当电气系统发生灾难性故障时,其损害可能是毁灭性的——设备烧毁、火灾隐患以及昂贵的维修费用。而预防这些灾难的核心在于一个简单却关键的部件:保险丝座。理解 保险丝座的工作原理 不仅是一项技术知识,更是每位电工、汽车技师和DIY爱好者必须掌握的重要安全信息。.

保险丝座远不止是一个安装装置。它是一个精密设计的部件,能确保可靠的电气连接、提供环境保护,并在发生过流事件时实现安全的保险丝更换。无论您是在处理汽车电气系统、船舶安装还是家庭布线项目,了解保险丝座的功能都将帮助您构建更安全、更可靠的电气系统。.

什么是保险丝座?为何它至关重要?

ກ ຜູ້ຖືຟິວ 保险丝座是一种专门设计用于在电路中安全安装并电气连接保险丝的保护装置。虽然保险丝通过达到危险电流时熔断来提供实际的过流保护,但保险丝座是保险丝与电气系统之间的关键接口。.

ຫນ້າທີ່ຕົ້ນຕໍຂອງການຖື fuse ປະກອບມີ:

- ການຕິດຕັ້ງທີ່ປອດໄພ安全固定:防止保险丝因振动而松动或移位,从而避免间歇性连接或完全电路故障。.

- 可靠的电气连接:通过精密设计的接触点确保电流稳定传输,最大限度地减少电阻和热量积聚。.

- ການປົກປ້ອງສິ່ງແວດລ້ອມ环境保护:保护保险丝免受湿气、灰尘、腐蚀及其他可能影响性能的环境因素侵害。.

- 安全可操作性:便于保险丝检查和更换,无需用户接触危险电压或拆卸电路。.

若没有合适的保险丝座,即使最高质量的保险丝也无法提供可靠保护。不良连接会产生热点、导致电压下降,或在过流情况下阻碍保险丝正常运作。.

保险丝座如何工作?完整机制解析

ຫຼັກການປະຕິບັດການພື້ນຖານ

ຄວາມເຂົ້າໃຈ 保险丝座的工作原理 需要审视从电路输入到输出的完整电流路径。当电流流经正确安装的保险丝座时,会遵循以下精确顺序:

- Current Entry: Electrical current enters the fuse holder through the input terminal, which is typically connected to the power source or upstream circuit.

- Terminal Contact: The current flows from the terminal through carefully designed contact surfaces that grip the fuse end caps.

- Fuse Path: Current passes through the fuse element itself, where the protective function occurs.

- Exit Contact: After passing through the fuse, current flows through the output contact to the exit terminal.

- Circuit Completion: The current continues to the protected load or downstream circuit components.

This seemingly simple process requires precise engineering to ensure low resistance connections, proper heat dissipation, and reliable contact pressure under various environmental conditions.

Key Components of a Fuse Holder

Every fuse holder contains several critical components that work together to provide reliable operation:

- ສະຖານີ: These serve dual purposes—accepting incoming current from the circuit and delivering it back to the circuit after passing through the fuse. Terminals are typically made from copper alloys with plating finishes like tin or silver to prevent corrosion and ensure optimal conductivity.

- ຕິດຕໍ່ພົວພັນ: The most critical component, contacts physically engage with the fuse end caps to create the electrical connection. These are often designed as spring clips, clamps, or sockets that provide consistent pressure and accommodate slight variations in fuse dimensions.

- ທີ່ຢູ່ອາໄສ: The outer shell provides mechanical protection, environmental sealing, and electrical insulation. Materials range from plastic for basic applications to metal or ceramic for high-temperature or harsh environment uses.

- Mounting System: Depending on the type, this includes PCB mounting pins, panel mounting threads, wire attachment points, or inline connection points.

Step-by-Step Operation Process

The operational sequence of a fuse holder during normal and fault conditions demonstrates its critical safety role:

- ການດໍາເນີນງານປົກກະຕິ: Current flows smoothly through the holder’s terminals and contacts to the fuse element. Properly designed holders maintain low resistance connections that generate minimal heat, ensuring efficient power transfer and long component life.

- Overcurrent Detection: When dangerous current levels occur, the fuse element begins to heat up. The holder must maintain reliable contact during this critical period while protecting surrounding components from excessive heat.

- Circuit Interruption: As the fuse element melts and creates an arc, the holder’s design must safely contain this arc until it extinguishes, preventing damage to the holder itself and surrounding equipment.

- Post-Fault Safety: After fuse operation, the holder must clearly indicate the blown fuse condition and allow for safe replacement without exposing users to hazardous voltages.

Types of Fuse Holders and How They Work

The electrical industry uses several distinct fuse holder designs, each optimized for specific applications and installation requirements.

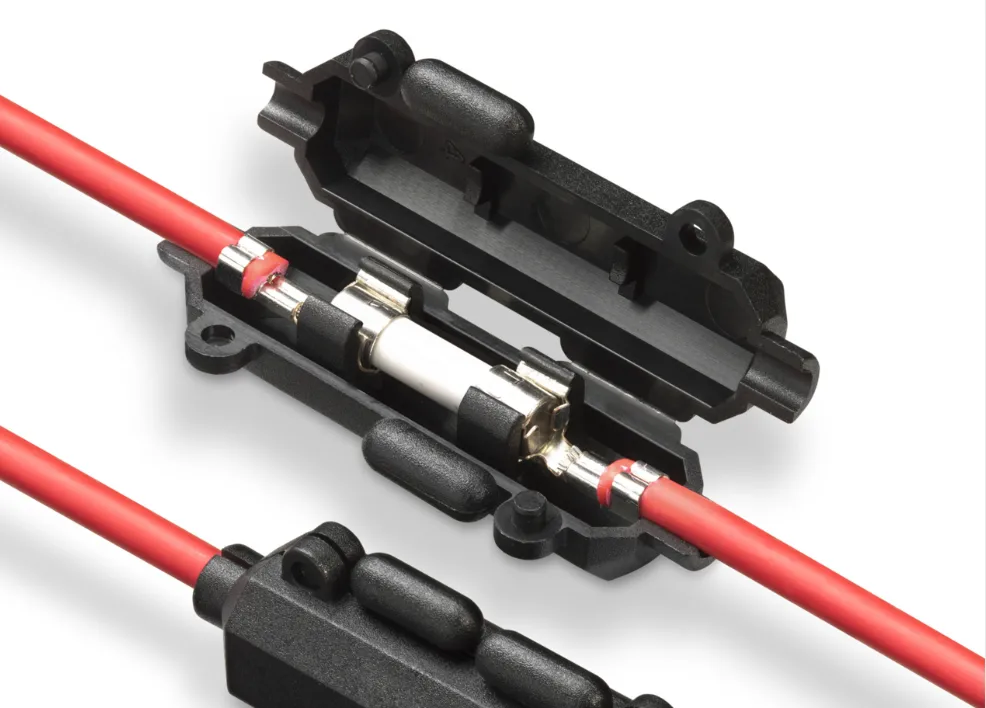

Inline Fuse Holders

Inline fuse holders represent the most common type found in automotive and marine applications. These holders install directly into wire harnesses, creating a protected junction point along the current path.

The working mechanism involves two wire connection points—input and output—with the fuse creating the bridge between them. When installed properly, inline holders provide excellent protection for branch circuits while maintaining the flexibility to route protection exactly where needed.

Key advantages include easy installation in existing wiring, excellent environmental sealing options, and the ability to place protection close to potential fault sources. Many inline holders feature transparent or translucent housings that allow visual fuse inspection without disassembly.

DIN Rail Fuse Holders

DIN rail fuse holders are specifically designed for industrial control panel installations using standard DIN rail mounting systems. These holders, including popular series like the RT18, provide professional-grade fuse protection in organized, accessible panel layouts.

The working mechanism involves a spring-loaded mounting system that clips securely onto standard 35mm DIN rails while providing screw terminal connections for reliable field wiring. The RT18 series and similar holders typically feature:

- Modular Design: Individual holders can be mounted side-by-side for multi-circuit protection, with configurations available from 1P to 4P (including 3P+N for three-phase systems)

- ການຕິດຕັ້ງງ່າຍ: Snap-on DIN rail mounting requires no tools for basic installation

- LED Indicator Lights: Built-in visual indicators show fuse status, with some models featuring dual LED systems for enhanced visibility

- ຄວາມສາມາດແຕກສູງ: Professional-grade holders like the RT18 offer breaking capacities up to 100kA at 500VAC, making them suitable for demanding industrial applications

- Multiple Voltage Ratings: Available in AC versions (500VAC/690VAC) and DC versions (up to 1000VDC for photovoltaic applications)

- ລັກສະນະມືອາຊີບ: Uniform mounting creates clean, organized panel layouts that meet industrial standards

ຂໍ້ມູນຈໍາເພາະ (RT18 Series Example):

- Current ratings: 32A, 63A, or 125A depending on model

- Fuse sizes: 10x38mm, 14x51mm, or 22x58mm cartridge fuses

- Compliance: IEC 60269-2 and GB/T 13539.2 standards

- Installation: Standard 35mm DIN rail mounting

- Materials: PA66-V0 flame-retardant plastic housing with copper contacts

DIN rail fuse holders excel in industrial automation, control panels, photovoltaic systems, and commercial electrical installations where organized, maintainable fuse protection is essential. Many incorporate test points, security locks, and modular accessories for enhanced functionality in professional applications.

Panel Mount Fuse Holders

ກະດານ mount ຜູ້ຖື fuse are designed for installation through enclosure walls or control panels, providing accessible fuse replacement while maintaining electrical safety. These holders work by creating a secure mounting interface that isolates the fuse from direct contact while maintaining reliable electrical connections.

The mounting mechanism typically involves threaded components that secure the holder to the panel, with removable caps or carriers that allow fuse access from the front of the panel. This design enables maintenance personnel to replace fuses quickly without opening the main enclosure or exposing themselves to other electrical hazards.

Panel mount holders often incorporate additional safety features like finger-safe designs that prevent accidental contact with live terminals, and some include blown fuse indicators for quick visual status checks.

PCB Fuse Holders (Printed Circuit Board)

PCB fuse holders mount directly to printed circuit boards using surface mount or through-hole techniques. These holders work by providing a compact, secure mounting solution that integrates fuse protection directly into electronic assemblies.

The mechanism relies on precisely positioned contacts that align with the PCB layout to ensure proper electrical connections while maintaining the compact footprint required in modern electronics. Many PCB holders use spring-loaded contacts that accommodate component tolerances while providing consistent connection force.

These holders often incorporate design features that prevent incorrect fuse installation and may include test points for troubleshooting without fuse removal.

Fuse Clips

Fuse clips represent the most economical fuse holder option, providing basic mounting and electrical connection with minimal additional features. They work through simple spring-loaded contacts that grip the fuse end caps while allowing easy insertion and removal.

While lacking the environmental protection and advanced features of enclosed holders, fuse clips offer advantages in applications where cost is critical and environmental conditions are controlled. They’re commonly used in electronics prototyping and temporary installations.

Fuse Holder Installation and Wiring Guide

Safety Precautions Before Installation

Before beginning any fuse holder installation, ensure electrical safety by following these critical precautions:

- ການແຍກພະລັງງານ: Always disconnect power at the source and verify zero energy using appropriate test equipment

- Lockout/Tagout: Follow proper LOTO procedures to prevent accidental re-energization

- ອຸປະກອນປ້ອງກັນສ່ວນບຸກຄົນ: Use appropriate PPE including safety glasses and insulated tools

- Circuit Analysis: Verify the circuit requirements match the fuse holder specifications

Tools and Materials Needed

Successful installation requires proper tools and materials:

- Wire strippers rated for the wire gauge being used

- Crimping tools appropriate for the terminal types

- Multimeter for continuity and voltage verification

- Heat shrink tubing and heat gun for connection protection

- Electrical tape for additional insulation

- Mounting hardware specific to the holder type

ຂັ້ນຕອນການຕິດຕັ້ງຂັ້ນຕອນໂດຍຂັ້ນຕອນ

For Inline Fuse Holders:

- Select the installation location, ensuring adequate clearance for fuse replacement

- Cut the circuit wire at the chosen protection point

- Strip wire ends to the length specified by the holder manufacturer

- Connect wires to the holder terminals using appropriate termination method

- Secure all connections and apply environmental protection as needed

- Install the fuse and verify proper seating

- Test the installation before applying full power

For Panel Mount Holders:

- Mark and drill the mounting hole according to manufacturer specifications

- Install the holder base through the panel opening

- Secure with the provided mounting hardware

- Connect circuit wires to the rear terminals

- Install the fuse carrier and verify smooth operation

- Test the complete assembly

ຄວາມຜິດພາດການຕິດຕັ້ງທົ່ວໄປເພື່ອຫຼີກເວັ້ນການ

- Using undersized wire that creates voltage drop or heating

- Failing to properly torque terminal connections

- Installing fuses with incorrect ratings

- Inadequate environmental sealing in harsh conditions

- Poor strain relief that stresses connections over time

Fuse Holder Applications Across Industries

Automotive Electrical Systems

In automotive applications, fuse holders protect critical systems from overcurrent damage while providing accessible service points. Modern vehicles may contain dozens of fuse holders in multiple locations, each protecting specific circuits like lighting, ignition, fuel injection, or entertainment systems.

Automotive fuse holders must withstand vibration, temperature extremes, and corrosive environments while maintaining reliable operation over the vehicle’s lifetime. Many incorporate color-coding systems and clear labeling to assist technicians during troubleshooting and maintenance.

Marine and Boat Electronics

Marine environments present unique challenges requiring specialized fuse holder designs. Waterproof fuse holders with IP67 or higher ratings protect against saltwater intrusion while maintaining electrical integrity in the constantly moving environment of a boat.

These applications often require tinned copper components and stainless steel hardware to resist corrosion, along with robust sealing systems that maintain protection even when subjected to spray, submersion, or pressure washing.

Home Electrical Installations

Residential applications typically use fuse holders in distribution panels, outdoor equipment, and specialty circuits where traditional circuit breakers aren’t suitable. Home fuse holders must comply with electrical codes while providing safe, accessible protection for household circuits.

Modern home installations increasingly use fuse holders for solar panel systems, electric vehicle charging stations, and other high-current applications where specific fuse characteristics provide better protection than circuit breakers.

Industrial Equipment Protection

Industrial fuse holders protect expensive machinery and process equipment from damage while minimizing downtime during maintenance. These applications often require holders rated for harsh environments, high temperatures, and heavy vibration.

Industrial fuse holders frequently incorporate monitoring systems that provide remote indication of fuse status, allowing maintenance personnel to identify and replace blown fuses quickly during planned maintenance windows.

Choosing the Right Fuse Holder for Your Application

Selecting the optimal fuse holder requires careful consideration of multiple factors:

- ການຈັດອັນດັບປັດຈຸບັນ: The holder must be rated for at least the maximum continuous current expected in the circuit, with appropriate derating for temperature and environmental conditions.

- Voltage Requirements: Voltage ratings must exceed the maximum system voltage with appropriate safety margins. This includes consideration of transient overvoltages that may occur during switching operations.

- ປັດໄຈສິ່ງແວດລ້ອມ: Consider temperature ranges, moisture exposure, chemical exposure, vibration levels, and other environmental stresses that could affect performance.

- Physical Constraints: Mounting space, access requirements, and mechanical constraints may limit holder options and influence the final selection.

- Certification Standards: Applications may require specific certifications like UL 4248 for North America or IEC 60127-6 for international use.

Troubleshooting Common Fuse Holder Issues

Loose Connections and Poor Contact

Symptoms include intermittent operation, voltage drops, and heating at connection points. This often results from inadequate terminal torque, corrosion, or contact wear over time.

Solutions involve cleaning contacts, re-torquing connections to specification, and replacing worn components. Regular inspection and maintenance can prevent most connection problems.

ບັນຫາຄວາມຮ້ອນເກີນ

Excessive heat indicates problems with connections, oversized fuses, or inadequate ventilation. Overheating can cause permanent damage to the holder and surrounding components.

Address overheating by verifying proper fuse ratings, improving ventilation, checking connections, and ensuring the holder is rated for the application’s thermal requirements.

Corrosion and Environmental Damage

Environmental exposure can cause contact corrosion, seal failure, and housing degradation. This is particularly common in marine, automotive, and outdoor applications.

Prevention involves using properly rated holders with appropriate sealing, applying protective coatings where necessary, and implementing regular inspection schedules.

Incorrect Fuse Selection

Using fuses with wrong ratings or characteristics can prevent proper protection or cause nuisance failures. This includes both overcurrent ratings and other characteristics like time-delay curves.

Ensure fuse selection matches both the circuit protection requirements and the holder’s specifications. Consult manufacturer documentation and electrical codes as needed.

Maintenance and Safety Best Practices

Regular maintenance ensures reliable fuse holder operation and extends service life:

- ການກວດກາສາຍຕາ: Check for signs of overheating, corrosion, mechanical damage, or loose connections during routine maintenance.

- ການຢືນຢັນການເຊື່ອມຕໍ່: Periodically check terminal tightness and clean connections as needed to maintain low resistance.

- ການປົກປ້ອງສິ່ງແວດລ້ອມ: Verify sealing integrity and replace gaskets or seals showing signs of deterioration.

- ເອກະສານ: Maintain records of fuse replacements, including ratings and replacement dates, to identify potential circuit problems.

- Safety Compliance: Ensure all work follows applicable electrical codes and safety standards, with proper lockout/tagout procedures.

Future of Fuse Holder Technology

The evolution of electrical systems drives innovation in fuse holder design:

- ການຕິດຕາມອັດສະລິຍະ: Advanced holders incorporate sensors and communication capabilities to provide remote status monitoring and predictive maintenance capabilities.

- Improved Materials: New materials offer better corrosion resistance, higher temperature ratings, and improved electrical performance.

- Integration Features: Modern designs integrate more closely with control systems, providing enhanced diagnostics and system integration capabilities.

- ການຂະຫຍາຍຂະໜາດນ້ອຍ: Ongoing miniaturization enables protection in increasingly compact electronic devices while maintaining full functionality.

ສະຫລຸບ

ຄວາມເຂົ້າໃຈ 保险丝座的工作原理 reveals the sophisticated engineering behind these seemingly simple components. From the precise contact design that ensures reliable current flow to the environmental protection that enables operation in harsh conditions, fuse holders play a critical role in electrical system safety and reliability.

Whether you’re installing automotive accessories, wiring marine electronics, or designing industrial control systems, proper fuse holder selection and installation protects both equipment and personnel from electrical hazards. The key lies in matching the holder’s capabilities to the application’s requirements while following proper installation and maintenance practices.

When working with electrical systems, never compromise on safety or quality. Consult with qualified electrical professionals when in doubt, and always follow applicable codes and standards. Your investment in proper fuse holder technology today prevents costly failures and dangerous situations tomorrow.