If you’ve ever looked at electrical control panel specifications and wondered whether “cam switch” and “rotary switch” mean different things, you’re not alone. Manufacturers use these terms inconsistently. Some catalogs list “rotary cam switches,” others show “cam-operated switches,” and still others simply say “rotary switches.”

Rotary switch describes how the device is operated (manual rotation). Cam switch describes the internal mechanism (cam-driven contact sequencing). Most industrial devices marketed as “cam switches” are also rotary switches—they use a rotating handle that turns a cam mechanism inside. Understanding this difference helps you select the right device for motor control, power distribution, and changeover applications.

What Is a Rotary Switch?

A rotary switch is any manually operated switch with a rotating handle or knob. Turn the handle, and the switch changes position—opening or closing electrical contacts. The term “rotary” refers strictly to the actuation method: the operator rotates a shaft rather than flipping a toggle, pressing a button, or sliding a lever.

Rotary switches come in many forms:

- Wafer rotary switches: Low-current devices used in electronics and instrumentation, found in audio equipment, multimeters, and test instruments.

- Cam-operated rotary switches: Industrial switches that use a cam mechanism to sequence multiple contacts. These are the devices most commonly called “cam switches” in control panel applications.

- Rotary selector switches: Multi-position switches used for mode selection, instrument measurement, or circuit changeover.

- Rotary disconnectors: Switches designed specifically for load isolation and safety disconnection, often with visible contact separation.

The key point: “rotary switch” is a broad category defined by how you operate it. If it rotates, it’s a rotary switch—but that tells you nothing about current capacity or whether it meets industrial standards.

What Is a Cam Switch?

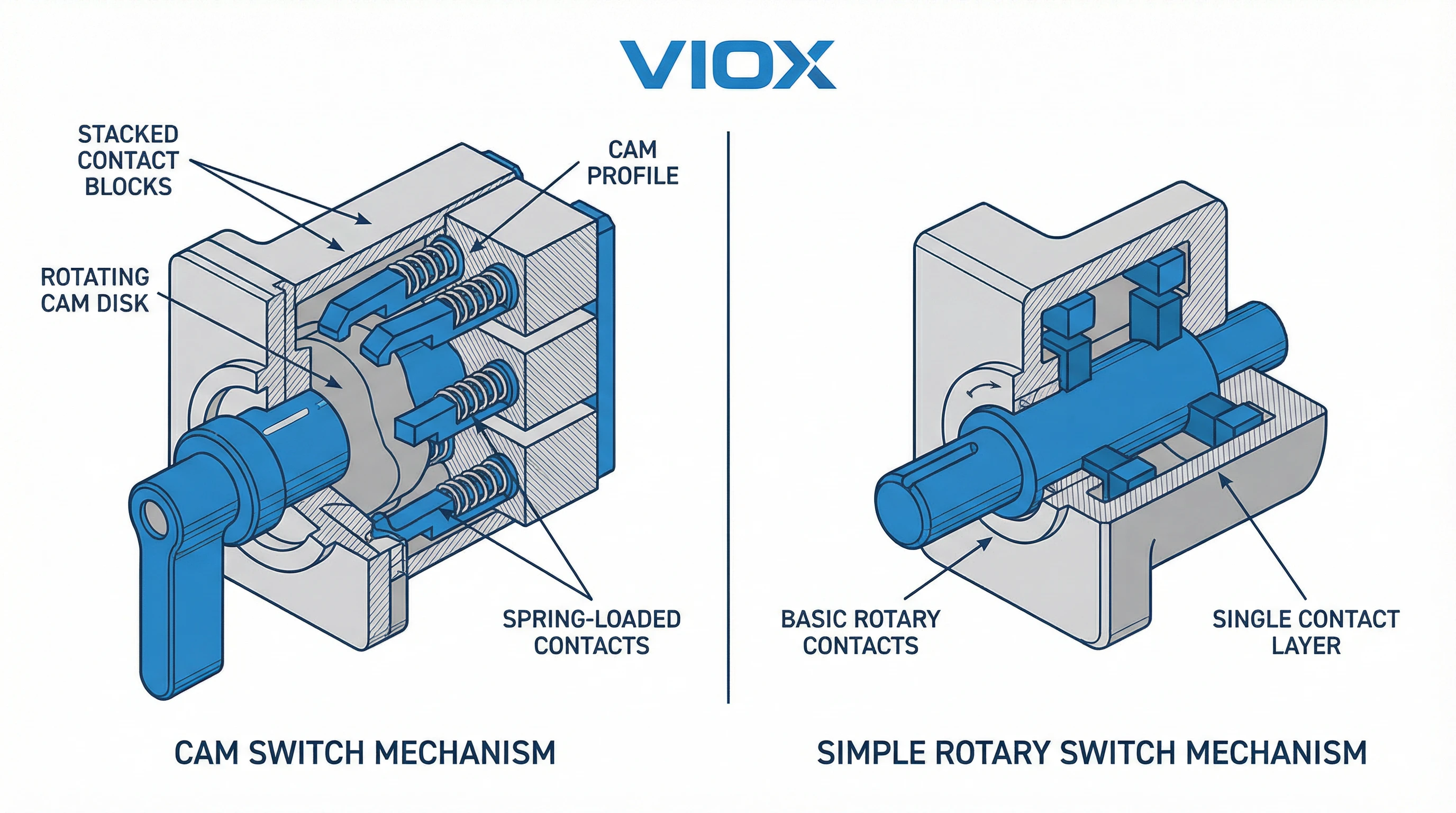

A cam switch (also called a cam-operated switch or rotary cam switch) is a type of rotary switch that uses an internal cam mechanism to control contact sequencing. The cam is a profiled disk (or set of disks) mounted on the rotating shaft. As the handle turns, the cam’s contoured edge pushes against spring-loaded actuators, forcing electrical contacts to open or close in a specific, predetermined sequence.

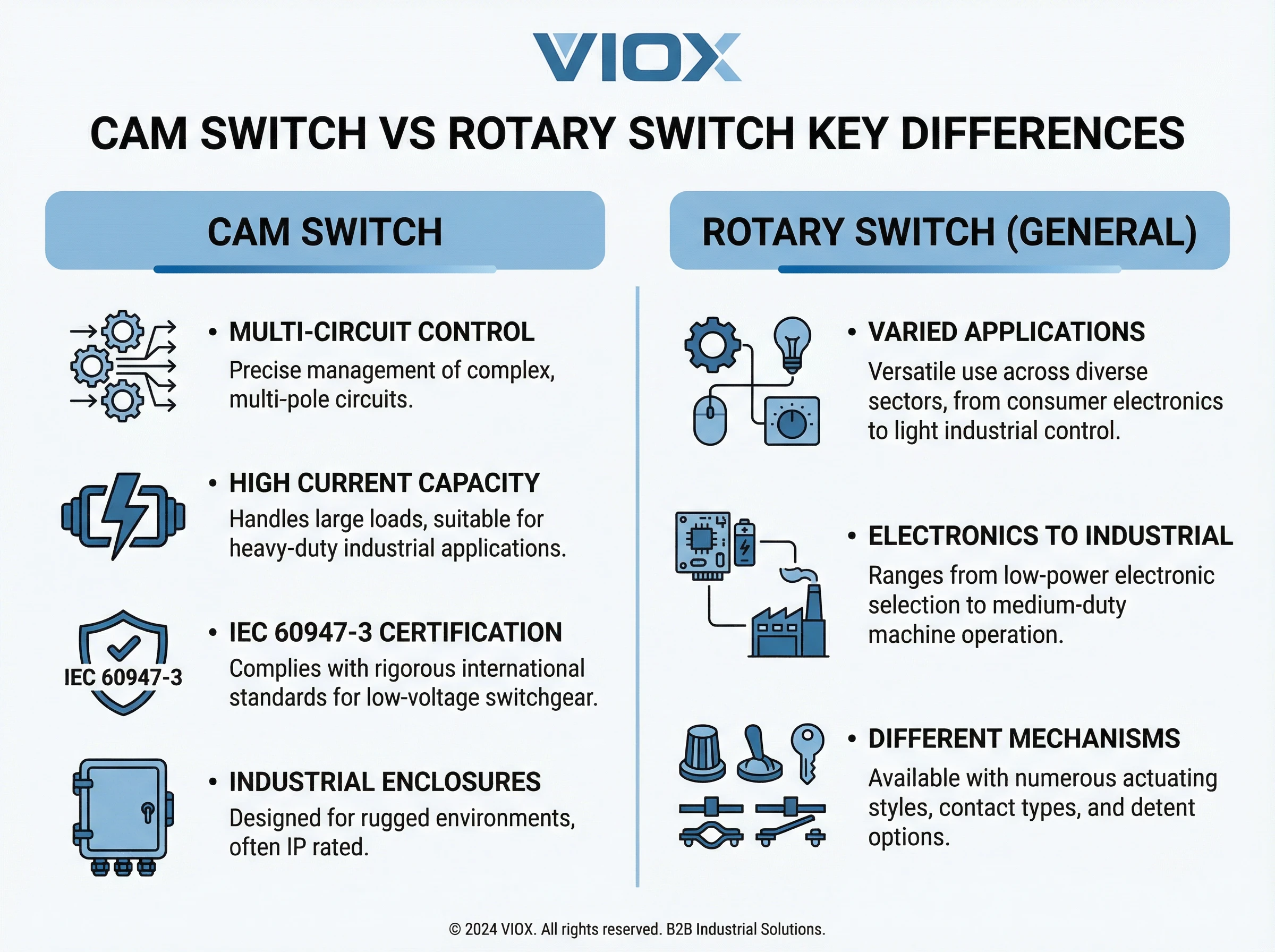

This cam-driven contact mechanism is what makes cam switches ideal for industrial control. A single cam switch can simultaneously control multiple independent circuits (poles)—a 4-pole cam switch manages four separate electrical paths. The cam profile determines which contacts close and when; the switching program is mechanically fixed into the cam shape. No programmable logic, no firmware, no software bugs. The switching sequence is locked in and can’t be accidentally changed.

Cam switches meet IEC 60947-3, the international standard for low-voltage switches and switch-disconnectors, with ratings for specific utilization categories (AC-21, AC-23, etc.) that define their load-breaking capability.

Cam switches are used extensively in motor control (forward/reverse), power source changeover (mains/generator), multi-speed control, and instrumentation selector applications. The term “cam switch” signals that the device is purpose-built for industrial control duties, with robust construction, defined current ratings, and compliance with electrical standards.

Key Differences: Cam Switch vs Rotary Switch

Here’s the practical comparison that matters when you’re selecting a device.

| Aspect | Rotary Switch (General) | Cam Switch (Cam-Operated Rotary Switch) |

|---|---|---|

| Definition | Any switch operated by rotating a handle or knob | A rotary switch that uses an internal cam mechanism to sequence contacts |

| Internal Mechanism | Varies: wafer contacts, cam mechanisms, or simple rotary contacts | Specifically uses cam disks to actuate spring-loaded contacts |

| Typical Current Capacity | Low to high: from milliamps (electronics) to hundreds of amps (industrial) | Industrial-rated: typically 10A to 315A or more |

| Voltage Rating | Varies widely: 5V to 690V or higher | Industrial LV: typically up to 690V AC or 1500V DC |

| Standards Compliance | May or may not conform to industrial standards | Typically designed to IEC 60947-3 (switches, switch-disconnectors) with defined duty categories |

| Multi-Position Capability | Yes, but varies by type | Yes—commonly 2 to 12 positions with detents |

| Pole Configuration | Varies: 1 to 12 poles depending on type | Industrial cam switches: typically 1 to 12 poles, customizable |

| Applications | Broad: electronics, instrumentation, lighting, industrial control | Industrial control: motor forward/reverse, power changeover, mode selection, measurement switching |

| Enclosure & IP Rating | Varies: open frame (electronics) to IP65 (industrial) | Industrial enclosures: IP40 to IP69K depending on environment |

| Load Breaking Duty | Not necessarily rated for load breaking under industrial conditions | Rated for specific utilization categories (AC-21, AC-23, etc.) per IEC 60947-3 |

| Typical Manufacturers | Broad range: electronics (C&K, Grayhill) to industrial (ABB, Schneider, Eaton, VIOX) | Industrial manufacturers: ABB, Schneider Electric, Eaton, Siemens, LOVATO, VIOX |

| Price Range | Wide: $1 for electronics wafer switches to $500+ for heavy-duty industrial units | Industrial focus: $20 to $500+ depending on current rating and customization |

Understanding the Overlap

The confusion arises because most industrial cam switches are also rotary switches, and manufacturers often use the terms together: “rotary cam switch.” When you see that phrase in a catalog, it means:

- Rotary = how you operate it (turn the handle)

- Cam = how it works inside (cam mechanism sequences the contacts)

In practice, if you’re specifying a switch for industrial motor control, power distribution, or changeover duty, you’re almost certainly looking at a cam switch, even if the catalog also calls it a “rotary switch” or “rotary selector switch.” The key is to verify that it meets IEC 60947-3 and is rated for your load type and current.

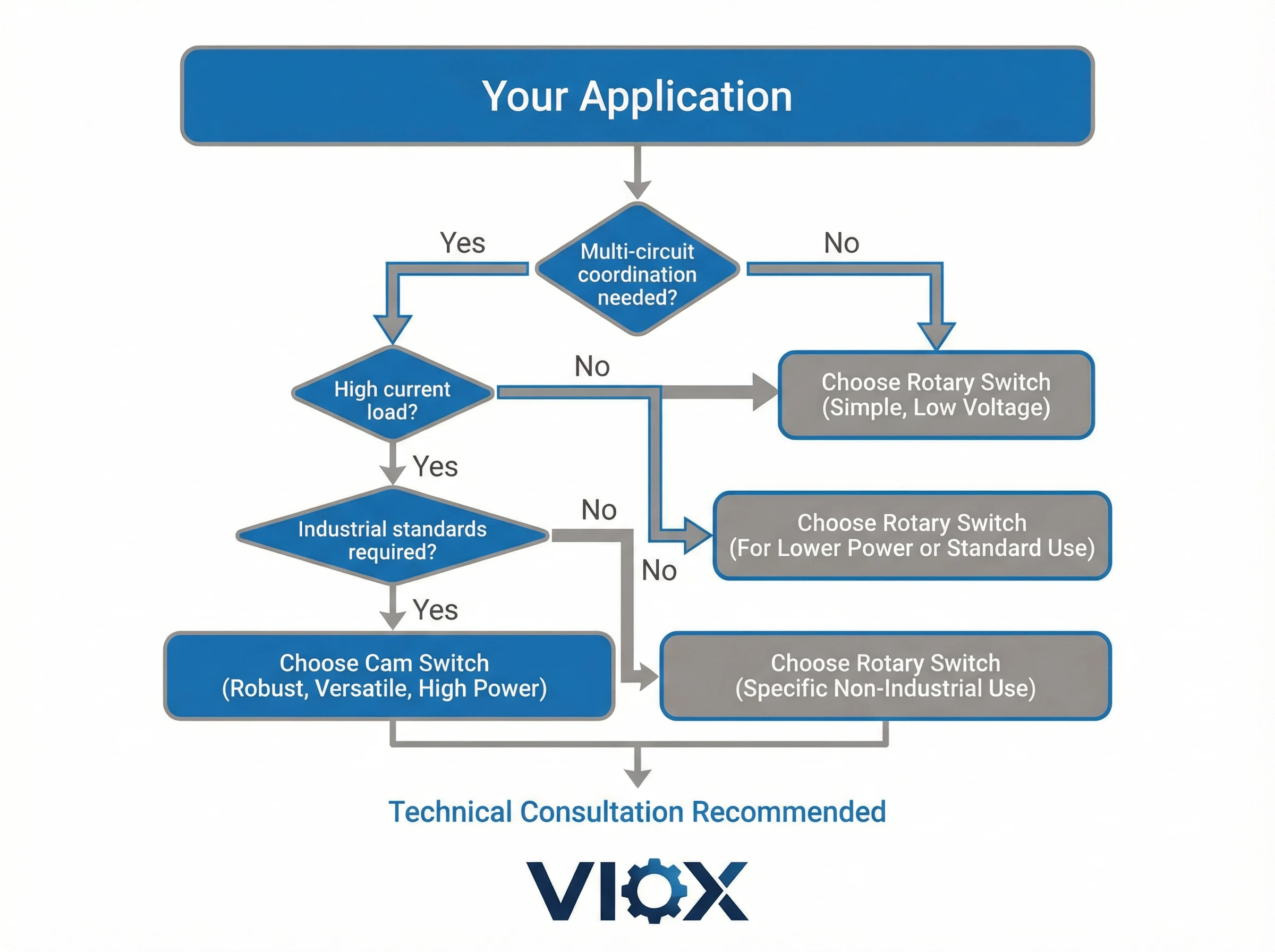

When to Use a Cam Switch

Choose a cam switch when your application requires:

Multi-Circuit Coordination: Cam switches excel when you need to control multiple independent circuits simultaneously. A three-phase motor reversing application requires swapping two phases—a single 3-pole cam switch configured as FORWARD-OFF-REVERSE does this in one motion. Applications include motor forward/reverse control (conveyors, hoists, cranes), star-delta motor starting, power source changeover (mains to generator), and voltmeter/ammeter selector switches.

Manual, Tactile Control: Direct, mechanical control with detent feedback. The operator feels each position and visually confirms the circuit state. Ideal for emergency manual override, maintenance isolation switches (LOTO—lockout/tagout), local control stations, and backup manual control when automation fails.

High Current, Industrial-Rated Load Breaking: Cam switches designed to IEC 60947-3 are tested for breaking loads under industrial conditions, including motor starting (high inrush) and inductive loads. Typical ratings: 10A to 315A (VIOX LW26 series), up to 690V AC, duty categories AC-21 (resistive loads) and AC-23 (motor loads).

Robust, Long-Life Reliability: Built for industrial environments with mechanical life ratings of 50,000 to over 1 million operations. Silver alloy contacts resist oxidation and arc damage. Enclosures rated IP40 to IP69K protect against dust, moisture, and washdown environments. Applications include heavy-duty manufacturing, outdoor installations, and marine/offshore environments.

When to Use a General Rotary Switch

Low-Current Signal Switching: Electronics and instrumentation applications use wafer rotary switches—compact, low-cost devices designed for milliamp-level signals. These are not cam switches and are not rated for industrial load breaking. Applications include multimeter function selection, audio equipment routing, and low-voltage control circuits (5V, 12V, 24V).

Compact Panel Space: Some compact rotary selector switches (like VIOX LW40 series) use cam mechanisms but are optimized for space-saving layouts where panel depth and cutout size are constrained.

Simple ON/OFF Switching: For basic two-position ON/OFF without multi-circuit coordination, a simple rotary disconnect may be more cost-effective. However, for ratings above 63A, cam-type rotary disconnectors are often standard.

Technical Specifications: What to Check

When comparing cam switches or rotary switches, verify:

- Current Rating (Ie): Match to your load’s full-load current. For motor applications, choose 1.5× motor FLA to handle starting inrush.

- Voltage Rating (Ue): Ensure it meets or exceeds your system voltage (e.g., 400V, 480V, 690V).

- Utilization Category: AC-21 for resistive loads; AC-23 for motor loads. DC categories (DC-21, DC-23) for DC motors.

- Pole and Position Configuration: Count how many circuits (poles) and positions (handle stops) you need. 3P3T is common for motor FORWARD-OFF-REVERSE.

- Standards Compliance: Look for IEC 60947-3, UL 508, or CE marking.

- IP Rating: IP20 for indoor clean panels; IP65 or IP69K for outdoor/washdown.

- Mechanical and Electrical Life: Industrial cam switches typically offer 50,000 to 100,000+ mechanical operations.

VIOX Rotary Cam Switches: LW26, LW30, LW40 Series

VIOX manufactures a comprehensive range of rotary cam switches designed specifically for industrial control applications. Our product line addresses the full spectrum of current ratings, pole configurations, and environmental requirements:

LW26 Series: 10A to 315A, 1-12 poles, 2-12 positions. The flagship series for motor control, power changeover, and multi-circuit switching. IEC 60947-3 certified, IP65 enclosures available, padlockable handles for safety lockout.

LW30 Series: 20A to 175A isolation switches with visible contact separation. Designed for load isolation and maintenance safety (LOTO applications). Double-break contacts, IP65 standard, extended handle with up to 3 padlock provisions.

LW40 Series: 20A to 100A compact rotary switches for space-constrained panels. Ideal for OEM equipment and control panels where panel depth is limited. IP40 standard, IP54 enclosures available.

All VIOX rotary cam switches carry multiple certifications: CE, UL, TUV, CCC, RoHS2.0, and full IEC 60947-3 compliance. Custom cam profiles and contact configurations are available for specialized switching sequences.

Common Questions

Q: Is a cam switch always a rotary switch?

A: In industrial control, yes—cam switches use a rotary handle. “Cam switch” and “rotary cam switch” are effectively synonyms.

Q: Can I use a rotary switch for motor control?

A: Only if it’s rated for motor duty. Check for IEC 60947-3 certification with AC-23 utilization category.

Q: What’s the difference between a cam switch and a contactor?

A: Cam switches are manually operated; contactors are remotely controlled (electromagnetic coil). Use cam switches for direct operator control, contactors for automation.

Q: How do I know if I need a cam mechanism?

A: If your application requires coordinated multi-circuit switching (motor reversing, star-delta starting, power changeover), a cam mechanism is the industry-standard solution.

Conclusion

Rotary switch tells you how the device is operated—by rotating a handle. Cam switch tells you how it works inside—with a cam mechanism that sequences multiple contacts. In industrial control applications, devices for motor control, power changeover, and multi-circuit switching are almost always cam-operated rotary switches.

When selecting, focus on current rating, voltage rating, utilization category, pole configuration, standards compliance (IEC 60947-3), and environmental protection (IP rating). For custom switching sequences, padlockable safety isolation, or high-current capacity, a cam switch delivers proven reliability.

Need help selecting the right cam switch or rotary switch? Contact VIOX technical support for specification assistance, or explore our LW26, LW30, and LW40 series rotary cam switches. We provide custom cam profiles, fast delivery, and full engineering support for control panel builders, OEMs, and system integrators worldwide.