When modular contactors fail prematurely in household and light commercial applications, the root cause often traces back to a critical specification error: using an AC-7a rated contactor for an AC-7b application. This seemingly minor distinction—defined by IEC 61095 standards—represents the difference between reliable operation and catastrophic failure when controlling inductive loads like motors, fans, and compressors.

Understanding the technical differences between AC-7a and AC-7b utilization categories isn’t just about compliance—it’s about preventing equipment damage, avoiding costly downtime, and ensuring system longevity. This guide breaks down the engineering fundamentals, failure mechanisms, and selection criteria that every electrical professional needs to master.

What Are AC-7a and AC-7b Utilization Categories?

Utilization categories, standardized by IEC 61095 for household and similar applications, define the electrical load characteristics and switching duty cycles that contactors must withstand. Unlike the more commonly known AC-1 and AC-3 categories (defined in IEC 60947-4-1 for industrial contactors), AC-7a and AC-7b specifically address residential and light commercial equipment with current ratings typically ≤63A.

AC-7a: Slightly Inductive Loads

AC-7a contactors are designed for resistive or slightly inductive loads with power factors ≥0.95. These applications include:

- Resistive heating elements

- Incandescent and LED lighting systems

- Electric ovens and cooktops

- Small power tools (drills, mixers)

- Television and entertainment systems

The key characteristic: minimal inrush current (typically 1.2-1.5× rated current) and negligible arcing during switching operations.

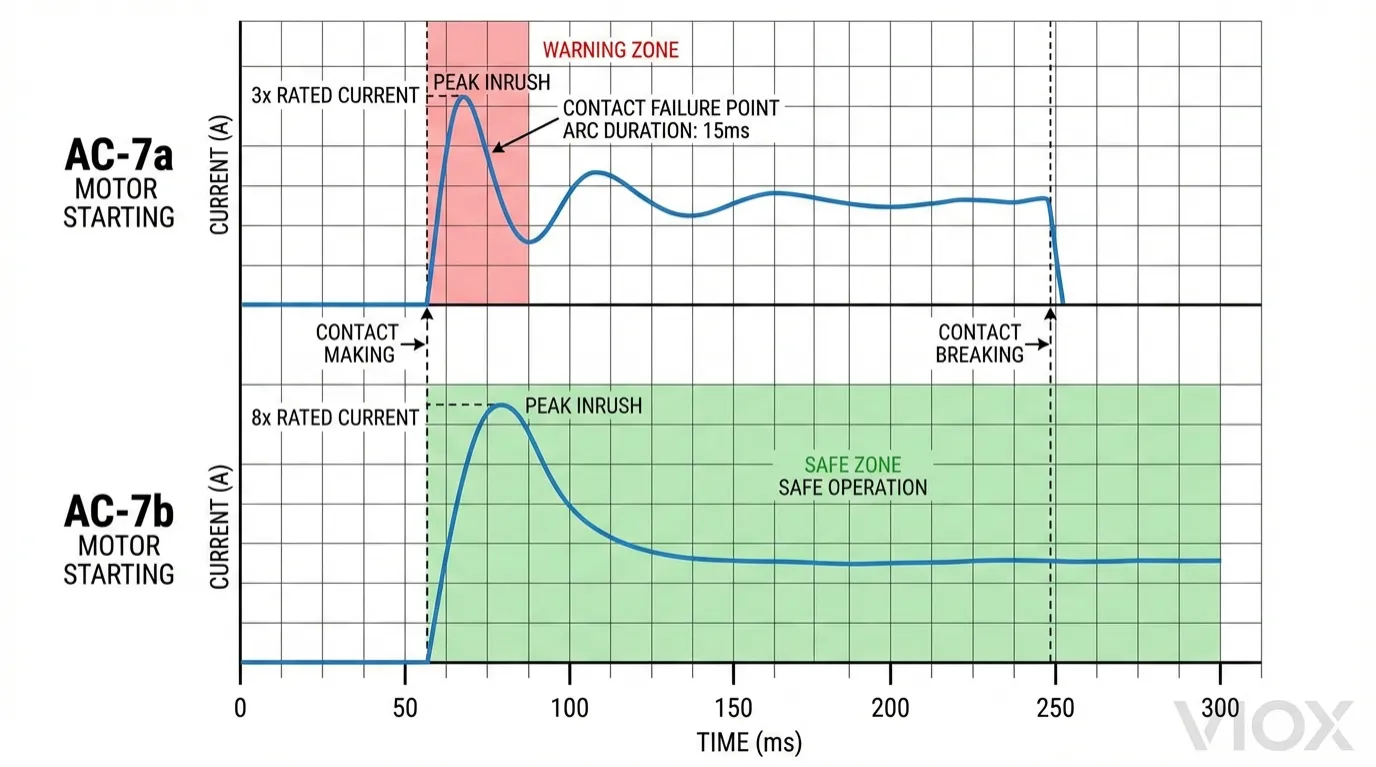

AC-7b: Motor and Rotating Machine Loads

AC-7b contactors handle household motor loads with significant inductive reactance and high starting currents (5-8× rated current). Typical applications:

- Single-phase induction motors

- Fans and ventilation systems

- Central vacuum cleaners

- Washing machines and dryers

- Συμπιεστές ψύξης

- Pool pumps and HVAC equipment

The critical difference: AC-7b contactors must withstand severe electrical stress during motor starting, including high inrush currents, voltage transients, and intense arcing at contact separation.

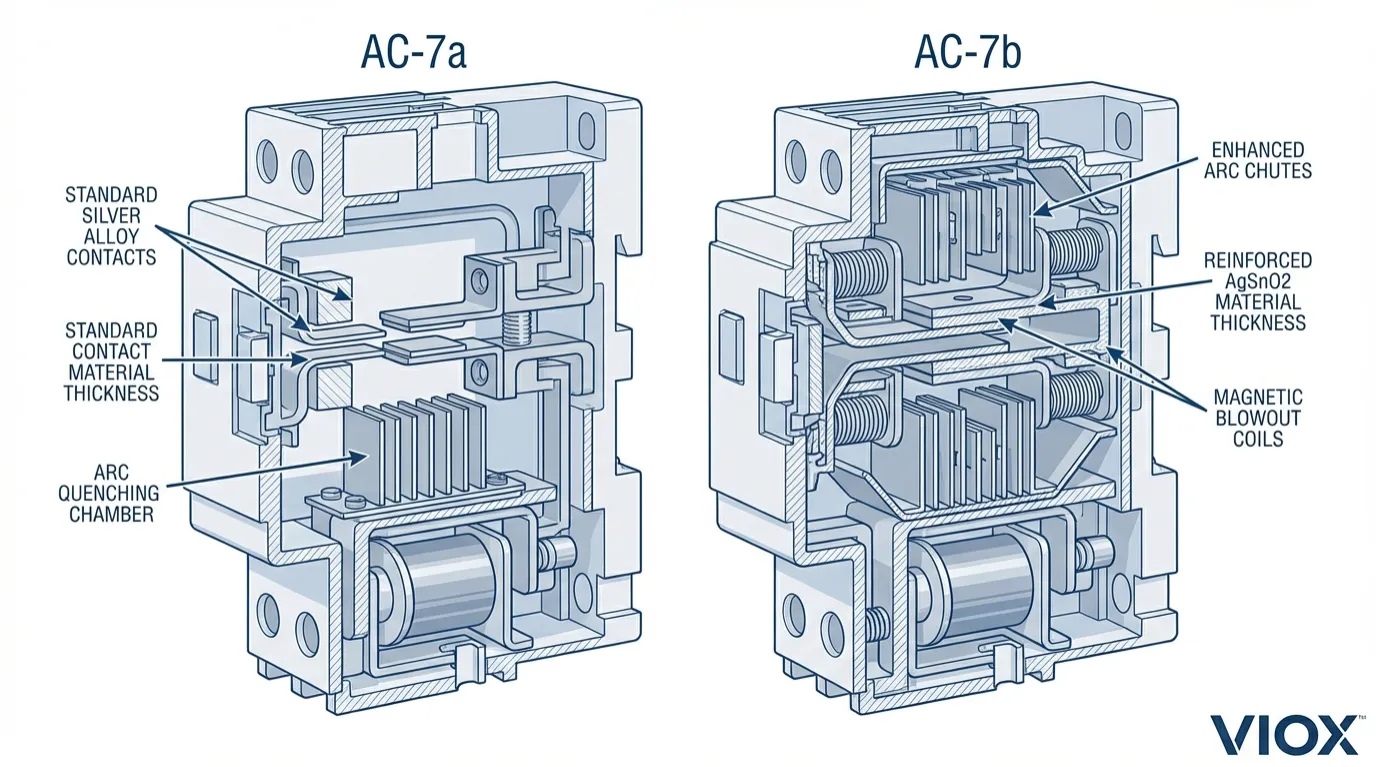

The Critical Differences: AC-7a vs. AC-7b

| Παράμετρος | AC-7a (Slightly Inductive) | AC-7b (Motor Loads) |

|---|---|---|

| Power Factor | ≥0.95 (nearly resistive) | 0.45-0.85 (highly inductive) |

| Ρεύμα Εισροής | 1.2-1.5× rated current | 5-8× rated current |

| Ικανότητα Δημιουργίας | Standard (1.5× Ie) | High (8-10× Ie) |

| Ικανότητα θραύσης | Low arc energy | High arc energy (motor back-EMF) |

| Υλικό επικοινωνίας | Standard silver alloy | AgSnO2 or AgCdO (arc-resistant) |

| Καταστολή τόξου | Minimal requirements | Enhanced arc chutes + magnetic blowout |

| Ηλεκτρική ζωή | 100.000-500.000 λειτουργίες | 50,000-100,000 operations |

| Μηχανική διάρκεια ζωής | 1-10 εκατομμύρια λειτουργίες | 1-5 million operations |

| Τυπική ονομαστική τιμή ρεύματος | Up to 63A | Derated to 25-32A (same frame size) |

| Coil Hold-In Power | Πρότυπο | Higher (to prevent dropout during voltage dips) |

| Συμμόρφωση με τα πρότυπα | IEC 61095 Table 6 | IEC 61095 Table 7 |

Βασική ιδέα: An AC-7b contactor rated at 25A can handle the same motor load that would require a 63A AC-7a contactor—but only the AC-7b design survives the starting transients.

Why AC-7a Contactors Fail on Motor Loads

1. Contact Welding from Inrush Current

When a motor starts, the inrush current (typically 6-8× rated current for 100-300ms) creates a magnetic force between contacts that can exceed the contact spring pressure. In AC-7a contactors with lighter spring tension, this causes:

- Contact bouncing during closure, creating multiple arc strikes

- Micro-welding at contact surfaces from repeated arcing

- Προοδευτική υποβάθμιση until contacts permanently weld closed

Παράδειγμα πραγματικού κόσμου: A 16A AC-7a contactor controlling a 1.5kW (7A) pool pump motor experiences 56A inrush current. The contacts, designed for 24A maximum making capacity (1.5× 16A), suffer immediate damage. After 50-100 starts, the contacts weld shut, causing the motor to run continuously and eventually overheat.

2. Arc Extinction Failure

Motor loads present a lagging power factor (0.45-0.85), meaning current and voltage are out of phase. When the contactor opens:

- Current continues flowing due to motor inductance (back-EMF)

- Arc voltage can reach 2-3× supply voltage

- AC-7a contacts lack sufficient arc chutes and magnetic blowout

- Prolonged arcing erodes contact material and carbonizes insulation

3. Thermal Overload

The higher I²t energy during motor starting heats contacts beyond their thermal design limits. AC-7a contactors typically use:

- Thinner contact material (0.5-1mm vs. 1.5-2mm in AC-7b)

- Lower thermal mass heat sinks

- Standard terminal connections without enhanced cooling

Result: Contact resistance increases, creating a positive feedback loop of heating → oxidation → higher resistance → more heating.

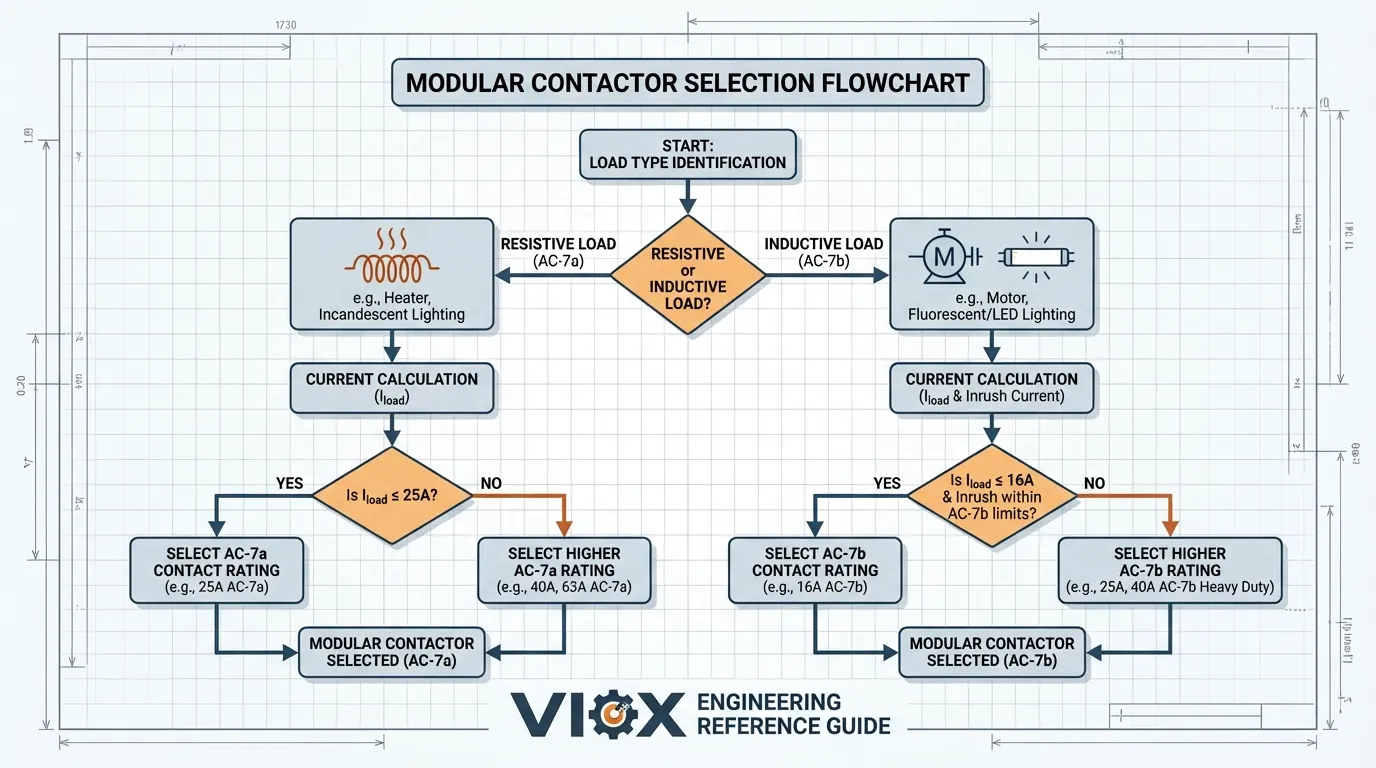

Πώς να επιλέξετε τον σωστό επαφέα

Step 1: Identify Load Characteristics

Use AC-7a for:

- Resistive heaters (power factor >0.95)

- Lighting circuits (LED, fluorescent with PFC)

- Non-motor appliances

- Loads with minimal starting surge

Use AC-7b for:

- Any single-phase motor (fans, pumps, compressors)

- Three-phase motors ≤2.2kW in residential settings

- Loads with starting current >3× rated current

- Equipment with frequent start/stop cycles

Step 2: Calculate Required Current Rating

For AC-7a loads:

For AC-7b motor loads:

But verify: Contactor making capacity ≥ Motor locked rotor current (typically 6-8× FLA)

Παράδειγμα υπολογισμού:

- Motor: 1.1kW, 230V, single-phase

- Full Load Current: 5.5A

- Locked Rotor Current: 33A (6× FLA)

- Required: AC-7b contactor rated ≥7A (5.5 × 1.25)

- Verify making capacity: Must handle 33A inrush

A 16A AC-7b contactor (making capacity ~128A) is appropriate. A 16A AC-7a contactor (making capacity ~24A) would fail immediately.

Step 3: Consider Operational Factors

| Παράγοντας | Επίπτωση στην Επιλογή |

|---|---|

| Duty Cycle | >10 starts/hour requires AC-7b even for “light” motors |

| Θερμοκρασία περιβάλλοντος | >40°C requires derating (typically 0.9× per 10°C) |

| Υψόμετρο | >2000m requires derating (0.95× per 1000m) |

| Τάση πηνίου | Match control circuit voltage; use DC coils for noise immunity |

| Βοηθητικές επαφές | Ensure sufficient NO/NC contacts for interlocking |

Learn more about modular contactor selection

Συνηθισμένα Λάθη και Πώς να τα Αποφύγετε

Mistake #1: Assuming “Higher Amperage = Better”

Λάθος: “I’ll use a 63A AC-7a contactor for a 10A motor—more capacity means more safety.”

Σωστό: A 25A AC-7b contactor is the correct choice. The AC-7a lacks the contact material and arc suppression needed for motor starting, regardless of current rating.

Mistake #2: Ignoring Derating for Mixed Loads

When controlling both resistive and motor loads on the same contactor (e.g., heater + fan), always use the AC-7b rating. The inductive component dominates failure mechanisms.

Παράδειγμα: A bathroom heater with a 2kW heating element (8.7A) and 50W fan motor (0.2A). Total current: 8.9A.

- Λανθασμένο: 16A AC-7a contactor (rated for resistive load)

- Σωστό: 16A AC-7b contactor (derated for motor component)

Mistake #3: Overlooking Frequent Switching

AC-7b contactors are designed for occasional starting (typically <5 starts/minute). Applications requiring frequent on/off cycles (e.g., compressor short-cycling) need:

- Upgraded AC-7b contactor with higher electrical life rating

- Soft-start circuits to reduce inrush current

- Time delay relays to prevent rapid cycling

Upgrading from AC-7a to AC-7b: Practical Considerations

Physical Compatibility

Most modular contactor families offer both AC-7a and AC-7b ratings in the same DIN rail footprint:

| Frame Size | Ονομαστική Τιμή AC-7a | Ονομαστική Τιμή AC-7b | DIN Modules |

|---|---|---|---|

| Μικρό | 25A | 16A | 2 ενότητες |

| Μεσαίο | 40A | 25A | 3 modules |

| Μεγάλο | 63A | 32A | 4 modules |

Retrofit Tip: When replacing a failed AC-7a contactor, the AC-7b equivalent typically fits the same mounting space but requires verification of terminal wire sizing for the derated current.

Ανάλυση κόστους

AC-7b contactors cost approximately 20-40% more than equivalent AC-7a models due to:

- Enhanced contact materials (AgSnO2 vs. standard silver)

- Reinforced arc suppression components

- Higher-grade coil insulation

- Extended testing and certification requirements

Υπολογισμός ROI: The premium pays for itself after the first prevented failure. A typical service call for contactor replacement costs $150-300 in labor alone, plus equipment downtime.

Wiring and Control Integration

Both AC-7a and AC-7b contactors use identical control interfaces:

- Standard coil voltages: 24V, 110V, 230V AC/DC

- Auxiliary contact configurations: 2NO, 2NC, 2NO+2NC

- Compatible with 2-wire and 3-wire control circuits

- DIN rail mounting per IEC 60715

Advanced Topics: Beyond Basic Selection

Coordination with Overload Protection

AC-7b contactors must coordinate with thermal overload relays or motor protection circuit breakers. The contactor’s making capacity must exceed the overload relay’s tripping threshold to prevent nuisance trips during starting.

Recommended coordination:

- Contactor making capacity ≥ 10× motor FLA

- Overload relay trip class: 10A or 20A per IEC 60947-4-1

- Short-circuit protection: Type 2 coordination per IEC 60947-4-1

Coil Suppression for Inductive Loads

When controlling motors, the contactor coil itself becomes an inductive load. Without proper suppression, coil de-energization creates voltage spikes that can damage control circuits. Solutions include:

- RC snubbers (resistor-capacitor networks) across coil terminals

- Varistor (MOV) suppression for transient absorption

- Δίοδοι ελεύθερης κύλισης for DC coils

Learn more about coil suppression techniques

Environmental Derating

Both AC-7a and AC-7b ratings assume standard test conditions (25°C ambient, sea level, pollution degree 2). Real-world installations require derating:

Υποβάθμιση θερμοκρασίας:

- 40°C: 100% rated current

- 50°C: 90% rated current

- 60°C: 80% rated current

Μείωση υψομέτρου:

- 0-2000m: 100% rated current

- 2000-3000m: 95% rated current

- 3000-4000m: 90% rated current

Troubleshooting Failed Contactors

Symptoms of AC-7a Misapplication on Motor Loads

- Συγκόλληση επαφών (contactor won’t open)

- Excessive coil buzzing during motor starting

- Visible arcing or light emission from contactor housing

- Burnt smell or discolored plastic near terminals

- Premature failure (<1000 operations vs. rated 100,000)

Διαγνωστική Διαδικασία

Βήμα 1: Verify load type and current

- Measure actual motor starting current with clamp meter

- Compare to contactor making capacity rating

Βήμα 2: Inspect contact condition

- Check for pitting, erosion, or welding

- Measure contact resistance (should be <1mΩ)

Βήμα 3: Evaluate operating environment

- Ambient temperature, humidity, pollution

- Switching frequency and duty cycle

Βήμα 4: Select appropriate replacement

- Use AC-7b rating for any motor load

- Size for 125% of motor FLA minimum

- Verify making capacity ≥ locked rotor current

Complete contactor troubleshooting guide

Standards and Compliance

IEC 61095:2023

The current standard for modular contactors in household applications defines:

- Utilization categories AC-7a, AC-7b, AC-7c (capacitor switching)

- Test procedures for making/breaking capacity

- Endurance testing requirements (electrical and mechanical life)

- Temperature rise limits and thermal testing

- Short-circuit coordination requirements

Key Change in 2023 Edition: Introduction of AC-7d category for electronic motor loads (VFD-controlled motors), now adopted into IEC 60947-4-1.

Απαιτήσεις Πιστοποίησης

Contactors must carry certification marks for the intended market:

| Περιοχή | Required Marks | Standards Referenced |

|---|---|---|

| Ευρωπαϊκή Ένωση | CE, ENEC | IEC 61095, EN 61095 |

| Βόρεια Αμερική | UL, CSA | UL 60947-4-1, CSA C22.2 |

| Κίνα | ΣΥΜΒΟΎΛΙΟ πολιτιστικής συνεργασίας | GB/T 14048.4 |

| Αυστραλία | SAA, RCM | AS/NZS 60947.4.1 |

VIOX Compliance: All VIOX modular contactors meet IEC 61095 and UL 60947-4-1 standards with third-party certification for global market access.

Βασικά συμπεράσματα

- ✅ AC-7a contactors are designed for resistive or slightly inductive loads (power factor ≥0.95) such as heaters and lighting—they will fail prematurely on motor loads.

- ✅ AC-7b contactors handle household motor loads with high starting currents (5-8× rated current) through reinforced contacts, enhanced arc suppression, and higher making capacity.

- ✅ The current rating alone doesn’t determine suitability—a 63A AC-7a contactor cannot safely control a 10A motor that a 25A AC-7b contactor handles reliably.

- ✅ Motor starting inrush current is the critical selection parameter—verify the contactor’s making capacity exceeds the motor’s locked rotor current (typically 6-8× full load current).

- ✅ Mixed loads require AC-7b rating—when controlling both resistive and motor loads on the same contactor, always use the AC-7b specification.

- ✅ Environmental factors require derating—high ambient temperature (>40°C), altitude (>2000m), and frequent switching reduce effective current capacity.

- ✅ Proper coordination with overload protection is essential—the contactor must withstand motor starting current without nuisance tripping of protective devices.

- ✅ AC-7b contactors cost 20-40% more than AC-7a but prevent catastrophic failures that cost far more in service calls, downtime, and equipment damage.

- ✅ IEC 61095 compliance ensures global market access—specify contactors with appropriate certification marks (CE, UL, CCC) for your region.

- ✅ Upgrading from AC-7a to AC-7b typically requires no panel modifications—most manufacturers offer both ratings in the same DIN rail footprint.

Συχνές Ερωτήσεις

Q: Can I use an AC-7b contactor for AC-7a applications?

A: Yes, AC-7b contactors are fully compatible with AC-7a loads. The enhanced contact materials and arc suppression provide no disadvantage for resistive loads, though you pay a premium for capabilities you don’t need. However, using AC-7a for AC-7b applications will cause failure.

Q: How do I identify if my existing contactor is AC-7a or AC-7b?

A: Check the nameplate or datasheet for the utilization category marking. It will explicitly state “AC-7a” or “AC-7b” along with the current rating. If only one current rating is listed, it’s likely AC-7a (the default for non-motor applications). AC-7b contactors typically show two ratings: a higher AC-7a value and lower AC-7b value.

Q: What’s the difference between AC-7b and AC-3 contactors?

A: AC-3 is an industrial motor contactor category (IEC 60947-4-1) for three-phase motors, typically >3kW, with higher voltage ratings (up to 690V) and current ratings (up to 1000A). AC-7b is specifically for household single-phase motors ≤2.2kW with current ratings ≤32A. AC-3 contactors are over-specified and more expensive for residential applications. Learn more about contactor standards

Q: How many starts per hour can an AC-7b contactor handle?

A: Standard AC-7b contactors are rated for occasional starting, typically ≤5 starts per minute or ≤10 starts per 10-minute period. For higher duty cycles (e.g., compressor applications), specify contactors with enhanced electrical life ratings or implement time delay protection.

Q: Do I need special wiring for AC-7b contactors?

A: No, the wiring requirements are identical to AC-7a. Use wire sized for 125% of the motor’s full load current per NEC Article 430 or IEC 60364. The contactor terminals accept the same wire gauges as the equivalent AC-7a model.

Q: Can I retrofit an AC-7b contactor into an existing AC-7a installation?

A: Yes, in most cases. Verify that:

- The DIN rail mounting footprint matches (usually identical within the same product family)

- Terminal wire sizing is adequate for the motor current

- The control circuit voltage matches the new contactor’s coil rating

- Overload protection is coordinated with the motor starting characteristics

Q: What causes the “buzzing” sound in contactors controlling motors?

A: Buzzing during motor starting indicates the coil voltage is dropping below the hold-in threshold due to supply voltage sag from the high inrush current. This is more common with AC-7a contactors that lack the reinforced coil design of AC-7b models. Solutions include using a DC coil with rectified supply or upgrading to an AC-7b contactor with enhanced coil hold-in characteristics. Troubleshooting guide

Q: Are there any safety concerns with using the wrong contactor category?

A: Yes. A failed contactor can weld closed, causing the motor to run continuously, leading to overheating and potential fire hazards. Alternatively, contacts can weld partially, creating high-resistance connections that generate excessive heat. Always use AC-7b contactors for motor loads to ensure safe operation and compliance with electrical codes.

Συμπέρασμα

The distinction between AC-7a and AC-7b modular contactors represents a fundamental engineering principle: matching component specifications to application requirements. While the 20-40% cost premium for AC-7b contactors may seem significant, it pales in comparison to the costs of premature failure, service calls, and potential safety hazards.

For electrical professionals, the selection criteria are clear: use AC-7a for resistive loads, AC-7b for motors—no exceptions. The enhanced contact materials, arc suppression systems, and making capacity of AC-7b contactors are not optional features but essential design elements for reliable motor control.

As household and light commercial equipment increasingly incorporates motor-driven components (HVAC systems, heat pumps, ventilation), the importance of proper contactor selection will only grow. By understanding the technical differences outlined in this guide and applying the selection methodology, you can ensure system reliability, safety, and longevity.

VIOX Electric manufactures a complete range of modular contactors with both AC-7a and AC-7b ratings, certified to IEC 61095 and UL 60947-4-1 standards. Our technical support team can assist with application-specific selection and coordination with protective devices. Επικοινωνήστε μαζί μας for detailed specifications and selection assistance.

Related Resources

- IEC 61095 vs. IEC 60947-4-1: Household and Industrial Contactor Standards

- Inside AC Contactor Components: Design Logic

- How to Choose Modular Contactor: AC vs DC

- Επαφείς έναντι ρελέ: Κατανόηση των βασικών διαφορών

- Contactor vs. Motor Starter: Complete Comparison

- Ρελέ Ασφαλείας έναντι Τυπικού Ρελέ: Οδηγός Επαφών Καθοδηγούμενης Δύναμης

- Industrial Contactor Maintenance Inspection Checklist

- Understanding 1 Pole vs. 2 Pole AC Contactors

- Πώς να επιλέξετε επαφείς και διακόπτες ισχύος με βάση την ισχύ του κινητήρα

- Star Delta Starter Wiring Diagram: Sizing & Selection Guide