When designing electrical distribution systems, choosing between a dry type transformer and an oil filled transformer is one of the most critical decisions that impacts safety, efficiency, and long-term operational costs. While both serve the same fundamental purpose of stepping voltage up or down, their construction, cooling methods, and applications differ significantly. This comprehensive guide examines the key differences to help you make an informed decision for your specific application.

Key Takeaways

- Cooling Medium: Dry type transformers use air for cooling, while oil filled transformers use insulating oil as both coolant and insulation

- Safety Profile: Dry type units eliminate fire risks from flammable liquids, making them ideal for indoor and populated areas

- Voltage Capacity: Oil filled transformers handle higher voltages (up to 1000 kV) compared to dry type (typically limited to 35 kV)

- Maintenance: Dry type transformers require minimal maintenance, while oil filled units need regular oil testing and filtration

- Initial Cost: Oil filled transformers have lower upfront costs, but dry type units offer lower total lifecycle costs for indoor applications

- Environmental Impact: Dry type transformers are more environmentally friendly with no risk of oil spills or contamination

Understanding Transformer Basics

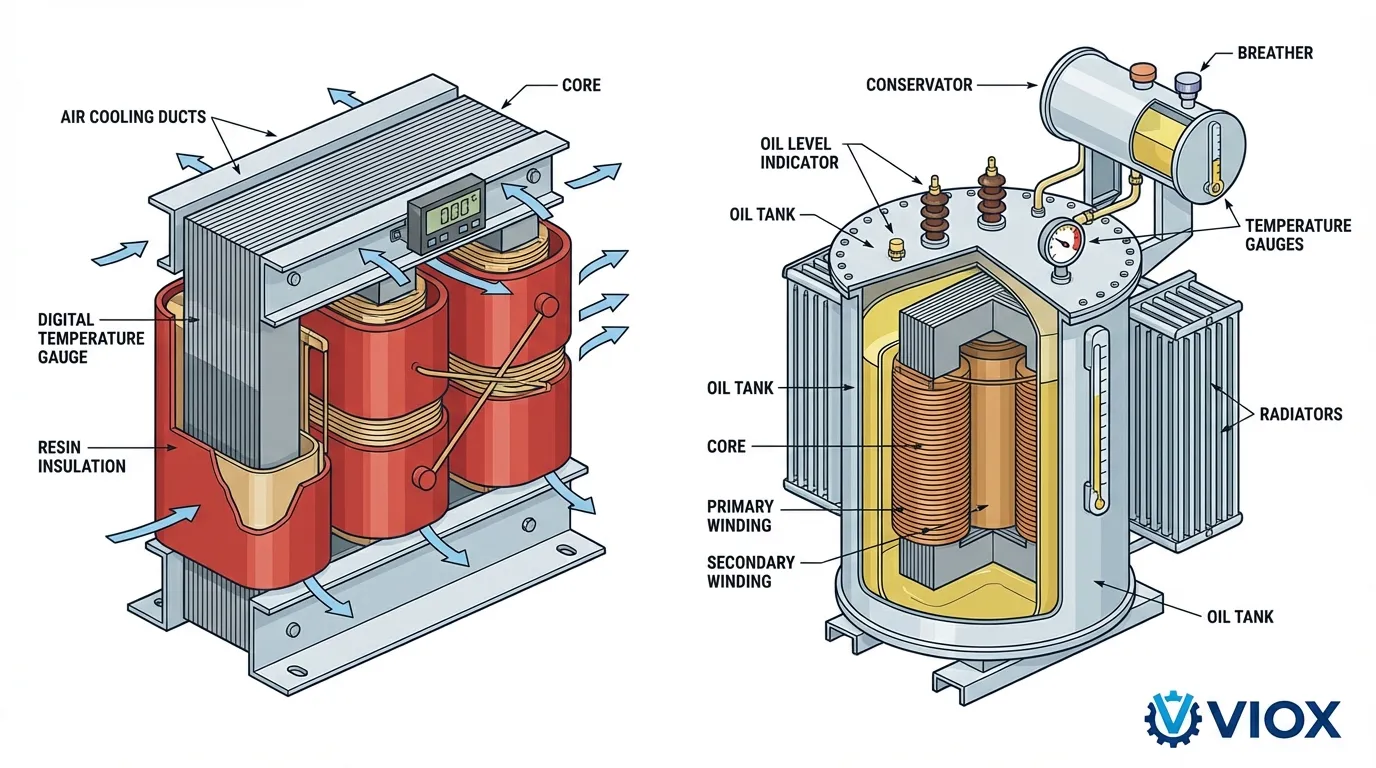

Both dry type and oil filled transformers operate on the same electromagnetic induction principle, consisting of a magnetic core and copper or aluminum windings. The fundamental difference lies in the insulation and cooling systems employed to manage heat generated during operation.

Core Differences: Dry Type vs Oil Filled Transformers

1. Insulation and Cooling Systems

Dry Type Transformers:

- Use solid insulation materials such as epoxy resin, vacuum pressure impregnation (VPI), or cast resin

- Rely on air (natural or forced) as the cooling medium

- Heat dissipates through convection and radiation

- No flammable liquids involved in operation

Oil Filled Transformers:

- Use mineral oil or synthetic ester fluids for insulation

- Oil serves dual purpose: electrical insulation and heat transfer

- Heat transfers from windings to oil, then to external radiators

- Superior cooling efficiency allows higher power ratings

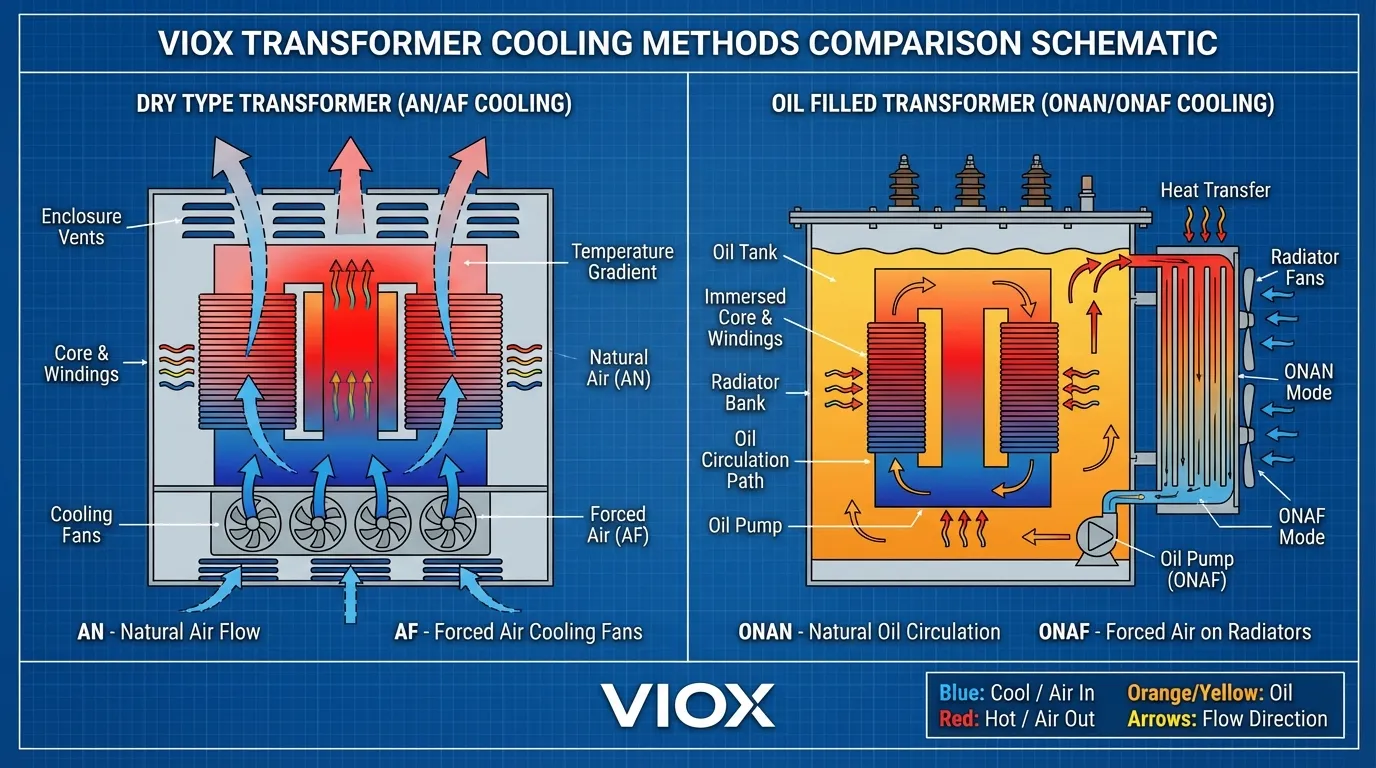

The cooling efficiency of oil (thermal conductivity approximately 0.13 W/m·K) significantly exceeds that of air (0.026 W/m·K), enabling oil filled transformers to handle higher loads in more compact designs for outdoor applications.

2. Safety and Fire Risk

| Safety Aspect | Dry Type Transformer | Oil Filled Transformer |

|---|---|---|

| Fire Hazard | Minimal – no flammable liquids | Higher – oil is combustible |

| Explosion Risk | Very low | Moderate (if oil overheats) |

| Toxic Gas Emission | Minimal during faults | Can produce toxic gases |

| Indoor Installation | Fully approved | Requires special fire protection |

| Environmental Spill Risk | None | Oil leakage possible |

| Self-Extinguishing | Yes (Class F/H insulation) | No – requires suppression systems |

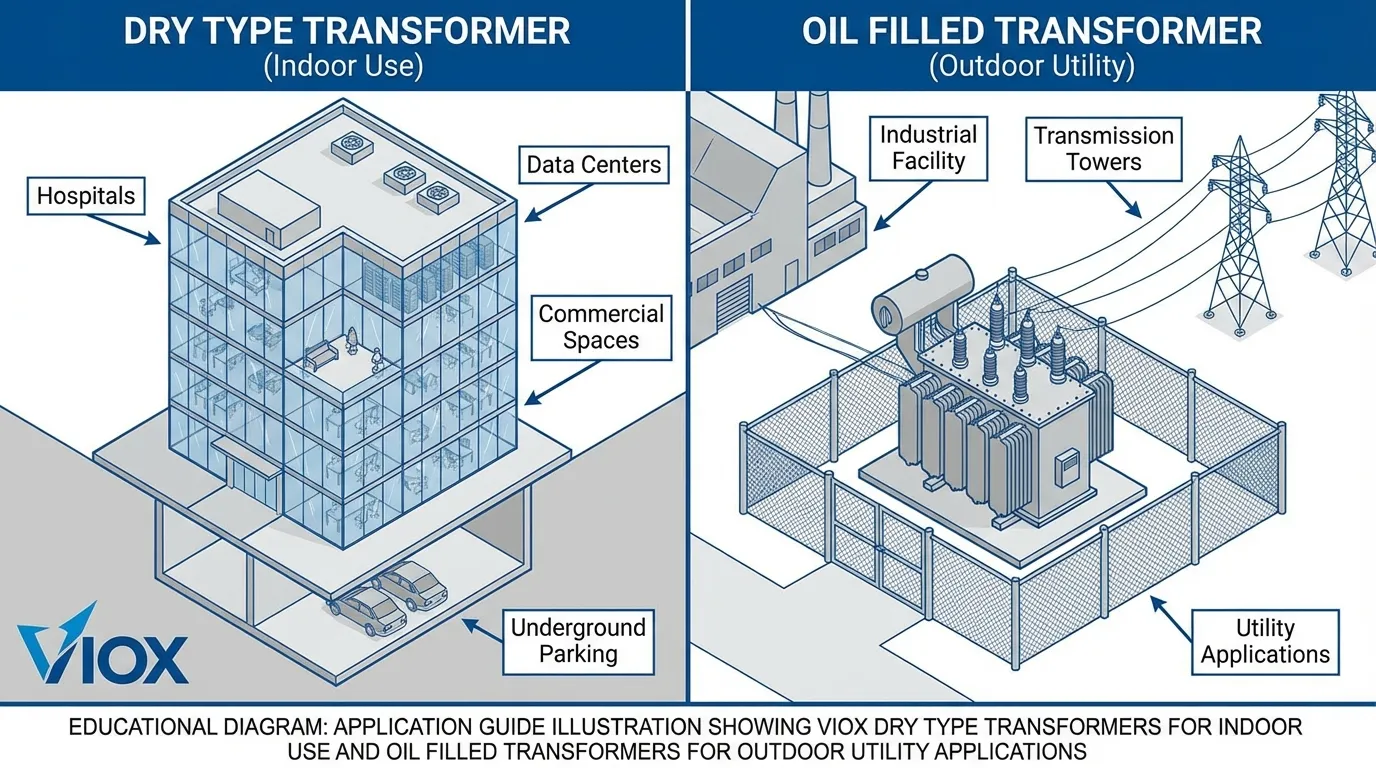

Dry type transformers are the preferred choice for hospitals, schools, commercial buildings, data centers, and any location where fire safety is paramount. Oil filled units require containment systems, fire walls, and adequate spacing per NFPA and NEC standards.

3. Voltage and Power Capacity

Dry Type Transformers:

- Voltage ratings: Typically up to 35 kV

- Power capacity: Usually limited to 2,500-5,000 kVA for air-cooled units

- Cooling limitations restrict higher ratings

- Ideal for low to medium voltage distribution

Oil Filled Transformers:

- Voltage ratings: Up to 1,000 kV and beyond

- Power capacity: From small distribution units to 500+ MVA power transformers

- Superior cooling enables unlimited scaling

- Standard for transmission and high-voltage applications

The voltage limitation in dry type transformers stems from air’s inferior dielectric strength compared to transformer oil. At higher voltages, the insulation system becomes impractically large and expensive.

4. Installation Requirements

| Installation Factor | Dry Type | Oil Filled |

|---|---|---|

| Indoor Use | Excellent – preferred choice | Possible with fire protection |

| Outdoor Use | Requires weatherproof enclosure | Standard – naturally protected |

| Space Requirements | Larger footprint for same rating | More compact for high power |

| Foundation | Lighter foundation acceptable | Requires stronger foundation |

| Ventilation | Adequate airflow essential | Minimal ventilation needed |

| Fire Protection | Not required | Oil containment, fire walls needed |

| Noise Level | Higher (especially with fans) | Lower operational noise |

| Accessibility | Can be located near load centers | Must maintain safety clearances |

For indoor installations, dry type transformers eliminate the need for oil containment pits, special fire suppression systems, and extensive safety clearances, significantly reducing installation costs and complexity.

5. Maintenance and Lifecycle Costs

Dry Type Transformers:

- Maintenance: Minimal – periodic cleaning and visual inspection

- No oil testing or filtration required

- No oil replacement costs over lifetime

- Longer intervals between service

- Lower ongoing operational expenses

- Typical lifespan: 25-30 years with proper maintenance

Oil Filled Transformers:

- Regular oil testing required (annually or semi-annually)

- Oil filtration and treatment needed

- Dissolved gas analysis (DGA) for fault detection

- Gasket and seal maintenance

- Oil replacement every 10-15 years

- Higher maintenance labor costs

- Typical lifespan: 30-40 years with proper oil maintenance

While oil filled transformers have higher maintenance requirements, their robust design and superior cooling can result in longer overall service life when properly maintained. The total cost of ownership depends heavily on the specific application and location.

Comparative Performance Analysis

Efficiency Comparison

| Parameter | Dry Type Transformer | Oil Filled Transformer |

|---|---|---|

| No-Load Losses | Higher (1.5-2.5% of rating) | Lower (0.5-1.5% of rating) |

| Load Losses | Comparable | Slightly better |

| Overall Efficiency | 96-98% | 98-99.5% |

| Overload Capacity | Limited (110-120%) | Better (130-150%) |

| Temperature Rise | 80-115°C | 55-65°C |

| Hot Spot Temperature | Higher | Lower due to oil circulation |

Oil filled transformers generally offer superior efficiency, particularly at higher power ratings. The better heat dissipation allows them to handle overload conditions more effectively, making them ideal for applications with variable or cyclical loads.

Transformer Cooling Class Designations

| Cooling Class | Description | Application |

|---|---|---|

| Dry Type | ||

| AN (Air Natural) | Natural air convection | Small indoor transformers |

| AF (Air Forced) | Forced air with fans | Medium power indoor units |

| Oil Filled | ||

| ONAN | Oil Natural, Air Natural | Standard distribution transformers |

| ONAF | Oil Natural, Air Forced | Medium power with fan cooling |

| OFAF | Oil Forced, Air Forced | Large power transformers |

| ODAF | Oil Directed, Air Forced | High-capacity units |

| OFWF | Oil Forced, Water Forced | Specialized high-power applications |

Understanding transformer cooling methods is essential for proper selection and operation.

Environmental and Regulatory Considerations

Dry Type Transformers:

- ✅ No oil spill risk – environmentally safer

- ✅ No soil or water contamination potential

- ✅ Recyclable resin and metal components

- ✅ Meets strict indoor air quality standards

- ✅ Compliant with green building certifications (LEED)

- ✅ Lower carbon footprint for indoor applications

Oil Filled Transformers:

- ⚠️ Requires oil spill containment systems

- ⚠️ Potential soil and groundwater contamination

- ⚠️ Oil disposal regulations and costs

- ⚠️ PCB contamination concerns (older units)

- ✅ Biodegradable ester oils available as alternative

- ✅ Better efficiency reduces operational carbon footprint

Modern environmental regulations increasingly favor dry type transformers for indoor and environmentally sensitive locations. However, natural ester fluids (like FR3) provide more environmentally friendly alternatives for oil filled transformers when outdoor installation is required.

Application-Specific Selection Guide

When designing electrical distribution systems, selecting between dry type and oil filled transformers requires careful evaluation of multiple factors:

When to Choose Dry Type Transformers:

- Indoor Installations: Commercial buildings, hospitals, schools, data centers

- Fire-Sensitive Areas: High-rise buildings, underground facilities, public spaces

- Environmental Concerns: Near water sources, protected areas, urban centers

- Low to Medium Voltage: Distribution systems up to 35 kV

- Limited Maintenance Resources: Locations with minimal technical staff

- Regulatory Requirements: Jurisdictions with strict fire codes

When to Choose Oil Filled Transformers:

- Outdoor Substations: Utility distribution and transmission systems

- High Voltage Applications: Above 35 kV voltage class

- Large Power Ratings: Above 5 MVA capacity requirements

- Cost-Sensitive Projects: Lower initial investment priority

- Overload Capability: Applications with significant load variations

- Extreme Environments: Very high ambient temperatures or harsh conditions

Cost Analysis: Initial Investment vs Total Lifecycle

Initial Purchase Cost Comparison (1000 kVA, 11kV/0.4kV example)

| Cost Component | Dry Type | Oil Filled |

|---|---|---|

| Transformer Unit | $45,000 – $60,000 | $30,000 – $40,000 |

| Installation | $8,000 – $12,000 | $15,000 – $25,000* |

| Fire Protection | Not required | $10,000 – $20,000 |

| Oil Containment | Not required | $5,000 – $10,000 |

| Total Initial Cost | $53,000 – $72,000 | $60,000 – $95,000 |

*Higher for indoor installation with fire protection

20-Year Lifecycle Cost Comparison

| Cost Factor | Dry Type | Oil Filled |

|---|---|---|

| Initial Investment | $60,000 | $75,000 |

| Annual Maintenance | $500/year = $10,000 | $2,000/year = $40,000 |

| Oil Testing & Treatment | $0 | $15,000 |

| Energy Losses (2% vs 1%) | $80,000 | $40,000 |

| Insurance Premium Difference | Lower | Higher (+$10,000) |

| Total 20-Year Cost | $150,000 | $180,000 |

For indoor applications, dry type transformers typically offer 15-25% lower total cost of ownership despite higher initial purchase price. For outdoor utility applications, oil filled transformers remain more economical.

Technical Specifications Comparison

| Specification | Dry Type Transformer | Oil Filled Transformer |

|---|---|---|

| Voltage Class | Up to 36 kV | Up to 1000 kV+ |

| Power Rating | Up to 30 MVA (typical max) | Unlimited (500+ MVA available) |

| Insulation Class | Class F (155°C) or H (180°C) | Class A (105°C) |

| Temperature Rise | 80-115 K | 55-65 K |

| Overload Capacity | 110-120% for short periods | 130-150% sustained |

| Efficiency at Full Load | 96-98.5% | 98.5-99.7% |

| Noise Level | 55-70 dB (with fans) | 45-55 dB |

| Expected Lifespan | 25-30 years | 30-40 years |

| Weight (per kVA) | Heavier | Lighter |

| Footprint (per kVA) | Larger | Smaller |

Understanding these specifications helps in selecting the appropriate transformer type based on electrical system requirements.

Frequently Asked Questions (FAQ)

Q1: Can a dry type transformer be used outdoors?

Yes, but it requires a weatherproof enclosure with proper ventilation. Dry type transformers are designed primarily for indoor use, but outdoor-rated models with NEMA 3R or IP54 enclosures are available. However, oil filled transformers are generally more suitable and cost-effective for outdoor installations.

Q2: Which transformer type is more environmentally friendly?

Dry type transformers are more environmentally friendly for indoor applications as they eliminate oil spill risks and soil contamination. However, oil filled transformers using natural ester fluids (biodegradable) can be environmentally acceptable for outdoor use and offer better energy efficiency, reducing operational carbon footprint.

Q3: How often does an oil filled transformer need maintenance?

Oil filled transformers require annual oil testing (dissolved gas analysis), visual inspections every 6 months, and oil filtration every 2-5 years depending on operating conditions. Complete oil replacement is typically needed every 10-15 years. Dry type transformers need only periodic cleaning and visual inspection annually.

Q4: What is the maximum voltage rating for dry type transformers?

Dry type transformers are typically limited to 36 kV class due to air’s lower dielectric strength compared to oil. While some manufacturers offer units up to 46 kV, oil filled transformers are standard for higher voltage applications. For distribution systems, this limitation rarely poses issues.

Q5: Are dry type transformers safer than oil filled transformers?

Yes, for indoor applications. Dry type transformers eliminate fire risks from flammable liquids, don’t produce toxic gases during faults, and have self-extinguishing insulation materials. This makes them significantly safer for buildings with occupants. Oil filled transformers require additional fire protection systems and containment measures.

Q6: Which transformer type has lower losses and better efficiency?

Oil filled transformers generally have lower losses and better efficiency (98.5-99.7%) compared to dry type units (96-98.5%), especially at higher power ratings. The superior cooling of oil allows for more efficient designs. However, for small to medium ratings, the efficiency difference is minimal and may not justify the additional maintenance costs of oil filled units.

Q7: Can I replace an oil filled transformer with a dry type?

Yes, but several factors must be considered: available space (dry type units are larger), ventilation requirements, voltage and power ratings, and whether the application suits dry type characteristics. Many facilities upgrade to dry type transformers during renovations to improve safety and reduce maintenance. Consult with a qualified engineer to ensure proper sizing and installation.

Q8: What is the typical lifespan of each transformer type?

Dry type transformers typically last 25-30 years with minimal maintenance, while oil filled transformers can last 30-40 years with proper oil maintenance and testing. The actual lifespan depends on operating conditions, load patterns, maintenance quality, and environmental factors. Proper circuit protection extends transformer life significantly.

Conclusion

Both dry type and oil filled transformers serve essential roles in modern electrical distribution systems. Dry type transformers excel in indoor, fire-sensitive, and environmentally conscious applications, offering superior safety and lower lifecycle costs despite higher initial investment. Oil filled transformers dominate high-voltage, high-power outdoor applications where their superior cooling efficiency, overload capability, and compact design provide unmatched performance.

Understanding the fundamental differences in cooling methods, safety profiles, maintenance requirements, and application suitability enables informed decision-making that optimizes both safety and total cost of ownership. As environmental regulations tighten and fire safety standards evolve, dry type transformers continue gaining market share in commercial and industrial sectors, while oil filled transformers remain indispensable for utility-scale power transmission and distribution.

VIOX Electric manufactures both dry type and oil filled transformers to meet diverse customer requirements across commercial, industrial, and utility applications. Our engineering team can help you select the optimal transformer solution for your specific needs, ensuring safety, efficiency, and long-term reliability.

For technical consultation on transformer selection or to learn more about our complete range of electrical distribution equipment, contact VIOX Electric today.