Основные выводы

- Регулируемые автоматические выключатели позволяют пользователям изменять настройки срабатывания (параметры тока и времени) в соответствии с конкретными требованиями нагрузки, в отличие от автоматических выключателей с фиксированными настройками

- Три основных типа регулировки: Защита от перегрузки по времени (тепловая), защита от кратковременного превышения тока и мгновенная защита (от короткого замыкания)

- Основные области применения: Промышленное управление двигателями, среды с переменной нагрузкой, системы HVAC, солнечные установки и оборудование с колеблющимся энергопотреблением

- Компромисс между стоимостью и гибкостью: Регулируемые автоматические выключатели стоят на 30-50% больше, чем фиксированные типы, но устраняют необходимость в нескольких запасах автоматических выключателей

- Обозначение типа A и типа B: Автоматические выключатели типа A позволяют неограниченное количество полевых регулировок; автоматические выключатели типа B можно регулировать только в сторону уменьшения от их максимального номинала

- Электронные расцепители предлагают наиболее точные возможности регулировки (точность ±5%), по сравнению с тепловыми магнитными типами (допуск ±20%)

Регулируемый автоматический выключатель - это защитное устройство, которое позволяет пользователям изменять свои настройки срабатывания, включая пороговые значения тока и временные задержки, чтобы точно соответствовать электрическим характеристикам защищаемой цепи или оборудования. В отличие от автоматических выключателей с фиксированными настройками, которые поставляются с предопределенными настройками с завода, регулируемые автоматические выключатели обеспечивают гибкость для точной настройки параметров защиты в полевых условиях, что делает их необходимыми для приложений, где условия нагрузки меняются или где требуется точная координация с другими защитными устройствами.

В промышленных и коммерческих электрических системах один размер редко подходит для всех. Регулируемый автоматический выключатель решает эту задачу, предлагая настраиваемую защиту, которая адаптируется к вашим конкретным потребностям - будь то защита двигателя с высоким пусковым током, координация нескольких автоматических выключателей в сложной системе распределения или учет будущих изменений нагрузки без замены оборудования.

Понимание основ: Автоматические выключатели с фиксированными и регулируемыми настройками

Что делает автоматический выключатель “регулируемым”?

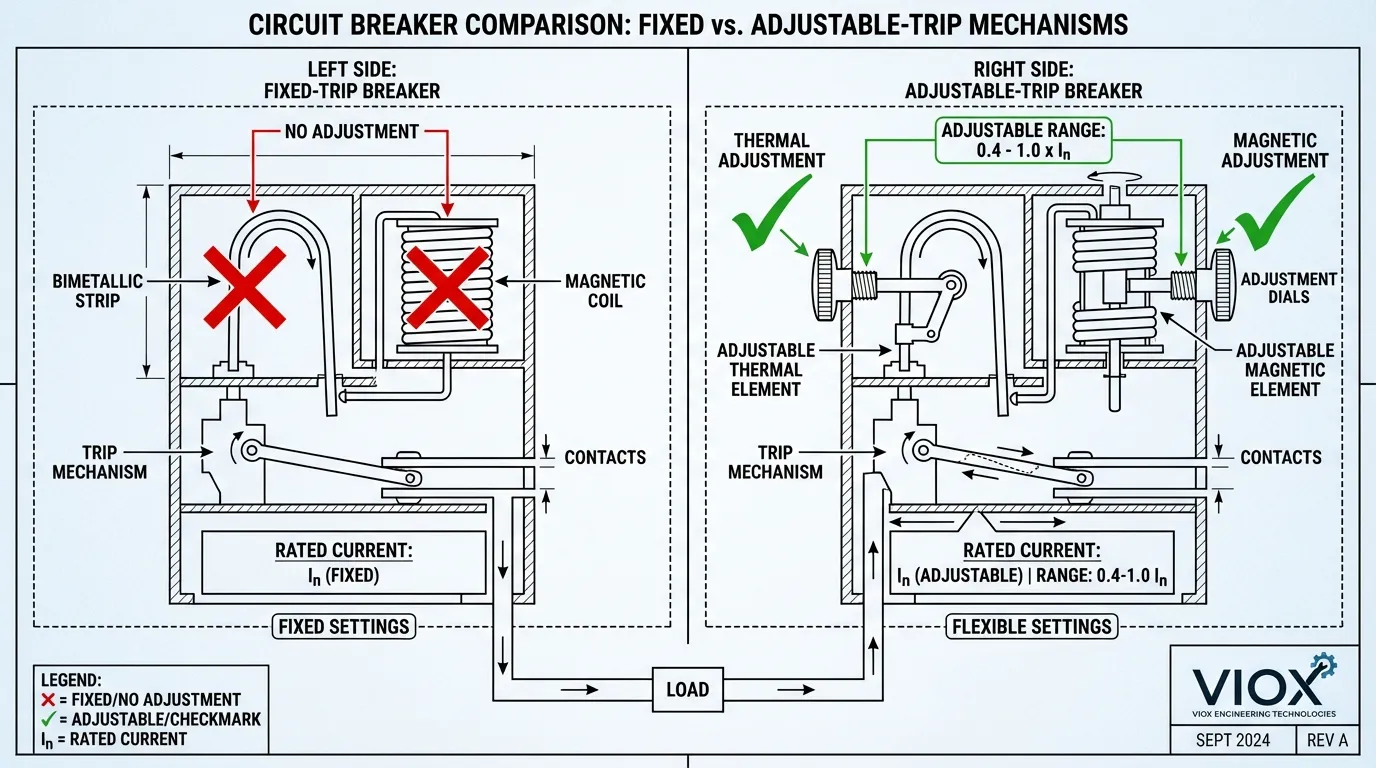

Термин “регулируемый” относится к способности автоматического выключателя изменять одну или несколько характеристик срабатывания после установки. Согласно статье 100 Национального электротехнического кодекса (NEC), регулируемый автоматический выключатель определяется как “квалифицирующий термин, указывающий на то, что автоматический выключатель может быть настроен на срабатывание при различных значениях тока, времени или и того, и другого, в пределах заданного диапазона”.”

Автоматические выключатели с фиксированными настройками имеют параметры защиты, установленные на постоянной основе во время производства. Например, стандартный 100A автоматический выключатель (MCB) сработает примерно при 100A в условиях перегрузки и при фиксированном множителе (обычно в 5-10 раз превышающем номинальный ток) при коротких замыканиях. Эти настройки нельзя изменить без замены всего автоматического выключателя.

Автоматические выключатели с регулируемыми настройками, обычно встречаются в автоматические выключатели в литом корпусе (MCCB) и воздушных автоматических выключателях (ACB), оснащены механизмами - либо механическими дисками, электронными элементами управления, либо сменными рейтинговыми заглушками - которые позволяют изменять пороги срабатывания и временные характеристики. Эта гибкость позволяет использовать один размер корпуса автоматического выключателя для нескольких применений с различными требованиями к защите.

Ключевые различия с первого взгляда

| Характеристика | Автоматический выключатель с фиксированными настройками | Автоматический выключатель с регулируемыми настройками |

|---|---|---|

| Ток отключения | Заводская установка, не регулируется | Регулируется в пределах указанного диапазона (например, 0,4-1,0 × In) |

| Задержка времени | Фиксированная тепловая кривая | Регулируемые задержки по времени и кратковременные задержки |

| Мгновенное срабатывание | Фиксировано при 5-10-кратном номинале | Регулируется от 2 до 40-кратного номинала (в зависимости от модели) |

| Типовые применения | Бытовые цепи, освещение, простые нагрузки | Двигатели, промышленное оборудование, системы, критичные к координации |

| Стоимость | Более низкая первоначальная стоимость | На 30-50% выше стоимость |

| Гибкость | Требуется замена для разных настроек | Один автоматический выключатель обслуживает несколько приложений |

| Сложность | Простота в эксплуатации | Требуются технические знания для правильной регулировки |

| Общие типы | MCB (6-125A) | MCCB (100-2500A), ACB (800-6300A) |

Типы регулируемых настроек в автоматических выключателях

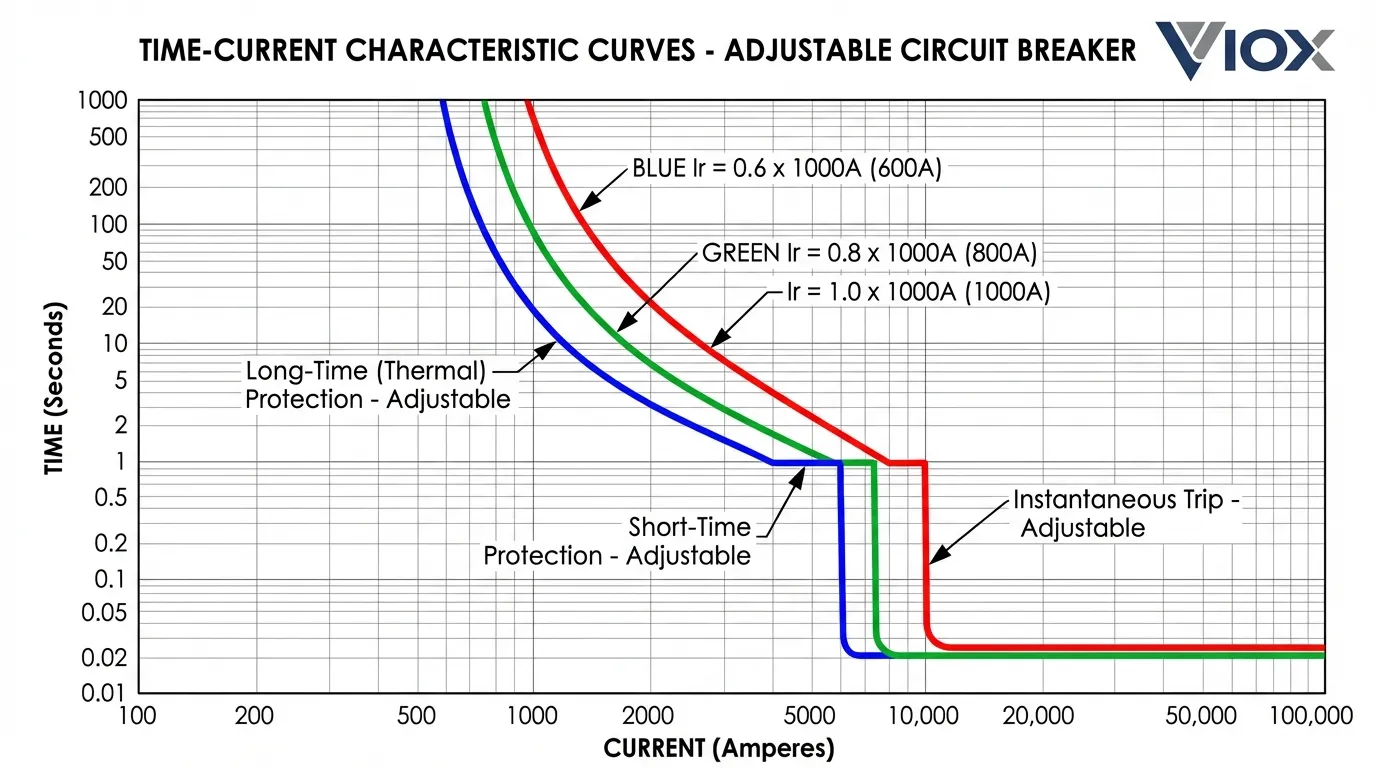

Современные регулируемые автоматические выключатели предлагают три основные функции защиты, каждая из которых имеет свои возможности регулировки. Понимание этих настроек имеет решающее значение для правильного применения и координации системы.

1. Защита от перегрузки по времени (тепловая)

Функция: Защищает от устойчивых перегрузок по току, которые могут повредить кабели, шины и подключенное оборудование из-за чрезмерного нагрева.

Параметры регулировки:

- Настройка тока (Ir): Обычно регулируется от 0,4 до 1,0 раза от номинального тока автоматического выключателя (In)

- Пример: Автоматический выключатель на 1000A можно установить в любом месте от 400A до 1000A

- Позволяет согласовать автоматический выключатель с фактическими требованиями нагрузки

- Временная задержка (tr): Регулируется от 60 до 600 секунд

- Определяет, как долго автоматический выключатель выдерживает перегрузку по току перед срабатыванием

- Использует обратно-временную характеристику: более высокая перегрузка по току = более быстрое срабатывание

Практическое применение: Если на вашем предприятии установлен MCCB на 1000A, но фактическая подключенная нагрузка составляет всего 600A, вы можете отрегулировать Ir до 0,6 × 1000A = 600A. Это обеспечивает оптимальную защиту без ложных срабатываний, сохраняя при этом гибкость для увеличения настройки, если вы добавите больше нагрузки в будущем.

2. Защита от кратковременного превышения тока

Функция: Обеспечивает защиту от временных перегрузок по току, которые превышают нормальные рабочие уровни, но ниже величин короткого замыкания. Эта настройка имеет решающее значение для селективной координации.

Параметры регулировки:

- Уставка кратковременного тока (Isd): Регулируется от 1,5 до 10 раз Ir

- Пример: При Ir = 600A уставка кратковременного тока может варьироваться от 900A до 6000A

- Кратковременная задержка (tsd): Доступно два режима

- Фиксированное время: От 0,05 до 0,5 секунды

- I²t Рампа: От 0,18 до 0,45 секунды (обратно-зависимая характеристика)

Почему это важно: Кратковременная задержка позволяет нижестоящим автоматическим выключателям отключать повреждения первыми, предотвращая ненужные отключения в незатронутых частях вашего объекта. Например, если происходит повреждение в ответвленной цепи, кратковременная задержка на главном автоматическом выключателе дает время ответвленному автоматическому выключателю сработать, поддерживая питание других цепей.

3. Мгновенная защита (от короткого замыкания)

Функция: Обеспечивает немедленную защиту от сильных токов короткого замыкания без преднамеренной задержки (обычно <50 миллисекунд).

Параметры регулировки:

- Уставка мгновенного срабатывания (Ii): Регулируется от 2 до 40 раз Ir (в зависимости от типа автоматического выключателя)

- Некоторые автоматические выключатели имеют фиксированные мгновенные уставки (распространены в небольших MCCB)

- Более крупные автоматические выключатели с электронными расцепителями предлагают более широкие диапазоны регулировки

Критическое соображение: Установка слишком низкой уставки мгновенного срабатывания может вызвать ложные срабатывания во время пуска двигателя или броска тока трансформатора. Установка слишком высокой уставки может ухудшить защиту. Оптимальная уставка зависит от доступного тока короткого замыкания в месте установки автоматического выключателя и требований к координации с вышестоящими/нижестоящими устройствами.

4. Защита от замыканий на землю (дополнительная функция)

Функция: Обнаруживает и прерывает токи замыкания на землю, которые могут вызвать пожары или повреждение оборудования.

Параметры регулировки:

- Уставка срабатывания по току замыкания на землю (Ig): Регулируется от 20% до 70% от номинального тока автоматического выключателя

- Временная задержка срабатывания по току замыкания на землю: Обычно 0,1 с, 0,2 с или 0,4 с

Приложение: Необходима для систем, где замыкания на землю могут не генерировать достаточный ток для срабатывания стандартной защиты от перегрузки по току, особенно в системах с глухим заземлением или там, где требуется снижение опасности возникновения дугового пробоя.

Как работают регулируемые автоматические выключатели: Технологии расцепителей

Термомагнитные расцепители (традиционные)

Тепловой элемент (Защита от перегрузки):

- Использует биметаллическую полосу, которая нагревается от протекающего тока

- По мере увеличения тока полоса изгибается из-за разного теплового расширения

- Когда перегрузка по току сохраняется, полоса изгибается достаточно, чтобы освободить механизм расцепления

- Регулировка обычно осуществляется с помощью диска, который изменяет механический рычаг или натяжение пружины

- Точность: Полоса допуска ±20% (обусловлена термической физикой)

Магнитный элемент (Мгновенная защита):

- Электромагнитная катушка генерирует магнитную силу, пропорциональную току

- Когда ток превышает пороговое значение, магнитная сила преодолевает натяжение пружины

- Мгновенно освобождает механизм расцепления

- Регулировка осуществляется путем изменения положения катушки, воздушного зазора или натяжения пружины

- Время отклика: <50 миллисекунд

Ограничения:

- Зависимость от температуры (температура окружающей среды влияет на тепловой элемент)

- Ограниченная точность регулировки

- Отсутствие возможности кратковременной задержки в базовых моделях

- Не может предоставлять расширенные функции, такие как измерение или связь

Электронные расцепители (современные)

Принцип работы:

- Трансформаторы тока (ТТ) измеряют ток в каждой фазе

- Микропроцессор непрерывно анализирует формы тока

- Сравнивает измеренные значения с запрограммированными кривыми отключения

- Приводит в действие механизм отключения при обнаружении аварийных условий

- Настройки конфигурируются через цифровой интерфейс, DIP-переключатели или программное обеспечение

Преимущества:

- Высокая точность: Точность ±5% во всем диапазоне рабочих температур

- Независимость от температуры: Цифровая обработка устраняет температурный дрейф

- Комплексная защита: Функции L-S-I-G (Длительная, Кратковременная, Мгновенная, Защита от замыканий на землю)

- Дополнительные возможности: Истинное среднеквадратичное измерение, фильтрация гармоник, мониторинг нагрузки

- Коммуникация: Варианты подключения Modbus, Profibus или Ethernet

- Регистрация данных: Записывает события отключения, профили нагрузки и данные о качестве электроэнергии

Методы регулировки:

- Поворотные диски: Физические диски с цифровым кодированием

- DIP-переключатели: Двоичные переключатели для дискретных значений настроек

- ЖК-интерфейс: Встроенный дисплей с навигацией по меню

- Конфигурация программного обеспечения: Программирование на ПК через USB или сетевое соединение

Регулируемые автоматические выключатели типа A и типа B: Понимание классификаций UL

Стандарт UL (Underwriters Laboratories) определяет две категории регулируемых автоматических выключателей на основе их возможностей регулировки в полевых условиях. Понимание этого различия имеет решающее значение для соответствия требованиям и правильного применения.

Автоматические выключатели с регулируемыми характеристиками, тип A

Определение: Могут быть многократно отрегулированы в полевых условиях для всех изменяемых характеристик без ограничений.

Основные характеристики:

- Неограниченная регулировка вверх или вниз в пределах указанного диапазона

- Маркируются с указанием номинального тока и диапазона регулировки (например, “800A” с “0.5-1.0 × 800A”)

- Обычно встречаются в автоматических выключателях с электронными расцепителями

- Требуют надлежащих инструментов и обучения для регулировки

- Должны быть маркированы для указания возможности регулировки

Типичная маркировка: “800A РЕГУЛИРУЕМЫЙ 400-800A”

Варианты использования:

- Промышленные объекты с изменяющимися профилями нагрузки

- Оборудование, требующее частой реконфигурации

- Приложения, где оптимизация нагрузки является непрерывным процессом

- Системы, где ожидается будущее расширение

Автоматические выключатели с регулируемыми характеристиками, тип B

Определение: После регулировки на определенный номинальный ток, не могут быть отрегулированы в полевых условиях на более высокое значение (могут быть отрегулированы только в меньшую сторону или возвращены к исходному).

Основные характеристики:

- Односторонняя регулировка (только вниз от максимальной настройки)

- Предотвращает непреднамеренное завышение номинала защиты

- Часто использует механические упоры или храповые механизмы

- Может потребоваться заводской сброс для увеличения настроек

- Более распространены в тепловых-магнитных расцепителях

Обоснование безопасности: Предотвращает несанкционированное или случайное увеличение уставок расцепления, которое может поставить под угрозу защиту проводников или нарушить электрические нормы.

Важное замечание: Хотя UL определяет эти категории, обозначение “Тип A” или “Тип B” не обязательно должно быть указано на самом выключателе - это классификация, используемая для целей оценки. Всегда обращайтесь к документации производителя, чтобы понять ограничения регулировки.

Применения: Когда использовать регулируемые автоматические выключатели

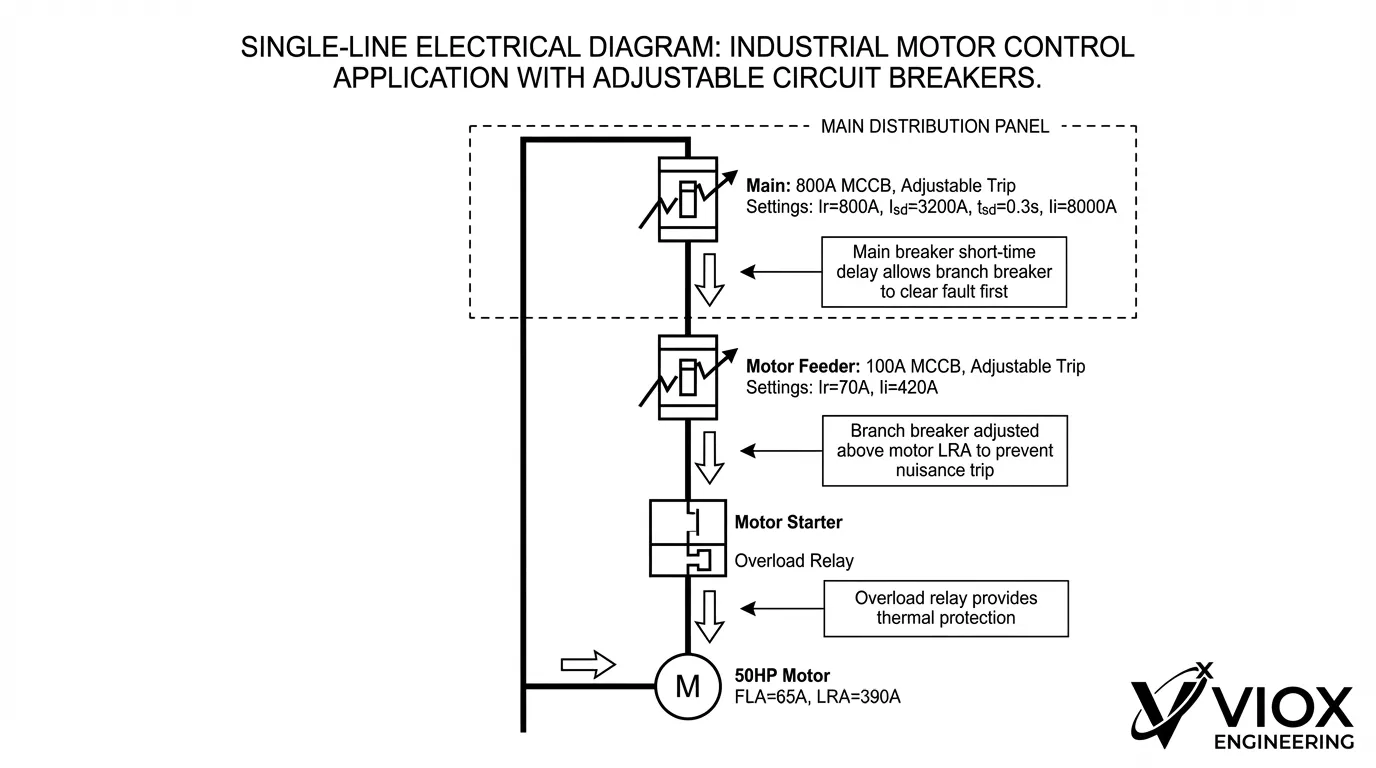

1. Защита и управление двигателями

Задача: Электрические двигатели потребляют ток, в 5-8 раз превышающий их ток полной нагрузки во время запуска (пусковой ток), что может привести к ложным срабатываниям автоматических выключателей с фиксированными уставками.

Решение: Регулируемые автоматические выключатели позволяют:

- Установить защиту от перегрузки по времени на ток полной нагрузки двигателя (FLA)

- Отрегулировать мгновенное расцепление выше тока заклинившего ротора двигателя (LRA)

- Координировать с реле перегрузки двигателя для комплексной защиты

Пример конфигурации:

- Двигатель 50 л.с., 480 В, FLA = 65A, LRA = 390A

- Использовать MCCB на 100A с регулируемым расцепителем

- Установить Ir = 0.7 × 100A = 70A (немного выше FLA)

- Установить Ii = 6 × 70A = 420A (выше LRA, ниже тока короткого замыкания)

Эта конфигурация защищает двигатель и проводники, обеспечивая успешные запуски без ложных срабатываний. Согласно NEC 430.52, автоматические выключатели с обратно зависимой характеристикой могут быть рассчитаны до 250% от FLA двигателя при использовании с отдельной защитой от перегрузки.

2. Селективная координация в распределительных системах

Задача: Когда происходит короткое замыкание, необходимо, чтобы сработал только автоматический выключатель, ближайший к месту повреждения, а не вышестоящие выключатели, которые могут вызвать масштабные отключения.

Решение: Регулируемые настройки выдержки времени короткого замыкания обеспечивают селективную координацию:

- Нижестоящие выключатели: Только мгновенное расцепление (без задержки)

- Выключатели среднего уровня: Выдержка времени короткого замыкания (0.1-0.3 секунды)

- Главные выключатели: Более длительная выдержка времени короткого замыкания (0.3-0.5 секунды)

Реальное воздействие: На производственном предприятии короткое замыкание в цепи одного станка приводит к срабатыванию только этого ответвительного выключателя, а не главного выключателя распределительной панели или вводного выключателя здания. Производство продолжается на всем остальном оборудовании, сводя к минимуму время простоя и потерю дохода.

3. Солнечные фотоэлектрические и возобновляемые энергетические системы

Задача: Солнечные батареи испытывают значительные колебания тока в зависимости от освещенности, температуры и конфигурации системы. Фиксированные выключатели могут не обеспечивать оптимальную защиту как при нормальной работе, так и при коротком замыкании.

Решение: Регулируемые автоматические выключатели постоянного тока позволяют:

- Точную настройку в соответствии с током строки (Isc × 1.56 согласно NEC 690.8)

- Координацию с вышестоящими объединителями и инверторами

- Адаптацию к расширению системы без замены выключателя

Приложение: Блок объединения солнечных батарей с 8 строками, каждая из которых производит 9A Isc, требует защиты при 9A × 1.56 = 14.04A. Регулируемый автоматический выключатель постоянного тока может быть точно настроен на это значение, в то время как фиксированные выключатели потребовали бы завышения до следующего стандартного номинала (15A или 20A), что потенциально может поставить под угрозу защиту.

4. Системы HVAC и здания

Задача: Системы отопления, вентиляции и кондиционирования воздуха имеют разнообразные нагрузки - компрессоры с высоким пусковым током, вентиляторы с непрерывной работой и цепи управления с минимальным током.

Решение: Регулируемые автоматические выключатели позволяют:

- Один тип выключателя для нескольких номиналов оборудования HVAC

- Адаптацию к сезонным колебаниям нагрузки

- Упрощенное управление запасами для бригад технического обслуживания

Экономическая выгода: Вместо хранения 10 различных номиналов автоматических выключателей с фиксированными уставками, предприятия могут поддерживать запас 3-4 размеров корпусов регулируемых автоматических выключателей, снижая затраты на запасные части на 40-60%.

5. Промышленное технологическое оборудование

Задача: Производственное оборудование часто работает в различных режимах (запуск, нормальное производство, высокоскоростная работа) с различными потребностями в токе.

Решение: Регулируемые настройки позволяют оптимизировать для:

- Применения с частотно-регулируемыми приводами (VFD) с гармоническим содержанием

- Сварочное оборудование с прерывистыми импульсами высокого тока

- Периодические процессы с циклическими схемами нагрузки

Как настроить параметры автоматического выключателя: пошаговое руководство

Меры предосторожности (КРИТИЧЕСКИ ВАЖНО)

⚠️ ПРЕДУПРЕЖДЕНИЕ: Настройка параметров автоматического выключателя требует квалифицированного электротехнического персонала. Неправильные настройки могут привести к:

- Недостаточной защите, приводящей к пожару или повреждению оборудования

- Ложным срабатываниям, вызывающим сбои в работе

- Нарушению электротехнических норм и требований страхования

- Травмам персонала от электрической дуги во время работы под напряжением

Перед выполнением каких-либо регулировок:

- Выполните анализ опасности возникновения электрической дуги и используйте соответствующие СИЗ

- Получите одобрение от инженера-электрика объекта или органа, обладающего юрисдикцией

- Ознакомьтесь с инструкцией по эксплуатации от производителя для конкретной модели выключателя

- Задокументируйте существующие настройки перед внесением изменений

- Убедитесь, что выключатель обесточен, если это требуется производителем (некоторые электронные блоки допускают регулировку под напряжением)

Процедура регулировки для тепловых-магнитных расцепителей

Шаг 1: Определите механизмы регулировки

- Регулировка длительной задержки: Обычно это диск или ползунок с маркировкой “Ir” или “Thermal”

- Регулировка мгновенного срабатывания: Диск или кнопки с маркировкой “Ii” или “Magnetic”

- Настройки обычно обозначаются как множители (например, 0,5, 0,6, 0,7…1,0)

Шаг 2: Рассчитайте необходимые настройки

- Длительная задержка (Ir): Установите на 100-125% от максимальной ожидаемой непрерывной нагрузки

- Пример: Непрерывная нагрузка 480A → Установите Ir = минимум 500A

- Мгновенное срабатывание (Ii): Установите выше максимального переходного тока, но ниже минимального тока короткого замыкания

- Должно быть согласовано с нижестоящими устройствами

- Типичный диапазон: 5-10 × Ir для большинства применений

Шаг 3: Выполните регулировку

- Используйте соответствующий инструмент (отвертку, шестигранный ключ или инструмент для регулировки)

- Поверните диски в нужное положение

- Убедитесь, что все три полюса установлены идентично (для многополюсных выключателей)

- Убедитесь, что настройки хорошо видны и соответствуют расчетам

Шаг 4: Задокументируйте и промаркируйте

- Запишите настройки в электротехнической документации объекта

- Нанесите прочную этикетку рядом с выключателем, на которой указано:

- Дата регулировки

- Настройки (Ir, tsd, Ii)

- Инициалы лица, выполнившего регулировку

- Обновите однолинейные схемы и исследования координации

Процедура регулировки для электронных расцепителей

Шаг 1: Получите доступ к интерфейсу программирования

- Модели с ЖК-дисплеем: Используйте кнопки навигации для входа в меню настроек

- Модели с DIP-переключателями: Обратитесь к таблице кодов производителя

- Программируемые с помощью программного обеспечения: Подключите ноутбук через USB или сетевой кабель

Шаг 2: Настройте функции защиты

- Длительная задержка (L): Установите Ir (ток) и tr (время задержки)

- Кратковременная задержка (S): Установите Isd (ток) и tsd (время задержки или кривую I²t)

- Мгновенное срабатывание (I): Установите Ii (порог тока)

- Замыкание на землю (G): Установите Ig (ток) и tg (время задержки), если применимо

Шаг 3: Проверьте настройки

- Электронные блоки обычно имеют режим “просмотра” или “отображения”

- Прокрутите все настройки, чтобы подтвердить правильность значений

- Для некоторых блоков требуется пароль для предотвращения несанкционированных изменений

Шаг 4: Протестируйте (если требуется)

- Первичная токовая инжекция проверяет фактические характеристики срабатывания

- Выполняется квалифицированной испытательной компанией со специализированным оборудованием

- Рекомендуется после первоначального ввода в эксплуатацию и каждые 3-5 лет

Преимущества и ограничения регулируемых автоматических выключателей

Преимущества

1. Гибкость и перспективность

- Возможность адаптации к изменениям нагрузки без замены оборудования

- Один типоразмер выключателя подходит для различных применений

- Адаптация к модификациям или расширениям системы

- Снижение потребности в автоматических выключателях с завышенными характеристиками “на всякий случай”

2. Улучшенная координация системы

- Точная настройка для оптимальной селективности

- Минимизация ложных срабатываний

- Координация с предохранителями, реле и другими автоматическими выключателями

- Снижение опасности возникновения дугового пробоя за счет правильной координации

3. Экономическая эффективность (в долгосрочной перспективе)

- Сокращение запасов запасных частей (меньше типов выключателей для хранения)

- Снижение затрат на замену при изменении нагрузок

- Сокращение времени простоя благодаря более точно подобранной защите

- Упрощенные процедуры обслуживания

4. Улучшенная защита

- Точное соответствие фактическим характеристикам нагрузки

- Улучшенная защита чувствительного оборудования

- Снижение риска перегрева проводников

- Оптимальный баланс между защитой и доступностью

5. Расширенные функции (электронные типы)

- Мониторинг и измерение нагрузки в реальном времени

- Связь с системами управления зданием

- Прогнозируемое обслуживание посредством регистрации данных

- Возможности удаленного мониторинга и управления

Ограничения

1. Более высокая начальная стоимость

- Регулируемые MCCB стоят на 30-50% больше, чем фиксированные типы

- Электронные расцепители увеличивают стоимость выключателя на 50-100%

- Требуются инвестиции в испытательное оборудование для проверки

2. Сложность

- Требуется обученный персонал для правильной регулировки

- Риск неправильных настроек при неправильной конфигурации

- Более сложные процедуры поиска и устранения неисправностей

- Возможность несанкционированных или случайных изменений

3. Требования к техническому обслуживанию

- Настройки следует периодически проверять (каждые 3-5 лет)

- Электронные блоки могут потребовать замены батареи

- Возможен дрейф калибровки в термомагнитных типах

- Документация должна поддерживаться и обновляться

4. Нормативные соображения

- В некоторых юрисдикциях полевые регулировки ограничены

- Может потребоваться утверждение инженера-электрика для изменения настроек

- Страховые требования могут предписывать определенные настройки

- Соответствие нормам должно быть проверено после регулировок

Пример анализа затрат и выгод

Сценарий: Промышленный объект с 20 цепями двигателей в диапазоне от 30А до 100А

Вариант 1: Автоматические выключатели с фиксированным расцепителем

- Стоимость: 20 выключателей × 150 долларов США в среднем = 3000 долларов США

- Инвентарь: Необходимо хранить 5 различных номиналов в качестве запасных = 750 долларов США

- Будущие изменения: Замена выключателя при замене двигателя = 150 долларов США за изменение

- Общая стоимость за 5 лет: 3000 долларов США + 750 долларов США + (оценочно 8 изменений × 150 долларов США) = 4950 долларов США

Вариант 2: Автоматические выключатели с регулируемым расцепителем

- Стоимость: 20 выключателей × 225 долларов США в среднем = 4500 долларов США

- Инвентарь: Хранить 2 типоразмера корпуса в качестве запасных = 450 долларов США

- Будущие изменения: Только регулировка настроек = 0 долларов США за изменение

- Общая стоимость за 5 лет: $4,500 + $450 = $4,950

Точка безубыточности: Примерно 3 изменения нагрузки в течение 5 лет

Дополнительные преимущества регулируемых (не указано выше):

- Сокращение времени простоя благодаря лучшей координации

- Улучшенная защита оборудования

- Гибкость для будущих неизвестных изменений

Выбор правильного регулируемого автоматического выключателя

Ключевые критерии отбора

1. Номинальное напряжение

- Должен превышать максимальное напряжение системы

- Общие номиналы: 240 В, 480 В, 600 В (AC); 250 В, 500 В, 1000 В (DC)

- Учитывайте переходные процессы напряжения и заземление системы

2. Номинальный ток (размер корпуса)

- Выберите размер корпуса на основе максимальной ожидаемой нагрузки

- Оставьте запас в 20-30% для будущего роста

- Учитывайте снижение номинальных характеристик из-за температуры окружающей среды (обычно эталонное значение 40°C)

3. Отключающая способность (Номинальная отключающая способность по току короткого замыкания)

- Должна превышать доступный ток короткого замыкания в точке установки

- Распространенные номиналы: 10кА, 25кА, 35кА, 50кА, 65кА, 100кА

- Проверьте с помощью исследования короткого замыкания или данных от энергоснабжающей организации

- Более высокие номиналы стоят дороже, но обеспечивают запас прочности

4. Тип расцепителя

- Тепловой-магнитный: Более низкая стоимость, проверенная технология, подходит для большинства применений

- Электронный: Более высокая точность, расширенные функции, требуется для сложной координации

- Учитывайте будущие потребности: связь, измерение, прогнозирующее обслуживание

5. Диапазон регулировки

- Убедитесь, что диапазон регулировки охватывает все предполагаемые сценарии нагрузки

- Типичный диапазон: 0,4-1,0 × номинал корпуса для защиты от перегрузки по времени

- Более широкий диапазон = большая гибкость, но может усложнить настройки

6. Соответствие стандартам

- Северная Америка: UL 489 (MCB/MCCB), UL 1066 (Силовые автоматические выключатели), CSA C22.2

- Международный: IEC 60947-2 (MCCB), IEC 60947-1 (Общие)

- Убедитесь, что выключатель внесен в список/сертифицирован для вашей юрисдикции

7. Факторы окружающей среды

- Диапазон температуры окружающей среды (снижение номинальных характеристик может применяться при температуре выше 40°C)

- Высота над уровнем моря (требуется снижение номинальных характеристик выше 2000 м)

- Влажность, коррозионная атмосфера, вибрация

- Установка внутри или снаружи помещения (степень защиты корпуса)

8. Монтаж и установка

- Фиксированный или выкатной (съемный) тип

- Требования к месту на панели

- Тип и размер клемм

- Доступность вспомогательных контактов и принадлежностей

Сравнение: MCB vs. MCCB vs. ACB Регулируемость

| Характеристика | MCB (Миниатюрный) | MCCB (в литом корпусе) | ACB (Воздушный) |

|---|---|---|---|

| Текущий диапазон | 0,5-125А | 15-2500А | 800-6300А |

| Возможность регулировки | Только фиксированный расцепитель (редкие исключения) | Регулируемый в больших размерах (>100A) | Всегда регулируемый |

| Тип расцепителя | Тепловой-магнитный (фиксированный) | Термомагнитный или электронный | Электронный (продвинутый) |

| Параметры регулировки | Никто | Ir, tr, Ii (в некоторых моделях: Isd, tsd) | Полная L-S-I-G с точным управлением |

| Типовые применения | Жилые, легкие коммерческие | Коммерческое, промышленное применение | Тяжелая промышленность, коммунальное хозяйство, центры обработки данных |

| Диапазон затрат | $10-$100 | $100-$2,000 | $2,000-$20,000+ |

| Стандарты | UL 489, IEC 60898 | UL 489, IEC 60947-2 | UL 1066, IEC 60947-2 |

Распространенные ошибки, которых следует избегать

1. Установка слишком высоких значений регулируемых выключателей

Проблема: Регулировка уставок срабатывания выше допустимой токовой нагрузки проводника для предотвращения ложных срабатываний.

Последствие: Проводники могут перегреться без защиты выключателя, что создает опасность пожара и нарушение норм.

Решение: Если выключатель часто срабатывает при правильных настройках, выясните основную причину:

- Проводники недостаточного сечения для фактической нагрузки

- Чрезмерное падение напряжения, вызывающее более высокий ток

- Неисправность или износ оборудования

- Неправильные расчеты нагрузки

Требования норм: NEC 240.4 требует, чтобы защита от перегрузки по току не превышала допустимую токовую нагрузку проводника (с конкретными исключениями).

2. Игнорирование исследований координации

Проблема: Регулировка одного выключателя без учета влияния на координацию системы.

Последствие: Потеря селективности — вышестоящие выключатели срабатывают при нижестоящих неисправностях, вызывая масштабные отключения.

Решение:

- Выполните исследование координации с использованием анализа время-токовых характеристик

- Систематически регулируйте настройки от нижестоящего к вышестоящему

- Поддерживайте достаточный временной интервал между устройствами (обычно 0,2-0,4 секунды)

- Проверяйте координацию после любых изменений настроек

3. Несогласованные настройки многополюсных выключателей

Проблема: Установка разных значений на каждом полюсе трехфазного выключателя.

Последствие: Автоматический выключатель может сработать на одной фазе, в то время как другие остаются замкнутыми, создавая режим однофазной работы, который повреждает двигатели и другое трехфазное оборудование.

Решение: Всегда устанавливайте все полюса идентично, если только производитель специально не разрешает и применение не требует асимметричных настроек (редко).

4. Несвоевременное документирование изменений

Проблема: Изменение настроек без обновления документации или маркировки.

Последствие:

- Будущий обслуживающий персонал не знает о нестандартных настройках

- Расчеты координации становятся неточными

- Поиск неисправностей становится затруднительным

- Невозможно проверить соответствие нормам

Решение: Ведите подробную документацию, включающую:

- Актуальные однолинейные схемы с настройками автоматических выключателей

- Рабочие листы расчета настроек

- Дата и причина каждого изменения

- Инициалы лица, внесшего изменение

- Прочные этикетки на оборудовании

5. Настройка без надлежащей подготовки

Проблема: Неподготовленный персонал пытается настроить сложные электронные расцепители.

Последствие: Неправильные настройки ставят под угрозу защиту, нарушают нормы, аннулируют гарантии, создают угрозу безопасности.

Решение:

- Убедитесь, что настройки регулируют только квалифицированные электрики или инженеры

- Обеспечьте обучение от производителя для сложных электронных блоков

- Разработайте письменные процедуры для изменения настроек

- Требуйте инженерного анализа для критических цепей

6. Пренебрежение влиянием температуры окружающей среды

Проблема: Настройка тепловых магнитных выключателей без учета фактической температуры установки.

Последствие: Выключатели в жарких условиях (рядом с печами, под прямыми солнечными лучами, в плохо вентилируемых корпусах) могут срабатывать преждевременно.

Решение:

- Применяйте коэффициенты снижения номинальных характеристик в зависимости от температуры в соответствии с данными производителя.

- Типичное снижение номинальных характеристик: 1-3% на °C выше эталонной температуры 40°C

- Рассмотрите возможность использования электронных расцепителей для высокотемпературных применений (менее чувствительны к температуре)

- Улучшите вентиляцию корпуса, если это возможно

7. Слишком низкая установка мгновенного расцепителя

Проблема: Установка мгновенного расцепителя ниже пускового тока двигателя или тока намагничивания трансформатора.

Последствие: Ложные срабатывания во время нормального запуска оборудования.

Решение:

- Применение в двигателях: Установите Ii > 1,5 × ток заклинившего ротора

- Применение в трансформаторах: Установите Ii > 12 × номинальный ток трансформатора

- При возможности проверьте фактические измерения пускового тока

- Используйте кратковременную задержку вместо мгновенной для лучшей координации

Обслуживание и тестирование регулируемых автоматических выключателей

Плановый осмотр (ежегодно)

Визуальные проверки:

- Убедитесь, что настройки не изменились (сравните с документацией)

- Проверьте на наличие физических повреждений, коррозии или признаков перегрева

- Убедитесь, что механизмы регулировки перемещаются свободно (если они доступны)

- Убедитесь, что этикетки разборчивы и точны

- Осмотрите клеммы на предмет плотности и изменения цвета

Оперативные проверки:

- Вручную включите выключатель, чтобы убедиться в его плавной работе

- Проверьте механизм защиты от отключения (выключатель должен отключаться, даже если ручка удерживается)

- Проверьте вспомогательные контакты и принадлежности, если они есть

- Убедитесь, что индикаторные лампы или дисплеи работают правильно

Периодическое тестирование (3-5 лет)

Тестирование первичным током:

- Подает фактический ток через выключатель для проверки характеристик отключения

- Проверяет каждую функцию защиты при нескольких уровнях тока

- Проверяет соответствие времени отключения спецификациям производителя

- Выполняется квалифицированной испытательной компанией со специализированным оборудованием

Типичные точки тестирования:

- Длительное время: 150%, 200%, 300% от настройки Ir

- Кратковременное: 100% от настройки Isd (если применимо)

- Мгновенное: 100% от настройки Ii

- Замыкание на землю: 100% от настройки Ig (если применимо)

Критерии приемлемости:

- Время отключения в пределах допустимого диапазона производителя (обычно ±20% для тепловых магнитных, ±5% для электронных)

- Все полюса отключаются одновременно (в течение 1 цикла)

- Отсутствие видимых повреждений или перегрева во время испытания

Тестирование вторичным током (Электронные расцепители):

- Проверка электроники расцепителя без пропускания большого тока через выключатель

- Проверяет точность трансформаторов тока и логику расцепителя

- Может выполняться чаще, чем первичная проверка током

Калибровка и регулировка

Когда необходима калибровка:

- Результаты испытаний выходят за пределы допустимого диапазона

- Выключатель подвергался воздействию высокого тока короткого замыкания

- Тепловые-магнитные расцепители после 10+ лет эксплуатации

- Электронные расцепители в соответствии с рекомендациями производителя (обычно 5-10 лет)

Процесс калибровки:

- Должен выполняться производителем или авторизованным сервисным центром

- Требуется специализированное оборудование и обучение

- Может быть экономически выгоднее заменить старые выключатели

- Документируйте дату калибровки и результаты

Ведение записей

Ведите записи о:

- Результаты первоначальных приемочных испытаний

- Все результаты периодических испытаний с указанием даты и техника

- Любые изменения настроек с обоснованием

- Мероприятия по техническому обслуживанию (очистка, затяжка и т. д.)

- Операции при коротком замыкании (дата, тип, отключил ли выключатель короткое замыкание)

Рекомендуемая документация:

- Паспорта выключателей с серийными номерами

- Время-токовые характеристики с отмеченными настройками

- Отчеты об испытаниях от квалифицированной испытательной компании

- Журнал технического обслуживания для каждого выключателя

Часто задаваемые вопросы (FAQ)

В: Могу ли я регулировать автоматический выключатель, когда он находится под напряжением?

О: Это зависит от типа выключателя и спецификаций производителя. Многие электронные расцепители позволяют регулировать настройки под напряжением через свой интерфейс, поскольку регулировка является чисто цифровой. Однако тепловые-магнитные выключатели обычно требуют обесточивания для обеспечения безопасности, поскольку регулировка включает в себя перемещение механических компонентов. Всегда обращайтесь к руководству по эксплуатации производителя и соблюдайте надлежащие процедуры блокировки/маркировки. Анализ опасности возникновения электрической дуги и соответствующие СИЗ требуются для любых работ на оборудовании под напряжением.

В: Как узнать, регулируется ли мой автоматический выключатель?

О: Ищите следующие индикаторы: (1) Диски регулировки, кнопки или цифровой интерфейс, видимые на передней панели выключателя или расцепителя, (2) Маркировки, такие как “РЕГУЛИРУЕМЫЙ” или диапазон, например “400-800A” на паспортной табличке, (3) Номер модели, указывающий на регулируемый тип (см. каталог производителя), (4) Наличие электронного расцепителя (большинство из них регулируются). Если вы не уверены, проверьте техническое описание производителя для вашей конкретной модели. Обратите внимание, что большинство MCB (миниатюрных автоматических выключателей) до 100A имеют только фиксированный расцепитель.

В: В чем разница между регулируемым расцепителем и взаимозаменяемым расцепителем?

A: Регулируемый расцепитель означает, что вы можете изменять настройки расцепителя (значения тока и времени) в пределах указанного диапазона с помощью дисков, переключателей или программирования. Взаимозаменяемый расцепитель означает, что вы можете физически снять и заменить весь расцепитель другим номиналом. Взаимозаменяемые расцепители предлагают еще большую гибкость — вы можете заменить расцепитель на 600 А расцепителем на 800 А в той же раме выключателя, — но они дороже и обычно встречаются только в более крупных силовых выключателях. Некоторые выключатели предлагают обе функции: взаимозаменяемые расцепители, которые также регулируются.

В: Аннулирует ли регулировка моего автоматического выключателя гарантию или сертификацию UL?

О: Нет, если это сделано правильно. Регулируемые автоматические выключатели разработаны и сертифицированы UL специально для регулировки в полевых условиях в пределах указанного диапазона. Сертификация UL охватывает весь диапазон регулировки. Однако гарантия может быть аннулирована, если: (1) Настройки регулируются неквалифицированным персоналом, (2) Регулировки выполняются за пределами указанного диапазона, (3) Во время регулировки возникают физические повреждения, (4) Не используются надлежащие инструменты. Всегда следуйте инструкциям производителя и ведите документацию по регулировкам.

В: Как часто следует проверять или перекалибровывать настройки регулируемого автоматического выключателя?

A: Верификация (проверка соответствия настроек документации): Ежегодно во время плановых проверок. Тестирование (проверка фактической работы расцепителя): Каждые 3-5 лет посредством первичной проверки током или после любого случая высокого тока короткого замыкания. Перекалибровка (регулировка внутренних компонентов для восстановления точности): Только в том случае, если результаты испытаний выходят за пределы допустимого диапазона, обычно через 10+ лет для тепловых-магнитных типов или в соответствии с графиком производителя для электронных типов. Критически важные приложения (больницы, центры обработки данных, системы жизнеобеспечения) могут потребовать более частых испытаний в соответствии с NFPA 70B или требованиями страхования.

В: Могу ли я использовать регулируемый автоматический выключатель в жилом щитке?

О: Как правило, нет. Жилые щитки (центры нагрузки) предназначены для вставных миниатюрных автоматических выключателей (MCB), которые почти всегда имеют фиксированный расцепитель с номиналом 15-125 А. Регулируемые автоматические выключатели обычно представляют собой литые корпуса (MCCB) или воздушные автоматические выключатели (ACB) с болтовым креплением, используемые в коммерческих и промышленных щитах. Существуют редкие исключения — в некоторых элитных жилых помещениях используются небольшие регулируемые MCCB, — но стандартные жилые щитки не подходят для них. Кроме того, NEC и местные нормы могут ограничивать использование регулируемых выключателей в жилых помещениях из-за возможности неправильной регулировки неквалифицированными лицами.

В: Что произойдет, если я установлю слишком низкое значение регулируемого выключателя?

О: Установка слишком низкого значения тока отключения приведет к ложным срабатываниям во время нормальной работы. Выключатель будет прерывать подачу питания без необходимости, когда нагрузка достигнет нормального рабочего уровня, что приведет к остановке оборудования и сбоям в работе. Например, если вы установите выключатель на 50 А, но подключенная нагрузка регулярно потребляет 60 А во время нормальной работы, выключатель будет срабатывать повторно. Решение состоит в том, чтобы пересчитать правильную настройку на основе фактических требований к нагрузке (обычно 100-125% от максимальной непрерывной нагрузки), убедиться, что пропускная способность проводника достаточна, и отрегулировать соответствующим образом.

В: Требуют ли регулируемые автоматические выключатели специальных процедур установки?

О: Физическая установка такая же, как и у выключателей с фиксированным расцепителем того же типа — надлежащее крепление, моменты затяжки клемм и требования к зазорам. Однако регулируемые выключатели требуют дополнительных шагов: (1) Первоначальная конфигурация: Настройки должны быть рассчитаны и отрегулированы перед подачей напряжения, (2) Документация: Настройки должны быть записаны и помечены, (3) Проверка координации: Настройки должны быть проверены на соответствие исследованию координации системы, (4) Приемочные испытания: Многие спецификации требуют первоначальных испытаний расцепителя для проверки правильности работы. В некоторых юрисдикциях требуется утверждение настроек инженером-электриком перед подачей напряжения.

В: Могут ли регулируемые автоматические выключатели помочь снизить опасность возникновения электрической дуги?

О: Да, при правильном применении. Регулируемые выключатели с настройками короткой задержки могут быть сконфигурированы для “режима обслуживания” во время сервисных работ — временно уменьшая короткую задержку до нуля (только мгновенное отключение), что значительно снижает энергию падающей электрической дуги. Некоторые электронные расцепители имеют специальный переключатель “режима обслуживания”. Кроме того, надлежащая координация с использованием регулируемых настроек может сократить время отключения короткого замыкания, что напрямую снижает энергию электрической дуги (E = P × t). Однако снижение опасности возникновения электрической дуги требует всестороннего анализа и должно выполняться квалифицированными инженерами в соответствии с NFPA 70E и IEEE 1584.

Заключение: Правильный выбор для вашего приложения

Регулируемые автоматические выключатели представляют собой значительный прогресс в технологии электрической защиты, предлагая гибкость, точность и экономичность, которые не могут сравниться с выключателями с фиксированным расцепителем. Однако они не являются правильным выбором для каждого приложения.

Выбирайте регулируемые автоматические выключатели, когда:

- Условия нагрузки меняются или ожидается их изменение

- Требуется точная координация с другими защитными устройствами

- Пусковые токи двигателя или оборудования вызывают ложные срабатывания выключателей с фиксированным расцепителем

- Предполагается расширение системы в будущем

- Необходимы расширенные функции (измерение, связь)

- Приоритетами являются консолидация запасов и упрощение технического обслуживания

Используйте автоматические выключатели с фиксированными уставками, когда::

- Нагрузка стабильна и четко определена

- Простое бытовое или небольшое коммерческое применение

- Бюджетные ограничения значительны

- Квалифицированный персонал для регулировки отсутствует

- Нормы или требования страхования предписывают фиксированную защиту

Ключом к успешному применению регулируемых автоматических выключателей является правильный выбор, корректная начальная конфигурация, тщательная документация и периодическая проверка. При соблюдении этих элементов регулируемые выключатели обеспечивают превосходную защиту, эксплуатационную гибкость и долгосрочную ценность.

На сайте VIOX Electric, Мы производим широкий спектр устройств защиты цепей, включая регулируемые MCCB как с термомагнитными, так и с электронными расцепителями. Наша команда инженеров может помочь с правильным выбором, исследованиями координации и технической поддержкой, чтобы ваша система распределения электроэнергии обеспечивала оптимальную защиту и надежность.

Для получения дополнительной информации о выборе и применении автоматических выключателей ознакомьтесь со следующими ресурсами:

- Что такое автоматический выключатель в литом корпусе (MCCB)?

- Типы автоматических выключателей

- Как выбрать MCCB для панели

- Характеристики автоматических выключателей: ICU, ICS, ICW, ICM

- Понимание характеристик срабатывания автоматических выключателей

- MCB vs MCCB: Понимание ключевых различий

- Структура выбора защиты цепи: руководство из 5 шагов

- Как читать паспортные таблички MCCB для обеспечения электробезопасности

- Контактор против пускателя двигателя

- Что такое тепловые реле перегрузки?