Her yıl, endüstriyel tesisler plansız duruşlar nedeniyle küresel olarak tahmini 1 trilyon dolar kaybediyor ve hatalı zaman rölesi seçimi kontrol devresi arızalarının -18'ini oluşturuyor. Gecikmeli başlatma ve gecikmeli durdurma zamanlayıcıları arasında seçim yapmak sadece teknik bir karar değil; ekipman ömrü, enerji verimliliği ve operasyonel güvenlik açısından kritik bir faktördür.

Önemli Çıkarımlar

- Gecikmeli başlatma zamanlayıcıları (TON) giriş sinyalinden sonra çıkış aktivasyonunu geciktirerek yanlış başlatmaları ve ekipman aşırı gerilim hasarını önler

- Gecikmeli durdurma zamanlayıcıları (TOF) giriş kaldırıldıktan sonra çıkışı koruyarak uygun soğutma döngüleri ve kontrollü kapanmalar sağlar

- Zaman aralıkları, endüstriyel sınıf modellerde 0,1 saniyeden 999 saate kadar uzanır

- Voltaj uyumluluğu, IEC 61812-1 standartlarına göre 12VDC, 24VDC, 120VAC ve 240VAC konfigürasyonlarını içerir

- Kontak değerleri, genel endüstriyel uygulamalar için tipik olarak 250VAC'de 5A ila 16A arasında değişir

- PLC programlaması, önceden ayarlanmış süre (PT) ve geçen süre (ET) parametreleriyle TON ve TOF fonksiyon bloklarını kullanır

Gecikmeli Başlatma ve Gecikmeli Durdurma Zamanlayıcıları Nelerdir?

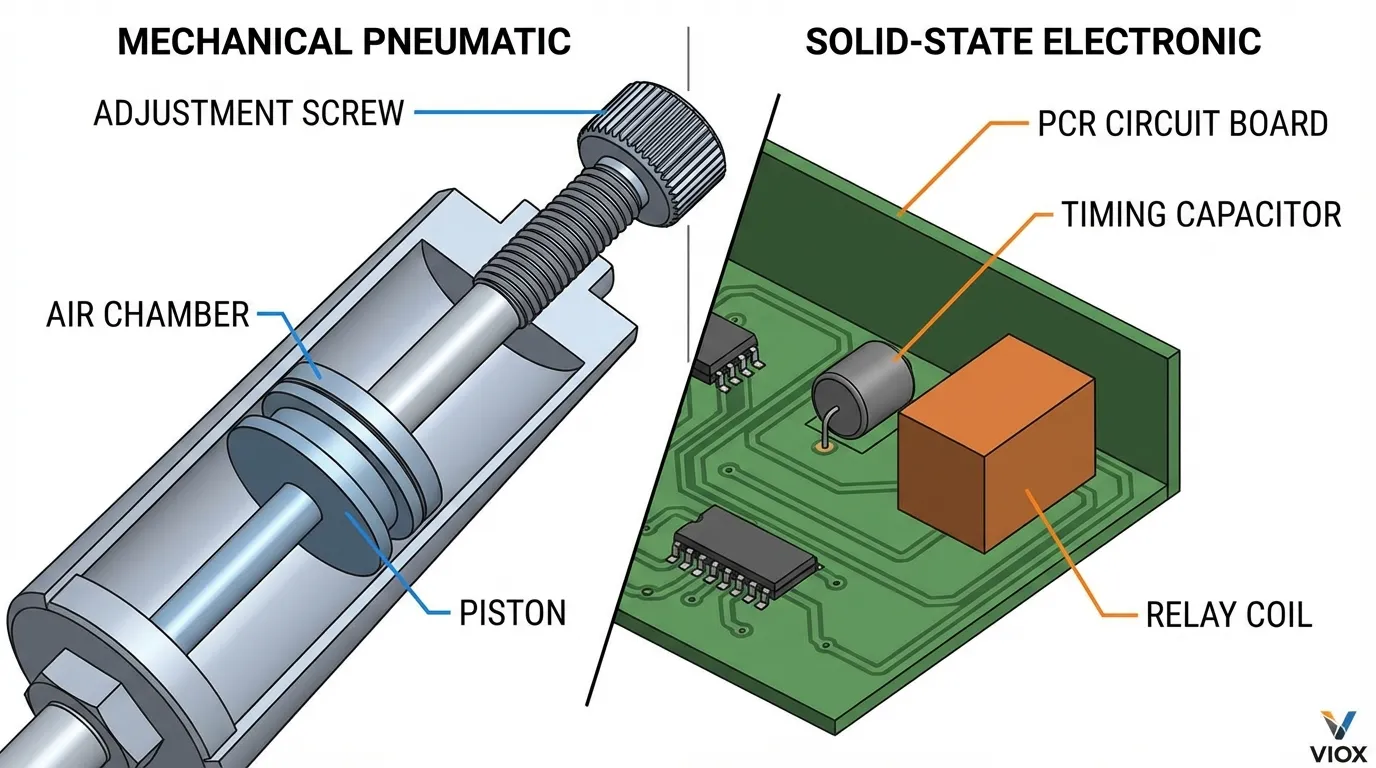

Zaman gecikmeli röleler, elektrik devrelerinde kontak çalışmasının zamanlamasını kontrol eden elektromekanik veya katı hal cihazlarıdır. Anında geçiş yapan standart rölelerin aksine, zaman gecikmesi röleleri giriş sinyalleri ve çıkış eylemleri arasında hassas, programlanabilir gecikmeler sağlar.

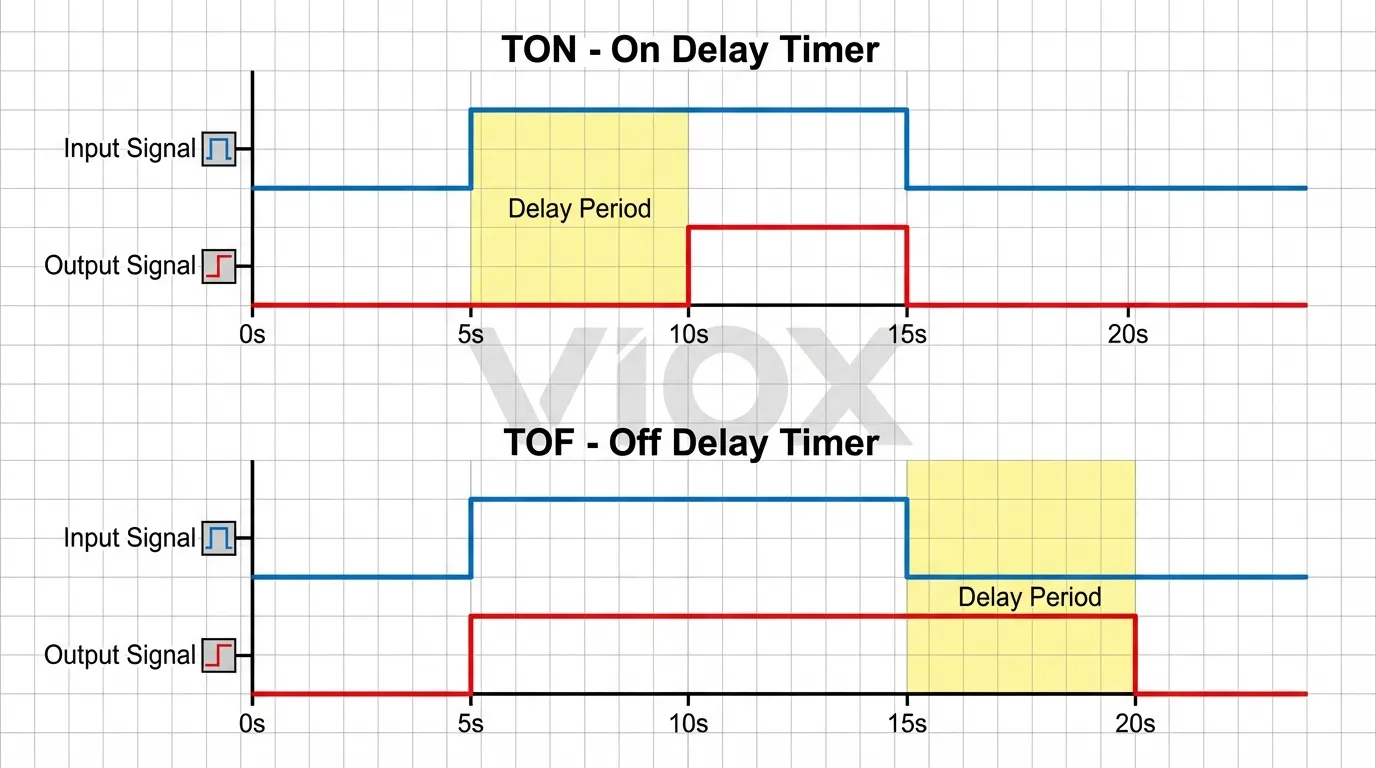

Gecikmeli Başlatma Zamanlayıcısı (TON) – “Gecikmeli bağlama” veya “gecikmeli çalıştırma” olarak da adlandırılan bu zamanlayıcı türü, bir giriş sinyali aldıktan sonra çıkış kontaklarının etkinleştirilmesini geciktirir. Çıkış, önceden ayarlanmış gecikme süresi boyunca KAPALI kalır ve yalnızca zamanlayıcı geri sayımını tamamladıktan sonra enerjilenir.

Gecikmeli Durdurma Zamanlayıcısı (TOF) – “Gecikmeli bırakma” olarak da bilinen bu yapılandırma, giriş enerjilendiğinde çıkışını hemen etkinleştirir, ancak giriş sinyali kaldırıldıktan sonra bu çıkışı belirli bir süre korur.

Her iki zamanlayıcı türü de endüstriyel zamanlama röleleri için IEC 61812-1 standartlarına ve Kuzey Amerika pazarları için UL 508 sertifikasına uygundur.

Gecikmeli Başlatma Zamanlayıcıları Nasıl Çalışır (TON)

Bir gecikmeli başlatma zamanlayıcısının çalışma sırası dört farklı aşamayı izler:

Aşama 1: Bekleme Durumu

- Giriş kontakları açık, zamanlayıcı bobini enerjisiz

- Çıkış kontakları normal durumda kalır (NA kontakları açık, NK kontakları kapalı)

- Geçen süre (ET) = 0

Aşama 2: Giriş Aktivasyonu

- Zamanlayıcı bobinine kontrol sinyali uygulanır (A1-A2 terminalleri)

- Dahili zamanlama mekanizması geri sayımı başlatır

- Çıkış kontakları ilk durumunu korur

- ET, önceden ayarlanmış süreye (PT) doğru artmaya başlar

Aşama 3: Zamanlama Süresi

- Zamanlayıcı 0'dan PT'ye kadar sayar (örneğin, 0'dan 10 saniyeye)

- PT'ye ulaşılmadan önce giriş sinyali kaldırılırsa, zamanlayıcı ET = 0'a sıfırlanır

- Çıkış, gecikme boyunca etkin kalır

Aşama 4: Çıkış Aktivasyonu

- ET = PT olduğunda, çıkış kontakları durum değiştirir

- NA kontakları kapanır, NK kontakları açılır

- Giriş sinyali korunduğu sürece çıkış enerjilenmiş kalır

- Giriş kaldırıldığında, çıkış hemen enerjisizleşir ve zamanlayıcı sıfırlanır

Bu zamanlama davranışı, TON zamanlayıcılarını, ekipmanı çalıştırmaya başlamadan önce sürekli talebin doğrulanmasını gerektiren uygulamalar için vazgeçilmez kılar. Hakkında daha fazla bilgi edinin motor yol verici uygulamaları için bir zaman rölesi nasıl bağlanır.

Gecikmeli Durdurma Zamanlayıcıları Nasıl Çalışır (TOF)

Gecikmeli durdurma zamanlayıcıları, gecikmeli başlatma türlerine kıyasla ters bir mantıkla çalışır:

Aşama 1: Bekleme Durumu

- Giriş kontakları açık, zamanlayıcı bobini enerjisiz

- Çıkış kontakları normal durumda

- ET = 0, zamanlayıcı tetikleyiciyi kabul etmeye hazır

Aşama 2: Anında Çıkış Aktivasyonu

- A1-A2 terminallerine kontrol sinyali uygulanır

- Çıkış kontakları anında durum değiştirir (NA kontakları kapanır)

- Bağlı yük gecikme olmadan enerjilenir

- Zamanlayıcı henüz zamanlama yapmadan beklemede kalır

Aşama 3: Giriş Sinyali Kaldırma

- Kontrol anahtarı açılır veya giriş sinyali kaldırılır

- Çıkış kontakları etkin durumda kalır

- Zamanlayıcı 0'dan PT'ye kadar geri saymaya başlar

- Çıkış enerjilenmiş kalırken ET artar

Aşama 4: Gecikmeli Devre Dışı Bırakma

- ET PT'ye ulaştığında (örneğin, 15 saniye), çıkış kontakları normal duruma döner

- NA kontakları açılır, NK kontakları kapanır

- Bağlı yük enerjisizleşir

- Zamanlama sırasında giriş yeniden uygulanırsa, çoğu TOF rölesi sıfırlanır ve sırayı yeniden başlatır

Bu davranış, ekipmanın başlatma sinyali kesildikten sonra kontrollü bir süre boyunca çalışmaya devam etmesini sağlar; bu, soğutma döngüleri, malzeme işleme ve güvenlik aydınlatması uygulamaları için kritik öneme sahiptir.

Kritik Farklılıklar: Yan Yana Karşılaştırma

| Özellik | Gecikmeli Başlatma Zamanlayıcısı (TON) | Gecikmeli Durdurma Zamanlayıcısı (TOF) |

|---|---|---|

| Zamanlama Tetikleyicisi | Giriş sinyali uygulaması | Giriş sinyali kaldırılması |

| Girişte Çıkış Davranışı | Gecikmeli aktivasyon (PT bekler) | Anında aktivasyon |

| Giriş Kaldırmada Çıkış Davranışı | Anında deaktivasyon | Gecikmeli deaktivasyon (PT bekler) |

| Birincil İşlev | Yanlış başlatmaları önler | Kontrollü kapanmayı sağlar |

| Tipik Zaman Aralığı | 0.1s – 999sa | 0.1s – 999sa |

| Sıfırlama Koşulu | Zamanlama sırasında girişin kaldırılması | Girişin yeniden uygulanması (modele bağlı) |

| IEC Sembolü | Kesikli çizgi girişten çıkışa | Düz çizgi girişten çıkışa |

| PLC Fonksiyon Bloğu | TON | TOF |

| Yaygın Uygulamalar | Motor yumuşak başlatma, HVAC sıralaması | Soğutma fanı gecikmesi, acil durum aydınlatması |

| Önler | Ani akım, yanlış tetiklemeler | Ani kapanmalar, termal şok |

| Güç Kaybı Davranışı | 0'a sıfırlanır | Çoğu model sıfırlanır (veri sayfasına bakın) |

| İletişim Yapılandırması | SPDT, DPDT mevcut | SPDT, DPDT mevcut |

Teknik Özellikler Karşılaştırması

| Parametre | Standart Aralık | Endüstriyel Sınıf | Uyum Standartları |

|---|---|---|---|

| Kontrol Voltajı (AC) | 24VAC, 120VAC, 240VAC | 90-265VAC evrensel | IEC 61812-1, UL 508 |

| Kontrol Voltajı (DC) | 12VDC, 24VDC, 48VDC | 12-48VDC aralığı | IEC 61812-1 |

| Zaman Ayar Aralığı | 0.1s – 30dk | 0.05s – 999sa | IEC 60255 |

| Zamanlama Doğruluğu | ±5% at 25°C | ±2% at 25°C | IEC 61812-1 |

| Kontak Değeri (Dirençli) | 5A @ 250VAC | 10A @ 250VAC | UL 508, IEC 60947-5-1 |

| Kontak Değeri (Endüktif) | 3A @ 250VAC (cosφ 0.4) | 5A @ 250VAC | IEC 60947-5-1 |

| Mekanik Ömür | 10 milyon işlem | 30 milyon işlem | IEC 61810-1 |

| Elektriksel Yaşam | Nominal yükte 100.000 işlem | 300.000 işlem | IEC 61810-1 |

| Çalışma Sıcaklığı | -10°C ila +55°C | -25°C ila +70°C | IEC 60068-2 |

| Montaj Tipi | DIN rayı (35mm), panel montajı | DIN rayı, soket, PCB | IEC 60715 |

| Koruma Derecesi | IP20 (standart) | IP40, IP54 (endüstriyel) | IEC 60529 |

| Dielektrik Dayanım | 2000VAC (1 dakika) | 4000VAC (1 dakika) | IEC 61812-1 |

Sektöre Göre Gerçek Dünya Uygulamaları

Üretim ve Endüstriyel Otomasyon

Konveyör Bant Sıralaması (TON Uygulaması)

- Sorun: Eş zamanlı motor çalıştırması voltaj düşüşüne ve devre kesici açmalarına neden olur

- Çözüm: Gecikmeli zaman röleleri, motor aktivasyonunu 3-5 saniyelik aralıklarla kademelendirir

- Ayarlar: PT = Motor başına 3-5s, 24VDC kontrol voltajı

- Sonuç: Yol verme akımını -75 oranında azaltır, gereksiz açmaları önler

Takım Tezgahı Soğutması (TOF Uygulaması)

- Sorun: İş mili motorları, termal çarpılmayı önlemek için kapatıldıktan sonra soğutucu sirkülasyonu gerektirir

- Çözüm: Kapatma gecikmeli zaman rölesi, işleme sonrası soğutma pompası çalışmasını sürdürür

- Ayarlar: PT = 120-180s, 120VAC kontrol

- Sonuç: İş mili yatak ömrünü oranında uzatır, termal bozulmayı azaltır

HVAC Sistemleri

Kompresör Kısa Çevrim Koruması (TON)

- Kompresörün kapatıldıktan sonra 3-5 dakika içinde yeniden başlatılmasını önler

- Sıvı soğutucu akışkan vuruntusuna ve yatak hasarına karşı korur

- Tipik ayar: PT = 180-300s

- ASHRAE 15 güvenlik standartlarına uygundur

Egzoz Fanı Temizleme Döngüsü (TOF)

- Ekipman kapatıldıktan sonra havalandırma fanı çalışmasını sürdürür

- Muhafazalardan tam duman/ısı tahliyesi sağlar

- Tipik ayar: PT = 60-120s

- NFPA 70 (NEC) Madde 430.44 gereksinimlerini karşılar

Motor Kontrol Uygulamaları

Yıldız-Üçgen Yol Verme Geçişi (TON)

- Motor çalıştırma sırasında yıldızdan üçgen yapılandırmaya geçişi geciktirir

- Yol verme akımını doğrudan çalıştırmaya göre oranında azaltır

- Tipik ayar: Motor ataletine bağlı olarak PT = 5-15s

- Referans: Yıldız Üçgen Yol Verici Bağlantı Şeması

Soğutma Fanı Son Çalıştırma (TOF)

- Termal yönetim için motor kapatıldıktan sonra fan çalışmasını sürdürür

- Kalan ısıdan kaynaklanan yatak hasarını önler

- Tipik ayar: PT = 30-90s

- Kapalı ortamlarda >10HP motorlar için kritik öneme sahiptir

Güvenlik ve Acil Durum Sistemleri

Acil Durum Aydınlatması (TOF)

- Güç kesintisinden sonra çıkış aydınlatmasını aktif tutar

- Yedek jeneratörün çalıştırılması veya güvenli tahliye için zaman sağlar

- Tipik ayar: PT = 30-60s

- NFPA 101 Yaşam Güvenliği Yasası'na uygundur

Yangın Söndürme Gecikmesi (TON)

- Söndürme sistemlerini etkinleştirmeden önce doğrulama süresi sağlar

- Geçici duman dedektörü sinyallerinden kaynaklanan yanlış deşarjı önler

- Tipik ayar: PT = 10-30s

- NFPA 72 yangın alarmı kodu gereksinimlerini karşılar

| Endüstri/Uygulama | Zamanlayıcı Tipi | Tipik PT Aralığı | Temel Fayda |

|---|---|---|---|

| Motor yumuşak yol verme | TON | 3-10s | Yol verme akımını azaltır |

| Soğutma fanı gecikmesi | TOF | 30-180s | Termal şoku önler |

| HVAC sıralaması | TON | 30-300s | Ekipman başlatmayı kademelendirir |

| Acil durum aydınlatması | TOF | 30-90s | Aydınlatmayı sürdürür |

| Pompa dönüşümü | TON | 1-60s | Aşınmayı eşitler |

| Konveyör sıralaması | TON | 2-5s | Aşırı yüklenmeyi önler |

| Kompresör koruması | TON | 180-300s | Kısa çevrim önleme |

| Havalandırma temizleme | TOF | 60-300s | Hava değişimini sağlar |

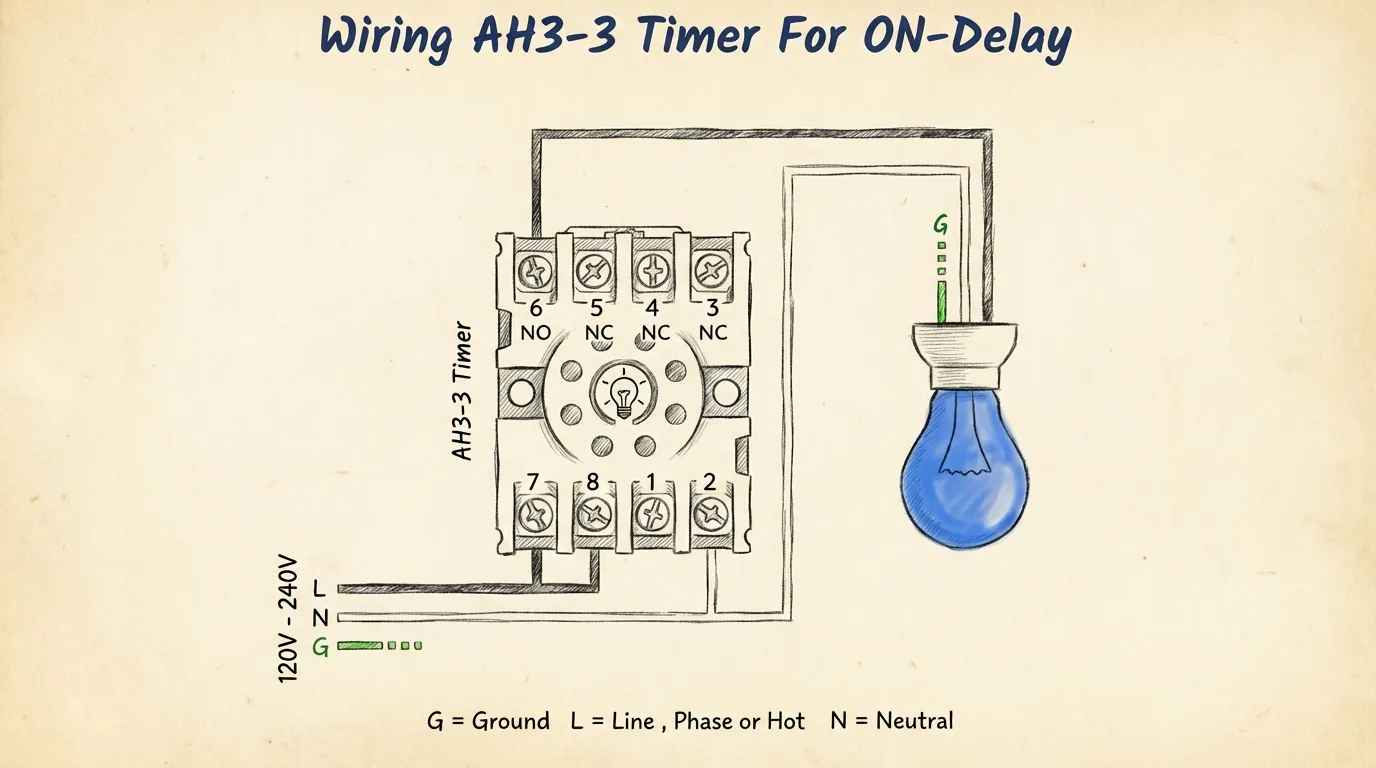

Kablolama Yöntemleri ve Devre Şemaları

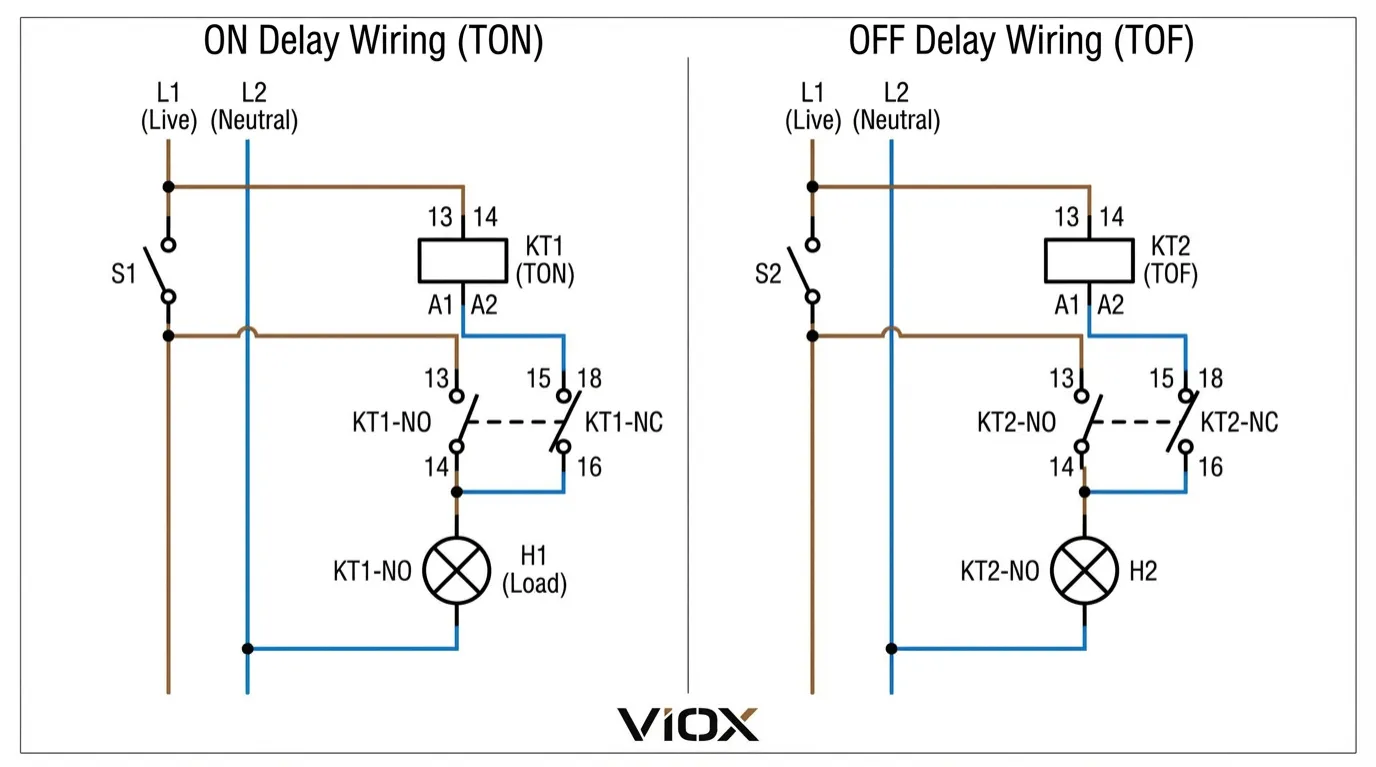

Açma Gecikmeli Zamanlayıcı Kablolaması (120VAC Kontrol)

Terminal Bağlantıları:

- A1, A2: Kontrol voltajı girişi (kontrol anahtarından 120VAC)

- 15-18: Normalde Açık (NA) zaman ayarlı kontak

- 15-16: Normalde Kapalı (NK) zaman ayarlı kontak

- Yük: Kontak 18 ve L2 (nötr) arasına bağlı

Operasyonel Sıra:

- Kontrol anahtarını kapat → A1-A2'ye 120VAC uygulanır

- Zamanlayıcı geri sayıma başlar (örn., PT = 10s)

- 10 saniye sonra, 15-18 kontağı kapanır, yük enerjilenir

- Kontrol anahtarını aç → 15-18 kontağı hemen açılır, yük enerjisi kesilir

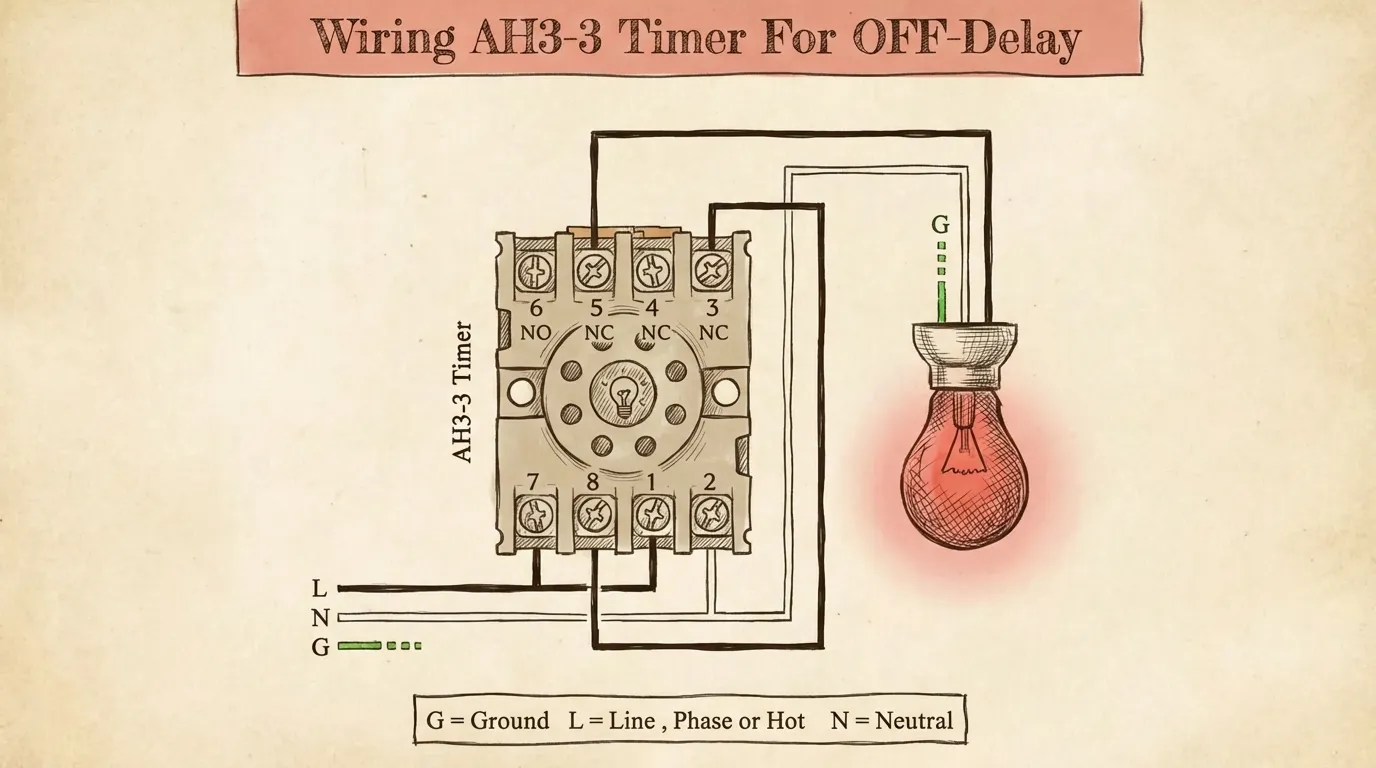

Kapama Gecikmeli Zamanlayıcı Kablolaması (24VDC Kontrol)

Terminal Bağlantıları:

- A1 (+), A2 (-): DC kontrol voltajı (PLC çıkışından 24VDC)

- 15-18: NA zaman ayarlı kontak

- 15-16: NK zaman ayarlı kontak

- Yük: 15-18 kontağı üzerinden bağlı

Operasyonel Sıra:

- PLC çıkışı YÜKSEK → A1-A2'ye 24VDC uygulanır

- 15-18 kontağı hemen kapanır, yük enerjilenir

- PLC çıkışı DÜŞÜK → zamanlayıcı geri sayıma başlar (örn., PT = 15s)

- 15 saniye sonra, 15-18 kontağı açılır, yük enerjisi kesilir

Kritik Bağlantı Notları:

- Her zaman bobin voltajının kontrol devresi voltajıyla eşleştiğini doğrulayın

- Kontak akımı için uygun değerde kablo çapı kullanın (15A devreler için 14 AWG)

- Endüktif yükler boyunca aşırı gerilim bastırma (RC snubber veya MOV) takın

- Motor kontrol devresi koruması için NEC Madde 430.72'yi izleyin

- IEC 60364-5-54'e göre uygun topraklamayı sağlayın

Kapsamlı kablolama kılavuzu için bkz. Zamanlayıcı Röle Voltajı Seçim Kılavuzu.

PLC Programlama: TON ve TOF Talimatları

Modern PLC'ler, zamanlayıcı fonksiyonlarını standartlaştırılmış IEC 61131-3 fonksiyon blokları olarak uygular. Bu blokları anlamak, endüstriyel otomasyon için gereklidir.

TON Fonksiyon Bloğu (Açma Gecikmeli)

Standart Parametreler:

- İÇİNDE (BOOL): Giriş tetikleme sinyali

- PT (TIME): Önceden ayarlanmış süre değeri (örn., T#10S 10 saniye için)

- Q (BOOL): Çıkış durumu (ET ≥ PT olduğunda DOĞRU)

- ET (TIME): IN DOĞRU olduğundan beri geçen süre

Merdiven Mantığı Örneği:

|--[ ]--[TON]--( )--|Operasyonel Mantık:

- IN YANLIŞ → DOĞRU geçiş yaptığında, ET artmaya başlar

- Q, ET = PT olana kadar YANLIŞ kalır

- IN, ET = PT'den önce YANLIŞ'a dönerse, zamanlayıcı sıfırlanır (ET = 0, Q = YANLIŞ)

- IN = DOĞRU ve ET ≥ PT olduğu sürece Q DOĞRU kalır

Tipik Uygulamalar:

- Kontaktörün yerleşmesine izin vermek için motor starter gecikmesi

- Sensör sekmeme giderme (PT = T#100MS)

- Sıralı makine başlatma

TOF Fonksiyon Bloğu (Kapama Gecikmeli)

Standart Parametreler:

- İÇİNDE (BOOL): Giriş tetikleme sinyali

- PT (TIME): Önceden ayarlanmış süre değeri

- Q (BOOL): Çıkış durumu (IN = DOĞRU VEYA zamanlama aktif olduğunda DOĞRU)

- ET (TIME): IN YANLIŞ olduğundan beri geçen süre

Merdiven Mantığı Örneği:

|--[ ]--[TOF]--( )--|Operasyonel Mantık:

- IN = DOĞRU olduğunda, Q hemen DOĞRU olur (ET = 0)

- IN, DOĞRU → YANLIŞ geçiş yaptığında, ET artmaya başlar

- Q, zamanlama periyodu boyunca DOĞRU kalır

- ET = PT olduğunda, Q YANLIŞ'a geçer

- IN, zamanlama sırasında DOĞRU'ya dönerse, ET 0'a sıfırlanır ve Q DOĞRU kalır

Tipik Uygulamalar:

- Motor kapatıldıktan sonra soğutma fanı çalıştırması

- Varlık sensörlü merdiven boşluğu aydınlatması

- Akış anahtarı açıldıktan sonra pompa çalışmaya devam ediyor

PLC Platform Varyasyonları:

- Siemens S7: IEC zamanlayıcı kütüphanesinde TON/TOF (T# formatında)

- Allen-Bradley: .PRE (ön ayar) ve .ACC (akümülatör) etiketleri ile TON/TOF

- Schneider: %TMi adreslemesi ile TON/TOF

- Mitsubishi: Ön ayar için K sabiti ile T (zamanlayıcı) komutu

Detaylı PLC programlama örnekleri için inceleyin Zaman Röleleri Kapsamlı Kılavuz.

Seçim Kılavuzu: Hangi Tür Ne Zaman Kullanılır

AÇMA GECİKMELİ (TON) Seçin Ne Zaman:

✅ Yanlış Başlangıçları Önleme

- Anlık sinyaller ekipmanı tetiklememelidir

- Sürekli talebin doğrulanması gerekli

- Örnek: 5s doğrulama gecikmeli basınç anahtarı

✅ Ekipman Başlangıcını Sıralama

- Birden fazla motor zaman aralıklarında başlamalıdır

- Eş zamanlı ani akımı önler

- Örnek: 3 motorlu sıralı konveyör sistemi

✅ Mekanik Kontakların Titreşimini Giderme

- Anahtar titreşimi birden fazla tetiklemeye neden olur

- Aşağı akış mantığı için temiz sinyal gerekli

- Örnek: 100ms titreşim gidermeli limit anahtarı

✅ Güvenlik Kilitleri

- Koruma kapısı, makine başlamadan önce belirli bir süre kapalı kalmalıdır

- Güvenlik sistemlerinin atlanmasını önler

- Örnek: Pres döngüsünden önce 3 saniyelik kapı doğrulaması

KAPAMA GECİKMELİ (TOF) Seçin Ne Zaman:

✅ Kontrollü Ekipman Kapatma

- Kademeli devre dışı bırakma hasarı önler

- Mekanik döngülerin tamamlanmasına izin verir

- Örnek: İş mili soğutma pompası 120s son çalıştırma

✅ Termal Yönetim

- Ekipman kapatıldıktan sonra soğutma gerekli

- Yatak/bileşen hasarını önler

- Örnek: Motor soğutma fanı 60s gecikme

✅ Aydınlatmayı Sürdürme

- Aydınlatma, doluluk sinyali sona erdikten sonra kısa bir süre açık kalmalıdır

- Güvenli çıkış süresi sağlar

- Örnek: Hareket algılamadan 45s sonra merdiven boşluğu ışıkları

✅ Süreç Tamamlama

- Malzeme bir sonraki döngüden önce tamamen temizlenmelidir

- Kaliteyi sağlar ve sıkışmaları önler

- Örnek: Paketleme hattı deşarj konveyörü 30s son çalıştırma

Karar Ağacı Yaklaşımı

Soru 1: Kontrol sinyali göründüğünde yükün hemen etkinleşmesi gerekiyor mu?

- EVET → TOF'u düşünün (anında etkinleştirme, gecikmeli devre dışı bırakma)

- HAYIR → TON'u düşünün (gecikmeli etkinleştirme)

Soru 2: Gecikme başlangıçta mı yoksa kapanışta mı gerekiyor?

- Başlangıç → TON

- Kapanış → TOF

Soru 3: Yanlış tetiklemeleri mi önlüyorsunuz yoksa döngülerin tamamlanmasını mı sağlıyorsunuz?

- Yanlış tetiklemeleri önleme → TON

- Döngülerin tamamlanmasını sağlama → TOF

Soru 4: Zamanlama sırasında güç kesilirse ne olur?

- Sıfırlanmalı ve yeniden başlatılmalı → Standart TON/TOF

- Son durumdan devam etmeli → Tutucu zamanlayıcı (RTO) gerekli

Kapsamlı röle seçim kriterleri için referans alın Doğru Zamanlayıcı Rölesi Nasıl Seçilir.

Yaygın Hatalar ve Sorun Giderme

| Sorun | Muhtemel Neden | Çözüm | Önleme |

|---|---|---|---|

| Zamanlayıcı zamanlamaya başlamıyor | Yanlış bobin voltajı | Voltaji multimetre ile doğrulayın; isim plakası değerini kontrol edin | Her zaman bobin voltajının kontrol devresiyle eşleştiğini doğrulayın |

| Çıkış hemen etkinleşiyor (TON) | Kablolama hatası – TOF modu seçili | Mod seçme anahtarını/jumper'ı kontrol edin; veri sayfasına göre doğrulayın | Kurulum sırasında zamanlayıcı tipini açıkça etiketleyin |

| Zamanlayıcı erken sıfırlanıyor | Giriş sinyali kararsız/sekiyor | Giriş terminallerine RC filtresi (0,1µF + 10kΩ) ekleyin | Mekanik anahtarlar için kontak sekmesini giderme kullanın |

| Tutarsız zamanlama | Sıcaklık değişimi doğruluğu etkiliyor | Zamanlayıcıyı ısı kaynaklarından uzağa yerleştirin; sıcaklık telafili model kullanın | Ortam sıcaklığını kalibrasyon sıcaklığının ±10°C içinde tutun |

| Kontakların kaynaklanması/arıza yapması | Kontak değerini aşma | Gerçek yük akımını ölçün; yükler için kontaktör ekleyin >80% değeri | Her zaman kontakların değerini maksimum değerin -80%'sine düşürün |

| Zamanlayıcı güç kaybından sonra sıfırlanmıyor | Kapasitör tabanlı zamanlayıcı şarjı tutuyor | Zamanlama kapasitörünü boşaltın (güç kapalıyken A1-A2'yi 5 saniye kısa devre yapın) | Güç kaybında garantili sıfırlama özelliğine sahip elektronik zamanlayıcılar kullanın |

| Gürültülü ortamda düzensiz çalışma | EMI / RFI paraziti | Kontrol kablolarına ferrit nüve takın; blendajlı kablo kullanın; MOV bastırma ekleyin | Kontrol kablolarını VFD'lerden, kontaktörlerden, kaynak makinelerinden uzağa yönlendirin |

Gelişmiş Sorun Giderme Teknikleri

Zamanlama Doğruluğunu Ölçme:

- A1-A2'ye nominal kontrol voltajı uygulayın

- Gerçek gecikmeyi ölçmek için kronometre veya osiloskop kullanın

- Önceden ayarlanmış süreyle (PT) karşılaştırın

- Kabul edilebilir tolerans: IEC 61812-1'e göre ±%5%

- Tolerans dışındaysa, voltaj değişimini kontrol edin veya zamanlayıcıyı değiştirin

Kontak Direnci Testi:

- Devreyi enerjisiz bırakın ve yükü ayırın

- Kontakları kapatmak için zamanlayıcıya enerji verin

- Milliohm metre ile NO kontakları arasındaki direnci ölçün

- Kabul edilebilir: yeni kontaklar için <50mΩ, eski kontaklar için <200mΩ

- >200mΩ oksidasyon/aşınma olduğunu gösterir—zamanlayıcıyı değiştirin

İzolasyon Direnci Testi:

- Enerjiyi kesin ve tüm kabloları ayırın

- Megohmmetre kullanarak bobin ve kontaklar arasına 500VDC uygulayın

- Kabul edilebilir: IEC 61810-1'e göre >100MΩ

- <10MΩ yalıtım arızası olduğunu gösterir—hemen değiştirin

SSS

Gecikmeli başlatma (on delay) ve gecikmeli durdurma (off delay) zaman röleleri arasındaki temel fark nedir?

Temel fark, zamanlama gecikmesinin ne zaman meydana geldiğidir. Bir gecikmeli başlatma zamanlayıcısı (TON) giriş sinyali uygulandıktan sonra çıkışının etkinleştirilmesini geciktirir—çıkış AÇILMADAN önce önceden ayarlanmış süreyi bekler. Bir gecikmeli durdurma zamanlayıcısı (TOF) giriş uygulandığında çıkışını hemen etkinleştirir ancak devre dışı bırakmayı geciktirir—çıkış, giriş kaldırıldıktan sonra kapanmadan önce önceden ayarlanmış süreyi bekler. Pratik olarak: TON = “başlamadan önce bekle”, TOF = “sinyal bittikten sonra çalışmaya devam et”.”

TON zamanlayıcısını TOF zamanlayıcısı yerine ne zaman kullanmalıyım?

Modern Düzeltme: TON zamanlayıcısı ekipmanı çalıştırmaya başlamadan önce bir koşulun sürdürüldüğünü doğrulamanız gerektiğinde. Bu şunlar için kritik öneme sahiptir:

- Yanlış başlangıçları önleme anlık sinyallerden (basınç yükselmeleri, voltaj geçişleri)

- Ekipmanı sıralama başlatmayı kademelendirmek ve ani akımı azaltmak için

- Güvenlik kilitlemeleri doğrulama süreleri gerektiren (koruma kapıları, iki elle kontrol)

- Mekanik anahtarların sekmesini giderme kontak sekmesini ortadan kaldırmak için

Modern Düzeltme: TOF zamanlayıcısı başlatma sinyali sona erdikten sonra ekipmanın çalışmaya devam etmesi gerektiğinde:

- Soğutma döngüleri motorlar, kompresörler veya ısı üreten ekipmanlar için

- Süreç tamamlama kapanmadan önce malzemelerin tamamen temizlendiğinden emin olunması

- Acil durum aydınlatması güç geçişleri sırasında aydınlatmanın korunması

- Havalandırma temizleme ekipman kapatıldıktan sonraki döngüler

Motor soğutma uygulamaları için gecikmeli bir zamanlayıcı kullanabilir miyim?

Hayır—motor soğutması için bir TON zamanlayıcısı kullanmak yanlıştır ve potansiyel olarak zararlıdır. Motor soğutması, fanın motor durduktan sonra çalışmaya devam etmesini gerektirir, bu da bir gecikmeli kapama (TOF) fonksiyonudur. Bir TON zamanlayıcısı, motor çalıştığında fanın çalışmasını geciktirir ve herhangi bir soğutma faydası sağlamaz. Doğru yapılandırma şöyledir:

- Motor kontaktör yardımcı kontağı → TOF zamanlayıcı girişi

- TOF zamanlayıcı çıkışı → Soğutma fanı kontaktör bobini

- Önceden ayarlanmış süre: motor boyutuna ve görev döngüsüne bağlı olarak 60-180 saniye

Bu, motor çalıştığında fanın hemen çalışmasını ve motor durduktan sonra önceden ayarlanmış süre boyunca devam etmesini sağlar. Ayrıntılı motor kontrol kablolaması için bkz. Kontaktörler ve Röleler: Temel Farklılıkları Anlamak.

Zaman gecikmeli rölem için hangi voltajı seçmeliyim?

Voltaj seçimi, kontrol devresi standardınıza bağlıdır:

- 24VDC – PLC kontrollü sistemler, düşük voltajlı güvenlik devreleri ve modern endüstriyel otomasyon için en yaygın olanıdır. Avantajları: Güvenli, gürültüye karşı bağışıklık, elektronik kontrollerle uyumlu.

- 120VAC – Kuzey Amerika konut/hafif ticari ve transformatörsüz doğrudan anahtar kontrolü için standart.

- 240VAC – Avrupa/uluslararası kurulumlarda (230VAC), ağır sanayi ekipmanlarında ve üç fazlı motor kontrol devrelerinde kullanılır.

- 12VDC – Otomotiv, mobil ekipman ve pille çalışan sistemler gibi özel uygulamalar.

- Evrensel voltaj (90-265VAC/DC) – Uluslararası ekipman, belirsiz voltaj ortamları ve kurulumda esneklik için en iyisi.

Sipariş vermeden önce kurulum yerinde mevcut olan kontrol voltajını her zaman doğrulayın. Kapsamlı rehberlik için şu kaynağa bakın: Zamanlayıcı Röle Voltaj Seçim Kılavuzu: 12V, 24V, 120V, 230V.

Bir kontrol devresinde gecikmeli kapama zamanlayıcısı nasıl bağlanır?

Temel Gecikmeli Kapama Kablolaması (120VAC):

- Güç Kaynağı: L1'i (sıcak) ve L2'yi (nötr) kontrol devresine bağlayın

- Kontrol Anahtarı: Kontrol anahtarını L1 ile seri bağlayın

- Zamanlayıcı Bobini: A1'i kontrol anahtarı çıkışına, A2'yi L2'ye bağlayın

- Yük Bağlantısı: Yükü zamanlayıcı NO kontağı (terminal 18) ile L2 arasına bağlayın

- Ortak Terminal: Zamanlayıcı ortak ucunu (terminal 15) L1'e bağlayın

Operasyon: Kontrol anahtarı kapandığında, zamanlayıcı bobini enerjilenir ve 15-18 kontağı hemen kapanarak yüke güç verir. Kontrol anahtarı açıldığında, yük önceden ayarlanmış süre boyunca enerjilenmeye devam eder, ardından enerjisi kesilir.

Kritik Güvenlik Notları:

- Uygun şekilde derecelendirilmiş kablo kullanın (15A devreler için minimum 14 AWG)

- NEC Madde 430.72 uyarınca aşırı akım koruması takın

- Endüktif yükler boyunca aşırı gerilim bastırma ekleyin (MOV veya RC snubber)

- NEC Madde 250 uyarınca kontrol panelinin uygun şekilde topraklanmasını sağlayın

Görsel kablolama şemaları ve adım adım prosedürler için bkz. Zaman Rölesi Nedir.

Zaman gecikmeli rölelerin yaygın arıza modları nelerdir?

1. Kontak Arızası (Arızaların 'ı)

- Belirtiler: Aralıklı çalışma, zamanlama tamamlanmasına rağmen çıkış yok

- Nedenler: Kontak değerini aşma, bastırma olmadan endüktif yük, çevresel kirlenme

- Önleme: Kontakları değerin -80'ine düşürün, ağır yükler için kontaktörler kullanın, IP54+ muhafazalara takın

2. Zamanlama Sapması (Arızaların 'i)

- Belirtiler: Gerçek gecikme önceden ayarlanmış değerle eşleşmiyor, tutarsız zamanlama

- Nedenler: Kondansatör yaşlanması (elektromekanik zamanlayıcılar), aşırı sıcaklıklar, voltaj değişimi

- Önleme: Kristal osilatörlü elektronik zamanlayıcılar kullanın, kararlı ortam sıcaklığını koruyun, kontrol voltajını düzenleyin

3. Bobin Yanması (Arızaların 'si)

- Belirtiler: Giriş sinyaline yanıt yok, bobin direnci sonsuz

- Nedenler: Aşırı voltaj, sürekli aşırı akım, yalıtım arızası

- Önleme: Voltaj uyumluluğunu doğrulayın, sigortalı kontrol devreleri kullanın, nemden kaçının

4. EMI/RFI Girişimi (Arızaların 'u)

- Belirtiler: Düzensiz zamanlama, yanlış tetikleme, erken sıfırlamalar

- Nedenler: VFD'lere, kontaktörlere, kaynakçılara veya radyo vericilerine yakınlık

- Önleme: Korumalı kontrol kabloları kullanın, ferrit nüveler takın, kontrol ve güç kablolarını >12 inç ayırın

5. Mekanik Aşınma (Arızaların %5'i)

- Belirtiler: Artan kontak direnci, gecikmeli kontak kapanması

- Nedenler: Mekanik ömür değerini aşma, titreşim, şok

- Önleme: Uygun mekanik ömür değerine sahip zamanlayıcılar seçin, titreşim sönümleme bağlantıları kullanın

Sonuç

Gecikmeli başlatma ve gecikmeli durdurma zamanlayıcıları arasında seçim yapmak, temel zamanlama davranışını anlamayı gerektirir: TON aktivasyonu geciktirir, sırasında TOF deaktivasyonu geciktirir. Görünüşte basit olan bu ayrım, ekipman koruması, enerji verimliliği ve operasyonel güvenlik açısından derin etkilere sahiptir.

Temel Karar Faktörleri:

- Uygulama gereksinimi: Başlangıç kontrolü (TON) - Kapanış kontrolü (TOF)

- Voltaj uyumluluğu: Kontrol devresi voltajını eşleştirin (12VDC - 240VAC)

- İletişim derecesi: -30 güvenlik payı ile yeterli kapasite sağlayın

- Zaman aralığı: Önceden ayarlanmış aralığın uygulamanızı kapsadığını doğrulayın (0,1 sn - 999 saat)

- Çevresel koşullar: Uygun IP derecesini ve sıcaklık aralığını seçin

- Standartlara uygunluk: IEC 61812-1, UL 508 veya eşdeğer sertifikayı doğrulayın

VIOX Zaman Röleleri hem gecikmeli açma hem de gecikmeli kapama uygulamaları için kapsamlı çözümler sunar:

- Kurulum esnekliği için evrensel voltaj girişleri (90-265VAC/DC)

- Neredeyse tüm endüstriyel uygulamaları kapsayan geniş zamanlama aralıkları (0,05 sn - 999 saat)

- Uzatılmış elektriksel ömürlü yüksek kapasiteli kontaklar (10A @ 250VAC)

- Küresel uyumluluk için IEC 61812-1 ve UL 508 sertifikalı

- Hızlı kurulum ve bakım için DIN rayı montajı

Uygulamanız için zaman rölesi seçimi konusunda teknik danışmanlık için VIOX teknik destek ile iletişime geçin: [email protected] veya sitemizi ziyaret edin: ürün seçim kılavuzu.