mm); precision flame paths |

| Flame Path Requirements | Not applicable | Gap ≤0.2 mm (IIA/IIB) or ≤0.1 mm (IIC); min. length 12.5-25 mm |

| Cable Entry | Knockouts with standard connectors | Threaded hubs (NPT/metric); 5+ full threads; certified glands required |

| Temperature Rating | Not specified for ignition risk | T1–T6 T-Code: max surface temp must be below material ignition temp |

| Gasket/Seal | No gasket or basic compression seal | Flame-resistant gasket; dust-ignition-proof seal for Class II |

| Material | Painted steel, ABS plastic | Copper-free aluminum (non-sparking), ductile iron, 316 SS (corrosive+hazard) |

| Weight | 0.5–2 lbs for typical 4×4″ box | 8–25 lbs for equivalent explosion-proof box (robust casting) |

| Certification Marks | UL general purpose listing (if any) | UL 1203/698 + Class/Div/Group marking; ATEX CE marking; IECEx certificate |

| NEC Article 500 Compliance | ❌ Prohibited in Class I/II/III locations (NEC 500.5, 501.5) | ✅ Required equipment per NEC 500.5(A), 501.5, 502.5 |

| Typical Cost Range | $12–$50 | $150–$1,800 (Class I Div 1 aluminum); $2,500+ (stainless, large sizes) |

| Best Use Cases | Indoor electrical rooms, dry basements, office spaces | Refineries, chemical plants, grain elevators, paint booths, gas processing |

| Consequence of Misuse | Code violation; insurance liability; explosion/fire/injury | N/A (proper application) |

| Expected Lifespan | 10–15 years indoors | 20–30+ years in hazardous environments (designed for harsh duty) |

Notice the stark divide in engineering and certification? That $432 difference at the Adrian grain facility wasn’t optional—it was the legal minimum for preventing dust ignition. Choose the wrong side of that divide, and you’re not risking a callback. You’re guaranteeing an OSHA citation and creating conditions for catastrophic failure.

What “Explosion-Proof” Actually Means: Ignition Containment in Flammable Atmospheres

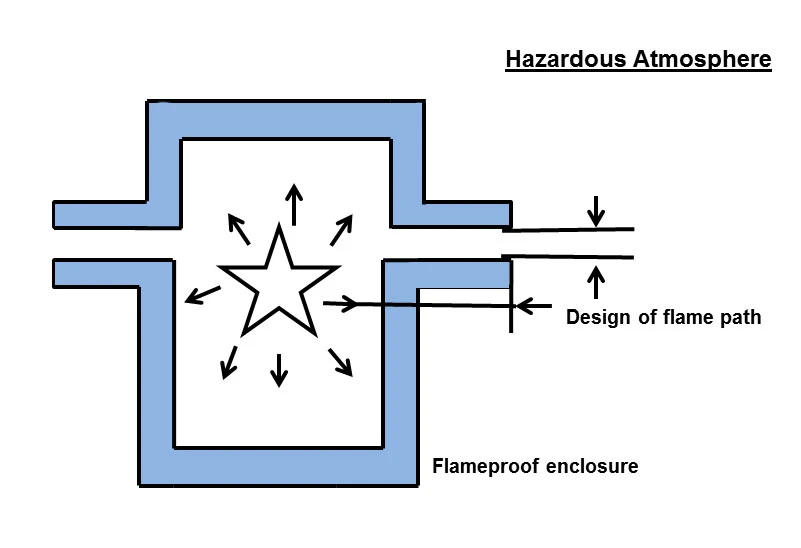

“Explosion-proof” doesn’t mean the box prevents explosions from occurring. It means the enclosure is engineered to contain an internal explosion and prevent it from igniting the surrounding hazardous atmosphere. This is a critical distinction that many specifiers miss.

When an arc, spark, or excessive heat occurs inside the junction box—from normal switching operations, a fault condition, or terminal loosening—and flammable gas or combustible dust has entered the enclosure, an explosion can occur inside. An explosion-proof box is designed to:

- Contain the explosion pressure without rupturing. The heavy cast walls (typically 6-10 mm thick aluminum or ductile iron) withstand the internal pressure spike.

- Cool the escaping gases below the ignition temperature of the external atmosphere. This happens through precision-machined flame paths—narrow gaps between mating surfaces (cover-to-body, threaded entries) that force hot gases to travel a specific distance through a controlled gap, dissipating heat.

- Prevent flame propagation to the outside. By the time gases exit the flame path, they’re cool enough that they won’t ignite the external flammable atmosphere.

This is the Ex d (flameproof) protection method defined in IEC 60079-1 and recognized under UL 1203. It’s the most common explosion protection for junction boxes in Class I (gas/vapor) environments.

For Class II combustible dust locations (grain elevators, pharmaceutical powder handling, metal dust operations), the requirement shifts slightly. “Dust-ignition-proof” enclosures prevent dust from entering and ensure surface temperatures remain below the dust’s ignition temperature. These are certified under UL 698 and must be completely sealed—dust ingress would allow accumulation on internal components, creating tracking paths and ignition risk.

Pro-tip: The Flame Path Principle. The engineering behind explosion-proof boxes centers on flame path design. For Group IIA gases (propane, butane), the maximum gap is 0.2 mm with a minimum path length of 12.5 mm for small enclosures. For Group IIC (hydrogen, acetylene), gaps shrink to 0.1 mm or even 0.04 mm for acetylene. These aren’t arbitrary—they’re test-validated dimensions that ensure gases cool below ignition temperature before reaching the external atmosphere. Any damage to flame path surfaces (gouges, corrosion, dirt accumulation) compromises protection and invalidates the rating.

Hazardous Area Classification: Understanding Class I/II/III and Division 1/2

Before you can select the right explosion-proof junction box, you must correctly classify the hazardous area. NEC Article 500 defines the classification system used in North America. Get the classification wrong, and you’ve either over-specified (wasting money) or under-specified (creating ignition risk and code violations).

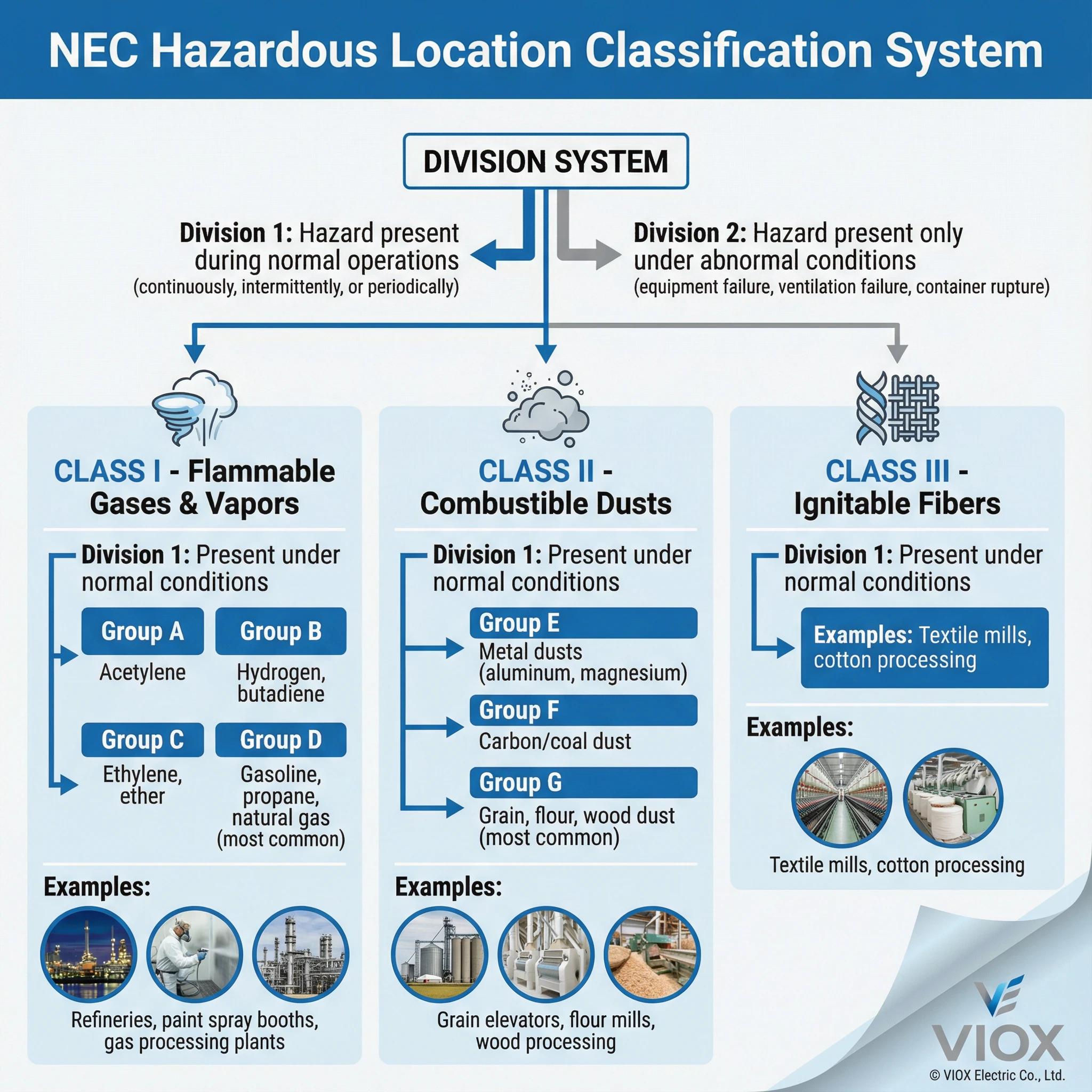

The Three Classes: Type of Hazardous Material

Class I – Flammable Gases and Vapors

Locations where flammable gases or vapors are present in the air in quantities sufficient to produce explosive or ignitable mixtures. Examples: petroleum refineries, gasoline dispensing areas, natural gas processing plants, paint spray booths, chemical processing areas handling volatile solvents.

Class I materials are further divided into Groups based on ignition characteristics:

- Group A: Acetylene only (extremely high explosion pressure)

- Group B: Hydrogen, butadiene, ethylene oxide, propylene oxide (very low ignition energy)

- Group C: Ethylene, diethyl ether, cyclopropane (intermediate)

- Group D: Gasoline, propane, natural gas, methane, acetone, butane, ethanol (most common)

Class II – Combustible Dust

Locations where combustible dust is present in quantities sufficient to produce explosive or ignitable mixtures. The Adrian grain facility was Class II, Group G. Examples: grain elevators, flour/feed mills, coal handling, metal powder processing (aluminum, magnesium), pharmaceutical powder operations, wood dust from sawmills.

Class II materials are divided into:

- Group E: Metal dusts (aluminum, magnesium – conductive and pyrophoric)

- Group F: Carbon black, coal dust, coke dust (conductive)

- Group G: Grain dust, flour, starch, sugar, wood dust, plastics (most common)

Class III – Ignitable Fibers and Flyings

Locations where easily ignitable fibers or flyings are present but not likely to be in suspension in quantities sufficient to produce ignitable mixtures. Examples: textile mills, cotton processing, sawmills (wood shavings), plants manufacturing rayon or cotton.

Divisions: Frequency and Duration of Hazard

Division 1 – Hazardous concentrations exist under normal operating conditions. This includes:

- Where ignitable concentrations are present continuously, intermittently, or periodically during normal operations.

- Where hazardous concentrations exist frequently due to repair, maintenance, or leakage.

- Where equipment breakdown could release hazardous concentrations and simultaneously cause electrical equipment failure (creating an ignition source at the moment of release).

Division 2 – Hazardous concentrations are not normally present and occur only under abnormal conditions:

- Flammable materials are handled, processed, or used but are normally confined in closed containers or systems from which they can escape only due to accidental rupture, breakdown, or abnormal operation.

- Hazardous concentrations are normally prevented by positive mechanical ventilation, but could occur due to ventilation failure.

- The location is adjacent to a Class I, Division 1 area, and hazardous concentrations could occasionally be communicated (unless prevented by adequate ventilation or physical barriers).

The Division 1 Line is the critical determination. If your area qualifies as Division 1, explosion-proof equipment is mandatory for all electrical installations. Division 2 allows some relaxation (certain equipment can use general-purpose enclosures if hermetically sealed or otherwise protected), but junction boxes in Division 2 still typically require explosion-proof or purged/pressurized protection.

Practical Classification Example:

A refinery pump area handling crude oil (Class I, Group D) where vapor release is expected during normal pump seal maintenance = Class I, Division 1, Group D. The same pump area with improved sealing where vapor release is unlikely except during abnormal seal failure = Class I, Division 2, Group D.

At the Adrian grain facility, areas around bucket elevators, grain legs, and dust-producing transfer points where grain dust was airborne during normal operations = Class II, Division 1, Group G. Storage silos with grain in enclosed bins where dust is generated only during abnormal bin rupture or spills = Class II, Division 2, Group G.

Classification authority: Only qualified personnel—typically professional engineers, certified industrial hygienists, or experienced plant safety engineers—should perform hazardous area classification. AHJs (building officials, fire marshals, OSHA inspectors) will verify classifications during inspections and investigations.

How Explosion-Proof Boxes Work: The Flame Path Principle

The core engineering that makes an explosion-proof junction box work is deceptively simple: controlled gaps that cool hot gases. But the precision required to achieve this is anything but simple.

When an internal explosion occurs—say, from an arc during a switching operation in a gas-filled enclosure—the pressure spike inside the box can reach 8-10 bar (115-145 psi) within milliseconds. The explosion-proof enclosure must:

- Withstand the pressure without structural failure. Heavy cast aluminum (6-10 mm wall thickness) or ductile iron construction provides the strength. Fasteners are sized and spaced to prevent the cover from blowing off.

- Force escaping gases through precision flame paths. These are the narrow gaps between the cover and body (flanged joints), threaded cable entries, and any removable parts. The gap width is tightly controlled—typically 0.15-0.2 mm for common Group D gases like propane.

- Cool the gases below ignition temperature. As hot combustion gases are forced through the narrow, long flame path, they contact the cooler metal surfaces. Heat transfers from the gas to the metal. The path length (typically 12.5-25 mm depending on enclosure volume and gas group) is calculated to ensure sufficient cooling.

By the time the gases exit the flame path, they’ve cooled from 1,500-2,000°C (combustion temperature) to below the ignition temperature of the external flammable atmosphere (300-500°C for most gases). The flame is quenched. External ignition is prevented.

Critical Construction Requirements:

- Threaded cable entries: Minimum 5 full threads of engagement (for NPT threads, typically 8 mm minimum engagement for Group IIA). Threads form a labyrinth seal that creates an extended flame path. Standard knockouts with compression connectors don’t provide adequate flame path.

- Flat gasket surfaces: Flame path surfaces must be machined flat and smooth (surface roughness Ra ≤ 6.3 µm) to maintain the gap tolerance. Damage, corrosion, or paint on flame path surfaces compromises the gap and invalidates the rating.

- Proper fastening: All cover screws must be tightened to maintain the flame path gap. Missing fasteners or loose covers allow wider gaps that won’t cool gases adequately.

- Certification marks: UL 1203 listing mark, Class/Division/Group rating, and T-Code must be permanently marked on the enclosure. A 2025 UL 1203 update adds marking requirements for enclosures tested with circuit breakers to warn about interrupting rating limits and temperature rise.

For Class II Dust-Ignition-Proof boxes, the approach differs. Instead of cooling explosion gases, the enclosure prevents dust from entering. Gasketed, tight-fitting covers and threaded entries with sealing create a dust-tight barrier. Surface temperature is controlled (through T-Code rating) to stay below the dust’s ignition temperature—critical because dust layers on the outside of the enclosure can ignite from surface heat even if no internal explosion occurs.

When Standard Boxes Become Ignition Sources: Real Failure Scenarios

Standard junction boxes aren’t just inadequate in hazardous locations—they become active ignition sources. Here’s what happens when you install a $18 NEMA 1 box in a Class I or Class II environment:

Failure Scenario 1: Dust Ingress and Arc Ignition (Class II)

A standard box in a grain elevator has gaps around the cover and open knockouts with standard connectors. Over weeks of operation, fine grain dust enters through these gaps. Dust accumulates on bus bars, terminals, and wire nuts inside. When a motor circuit opens (normal switching), the contactor arc inside the box ignites the accumulated dust. The flash fire propagates through the dust-laden atmosphere outside the box. If dust concentrations are in the explosive range (typically 40-4,000 g/m³ for grain dust), a dust explosion follows.

Time to ignition: 6-18 months depending on dust density and switching frequency. Cost: $100,000-$5M+ (explosion damage, injuries, facility shutdown, OSHA penalties, litigation).

Failure Scenario 2: Vapor Entry and Spark Ignition (Class I)

A paint spray booth uses standard junction boxes for exhaust fan controls. Solvent vapors from the spray process enter the box through cable entry gaps. Normal relay switching creates a spark inside the box, igniting the flammable vapor/air mixture inside. Because the box has no flame path, hot gases and flame propagate directly to the external atmosphere, igniting the vapor-laden booth environment.

Time to ignition: Can occur immediately upon first vapor exposure during switching. Cost: $50,000-$500,000+ (fire damage, equipment replacement, potential injuries, fire marshal investigation).

Failure Scenario 3: Hot Surface Ignition (Class II, Dust Layers)

Even without internal arcing, a standard box with poor ventilation and high current load develops hot spots on terminals. Surface temperatures reach 80-120°C. Grain dust (ignition temperature 430°C for cloud, but as low as 200°C for layers under smoldering conditions) accumulates on the outside of the box. Over time, the hot surface causes smoldering ignition of the dust layer, which propagates and eventually transitions to flaming combustion.

Time to ignition: Months to years depending on current load and dust accumulation. Often discovered during maintenance or after a fire.

Failure Scenario 4: Cable Entry Flame Propagation

A standard box with cable entering through a knockout and held by a simple compression connector. Flammable gas enters through the gap between cable jacket and connector. Arc inside the box ignites the gas. Flame propagates through the cable entry gap directly to the external atmosphere—there’s no flame path to cool the gases. External ignition follows.

These aren’t theoretical. OSHA combustible dust investigations document dust explosions ignited by non-rated electrical equipment. The U.S. Chemical Safety Board’s grain elevator explosion investigations repeatedly identify standard electrical enclosures as ignition sources. The Adrian, MO incident is one of dozens with the same root cause.

Application Decision Guide: Is Your Location Hazardous?

Determining whether your installation requires explosion-proof junction boxes starts with a single question: Are flammable gases, vapors, combustible dust, or ignitable fibers present or likely to be present in ignitable concentrations?

If yes, you have a hazardous location. The next question is classification.

Step-by-Step Classification

Step 1: Identify the hazardous material type

- Flammable gas or vapor (gasoline, propane, natural gas, solvent vapors) → Class I

- Combustible dust (grain, flour, metal powder, coal, sugar, wood) → Class II

- Ignitable fibers or flyings (cotton, rayon, wood shavings, textile fibers) → Class III

Step 2: Determine the hazard frequency

- Present under normal operating conditions (continuously, intermittently, or periodically) → Division 1

- Present only under abnormal conditions (equipment failure, container rupture, ventilation failure) → Division 2

Step 3: Identify the material group (Class I and II only)

- Class I: Determine gas/vapor group (A, B, C, or D) based on specific material. Group D (gasoline, propane, natural gas) is most common.

- Class II: Determine dust group (E, F, or G). Group G (grain, flour, starch, wood, plastics) is most common.

Step 4: Determine required T-Code (temperature class)

- Look up the auto-ignition temperature (AIT) of the specific material.

- Select equipment with T-Code rated below that AIT. For example, gasoline AIT is 280°C → requires T3 (200°C max) or lower.

Step 5: Select junction box rating

- Match the box certification to your classification: Class I, Division 1, Group D, T3 (for gasoline example).

- Verify UL 1203 (Class I) or UL 698 (Class II) listing mark.

- For international installations, verify ATEX (Europe) or IECEx certification.

Common Application Classifications

| Application | Typical Classification | Required Junction Box |

| Grain elevator bucket elevator area | Class II, Div 1, Group G | UL 698 dust-ignition-proof |

| Gasoline dispenser (pump island) | Class I, Div 1, Group D, T3 | UL 1203 explosion-proof |

| Paint spray booth | Class I, Div 1, Group D, T4 | UL 1203 explosion-proof |

| Natural gas compressor station | Class I, Div 2, Group D, T3 | Explosion-proof or purged/pressurized |

| Pharmaceutical powder processing room | Class II, Div 1, Group G | UL 698 dust-ignition-proof |

| Solvent storage room (closed containers) | Class I, Div 2, Group D (varies) | Explosion-proof or purged |

| Woodworking shop (dust collection) | Class II, Div 2, Group G | Dust-ignition-proof or sealed |

| Refinery crude oil pump area | Class I, Div 1, Group D, T2 or T3 | UL 1203 explosion-proof |

When explosion-proof is NOT required:

- Standard indoor electrical rooms with no flammable materials → NEMA 1 adequate.

- Outdoor locations with rain/dust exposure but no flammable gases or combustible dust → weatherproof (IP65, NEMA 4) adequate, not explosion-proof.

- Clean assembly areas, office spaces, residential → standard enclosures adequate.

Pro-tip: The Gray Area. If you’re uncertain whether a location qualifies as hazardous, err on the side of explosion-proof. The cost difference ($150-$450 vs $12-$50) is negligible compared to the liability, regulatory, and life-safety risk of under-specification. Consult with a qualified engineer or industrial hygienist for formal classification.

Cost Analysis: The $450 Premium vs Catastrophic Risk

The explosion-proof vs standard cost gap looks stark on a purchase order: $450 for a Class II, Division 1 aluminum junction box vs $18 for a NEMA 1 steel box—a 25× premium. But that’s the wrong calculation.

Total Risk-Adjusted Cost Formula:

TCO = (Equipment Cost) + (Installation Cost) + (Failure Probability × Incident Cost)

Scenario: Grain Elevator, 15 Junction Boxes in Class II, Div 1 Areas

Option A: Standard NEMA 1 Boxes (actual Adrian, MO approach)

- Equipment: 15 boxes × $18 = $270

- Installation: 15 boxes × 0.5 hr × $85/hr = $638

- Failure probability over 5 years: 60% (dust ingress is near-certain in grain environment)

- Incident cost range: $100,000–$5,000,000 (OSHA fines $143,860 + explosion damage + injury costs + shutdown)

- Expected incident cost: 0.60 × $1,000,000 (conservative mid-range) = $600,000

- 5-year TCO: $600,908

Option B: Explosion-Proof Class II, Div 1 Boxes (code-compliant)

- Equipment: 15 boxes × $450 = $6,750

- Installation: 15 boxes × 0.75 hr × $85/hr = $956 (slightly longer due to threaded entries)

- Failure probability over 5 years: <1% (assuming proper installation and maintenance)

- Expected incident cost: 0.01 × $1,000,000 = $10,000

- 5-year TCO: $17,706

Cost savings with explosion-proof: $600,908 – $17,706 = $583,202

The “expensive” explosion-proof boxes save $583,000 by eliminating the high-probability catastrophic failure that standard boxes guarantee in hazardous environments.

Break-even point: If the probability of a dust ignition incident exceeds 1.1% over the equipment lifetime, explosion-proof boxes are cost-justified on pure financial grounds—ignoring regulatory compliance, life safety, and liability. In Class II, Division 1 grain dust environments, ignition probability with standard boxes approaches 60-80% over 5-10 years.

When Standard Boxes Make Financial Sense

Never in classified hazardous locations. It’s not a financial decision when NEC Article 500 mandates explosion-proof equipment—it’s a legal requirement. Using standard boxes in Class I/II/III locations is a willful code violation.

NEC Article 500 Compliance: What You Must Know

NEC Article 500 isn’t guidance—it’s enforceable code adopted by virtually all U.S. jurisdictions. Here’s what it mandates for junction boxes in hazardous locations:

NEC 500.5(A): Equipment

All equipment used in hazardous (classified) locations must be approved for the specific Class, Division, and Group of the location. “Approved” means listed by a qualified testing laboratory (UL, ETL, CSA) for the specific hazardous location rating.

NEC 501.5(A): Class I Equipment (Gases/Vapors)

In Class I, Division 1 locations, all junction boxes and fittings must be listed for Class I locations and be explosion-proof. In Division 2, boxes may be explosion-proof or meet alternative protection methods (hermetically sealed, purged/pressurized).

NEC 502.5(A): Class II Equipment (Combustible Dust)

In Class II, Division 1 locations, all boxes and fittings must be listed for Class II locations and be dust-ignition-proof. Surface temperature must not exceed the ignition temperature of the specific dust (T-Code rating).

Critical Compliance Points:

- Listing marks required: Junction boxes must carry visible certification marks (UL, ETL, CSA) and hazardous location ratings permanently stamped or labeled on the enclosure.

- Proper installation: Threaded entries must have minimum 5 full threads engaged. Unused openings must be sealed with listed threaded plugs. Covers must be fully tightened.

- Maintenance of rating: Any modification, repair, or painting that affects flame paths, gasket surfaces, or threaded joints invalidates the listing. Field modifications are generally prohibited.

- AHJ authority: Building officials, fire marshals, and OSHA inspectors have authority to require hazardous area classification studies and verify proper equipment selection. Post-incident investigations (like Adrian, MO) routinely cite improper equipment as contributing factors.

Penalties for non-compliance:

- OSHA citations and fines (typically $7,000–$150,000 per violation)

- Insurance claim denial (using non-listed equipment voids coverage)

- Criminal liability if fatalities occur (willful safety violations can result in criminal charges)

- Civil litigation exposure (negligence claims from injured workers or affected parties)

Pro-tip: When the AHJ or inspector questions your junction box selection, point to the UL listing mark, the Class/Division/Group rating stamped on the enclosure, and the NEC 500/501/502 article compliance. Proper documentation—listing certificates, area classification drawings, equipment specifications—demonstrates due diligence.

Conclusion: Explosion-Proof Selection Checklist

Explosion-proof vs standard junction box selection isn’t a performance trade-off—it’s a life-safety and legal mandate. Choose standard boxes in hazardous locations, and you’ve locked in a foreseeable ignition scenario. Choose explosion-proof boxes matched to your classification, and you’ve purchased 20-30 years of safe, compliant service.

Use this checklist before specifying or purchasing:

✅ Hazardous Area Classification:

- Is flammable gas/vapor/dust/fiber present in ignitable concentrations? → If YES, classify the area.

- Class I (gas/vapor), Class II (dust), or Class III (fibers)?

- Division 1 (normal conditions) or Division 2 (abnormal conditions)?

- Material group: Class I (A/B/C/D), Class II (E/F/G)?

- Required T-Code based on material auto-ignition temperature?

✅ Equipment Selection:

- Junction box certified for specific Class, Division, Group, T-Code?

- UL 1203 (Class I) or UL 698 (Class II) listing mark visible on enclosure?

- For international: ATEX or IECEx certification if required?

- Material appropriate for environment: aluminum (most common), stainless steel (corrosive+hazardous), ductile iron?

✅ Installation Requirements:

- Threaded cable entries with minimum 5 full threads engaged?

- Certified cable glands used for all cable entries?

- Unused openings sealed with listed threaded plugs?

- Cover fasteners fully tightened to maintain flame path?

- Flame path surfaces undamaged (no gouges, corrosion, paint)?

- Proper grounding and bonding per NEC 501.30 (Class I) or 502.30 (Class II)?

✅ Documentation:

- Hazardous area classification drawings prepared by qualified personnel?

- Equipment listing certificates and specifications on file?

- Installation records showing proper thread engagement and torque?

✅ Cost-Benefit Verification:

- Life-cycle cost calculated including incident probability?

- Regulatory compliance (NEC 500/501/502) verified?

- Insurance and liability exposure assessed?

That $432 difference at the Adrian grain facility—between an $18 standard box and a $450 explosion-proof box—wasn’t optional cost engineering. It was the legal minimum for preventing ignition in Class II, Division 1 grain dust. The explosion didn’t care about the budget. It followed physics: dust + ignition source = explosion.

Hazardous area protection isn’t negotiable. Classify your location correctly, specify explosion-proof equipment matched to your Class/Division/Group, and lock in decades of safe operation.

Standards & Sources Referenced

- NEC 2023 Article 500 (Hazardous (Classified) Locations, Classes I, II, and III, Divisions 1 and 2)

- NEC 501 (Class I Locations)

- NEC 502 (Class II Locations)

- UL 1203 (Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations)

- UL 698 (Industrial Control Equipment for Use in Hazardous (Classified) Locations)

- IEC 60079-1 (Explosive atmospheres – Part 1: Equipment protection by flameproof enclosures “d”)

- OSHA 29 CFR 1910.272 (Grain Handling Facilities)

- ATEX Directive 2014/34/EU (Equipment for Explosive Atmospheres)

Timeliness Statement

All classifications, standards editions, and regulatory requirements accurate as of December 2025. NEC 2023 edition in effect. UL 1203 Standards Update Notice (2025) referenced for new marking requirements effective Dec. 31, 2029. OSHA grain facility investigation (Adrian, MO, Dec. 31, 2020) reflects documented incident.