Tek Bir Yanlış Bileşen Seçimi Size Binlerce Dolara Mal Olduğunda

50kW'lık ticari bir çatı güneş enerjisi kurulumunu tasarlamayı yeni bitirdiniz. On iki adet yüksek verimli panel dizisi. Üç adet dizi invertörü. Yerleşim optimize edildi, yapısal hesaplamalar kontrol edildi ve müşteriniz öngörülen yatırım getirisinden memnun. Tedarikçiniz basit bir soruyla aradığında malzeme listenizi sonlandırıyorsunuz:

“AC birleştirme kutusuna mı yoksa DC birleştirme kutusuna mı ihtiyacınız var?”

Duraklıyorsunuz. Bir birleştirme kutusuna ihtiyacınız olduğunu biliyorsunuz—sistemde birleştirilmesi gereken birden fazla çıkış var. Ancak aniden, ayrım kritik geliyor. Korku hikayeleri duydunuz: Phoenix'te iki türü karıştıran ve başarısız bir denetimle karşı karşıya kalan, eksiksiz bir elektrik revizyonuna zorlayan bir kurulumcu. DC tarafında AC dereceli bileşenler kullanan ve devreye almadan altı ay sonra 200kW'lık bir sistemi felaketle sonuçlanan bir ark hatasıyla kapatan başka bir yüklenici.

Riskler gerçek: Yanlış birleştirme kutusu türünü seçin ve reddedilen denetimlere, güvenli olmayan çalışmaya, pahalı yeniden kuruluma ve hasar görmüş bir profesyonel itibara bakıyorsunuz. İşte her güneş enerjisi profesyonelinin karşılaştığı soru: AC ve DC birleştirme kutuları arasındaki gerçek fark nedir ve her seferinde doğru seçimi nasıl yaparsınız?

Bu Kafa Karışıklığı Neden Var (Ve Neden Önemli)

Sorun isimle başlıyor. Her iki ürüne de “birleştirme kutuları” deniyor çünkü her ikisi de birden fazla elektrik çıkışını birleşik bir beslemeye birleştiriyor. Yüzeyde, birbirlerinin yerine geçebilir gibi görünüyorlar—sadece girişleri ve çıkışları olan kutular, değil mi?

Yanlış. Tehlikeli derecede yanlış.

İşte çoğu mühendisin kaçırdığı şey: AC ve DC birleştirme kutuları, güneş enerjisi dönüşüm sürecinde temelde farklı noktalarda çalışır. Bir DC birleştirme kutusu, doğrudan güneş panellerinizden gelen ham, yüksek voltajlı doğru akımı işler—modern sistemlerde 600V ila 1.500V DC'den bahsediyoruz. Öte yandan, bir AC birleştirme kutusu, invertörden geçtikten sonra dönüştürülmüş alternatif akımı, tipik olarak 120V ila 480V AC standart şebeke voltajlarında yönetir.

Ancak voltaj tek fark değil. DC ve AC elektriği, arıza koşullarında temelde farklı davranır. DC arklarının, AC arklarına kıyasla söndürülmesi son derece zordur (doğal olarak saniyede 120 kez sıfır geçiş noktalarında söner). Bu, bir DC uygulamasında AC dereceli devre kesicileri kullanmanın sadece verimsiz olmakla kalmayıp, aynı zamanda yaşanması beklenen bir yangın tehlikesi olduğu anlamına gelir. Bileşenler benzer görünüyor, ancak tamamen farklı elektriksel davranışlar için tasarlanmışlardır.

Özetle: Bu iki ürünü karıştırmak, aynı bileşenin iki markası arasında seçim yapmak gibi değildir. Hava hareket ettirmek için bir su pompası kullanmaya çalışmak gibidir—araç basitçe göreve uymuyor ve sonuçları ciddi olabilir.

“Aha!” Anı: Sistem Konumu Açısından Düşünün

İşte bunu kafa karıştırıcıdan kristal netliğine dönüştüren içgörü: Birleştirme kutularını birbirinin yerine geçebilir ürünler olarak düşünmeyi bırakın. Güneş enerjisi sisteminizin iki ayrı elektrik “tarafı” olduğunu düşünmeye başlayın.”

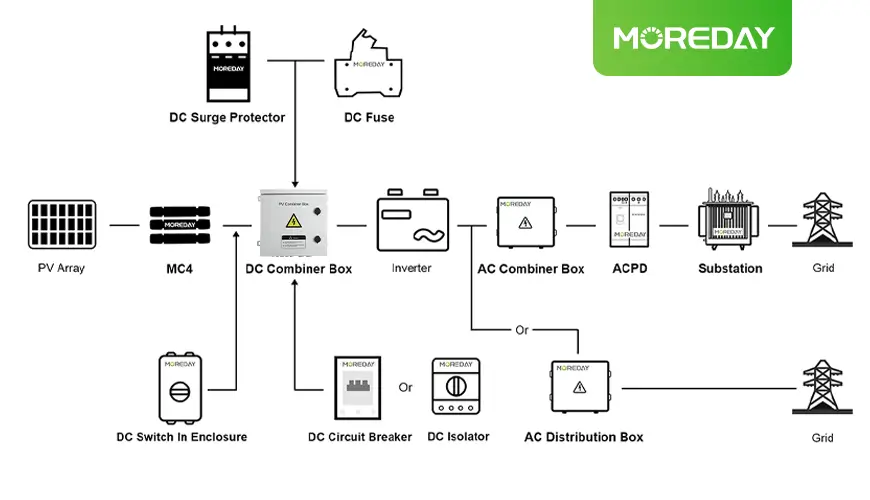

DC Tarafı: Güneş panelleri → DC birleştirme kutusu → İnvertör (giriş tarafı)

AC Tarafı: İnvertör (çıkış tarafı) → AC birleştirme kutusu → Şebeke bağlantısı

Güneş panelleriniz doğru akım üretir. Birden fazla panel dizisi birden fazla DC çıkışı üretir. Yeterli diziniz varsa (tipik olarak 4 veya daha fazla), bir DC birleştirme kutusuna ihtiyacınız vardır. Bu kutu, herhangi bir dönüşüm olmadan önce ham güneş enerjisini işleyen “DC bölgesi”nde bulunur.

İnvertör bu DC gücünü AC'ye dönüştürdükten sonra, farklı bir bölgedesiniz. Birden fazla invertörünüz varsa (büyük kurulumlarda yaygın) veya mikroinvertörler kullanıyorsanız (her panelin kendi küçük invertörü vardır), artık ana elektrik panelinize veya şebekeye bağlanmadan önce birleştirilmesi gereken birden fazla AC çıkışınız var. İşte bir AC birleştirme kutusu devreye giriyor.

Kritik ayrım: Bu kutular rekabet eden ürünler değildir—güç dönüştürme işleminin zıt taraflarına hizmet ederler. Bu tek kavramı anlamak, kafa karışıklığının 'ını ortadan kaldırır.

Mühendisin Üç Adımlı Seçim Çerçevesi

Artık temel farkı anladığınıza göre, doğru seçim için sistematik süreçte ilerleyelim. Bu üç adımı izleyin ve bir daha asla yanlış birleştirme kutusu seçmeyeceksiniz.

Adım 1: Sistem Mimarınızı ve Güç Akışınızı Haritalayın

İlk adım, sisteminizde gücü tam olarak nerede birleştirmeniz gerektiğini belirlemektir. Panellerden şebekeye olan güç akışınızı çizin ve birden fazla çıkışın birleştiği her noktayı işaretleyin.

Dizi invertör sistemleri için (çoğu ticari kurulum), birden fazla panel diziniz birden fazla DC çıkışı oluşturur. Bunların invertöre ulaşmadan ÖNCE birleştirilmesi gerekir. DC tarafına bakıyorsunuz, bu yüzden bir DC birleştirme kutusuna. DC birleştirme kutusuna ihtiyacınız var. Tipik kurulum şöyle görünür:

- 12 panel dizisi (her biri 600-1.000V DC'de 30-40A üretiyor)

- Tüm diziler bir DC birleştirme kutusuna beslenir

- Tek yüksek kapasiteli kablo (250-400A) birleştirme kutusundan dizi invertör girişine gider

Bu yapılandırma, 11 uzun kablo hattını ortadan kaldırarak kurulum maliyetlerini düşürür ve sorun gidermeyi önemli ölçüde basitleştirir.

Mikroinvertör sistemleri için (konut kurulumlarında popüler), her panel veya küçük panel grubu, rafa monte edilmiş kendi invertörüne sahiptir. Bunlar, ana panelinize bağlanmadan önce birleştirilmesi gereken birden fazla AC çıkışı oluşturur—potansiyel olarak düzinelerce. Artık AC tarafındasınız, bu yüzden bir AC birleştirme kutusu. AC birleştirme kutusuna ihtiyacınız var. Kurulum:

- 20 mikroinvertör (her biri 240V AC çıkış veriyor)

- Tüm AC çıkışları bir AC birleştirme kutusuna beslenir

- Tek AC beslemesi birleştirme kutusundan ana servis paneline gider

Uzman İpucu: Hem dizi invertörleri HEM de pil depolaması olan hibrit sistemlerde, HER İKİ türde birleştirme kutusuna da ihtiyacınız olabilir—invertöre giden panel dizileri için bir DC kutusu ve tesise veya şebekeye besleme yapan birden fazla invertörünüz varsa bir AC kutusu. Önemli olan, güç akışını izlemek ve her akım türünün nerede birleştirilmesi gerektiğini belirlemektir.

Adım 2: Voltajı, Akımı ve Bileşen Değerlerini Eşleştirin

İnvertörün hangi tarafında çalıştığınızı bildiğinizde, birleştirme kutunuzun o konumun elektriksel özelliklerini kaldırabildiğinden emin olmanız gerekir. Bileşen değerlerinin kritik hale geldiği yer burasıdır.

DC Birleştirme Kutusu Gereksinimler:

Modern güneş enerjisi sistemleri, akımı (ve dolayısıyla kablo boyutunu ve kaybını) azaltmak için voltaj sınırlarını daha yükseğe iter. Şebeke ölçekli kurulumlar giderek artan bir şekilde 1.500V DC sistemleri kullanıyor. DC birleştirme kutunuz, dizi yapılandırmanıza bağlı olarak tipik olarak 600V ila 1.500V DC arasında değişen bu yüksek voltajlar için derecelendirilmelidir.

Ancak işte kritik güvenlik noktası: Bir DC birleştirme kutusunun içindeki her bileşen DC dereceli olmalıdır. Buna şunlar dahildir:

- DC dereceli sigortalar veya devre kesiciler (tipik olarak panel özelliklerine bağlı olarak dizi başına 10-20A)

- Güvenli bakım için DC dereceli ayırma anahtarları Güvenli bakım için

- Tip 2 veya Tip 1+2 aşırı gerilim koruma cihazları (DC uygulamaları için derecelendirilmiş, yıldırım çarpmalarından kaynaklanan 20-40kA deşarj akımlarını kaldırabilen SPD'ler)

- Akım birleştirme için DC dereceli bara Neden önemli? Çünkü standart bir AC devre kesici, DC dereceli bir devre kesiciyle aynı görünebilir, ancak bir DC arkını güvenilir bir şekilde kesintiye uğratmaz.

Why does this matter? Because a standard AC circuit breaker might look identical to a DC-rated one, but it won’t reliably interrupt a DC arc. DC uygulamalarında AC bileşenleri kullanmak, güneş enerjisi sistemi yangınlarının önde gelen nedenlerinden biridir.

AC Birleştirme Kutusu Gereksinimleri:

AC birleştirme kutuları, genellikle konut, ticari veya endüstriyel bir ortamda olup olmadığınıza bağlı olarak, çok daha tanıdık voltaj seviyelerini (tipik olarak 120V, 208V, 240V veya 480V AC) işler. Bileşenler farklıdır:

- AC nominal devre kesiciler her bir invertör çıkışı için (invertör çıkış kapasitesine göre boyutlandırılır, tipik olarak 15-60A)

- AC aşırı gerilim tutucular şebeke voltajı yükselmelerine karşı koruma sağlamak için

- Akım transformatörleri (CT'ler) üretim takibi için

- Şebeke senkronizasyon bileşenleri daha büyük sistemlerde

Dört Dizi Kuralı: Gereksiz maliyetlerden tasarruf sağlayan pratik bir kılavuz: daha az dört güneş enerjisi dizisi olan sistemler, tipik olarak bir DC birleştirme kutusu olmadan doğrudan invertöre bağlanabilir. Dört veya daha fazla diziye ulaştığınızda, azaltılmış kablolamada maliyet tasarrufu ve merkezi korumadan kaynaklanan gelişmiş güvenlik, bir birleştirme kutusu eklemeyi haklı çıkarır. AC sistemleri için, üçten fazla mikroinvertörünüz veya birden fazla dizi invertörünüz varsa, bir birleştirme kutusu kurulumunuzu önemli ölçüde basitleştirir.

Adım 3: Güvenlik Özelliklerini ve Sertifikaları Doğrulayın

Son adım (ve uzun vadeli güvenilirliği sağlayan adım), birleştirme kutunuzun yargı alanınız için uygun güvenlik özelliklerine ve sertifikalara sahip olduğunu doğrulamaktır.

Temel DC Birleştirme Kutusu Güvenlik Özellikleri:

- Ark arıza koruması: Gelişmiş DC birleştirme kutuları, tehlikeli DC arklarının benzersiz imzasını algılayan ve yangın başlamadan önce devreyi kesen ark hatası devre kesicileri (AFCIs) içerir. DC arklarının 3.000°C'yi aşan sıcaklıklara ulaşabileceği göz önüne alındığında, bu büyük sistemler için isteğe bağlı değildir.

- Dizi seviyesi izleme: Kesinlikle bir güvenlik özelliği olmasa da, dizi seviyesindeki voltaj ve akım izleme, düşük performans gösteren veya arızalı dizileri hemen belirlemenizi, kademeli arızaları önlemenizi ve sorunları tehlikeli hale gelmeden yakalamanızı sağlar.

- Entegre ayırma anahtarları: Ulusal Elektrik Kodu (NEC), DC devreleri için erişilebilir ayırma noktaları gerektirir. DC birleştirme kutunuz bu işlevselliği sağlamalı ve bakım sırasında güvenli enerji kesilmesine izin vermelidir.

- IP65 veya NEMA 3R derecesi: Güneş enerjisi ekipmanı 25+ yıl dışarıda yaşar. Birleştirme kutusu muhafazanız neme, toza ve UV bozulmasına karşı dayanıklı olmalıdır.

Temel AC Birleştirme Kutusu Güvenlik Özellikleri:

- Uygun kesme değerlerine sahip aşırı akım koruması: AC devre kesicileriniz, belirli şebeke bağlantınız için yeterli kesme kapasitesine (AIC derecesi) sahip olmalıdır. Tipik bir şebeke şebekesi 10kA veya daha yüksek AIC dereceleri gerektirebilir.

- Topraklama hatası koruması: Şok tehlikelerini önlemek ve kod gereksinimlerini karşılamak için gereklidir. Birçok yargı alanı, güneş enerjisi kurulumlarının AC tarafında toprak arızası algılama gerektirir.

- AC uygulamaları için derecelendirilmiş aşırı gerilim koruması: Yıldırım ve şebeke geçişleri pahalı invertörleri yok edebilir. Uygun AC aşırı gerilim koruma cihazları (SPD'ler) yatırımınızı korur.

Sertifikasyon Gereksinimleri:

Satın alma işleminizi tamamlamadan önce, bu sertifikaları doğrulayın:

- UL 1741 (Kuzey Amerika): Şebekeye bağlı PV ekipmanı için gereklidir

- NEC uyumluluğu: Birleştirme kutunuz, mevcut Ulusal Elektrik Kodu gereksinimlerini (bu yazı itibariyle 2023 sürümü) karşılamalıdır

- IEEE 1547: Şebeke ara bağlantı standartları için

- IEC 61439 (uluslararası): Alçak gerilim anahtarlama ve kontrol tertibatları için

Uzman İpucu: Bir birleştirme kutusunun satılıyor olması nedeniyle gerekli tüm sertifikalara sahip olduğunu varsaymayın. Sertifika etiketlerini doğrulayın ve yargı alanınız için geçerli olduklarını onaylayın. Sertifikasız ekipman kullanmak sigortanızı geçersiz kılabilir, denetimi geçemez ve bir şeyler ters giderse sizi yasal tehlikeye sokabilir.

Eylemdeki Karar Çerçevesiniz

Şimdi tüm bunları gerçek dünya uygulama örnekleriyle bir araya getirelim:

Senaryo 1 – 50kW Ticari Çatı (Orijinal Sorunuz)

- Sistem: 3 dizi invertöre beslenen 12 panel dizisi

- Karar: DC birleştirme kutusu (invertörlerden önce 12 DC dizisini birleştirir)

- Gerekli özellikler: 1.000V DC derecesi, 12 giriş devresi, 250A+ çıkış kapasitesi, DC nominal sigortalar ve SPD'ler

- Sonuç: Tek bir birleştirme konumu ve invertörlere üç kablo ile temiz kurulum

Senaryo 2 – Mikroinvertörlü 15kW Konut

- Sistem: Her biri 240V AC çıkışlı kendi mikroinvertörüne sahip 40 güneş paneli

- Karar: AC birleştirme kutusu (mikroinvertörlerden 40 AC çıkışını birleştirir)

- Gerekli özellikler: 240V AC derecesi, 40 giriş kesicisi (tipik olarak her biri 15A), üretim ölçüm CT'leri

- Sonuç: Ana servis paneline tek besleme ile organize AC toplama noktası

Senaryo 3 – Batarya Depolamalı Hibrit Ticari Sistem

- Sistem: 2 dizi invertöre 8 dizi, ayrıca AC bağlantılı batarya sistemi

- Karar: Bir DC birleştirme kutusu VE bir AC birleştirme kutusu

- DC kutusu: 2 dizi invertörden önce 8 panel dizisini birleştirir

- AC kutusu: Şebeke bağlantısından önce 2 invertörden ve batarya invertöründen gelen çıkışları birleştirir

- Sonuç: Hem DC hem de AC taraflarında temiz güç akışı yönetimi

Sonuç: Güvenlik, Verimlilik ve Profesyonel Mükemmellik

Bu üç adımlı çerçeveyi izleyerek şunları sağlarsınız:

- Uygun bileşen seçimi sistem konumuna ve akım türüne göre

- Elektrik güvenliği doğru voltaj/akım değerleri ve DC'ye özgü bileşenler aracılığıyla

- Kod uyumluluğu uygun sertifikalar ve güvenlik özellikleriyle

- Uzun vadeli güvenilirlik her uygulama için amaca yönelik ekipmanlarla

- Profesyonel güvenilirlik ilk seferde doğru yaparak

“AC mi DC mi birleştirme kutusu?” sorusu önemsiz bir ayrıntı değil; güvenlik, performans ve yasal uygunluğu etkileyen temel bir sistem tasarım kararıdır. İyi haber? Bu ürünlerin invertörün zıt taraflarına (önce DC, sonra AC) hizmet ettiğini anladığınızda, seçim kolaylaşır.

Temel prensibi unutmayın: Panellerden şebekeye olan güç akışınızı takip edin. İnvertörden önce birden fazla DC kaynağını birleştirmeniz gerektiğinde, DC değerine sahip bileşenlere sahip bir DC birleştirme kutusu belirtin. İnvertörden sonra birden fazla AC kaynağını birleştirmeniz gerektiğinde, AC değerine sahip bileşenlere sahip bir AC birleştirme kutusu belirtin. Bileşen değerlerinizi voltaj ve akım gereksinimlerinize uygun hale getirin. Yetki alanınız için sertifikaları doğrulayın.

Bunu doğru yapın ve onlarca yıl boyunca kusursuz bir şekilde çalışan güvenli, verimli, yasalara uygun güneş enerjisi kurulumları sağlayacaksınız. Yanlış yaparsanız, başarısız denetimler, tehlikeli çalışma ve maliyetli yeniden işleme ile karşı karşıya kalırsınız.

Seçim sizin, ancak artık her zaman doğru seçimi yapacak bilgiye sahipsiniz.

Belirli projeniz için doğru birleştirme kutusunu belirleme konusunda yardıma mı ihtiyacınız var? Bileşen seçimlerinizin sistem gereksinimlerinize ve yerel yasalara uygun olduğunu doğrulamak için elektrik distribütörünüze veya bir güneş enerjisi tasarım mühendisine danışın. Şüphe duyduğunuzda, maliyet tasarruflarından ziyade her zaman güvenliğe ve yasal uygunluğa öncelik verin.