Specifikace svorkovnic pro průmyslový panel by měla být přímočará. Ale když se v e-mailech z oddělení nákupu ptají, zda použít šroubové svorky nebo pružinové svorky, nebo když specifikace uvádějí “bariérové bloky” bez kontextu, stává se jasnost kritickou. Elektrotechnici potřebují přesná kritéria výběru. Dodavatelé potřebují jistotu, že objednávají správný hardware. Správci zařízení chtějí zakončení, která zůstanou bezpečná i po letech vibrací a teplotních cyklů.

Svorkovnice – izolovaná modulární zařízení, která mechanicky a elektricky spojují vodiče – tvoří páteř organizované kabeláže v ovládacích panelech, strojích a automatizaci budov. Montují se na DIN lištu uvnitř skříní a transformují chaotickou kabeláž bod-bod do strukturovaných, označených obvodů.

Tato příručka stanovuje jasnou taxonomii typů svorkovnic, poskytuje srovnávací tabulky pro specifikaci a poskytuje praktické pokyny pro výběr v souladu s normami IEC 60947-7-1 a UL 1059.

Co je Svorkovnice?

Svorkovnice je modulární izolované pouzdro obsahující:

- Vodivý prvek: Kovový kontakt (obvykle měď nebo mosaz), který vede proud mezi vodiči

- Upínací mechanismus: Šroub, pružina nebo zásuvné zařízení, které zajišťuje odizolované konce vodičů

- Izolační těleso: Nehořlavý plast (polyamid, polykarbonát) poskytující elektrickou izolaci a mechanickou ochranu

- Montážní systém: DIN lištová spona (EN 60715) nebo otvory pro šrouby panelu pro bezpečnou instalaci

Dodržování norem

Svorkovnice pro průmyslové, komerční a rezidenční aplikace splňují:

- IEC 60947-7-1:2025 (Vydání 4.0): Nízkonapěťové spínací a řídicí přístroje – Svorkovnice pro měděné vodiče; zahrnuje elektrické parametry, zkušební metody, velikosti vodičů a mechanické požadavky

- UL 1059: Svorkovnice pro severoamerické trhy; definuje konstrukci, rozteč, nárůst teploty a zkoušky zkratu

- EN 60715: Normy pro profily DIN lišt zajišťující mechanickou kompatibilitu mezi výrobci

Svorkovnice pracují v obvodech do 1000 V AC (≤1000 Hz) nebo 1500 V DC, podporující velikosti vodičů od 0,2 mm² do 300 mm² (AWG 24 až 600 kcmil), s proudovým zatížením v rozsahu 6 A až 400 A.

Typy svorkovnic: Podle metody upínání

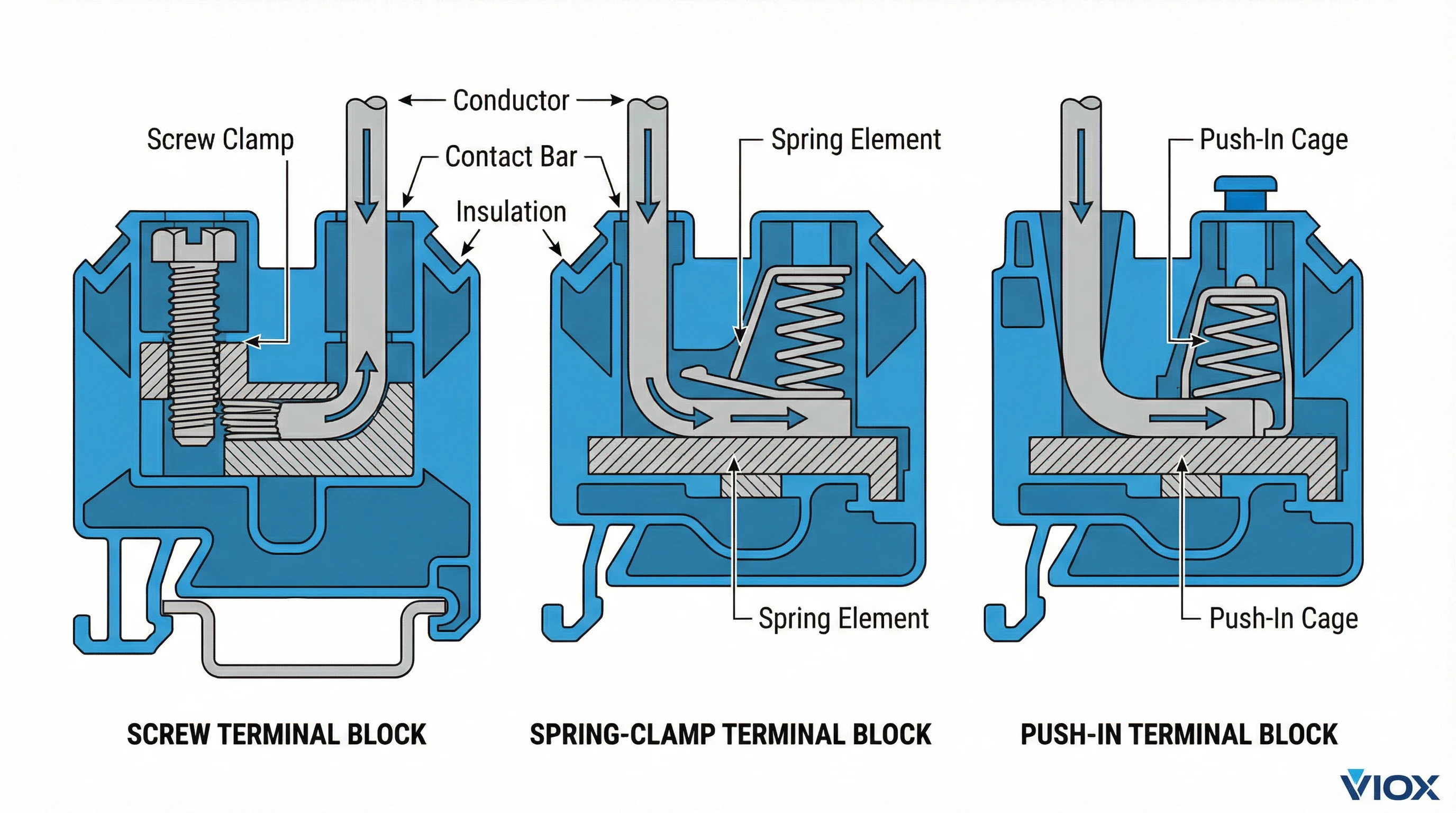

Šroubové svorkovnice

Stavebnictví: Závitový šroub stlačuje vodič proti kontaktu. Utahovací moment vytváří elektrickou kontinuitu.

Výhody:

- Široký rozsah vodičů v jednom zařízení (např. 0,5 mm² až 6 mm²)

- Vysoká mechanická odolnost vhodná pro aplikace s vysokým proudem (až 150 A+)

- Známá metoda instalace; všeobecně přijímaná

- Nižší cena za pozici ve srovnání s pružinovými technologiemi

Úvahy:

- Instalace vyžaduje kalibrované momentové šroubováky (typicky: 0,5-2,5 N·m v závislosti na velikosti)

- Vibrace nebo teplotní cykly mohou uvolnit spoje; doporučuje se pravidelné dotahování

- Doba instalace delší než u pružinových alternativ

- Zručnost instalatéra ovlivňuje kvalitu připojení

Typické aplikace: Kabeláž budov, rozvodné panely, obvody řízení strojů, dodatečné instalace

Pružinové svorkovnice

Stavebnictví: Předepjatý pružinový prvek vyvíjí konstantní upínací sílu. Šroubovák nebo tlačítko uvolní pružinu pro vložení/vyjmutí vodiče.

Výhody:

- Rychlejší instalace – není vyžadována specifikace točivého momentu

- Udržuje konstantní tlak bez ohledu na vibrace nebo změnu teploty

- Snížené požadavky na školení instalatérů

- Vynikající výkon v prostředích s vysokými vibracemi (motory, kolejová vozidla, těžké stroje)

- Nižší údržba – žádné pravidelné dotahování

Úvahy:

- Vyšší cena za pozici než u šroubových svorek

- Kritická příprava vodiče (délka odizolování, použití dutinek)

- Pružinový prvek se může unavit po mnoha cyklech vložení (typicky jmenovitě >20 cyklů)

Typické aplikace: Průmyslová automatizace, ovládací skříně vystavené vibracím, instalace vyžadující časté změny obvodů, systémy obnovitelné energie

Zásuvné svorkovnice

Stavebnictví: Beznástrojové vložení dutinkového nebo plného vodiče do pružinové klece. Uvolnění pomocí tlačítka nebo štěrbiny pro šroubovák.

Výhody:

- Nejrychlejší způsob instalace– pro připojení nejsou potřeba žádné nástroje

- Ultra-kompaktní design maximalizuje hustotu panelu

- Ideální pro vysokofrekvenční změny kabeláže

- Vynikající v drsných prostředích (námořní, chemické, venkovní)

- Snížení chyb kabeláže díky jednoduchému vložení

Úvahy:

- Vyžaduje dutinky na lankových vodičích pro spolehlivý kontakt

- Není vhodné pro velmi jemné vodiče (typicky ≥0,5 mm²)

- Omezeno na nižší proudové zatížení (typicky ≤32 A)

Typické aplikace: Ovládací panely s vysokou hustotou, I/O kabeláž, distribuovaná automatizace, modulární stavba strojů

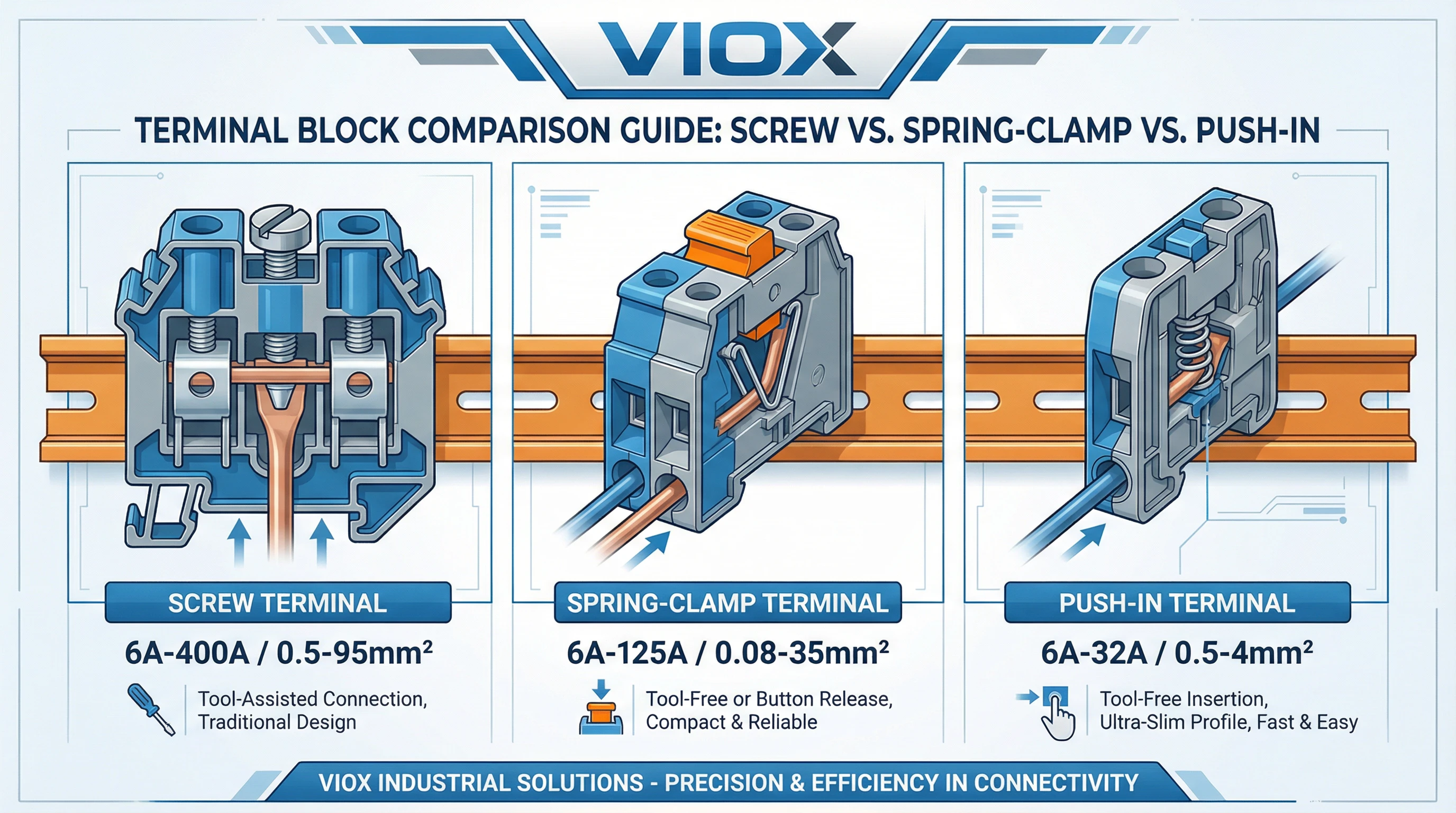

Srovnávací tabulka: Metody upínání

| Funkce | Šroubová svorka | Pružinová svorka | Zásuvná svorka |

|---|---|---|---|

| Rychlost instalace | Střední (požadovaný točivý moment) | Rychlé (žádný točivý moment) | Velmi rychlé (bez použití nástrojů) |

| Vyžaduje zručnost | Střední (řízení točivého momentu) | Nízká | Velmi nízké |

| Odolnost proti vibracím | Střední (lze povolit) | Vynikající (konstantní tlak) | Vynikající |

| Údržba | Periodické dotahování | Minimální | Minimální |

| Aktuální hodnocení | 6A – 400A | 6A – 125A | 6A – 32A |

| Cena za pozici | Nízká | Střední-Vysoká | Střední-Vysoká |

| Typický rozsah vodičů | 0.5mm² – 95mm² | 0.08mm² – 35mm² | 0.5mm² – 4mm² |

| Nejlepší aplikace | Distribuce energie, vysoký výkon | Vibrace, časté změny | Vysoká hustota, rychlá instalace |

Typy svorkovnic: Podle funkce a konfigurace

Kromě metody upínání se svorkovnice kategorizují podle funkce obvodu, stylu montáže a speciálních funkcí.

Průchozí svorkovnice

Funkce: Zajišťují propojení vodič-vodič s vstupními body na protilehlých stranách bloku. Žádné vnitřní propojky nebo přepínání – čistý průchod.

Případy použití: Obecné rozvody, prodloužení obvodů, propojení panelů

Specifikace: Dostupné ve všech typech upínání; jmenovité proudy 6A-150A; jednoúrovňové nebo víceúrovňové konfigurace

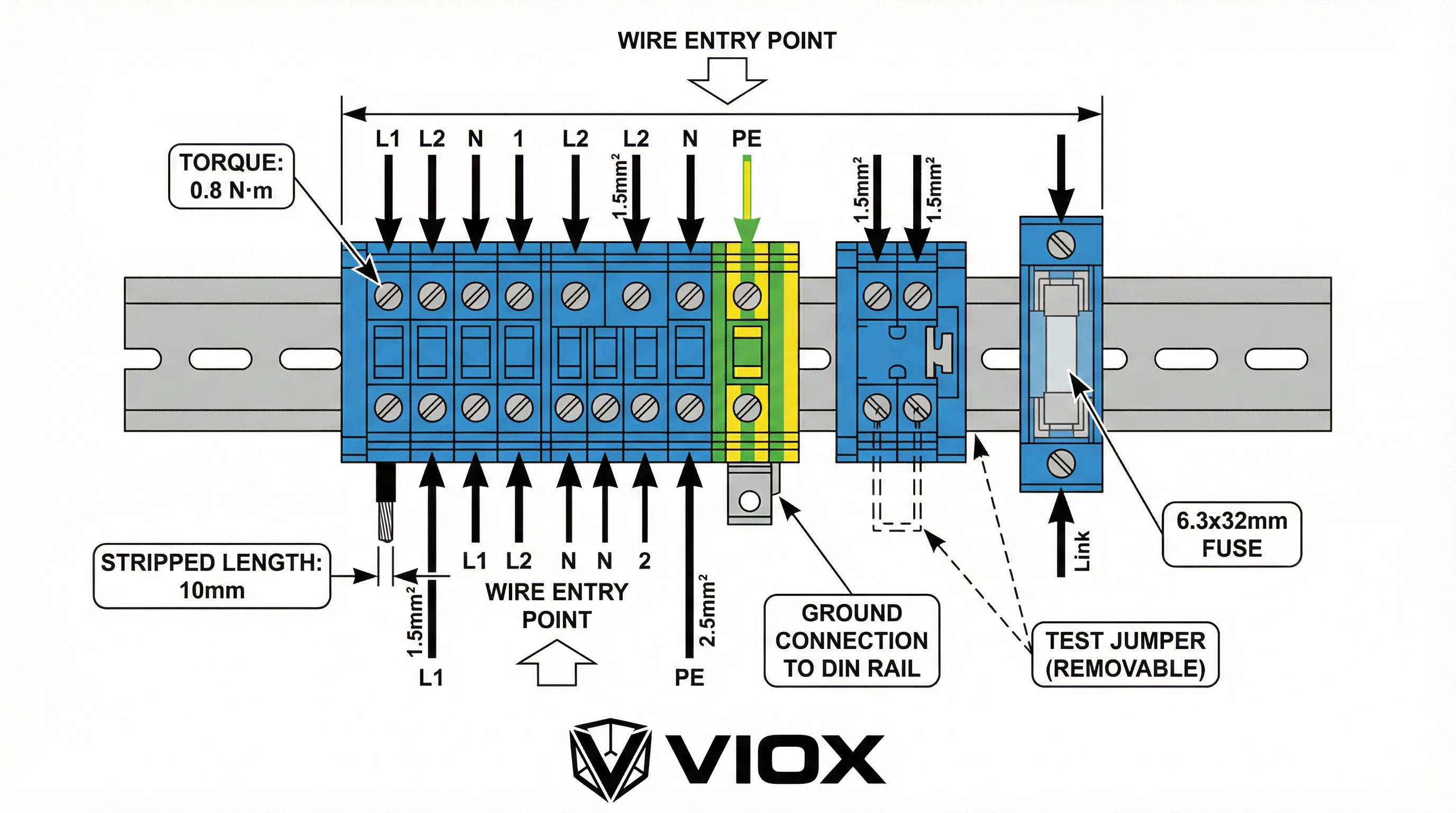

Uzemňovací svorkovnice

Funkce: Připojují ochranné vodiče (PE) k DIN liště nebo vyhrazené zemnicí sběrnici. Často mají zeleno/žlutou izolaci a přímý kovový kontakt s lištou.

Případy použití: Každý ovládací panel nebo rozvaděč vyžaduje vyhrazené zemnicí svorky

Odpojovací (testovací) svorkovnice

Funkce: Obsahují odnímatelnou propojku, spojku nebo nožový spínač, který přeruší obvod pro testování nebo izolaci bez odpojování vodičů.

Případy použití: Místa měření proudu, obvody kalibrace snímačů, přístup pro uvedení do provozu

Pojistkové svorkovnice

Funkce: Integrují držák pojistky a kontakty do jednoho modulu DIN lišty, čímž zajišťují nadproudovou ochranu v místě ukončení.

Výhody: Eliminuje samostatné držáky pojistek, snižuje kabeláž, zjednodušuje odstraňování problémů (viditelná spálená pojistka)

Typy pojistek: Přijímá válcové pojistky 5x20mm, 6.3x32mm nebo 10x38mm; některé modely obsahují indikátory spálené pojistky

Případy použití: Ochrana odbočovacích obvodů, ochrana vstupu zařízení, izolace jednotlivých zátěží

Víceúrovňové svorkovnice

Funkce: Skládají dva nebo tři nezávislé obvody do jedné stopy modulu (vertikální stohování). Každá úroveň je elektricky izolovaná.

Výhody: Šetří místo na DIN liště (2x-3x zlepšení hustoty), organizuje související signály (např. 0V, +24V, signál)

Případy použití: Panely s vysokou hustotou, kompaktní skříně, distribuce signálu + napájení v automatizačních skříních

Bariérové svorkovnice (bariérové lišty)

Funkce: Jednořadé svorkovnice se zvýšenými izolačními bariérami mezi každou pozicí, které zabraňují náhodnému kontaktu mezi sousedními obvody.

Montáž: Obvykle se šroubují k panelu nebo skříni (ne k DIN liště)

Případy použití: Obvody vysokého napětí, připojení napájecího zdroje, prostředí náchylné k vibracím, starší instalace

Power Distribution Blocks

Funkce: Odolné svorky určené pro hlavní napájecí přívody nebo připojení velkých zátěží. Více výstupních pozic napájených z jednoho vstupu.

Specifikace: Vysoká proudová zatížitelnost (150A-600A), velký rozsah vodičů (35mm²-300mm²), izolované nebo prstům bezpečné kryty

Případy použití: Připojení hlavních přípojnic, napáječe motorů, třífázová distribuce

Tabulka porovnání funkcí

| Typ svorkovnice | Primární funkce | Montáž | Typický proudový rozsah | Klíčová vlastnost |

|---|---|---|---|---|

| Průchozí | Průchod vodič-vodič | Lišta DIN | 6A – 150A | Jednoduchá distribuce |

| Uzemnění (PE) | Připojení ochranného uzemnění | Lišta DIN | 6A – 150A | Přímý kontakt s lištou, zeleno/žluté kódování |

| Odpojovací (testovací) | Přerušení obvodu bez odpojení | Lišta DIN | 6A – 125A | Odnímatelná propojka nebo nožový spínač |

| Pojistková svorkovnice | Integrovaná nadproudová ochrana | Lišta DIN | 6A – 32A | Indikátor spálené pojistky, modulární |

| Víceúrovňová | Skládané obvody (2-3 úrovně) | Lišta DIN | 6A – 32A na úroveň | Prostorově úsporné, uspořádané signály |

| Svorkovnice | Izolované jednořadé pozice | Montáž pomocí šroubů do panelu | 15A – 100A | Zvýšené bariéry, vysokonapěťová izolace |

| Distribuce energie | Hlavní přívody vysokého proudu | Přípojnic nebo montáž do panelu | 150A – 600A | Silné vodiče, více výstupů |

Technické specifikace a kritéria výběru

Specifikace správné svorkovnice vyžaduje sladění elektrických požadavků, mechanických omezení a instalačního prostředí.

Jmenovitý proud (In): Maximální trvalý proud bez překročení limitů nárůstu teploty (typicky 50K nad okolní teplotu).

Jmenovité napětí (Ue): Maximální provozní napětí (AC nebo DC). Určuje povrchové cesty a vzdušné vzdálenosti.

Kompatibilita velikosti vodiče:

| Jmenovitý proud svorky | Plný vodič (mm²) | Splétaný vodič (mm²) | Lanko + dutinka (mm²) | Ekvivalent AWG |

|---|---|---|---|---|

| 6A – 10A | 0.2 – 2.5 | 0.2 – 2.5 | 0.25 – 2.5 | 24 – 14 |

| 17A – 24A | 0.5 – 4.0 | 0.5 – 4.0 | 0.5 – 4.0 | 20 – 12 |

| 32A – 41A | 1.0 – 6.0 | 1.0 – 6.0 | 1.5 – 6.0 | 16 – 10 |

| 57A – 76A | 2.5 – 10 | 2.5 – 10 | 4.0 – 10 | 12 – 8 |

| 101A – 125A | 10 – 35 | 10 – 35 | 16 – 35 | 8 – 2 |

| 150A+ | 25 – 95+ | 25 – 95+ | 35 – 95+ | 2 – 4/0+ |

Poznámka: Hodnoty dle IEC 60947-7-1; skutečná kapacita závisí na materiálu vodiče, okolní teplotě a konfiguraci instalace.

Rozteč svorek: Vzdálenost od středu ke středu mezi sousedními svorkami: 2.54mm (ultra-kompaktní signály), 5.0mm/5.08mm (standardní ovládání), 7.5mm (středně náročné), 10mm/12mm (pro náročné provozy), 15mm+ (vysoký výkon)

Počet sloupů: Kolik nezávislých obvodů existuje v jednom pouzdře svorkovnice

- Jednopólové (1P): Jeden obvod na blok

- Vícepólové (2P, 3P, 4P): Více obvodů sdílí společné pouzdro (běžné v rozvodu energie)

Kompatibilita s DIN lištou: Standardní 35mm × 7.5mm nebo 35mm × 15mm (EN 60715)

Faktory prostředí a instalace

| Faktor výběru | Úvahy | Doporučení |

|---|---|---|

| Vibrační prostředí | Motory, kolejová vozidla, těžké stroje | Pružinová svorka nebo zasouvací; vyhněte se šroubům, pokud není ověřeno utahovací moment |

| Teplotní rozsah | Venkovní prostředí, motorové prostory, pece | Zkontrolujte teplotní rozsah svorkovnice (typicky -40°C až +105°C) |

| Chemická expozice | Námořní prostředí, chemické závody, čistírny odpadních vod | Kontakty z nerezové oceli, speciální polymery (např. PA66-GF) |

| Časté odpojování | Zkušební zařízení, modulární stroje, dočasné instalace | Pružinová svorka nebo zasouvací (cykly zasunutí >20) |

| Vysoká hustota vodičů | Kompaktní skříně, mobilní zařízení, distribuované I/O | Zásuvné svorky, víceúrovňové bloky |

| Regulační prostředí | Severní Amerika (UL/CSA), Evropa (CE), globální projekty | Ověřte UL 1059, IEC 60947-7-1 a označení CE |

| Dostupnost údržby | Vzdálené instalace, utěsněné kryty | Šroubové svorky jsou přijatelné, pokud jsou přístupné; pružinové svorky, pokud jsou utěsněné |

Aplikační příručka: Výběr správné svorkovnice

Pro optimální výkon, bezpečnost a náklady životního cyklu zvolte typ svorkovnice odpovídající požadavkům aplikace.

Průmyslové řídicí panely

Požadavky: Smíšené signálové a silové obvody, časté úpravy, vibrace od blízkých motorů

Doporučené řešení: Pružinové svorky (6A-24A) pro signály; šroubové nebo pružinové svorky (32A-76A) pro napájení; víceúrovňové bloky pro husté I/O

Automatizace budov a HVAC

Požadavky: Dlouhá životnost, zřídkavý přístup, mírné proudy, shoda se stavebními předpisy

Doporučené řešení: Šroubové svorky (nákladově efektivní pro obvody 10A-20A); bariérové lišty pro připojení k síti; pojistkové svorky pro ochranu odboček

Výroba strojů a zařízení

Požadavky: Modulární design, rychlá montáž, globální shoda, servisovatelnost

Doporučené řešení: Zásuvné svorky pro řídicí obvody (rychlé zapojení ve výrobě); pružinové svorky pro napájení; odpojovací svorky pro testovací body; certifikace UL + IEC

Obnovitelná energie (solární, větrná)

Požadavky: Venkovní expozice, UV odolnost, vysoké napětí (až 1500 V DC), teplotní cyklování

Doporučené řešení: Svorkovnice s PV certifikací (IEC 60947-7-4); velké povrchové cesty; pružinové svorky pro odolnost proti vibracím

Železnice a doprava

Požadavky: Extrémní vibrace, otřesy, teplotní rozsah (-40 °C až +85 °C), požární bezpečnost (EN 45545)

Doporučené řešení: Pružinové nebo zásuvné svorky; bezhalogenové materiály zpomalující hoření; nerezové kontakty; vysoká životnost z hlediska počtu zasunutí

Námořní a pobřežní průmysl

Požadavky: Odolnost proti korozi, vysoká vlhkost, solná mlha, častá údržba

Doporučené řešení: Nerezové kontakty; speciální polyamidové nebo polykarbonátové pouzdra; zásuvné nebo pružinové svorky; krytí IP67

Instalace a údržba

Příprava drátů

- Délka pásu: Dodržujte specifikace výrobce (obvykle 8-12 mm pro šroubové, 10-11 mm pro pružinové)

- Kabelové koncovky: Povinné pro lankové vodiče v pružinových a zásuvných svorkách; zlepšuje kontakt a zabraňuje lámání lanek

- Zákrut vodiče: Nikdy nezkrucujte lankový vodič bez kabelových koncovek – jednotlivá lanka se mohou zlomit a vytvořit odpor

Šroubové svorky vyžadují kalibrované momentové šroubováky. Nedostatečné utažení způsobuje zahřívání; přílišné utažení poškozuje vodiče.

| Jmenovitý proud svorky | Typický rozsah točivého momentu |

|---|---|

| 6A – 10A | 0.5 – 0.6 N·m |

| 17A – 24A | 0.8 – 1.2 N·m |

| 32A – 41A | 1.2 – 1.8 N·m |

| 57A – 76A | 2.0 – 2.5 N·m |

| 101A+ | 3.0 – 6.0 N·m |

Označování a údržba

- Používejte tištěné štítky identifikující funkci obvodu; udržujte schémata zapojení

- Barevně odlište obvody (modrá pro nulový vodič, zelená/žlutá pro zem podle IEC 60446)

- Šroubové svorky: Ročně dotahujte v prostředích s vibracemi

- Pružinové/zásuvné: Pouze vizuální kontrola; není nutné dotahování

- Všechny typy: Termovizní kontrola během uvádění do provozu

Často Kladené Otázky

Otázka: Jaký je rozdíl mezi svorkovnicí a svorkovou lištou?

Odpověď: “Svorková lišta” a “bariérová lišta” obvykle označují jednořadé svorkovnice montované přímo na panely pomocí šroubů, nikoli na DIN lištu. Slouží ke stejné funkci, ale používají různé způsoby montáže.

Otázka: Mohu na stejné DIN liště kombinovat šroubové a pružinové svorkovnice?

Odpověď: Ano. Montáž na DIN lištu umožňuje kombinovat různé typy a značky, pokud každý splňuje požadované specifikace pro svůj obvod.

Otázka: Jsou kabelové koncovky povinné pro lankové vodiče?

Odpověď: Povinné pro pružinové a zásuvné svorky. Doporučeno, ale ne vždy vyžadováno pro šroubové svorky, v závislosti na specifikaci výrobce.

Otázka: Proč mají svorkovnice různé možnosti rozteče (rozestupu)?

Odpověď: Rozteč určuje proudovou zatížitelnost a přístup k vodičům. Úzká rozteč (5 mm) šetří místo pro signály s nízkým proudem; široká rozteč (10 mm+) pojme větší vodiče a vyšší proudy.

Otázka: Jak mám zvolit jmenovitý proud, když je velikost vodiče mezi dvěma standardními hodnotami?

Odpověď: Vždy vyberte svorkovnici dimenzovanou pro nejbližší vyšší velikost vodiče. Nikdy nepřekračujte jmenovitý proud, i když se vodič fyzicky vejde.

Otázka: Co znamená “bezpečné na dotyk prstem” nebo krytí IP20 pro svorkovnice?

Odpověď: IP20 (IEC 60529) poskytuje ochranu proti náhodnému dotyku živých částí prsty nebo předměty o průměru >12,5 mm. Mnoho svorkovnic obsahuje odnímatelné kryty nebo zapuštěné kontakty, aby splňovaly tento požadavek.

Závěr

Svorkovnice transformují zapojení panelu z ad-hoc bod-bod spojů na organizované, testovatelné a udržovatelné elektrické systémy. Výběr správného typu – ať už šroubové, pružinové nebo zásuvné upínání; průchozí, odpojovací nebo pojistková funkce; standardní nebo víceúrovňová konfigurace – závisí na elektrických parametrech, instalačním prostředí, přístupu k údržbě a požadavcích na životní cyklus.

VIOX Electric vyrábí komplexní řadu svorkovnic na DIN lištu, které splňují normy IEC 60947-7-1 a UL 1059. Náš sortiment zahrnuje šroubové, pružinové a zásuvné svorkovnice s jmenovitými proudy od 6A do 400A, které slouží pro průmyslovou automatizaci, distribuci energie, stavební systémy a specializované aplikace.

Ať už specifikujete komponenty řídicího panelu, pořizujete náhradní hardware nebo navrhujete nové zařízení, náš technický tým poskytuje aplikační poradenství a zakázková řešení pro vaše požadavky na svorkovnice.

Kontakt VIOX Electric ještě dnes a prodiskutujte specifikace vašeho projektu a získejte odborná doporučení pro spolehlivá řešení svorkovnic, která splňují normy.