Průmyslové ovládací panely slouží jako centrální nervový systém moderních výrobních a automatizačních systémů. Tyto sofistikované elektrické sestavy obsahují kritické komponenty, které monitorují, řídí a chrání průmyslové zařízení v různých aplikacích – od automatizovaných výrobních linek po systémy HVAC a sítě pro distribuci energie. Pochopení komponent uvnitř těchto panelů je zásadní pro inženýry, správce zařízení a odborníky na nákup, kteří se snaží optimalizovat výkon systému, zajistit dodržování bezpečnostních předpisů a minimalizovat provozní prostoje.

Klíčové poznatky

- Ovládací panely integrují základní elektrické komponenty včetně jističů, PLC, stykačů a transformátorů pro správu průmyslových automatizačních systémů

- Výběr komponent přímo ovlivňuje spolehlivost systému, dodržování bezpečnostních předpisů (UL 508A, IEC 61439) a celkové náklady na vlastnictví

- Správné uspořádání kabelů a návrh rozvržení může zkrátit dobu odstraňování problémů až o 50 % a zabránit nákladným elektrickým poruchám

- Pochopení hodnot SCCR je kritické – komponenta s nejnižším hodnocením určuje schopnost ochrany celého panelu proti zkratu

- Moderní ovládací panely vyžadují pečlivé zvážení distribuce energie, odvodu tepla a elektromagnetické kompatibility pro optimální výkon

Co je průmyslový ovládací panel?

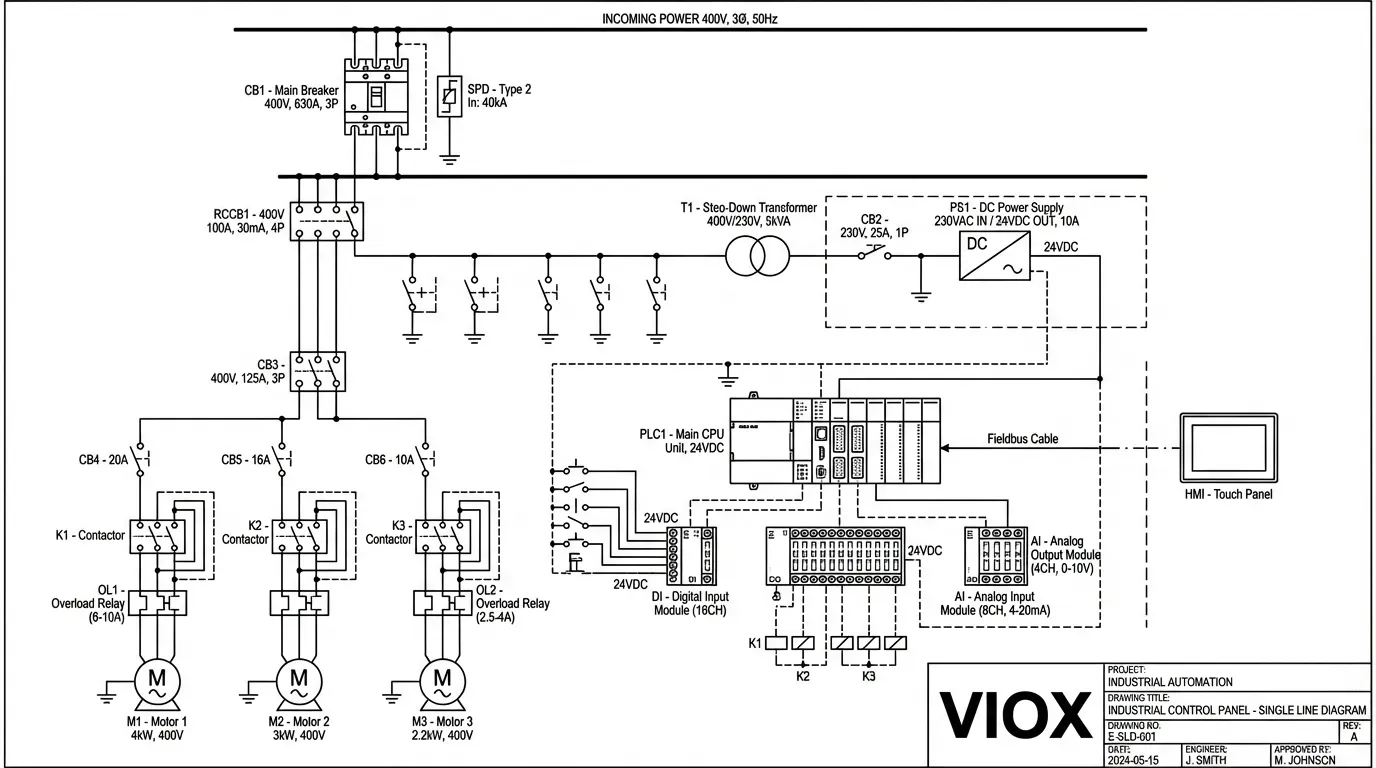

Průmyslový ovládací panel je zakázkově navržená sestava elektrických zařízení určená ke správě, monitorování a řízení průmyslových zařízení a procesů. Podle Národního elektrotechnického předpisu (NEC) oddíl 409.2 je průmyslový ovládací panel definován jako “sestava dvou nebo více komponent silových obvodů, komponent řídicích obvodů nebo jakákoli kombinace komponent silových a řídicích obvodů.”

Tyto panely sdružují spínače, indikátory, relé, jističe, transformátory a svorkovnice do jednoho ochranného krytu, což umožňuje efektivní řízení složitých strojů. Ovládací panely se pohybují od jednoduchých elektrických ovládacích panelů se základními spínacími funkcemi až po vysoce sofistikované průmyslové ovládací panely s programovatelnými logickými automaty (PLC) a rozhraními člověk-stroj (HMI) pro pokročilou automatizaci.

Mezi hlavní funkce průmyslových ovládacích panelů patří:

- Distribuce a správa energie napříč více obvody a zařízeními

- Automatizace procesů prostřednictvím programovatelné logiky a sekvenčního řízení

- Monitorování systému prostřednictvím senzorů, měřičů a diagnostických displejů

- Bezpečnostní ochrana proti elektrickým poruchám, přetížení a zkratům

- Uživatelské rozhraní pro manuální ovládání a viditelnost stavu systému

Základní komponenty ovládacího panelu

1. Zařízení pro ochranu obvodů

Ochrana obvodů tvoří základ bezpečného provozu ovládacího panelu a chrání zařízení i personál před elektrickými riziky.

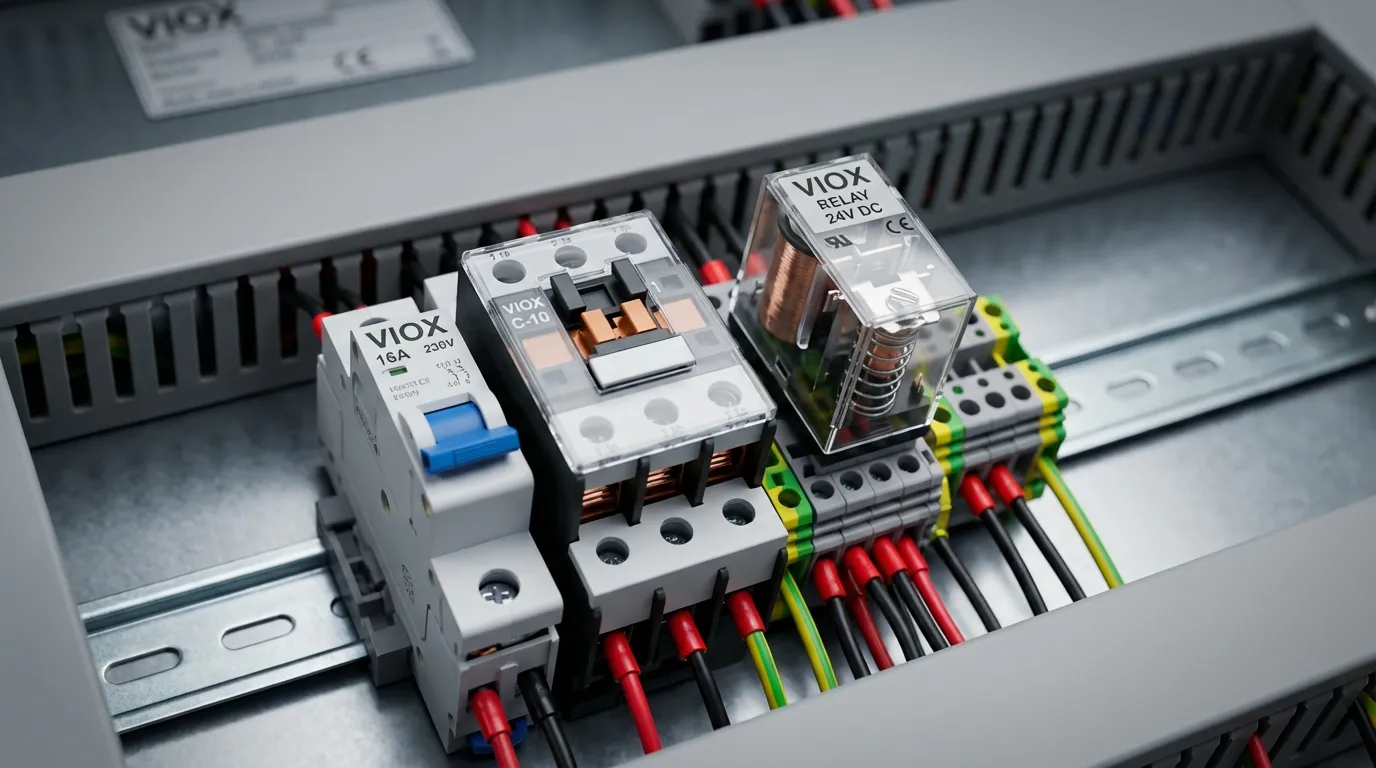

Miniaturní jističe (MCB)

MCB poskytují nadproudovou ochranu pro řídicí obvody pracující při 120 V–480 V ve většině průmyslových aplikací. Tato kompaktní zařízení automaticky přeruší tok proudu při detekci přetížení nebo zkratu. MCB obsahují tepelné (přetížení) i magnetické (zkrat) vypínací mechanismy, s vypínacími schopnostmi obvykle v rozmezí od 6 kA do 10 kA.

Jističe s lisovanou skříní (MCCB)

Pro aplikace s vyšším proudem, MCCB zvládají 15 A až 2500 A s nastavitelnými vypínacími nastaveními. Tato robustní zařízení chrání hlavní napájecí přívody a velké motorové obvody. Moderní MCCB mohou zahrnovat elektronické vypínací jednotky s ochranou proti zemnímu spojení a komunikačními schopnostmi pro prediktivní údržbu.

Proudové chrániče (RCCB)

RCCB detekují zemní svodové proudy a poskytují kritickou ochranu proti úrazu elektrickým proudem. Tato zařízení jsou nezbytná v aplikacích, kde může personál přijít do kontaktu se zařízením, zejména v instalacích nabíjení EV kde jsou vyžadovány specializované RCCB typu B nebo typu EV.

Pojistky

Průmyslové pojistky poskytují rychlou nadproudovou ochranu, zejména pro polovodičová zařízení a citlivou elektroniku. Pojistky s vysokou vypínací schopností (HRC) nabízejí vynikající vypínací výkon v prostředích s vysokým poruchovým proudem, zatímco DC pojistky jsou speciálně navrženy pro solární FV a aplikace pro ukládání baterií.

2. Řídicí a spínací zařízení

Stykače a spouštěče motorů

Stykače jsou elektricky ovládané spínače, které řídí vysoce výkonné zátěže na základě nízkonapěťových řídicích signálů. Tato elektromagnetická zařízení zapínají nebo vypínají silové obvody motorů, ohřívačů a osvětlovacích systémů. Modulární stykače nabízejí prostorově úspornou montáž na DIN lištu pro rezidenční a lehké komerční aplikace, zatímco tradiční stykače zvládají průmyslové úkoly řízení motorů.

Motorové spouštěče kombinují stykače s relé pro ochranu proti přetížení a poskytují kompletní řízení a ochranu motoru v jedné sestavě. Výběr mezi kategoriemi použití AC-1, AC-3 a AC-4 závisí na konkrétní aplikaci motoru a pracovním cyklu.

Relé

Relé slouží jako rozhraní mezi řídicími obvody a silovými obvody, izolují nízkonapěťové řídicí signály od vysokonapěťových zátěží. Ovládací panely obvykle obsahují několik typů relé:

- Řídicí relé pro logické funkce a blokování

- Časová zpožďovací relé pro sekvenční operace a ochranu čerpadel

- Tepelná nadproudová relé pro ochranu motoru

- Relé pro monitorování napětí pro sledování kvality energie

Tlačítka a přepínače

Ruční ovládací zařízení poskytují operátorovi rozhraní pro spouštění, zastavování a výběr režimu. Nouzová stop tlačítka musí být snadno přístupná a musí splňovat bezpečnostní normy, s pozitivně otevíracími kontakty, které zajišťují přerušení obvodu i v případě svaření kontaktů.

3. Programovatelné logické automaty (PLC)

PLC fungují jako “mozek” moderních průmyslových ovládacích panelů, provádějí programovanou logiku pro automatizaci procesů a koordinaci provozu zařízení. Tyto průmyslové počítače přijímají vstupy ze senzorů a spínačů, zpracovávají logiku podle naprogramovaných instrukcí a řídí výstupy do akčních členů, motorů a indikátorů.

Moderní PLC nabízejí:

- Škálovatelné konfigurace I/O od kompaktních jednotek po velké distribuované systémy

- Více komunikačních protokolů včetně Ethernet/IP, Modbus a Profibus

- Vestavěná diagnostika pro rychlé odstraňování problémů

- Moduly vyměnitelné za provozu pro minimální prostoje během údržby

PLC ve velké míře nahradily reléovou logiku v průmyslových aplikacích díky své flexibilitě, spolehlivosti a snadnosti programovacích úprav.

4. Rozhraní člověk-stroj (HMI)

HMI poskytují grafická operátorská rozhraní pro monitorování stavu systému, úpravu parametrů a diagnostiku poruch. Tyto dotykové displeje nebo terminály montované na panel umožňují operátorům interakci s PLC a dalšími řídicími zařízeními bez nutnosti znalosti programování. Moderní HMI nabízejí:

- Vizualizaci dat v reálném čase s trendy a alarmy

- Správu receptur pro změny produktů

- Možnosti vzdáleného přístupu pro vzdálené monitorování

- Vícejazyčná podpora pro globální operace

5. Komponenty rozvodu energie

Transformers

Transformátory v rozvaděči převádějí vstupní síťové napětí (typicky 480 V nebo 240 V AC) na nižší řídicí napětí (120 V nebo 24 V AC) požadované řídicími zařízeními, PLC a indikačními světly. Správné dimenzování transformátoru musí zohledňovat náběhové proudy a trvalé VA jmenovité hodnoty všech připojených zátěží.

Napájecí zdroje

Spínané zdroje převádějí střídavé napětí na regulované stejnosměrné napětí (obvykle 24 V DC) pro napájení PLC, senzorů a polovodičových zařízení. Průmyslové napájecí zdroje musí odolat kolísání napětí, poskytovat nadproudovou ochranu a udržovat regulaci za různých podmínek zatížení.

Přípojnice a distribuční bloky

Přípojnice efektivně distribuují energii v celém panelu, snižují nepořádek v kabelech a zlepšují proudovou zatížitelnost. Bloky rozvodu energie poskytují více připojovacích bodů z jednoho vstupního zdroje, což zjednodušuje zapojení paralelních obvodů.

6. Přepěťové ochrany (SPD)

Přepěťová ochranná zařízení chrání citlivou elektroniku před přechodnými přepětími způsobenými údery blesku, spínacími operacemi nebo poruchami v síti. SPD typu 1, typu 2 a typu 3 poskytují koordinovanou ochranu na vstupu, distribuci a úrovni zařízení. Správný výběr SPD vyžaduje porozumění Hodnocení MCOV a konfiguraci uzemnění systému.

7. Svorkovnice a kabelážní infrastruktura

Svorkovnice

Svorkovnice poskytují organizované a přístupné připojovací body pro polní kabeláž a vnitřní připojení panelu. Různé typy slouží různým funkcím:

- Průchozí svorky pro jednoduché propojení vodič-vodič

- Pojistkové svorkovnice kombinující připojení a ochranu

- Odpojovací svorky umožňující izolaci obvodu bez odpojování vodičů

- Keramické svorkovnice pro vysokoteplotní aplikace

Kolejnice DIN

DIN lišty poskytují standardizovanou montáž pro modulární komponenty, umožňující flexibilní uspořádání panelu a zjednodušenou výměnu komponent. DIN lišta TH35 (35 mm) se stala průmyslovým standardem pro montáž jističů, relé, svorkovnic a dalších řídicích zařízení.

Kabelové žlaby a správa kabelů

Správné vedení kabelů pomocí kabelových žlabů, stahovacích pásek a kabelové vývodky zajišťuje organizovanou kabeláž, která usnadňuje odstraňování problémů a údržbu. Dobře spravovaná kabeláž také zlepšuje odvod tepla a snižuje elektromagnetické rušení mezi obvody.

8. Indikační a monitorovací zařízení

Signalizační světla a indikátory

LED indikační světla poskytují vizuální zpětnou vazbu o stavu napájení, provozu zařízení a alarmových stavech. Barevně odlišené indikátory se řídí průmyslovými konvencemi (zelená pro běh, červená pro zastavení, oranžová pro alarmové stavy).

Měřiče a displeje

Digitální měřiče monitorují napětí, proud, výkon a spotřebu energie. Moderní multifunkční měřiče poskytují komplexní analýzu kvality energie a mohou komunikovat data do nadřazených systémů prostřednictvím protokolů Modbus nebo Ethernet.

Senzory přiblížení

Indukční, kapacitní a fotoelektrické bezkontaktní snímače detekují přítomnost objektu bez fyzického kontaktu, což umožňuje automatizované řízení procesů a bezpečnostní blokování.

9. Komunikační a síťová zařízení

Ethernetové přepínače

Průmyslové ethernetové přepínače umožňují síťovou komunikaci mezi PLC, HMI, měniči frekvence (VFD) a systémy SCADA. Řízené přepínače poskytují segmentaci VLAN, kvalitu služeb (QoS) a síťovou diagnostiku pro kritické aplikace.

Protokolové převodníky

Brány převádějí mezi různými průmyslovými protokoly (Modbus RTU na Modbus TCP, Profibus na Ethernet/IP), což umožňuje integraci starších zařízení s moderními řídicími systémy.

10. Skříně a ochrana životního prostředí

Skříň rozvaděče poskytuje fyzickou ochranu komponent a zároveň splňuje environmentální požadavky. Hodnocení NEMA a IP specifikují úrovně ochrany proti prachu, vlhkosti a fyzickému nárazu. Výběr skříně musí zohledňovat:

- Provozní prostředí (vnitřní, venkovní, nebezpečné prostory)

- Regulaci teploty (větrání, klimatizace, ohřívače)

- Přístupnost pro provoz a údržbu

- Výběr materiálu (nerezová ocel vs. hliník pro korozivní prostředí)

Srovnávací tabulka komponent řídicího panelu

| Typ komponentu | Primární funkce | Typický rozsah napětí | Klíčová kritéria výběru | Běžné aplikace |

|---|---|---|---|---|

| MCB | Nadproudová ochrana | 120-480V AC | Vypínací schopnost (kA), vypínací charakteristika (B, C, D) | Osvětlení, řídicí obvody, malé motory |

| MCCB | Ochrana proti vysokým proudům | 120-690V AC | Jmenovitý proud (15-2500A), nastavitelné vypínání | Hlavní přívody, velké motory, distribuce |

| RCCB | Ochrana proti zemnímu úniku | 120-480V AC | Citlivost (30mA, 100mA, 300mA), Typ (AC, A, B) | Ochrana osob, uzemnění zařízení |

| Stykač | Spínání zátěže | 120-690V AC/DC | Kategorie využití (AC-1, AC-3), napětí cívky | Řízení motorů, topení, osvětlení |

| Relé | Izolace/řízení signálu | 12-240 V AC/DC | Konfigurace kontaktů (SPDT, DPDT), typ cívky | Blokování, logika, rozhraní |

| PLC | Automatizace procesů | 24V DC (I/O) | Počet I/O, paměť, komunikační protokoly | Výroba, řízení procesů, automatizace budov |

| Transformátor | Převod napětí | 120-480V vstup | VA rating, poměr napětí, regulace | Řídicí napájení, izolace |

| Napájení | Převod AC na DC | 120-240V AC vstup | Výstupní napětí/proud, účinnost, doba udržení | Napájení PLC, napájení senzorů, DC zátěže |

| SPD | Potlačení přechodových jevů | Systémové napětí | Typ (1/2/3), MCOV, výbojový proud (kA) | Ochrana před bleskem, zmírnění spínacích rázů |

| Svorkovnice | Připojení vodičů | Až 1000 V | Jmenovitý proud, kapacita průřezu vodiče, typ | Terénní zapojení, vnitřní připojení |

Normy a shoda pro návrh řídicích panelů

Průmyslové řídicí panely musí splňovat přísné bezpečnostní a výkonnostní normy, aby byla zajištěna spolehlivá funkčnost a regulační přijatelnost.

UL 508A – Průmyslové řídicí panely

UL 508A je primární norma pro konstrukci a certifikaci průmyslových řídicích panelů v Severní Americe. Tato norma stanovuje požadavky na:

- Výběr komponent používání zařízení uvedených nebo uznávaných UL

- Jmenovitý zkratový proud (SCCR) výpočet a označení

- Metody zapojení včetně dimenzování vodičů, vedení a zakončení

- Nadproudová ochrana koordinace

- Výběr skříně a environmentální hodnocení

- Označení a dokumentace požadavky

SCCR představuje maximální poruchový proud, kterému panel dokáže bezpečně odolat. Kriticky, komponenta s nejnižším jmenovitým proudem určuje SCCR celého panelu – běžný přehled, který může ohrozit bezpečnost a selhat při kontrole.

NFPA 70 (Národní elektrotechnický předpis)

NEC poskytuje komplexní požadavky na elektrické instalace, včetně řídicích panelů. Mezi klíčová ustanovení patří:

- Článek 409 – Průmyslové řídicí panely

- Článek 430 – Motory, motorové obvody a ovladače

- Článek 670 – Průmyslové stroje

- Článek 110.26 – Pracovní prostory kolem elektrického zařízení

NFPA 79 – Elektrická norma pro průmyslové stroje

NFPA 79 se zabývá elektrickým zařízením průmyslových strojů pracujících při napětí 600 V nebo méně a poskytuje podrobné pokyny pro dimenzování vodičů, barevné kódování a metody instalace specifické pro panely řízení strojů.

Normy IEC

Pro mezinárodní aplikace poskytují normy IEC ekvivalentní požadavky:

- IEC 61439 – Rozváděče a řídicí přístroje nn

- IEC 60204-1 – Bezpečnost strojních zařízení – Elektrické vybavení strojů

- IEC 60947 – Rozváděče a řídicí přístroje nn

Označení CE a směrnice EU

Řídicí panely určené pro evropské trhy musí splňovat příslušné směrnice EU a nést označení CE, které prokazuje shodu s:

- Směrnice o nízkém napětí (LVD) 2014/35/EU

- Směrnice o strojních zařízeních 2006/42/ES

- Směrnice o elektromagnetické kompatibilitě (EMC) 2014/30/EU

Osvědčené postupy pro zapojení ovládacích panelů

Správné postupy zapojení přímo ovlivňují spolehlivost, bezpečnost a udržovatelnost ovládacího panelu. Dobře uspořádané zapojení může zkrátit dobu odstraňování problémů až o 50 %, zatímco špatné postupy zapojení vedou k předčasným poruchám a bezpečnostním rizikům.

Výběr a dimenzování vodičů

Typ vodiče

Průmyslové ovládací panely obvykle používají vodiče MTW (Machine Tool Wire) s jmenovitým napětím 600 V a teplotou 90 °C. Tento lankový měděný vodič poskytuje flexibilitu pro zapojení panelu při zachování trvanlivosti. Pro venkovní zapojení a vedení v trubkách jsou standardem vodiče THHN/THWN.

Výběr průřezu drátu

Dimenzování vodiče musí zohledňovat:

- Trvalý proud připojeného zátěže

- Okolní teplota a redukční faktory

- Úbytek napětí omezení (obvykle maximálně 3 %)

- Nadproudové ochranné zařízení jmenovitý proud

- Seskupování a svazkování vlivy na odvod tepla

NFPA 79 poskytuje podrobné tabulky pro dimenzování vodičů na základě těchto faktorů. Poddimenzované vodiče vedou k přehřátí, degradaci izolace a potenciálnímu nebezpečí požáru.

Standardy barevného kódování

Konzistentní barevné kódování vodičů zvyšuje bezpečnost a zjednodušuje odstraňování problémů:

Severoamerická konvence:

- Černá, červená, modrá – Fázové vodiče (L1, L2, L3)

- Bílá nebo šedá – Nulový vodič

- Zelená nebo zeleno/žlutá – Uzemňovací vodič

- Červená – Napájení řídicího obvodu (fáze)

- Černá nebo modrá – Napájení řídicího obvodu (návrat)

- Oranžová – 24 V DC kladné

- Modrá – 24 V DC záporné

IEC konvence:

- Hnědá, černá, šedá – Fázové vodiče (L1, L2, L3)

- Modrá – Nulový vodič

- Zeleno/žlutá – Ochranné uzemnění

- Červená – Řídicí obvody

- Černá – DC záporné

- Červená – DC kladné

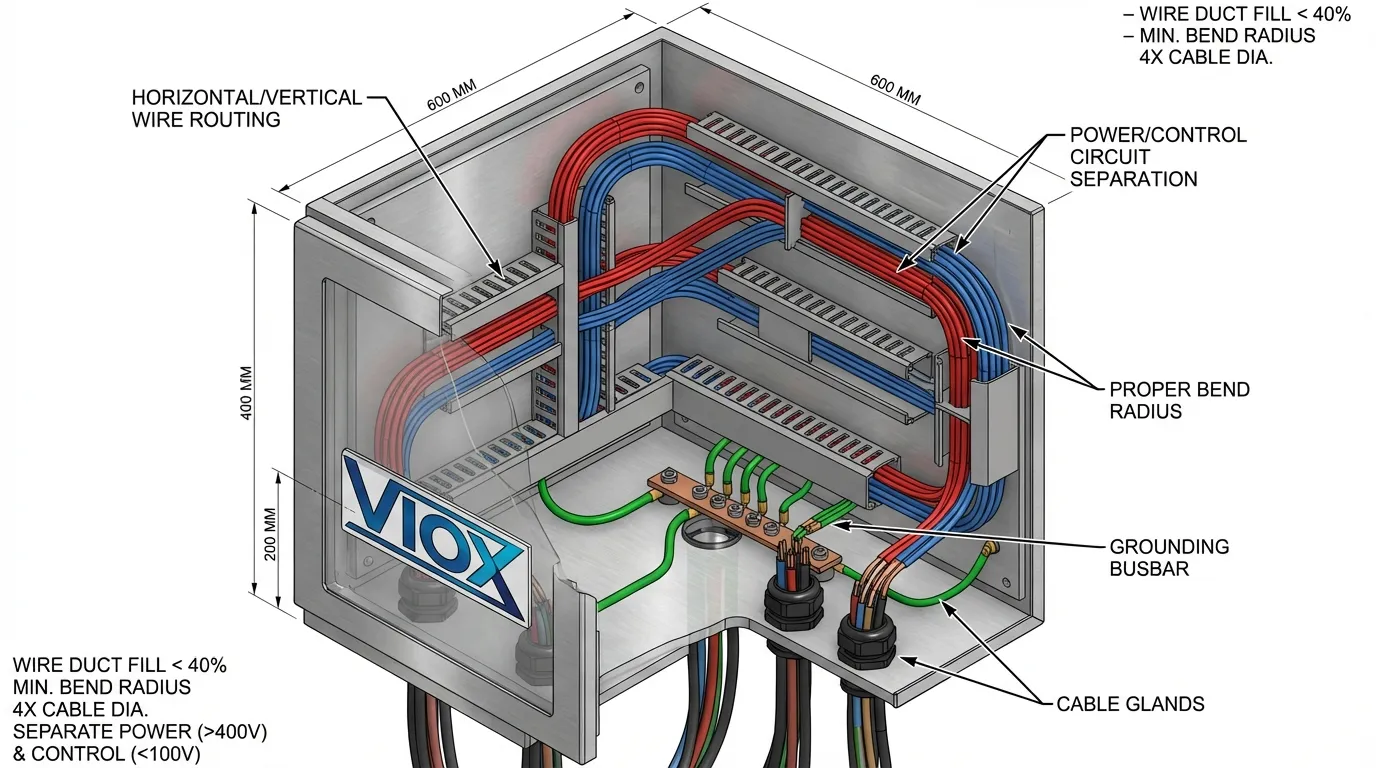

Vedení a správa vodičů

Horizontální a vertikální vedení

Vodiče by měly být vedeny v horizontálních a vertikálních liniích – nikdy diagonálně. Tento organizovaný přístup usnadňuje vizuální sledování a vytváří profesionální vzhled, který odráží kvalitní provedení.

Požadavky na oddělení

Dodržujte oddělení mezi:

- Silové a řídicí obvody pro snížení elektromagnetického rušení

- Vysokonapěťové a nízkonapěťové zapojení pro bezpečnost

- Vstupní a výstupní obvody aby se zabránilo vazbě šumu

UL 508A specifikuje minimální vzdálenosti oddělení na základě úrovní napětí a typů obvodů.

Optimalizace délky vodičů

Vodiče by měly být dostatečně dlouhé, aby umožňovaly výměnu a údržbu komponent, ale ne tak dlouhé, aby vytvářely zamotané zapojení typu “špagety”. Nadměrná délka vodičů zvyšuje úbytek napětí, vytváří hromadění tepla ve svazcích a komplikuje odstraňování problémů.

Poloměr ohybu

Dodržujte specifikace minimálního poloměru ohybu, abyste zabránili poškození vodiče. Obecně platí, že pro lankové vodiče dodržujte poloměry ohybu alespoň 6násobku průměru vodiče.

Techniky zakončení

Kabelové koncovky

Kabelové koncovky poskytují profesionální zakončení pro lankové vodiče, zabraňují lámání pramenů a zajišťují spolehlivé připojení ve šroubových svorkách. Kabelové koncovky jsou zvláště důležité pro jemně lankové vodiče a v aplikacích vystavených vibracím.

Specifikace točivého momentu

Dodržujte hodnoty utahovacího momentu specifikované výrobcem pro svorkovnice. Nedotažené spoje vytvářejí vysoký odpor a hromadění tepla, zatímco přetažené spoje poškozují svorky a vodiče.

Organizace svorkovnic

Seskupujte související obvody na sousedních svorkách a udržujte konzistentní číslování svorek, které odpovídá schématickým výkresům. Tato organizace dramaticky zkracuje dobu odstraňování problémů.

Označování a dokumentace

Identifikace drátu

Každý vodič by měl být označen na obou koncích jedinečným identifikátorem, který odpovídá schématu ovládacího panelu. Používejte trvanlivé štítky vhodné pro provozní prostředí – smršťovací štítky pro aplikace s vysokou teplotou, obalové štítky pro obecné použití.

Označování komponent

Označte všechny komponenty označeními odpovídajícími schématu (např. M1 pro spouštěč motoru 1, CR5 pro řídicí relé 5). Tato korespondence mezi fyzickým zařízením a výkresy je nezbytná pro údržbu a odstraňování problémů.

Přesnost výkresů

Udržujte výkresy skutečného provedení, které přesně odrážejí instalovanou konfiguraci. Nesrovnalosti mezi výkresy a skutečným zapojením vytvářejí bezpečnostní rizika a noční můry údržby.

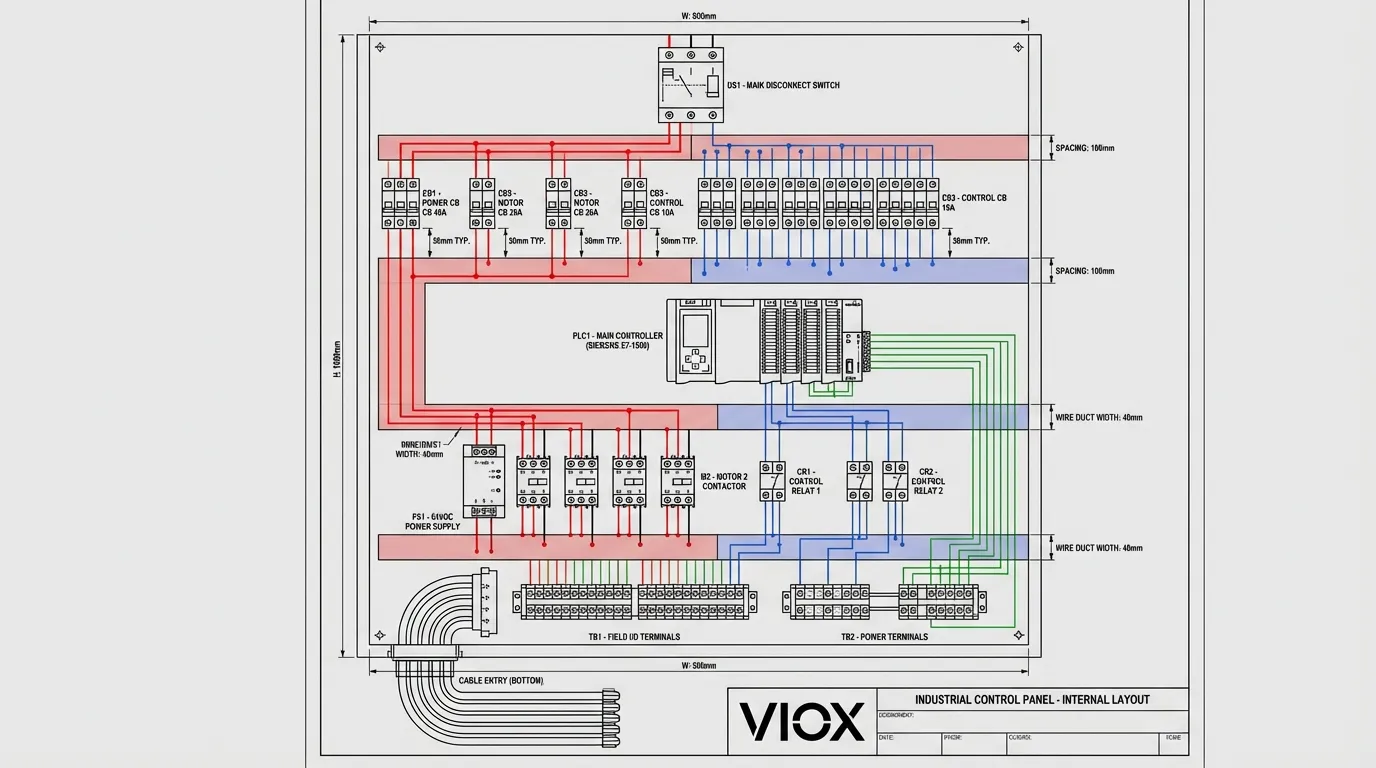

Rozvržení a konstrukční aspekty ovládacího panelu

Promyšlené uspořádání ovládacího panelu zvyšuje funkčnost, bezpečnost a udržovatelnost a zároveň optimalizuje využití prostoru.

Seskupování komponent

Funkční seskupování

Uspořádejte komponenty podle funkce:

- Distribuce energie komponenty v horní části

- Řídicí logika (PLC, relé) ve střední části

- I/O terminály v blízkosti vstupních bodů kabelů

- Uživatelské rozhraní zařízení na dveřích nebo v dostupné výšce

Oddělení napětí

Fyzicky oddělte vysokonapěťové a nízkonapěťové sekce pomocí bariér nebo vyhrazených zón. Toto oddělení snižuje riziko úrazu elektrickým proudem během údržby a minimalizuje elektromagnetické rušení.

Řízení tepla

Elektrické komponenty generují během provozu teplo. Nedostatečný odvod tepla vede k předčasnému selhání a snížení spolehlivosti.

Výpočet tepelné zátěže

Vypočítejte celkovou produkci tepla ze všech komponent (zejména napájecích zdrojů, VFD a velkých stykačů). Pokud vypočtená vnitřní teplota překročí jmenovité hodnoty komponent, implementujte řešení chlazení:

- Přirozené větrání se správně dimenzovanými větracími otvory

- Nucené chlazení vzduchem pomocí ventilátorů a filtrů

- Klimatizace pro vysoké tepelné zatížení nebo extrémní okolní podmínky

- Chladiče pro výkonové polovodiče

Rozteč součástí

Udržujte dostatečné mezery mezi komponentami generujícími teplo, aby byla umožněna cirkulace vzduchu. Stísněné uspořádání zachycuje teplo a vytváří horká místa, která urychlují stárnutí komponent.

Přístupnost a údržba

Servisní prostory

Navrhujte rozvržení, která umožňují přístup ke komponentám vyžadujícím pravidelnou údržbu nebo seřízení. Často servisované položky (pojistky, nastavitelná relé, svorkovnice) by měly být snadno přístupné bez demontáže jiných komponent.

Komponenty montované na dveře

Namontujte zařízení operátorského rozhraní (tlačítka, přepínače, HMI, kontrolky) na dveře skříně pro snadný přístup. Zajistěte, aby komponenty montované na dveře měly dostatečnou délku vodiče a odlehčení tahu, aby se přizpůsobily otevírání dveří.

Testovací body

Zajistěte přístupné testovací body pro měření napětí a monitorování signálu během uvádění do provozu a odstraňování problémů.

Uzemnění a propojení

Správné uzemnění je nezbytné pro bezpečnost a odolnost proti rušení:

- Uzemnění zařízení připojuje všechny kovové části skříně k zemi

- Samostatné zemnicí lišty pro napájecí a řídicí uzemnění (je-li to vyžadováno)

- Uzemnění do hvězdy pro citlivé analogové obvody

- Uzemnění stíněného kabelu pouze na jednom konci, aby se zabránilo zemním smyčkám

Běžné aplikace ovládacích panelů

Průmyslové ovládací panely slouží různým aplikacím v mnoha průmyslových odvětvích:

Řídicí centra motorů (MCC)

MCC konsolidují spouštěče motorů, VFD a související řídicí zařízení pro více motorů do jedné sestavy. Tyto panely jsou běžné ve výrobních závodech, úpravnách vody a systémech HVAC, kde četné motory vyžadují centralizované řízení.

PLC ovládací panely

PLC panely slouží jako automatizační centrum pro výrobní linky, balicí zařízení a systémy řízení procesů. Tyto panely integrují PLC, I/O moduly, napájecí zdroje a komunikační zařízení pro provádění složitých automatizačních sekvencí.

Rozvodné panely

Elektrické rozvodné panely distribuují příchozí energii do více odbočných obvodů, včetně hlavních jističů, ochrany odbočných obvodů a měření. Tyto panely sahají od rezidenčních zátěžových center po průmyslové rozvodné desky obsluhující celé provozy.

Panely automatického přepínání (ATS)

Panely ATS automaticky přepínají mezi napájením z veřejné sítě a záložním generátorem během výpadků, čímž zajišťují nepřetržitý provoz kritických zátěží. Tyto panely jsou nezbytné pro nemocnice, datová centra a nouzové systémy.

Solární kombinované boxy

PV slučovací boxy konsolidují výstupy z více řetězců solárních panelů, včetně DC jističů, pojistek a přepěťové ochrany před napájením střídače. Tyto specializované panely musí odolat venkovnímu prostředí a splňovat NEC článek 690.

Specializované ovládací panely

- Řídicí panely HVAC pro automatizaci budov

- Panely řízení čerpadel s regulací hladiny a střídáním

- Nabíjecí stanice pro elektromobily se specializovanou ochranou

- Panely požárního poplachu a ochrany života

Výběr správných komponent ovládacího panelu

Výběr komponent přímo ovlivňuje spolehlivost systému, celkové náklady na vlastnictví a soulad s předpisy.

Požadavky na výkon

Definujte provozní parametry:

- Napětí a frekvence napájecího zdroje

- Aktuální hodnocení pro všechny obvody

- Zatěžovací cyklus (nepřetržitý, přerušovaný, krátkodobý)

- Podmínky prostředí (teplota, vlhkost, kontaminace)

- Řízení složitosti (jednoduché zapnutí/vypnutí vs. komplexní automatizace)

Bezpečnost a dodržování předpisů

Zajistěte, aby komponenty splňovaly platné normy:

- UL listing nebo uznání pro severoamerické instalace

- Označení CE pro evropské trhy

- Odpovídající jmenovité hodnoty pro danou aplikaci (napětí, proud, vypínací schopnost)

- Hodnocení prostředí odpovídající instalačním podmínkám

Kvalita a spolehlivost

Zvažte:

- Pověst výrobce a historie

- Střední doba mezi poruchami (MTBF) data

- Záruční podmínky a dostupnost technické podpory

- Dostupnost náhradních dílů pro dlouhodobou údržbu

Celkové náklady na vlastnictví

Dívejte se za počáteční nákupní cenu:

- Energetická účinnost (zejména u napájecích zdrojů a VFD)

- Požadavky na údržbu a intervaly

- Očekávaná životnost před výměnou

- Náklady na prostoje spojená s poruchami komponent

Výběr dodavatele

Spolupracujte s renomovanými dodavateli, jako jsou VIOX Electric které nabízejí:

- Komplexní produktová portfolia pro komplexní nákup

- Technická podpora pro výběr a aplikaci komponent

- Certifikace kvality (ISO 9001, UL, CE)

- Konzistentní dostupnost a spolehlivé dodávky

- Konkurenční ceny pro objemové nákupy

Odstraňování problémů s ovládacím panelem

Systematické odstraňování problémů minimalizuje prostoje a identifikuje hlavní příčiny spíše než symptomy.

Běžné problémy s ovládacím panelem

Nepříjemné zakopnutí

Jističe, které opakovaně vypadávají mohou indikovat:

- Přetížené obvody vyžadující snížení zátěže nebo větší jističe

- Zemní poruchy z poškozené izolace nebo vniknutí vlhkosti

- Volné spoje vytvářející oblouk a teplo

- Nesprávná velikost jističe pro danou aplikaci

Selhání stykače

Problémy se stykačem zahrnout:

- Spálení cívky z přepětí nebo nadměrného zatěžovacího cyklu

- Svařování kontaktů z vysokých zapínacích proudů nebo nedostatečného jmenovitého proudu

- Mechanické opotřebení vyžadující výměnu

- Bzučení nebo chvění z nízkého napětí nebo mechanického zablokování

Selhání komunikace

Problémy se síťovou komunikací často pramení z:

- Uvolněné kabelové spoje na terminálech

- Nesprávná konfigurace sítě (IP adresy, masky podsítě)

- EMI rušení z nestíněných kabelů nebo nesprávného uzemnění

- Vadné síťové přepínače nebo moduly

Přehřátí

Nadměrné teplo indikuje:

- Nedostatečné větrání nebo zablokované větrací otvory

- Přetížené komponenty provoz mimo jmenovité hodnoty

- Špatné spoje vytvářející vysoký odpor

- Okolní teplota překračující konstrukční limity

Diagnostické techniky

Vizuální kontrola

Začněte důkladnou vizuální kontrolou:

- Zbarvené nebo spálené komponenty indikující přehřátí

- Uvolněné nebo zkorodované spoje

- Fyzické poškození ke komponentům nebo kabeláži

- Kontrolky zobrazující poruchové stavy

Měření napětí

Ověřte správné napětí na:

- Vstupech a výstupech napájecího zdroje

- Řídicí napájecí transformátor sekundární

- Napájecí zdroj PLC a I/O moduly

- Napětí cívek na stykačích a relé

Měření proudu

Změřte skutečné zatěžovací proudy a porovnejte s:

- Údaje na štítku připojeného zařízení

- Jistič a jmenovité proudové zatížitelnosti vodičů

- Očekávané hodnoty na základě návrhu systému

Termovizní zobrazování

Infračervené kamery identifikují horká místa indikující:

- Volné spoje s vysokým odporem

- Přetížené obvody nebo komponenty

- Nedostatečný odvod tepla

Preventivní údržba

Pravidelná údržba předchází poruchám:

- Čtvrtletní kontroly připojení, indikátorů a fyzického stavu

- Roční testování ochranných zařízení a blokování

- Čištění k odstranění prachu a nečistot

- Termální skenování k identifikaci rozvíjejících se problémů

- Dokumentace zjištění a nápravných opatření

Často kladené otázky (FAQ)

Otázka: Jaký je rozdíl mezi elektrickým rozvaděčem a průmyslovým rozvaděčem?

Odpověď: Elektrický rozvaděč obvykle obsahuje základní komponenty, jako jsou jističe, pojistky, relé a transformátory pro správu elektrických zařízení. Průmyslový rozvaděč obsahuje tyto komponenty plus pokročilá automatizační zařízení, jako jsou PLC a HMI, pro řízení složitých průmyslových procesů a strojů. Průmyslové rozvaděče jsou speciálně navrženy pro automatizaci a aplikace řízení procesů.

Otázka: Jak vypočítám jmenovitý zkratový proud (SCCR) pro můj rozvaděč?

Odpověď: SCCR je určen komponentou s nejnižším jmenovitým proudem v rozvaděči. Zkontrolujte jmenovité zkratové proudy všech jističů, stykačů, relé a dalších zařízení. Komponenta s nejnižší vypínací schopností stanoví maximální poruchový proud, který rozvaděč bezpečně vydrží. Tato hodnota musí být vyznačena na štítku rozvaděče a musí překračovat dostupný poruchový proud v místě instalace. Pro podrobné výpočty nahlédněte do UL 508A Supplement SB nebo spolupracujte s certifikovanou dílnou rozvaděčů.

Otázka: Jakou velikost vodiče mám použít pro kabeláž rozvaděče?

Odpověď: Velikost vodiče závisí na trvalém proudu připojeného zatížení, okolní teplotě, faktorech svazkování a úvahách o úbytku napětí. Pro řídicí obvody pracující při 120 V AC je běžný vodič 14 AWG (2,5 mm²) pro zatížení do 15 A. Napájecí obvody vyžadují větší vodiče na základě tabulky NEC 310.16 nebo požadavků NFPA 79. Vždy se řiďte platnými normami a použijte příslušné redukční faktory pro teplotu a svazkování.

Otázka: Jak často by se měly rozvaděče kontrolovat a udržovat?

Odpověď: Provádějte vizuální kontroly čtvrtletně, abyste zkontrolovali uvolněné spoje, poškozené komponenty a správnou funkci indikátorů. Provádějte komplexní roční údržbu včetně kontroly utahovacího momentu spojů, termovizního snímání, testování ochranných zařízení a čištění. Vysoce zatížené nebo kritické aplikace mohou vyžadovat častější kontroly. Dokumentujte všechny údržbové činnosti a zjištění.

Otázka: Mohu vyměnit jistič za jistič s vyšším jmenovitým proudem?

Odpověď: Ne. Výměna jističe za jistič s vyšším jmenovitým proudem bez upgradu velikosti vodiče vytváří vážné nebezpečí požáru. Jistič musí být dimenzován tak, aby chránil vodič, nejen zatížení. Pokud stávající jistič často vypíná, prošetřete příčinu (přetížení, zemní porucha nebo vadný jistič), místo abyste jednoduše zvětšili velikost jističe.

Otázka: Jaký je rozdíl mezi normami UL 508A a IEC 61439?

Odpověď: UL 508A je severoamerická norma pro průmyslové rozvaděče, která se zaměřuje na jednotlivé sestavy rozvaděčů a vyžaduje výpočty SCCR a specifická kritéria výběru komponent. IEC 61439 je mezinárodní norma, která pokrývá celé elektrické sestavy včetně rozváděčů a distribučních desek, s různými metodami ověřování a požadavky na typové zkoušky. Rozvaděče pro americký trh vyžadují shodu s UL 508A, zatímco mezinárodní trhy obvykle dodržují normy IEC.

Otázka: Potřebuji pro svůj rozvaděč PLC?

Odpověď: PLC jsou výhodné, když vaše aplikace vyžaduje složitou logiku, více sekvencí, časté změny programu nebo integraci s jinými systémy. Jednoduché aplikace se základním zapínáním/vypínáním mohou být adekvátně obslouženy reléovou logikou nebo vyhrazenými regulátory. Zvažte PLC, když potřebujete flexibilitu, škálovatelnost nebo pokročilé funkce, jako je správa receptur, záznam dat nebo vzdálené monitorování.

Otázka: Jak vyberu správný stykač pro řízení motoru?

A: Výběr stykače vyžaduje znalost proudu motoru při plném zatížení, metody spouštění (DOL, hvězda-trojúhelník, soft start), pracovního cyklu a řídicího napětí. Vyberte stykač s kategorií použití odpovídající vaší aplikaci (AC-3 pro standardní motory, AC-4 pro náročné spouštění). Jmenovitý provozní proud stykače musí překračovat proud motoru při plném zatížení s příslušnou bezpečnostní rezervou. Ověřte, zda napětí cívky odpovídá vašemu řídicímu napájecímu zdroji.

Závěr

Průmyslové rozvaděče představují sofistikované sestavy elektrických a elektronických komponent, které spolupracují na správě, ochraně a automatizaci průmyslového zařízení. Pochopení funkce a kritérií výběru pro každou komponentu – od jističů a stykačů po PLC a komunikační zařízení – umožňuje inženýrům a správcům zařízení navrhovat, specifikovat a udržovat řídicí systémy, které poskytují spolehlivý výkon, zajišťují bezpečnost personálu a splňují platné normy a standardy.

Správný výběr komponent, dodržování osvědčených postupů pro kabeláž a shoda s normami UL 508A, NEC a IEC tvoří základ bezpečného a efektivního návrhu rozvaděče. Ať už specifikujete nový rozvaděč, upgradujete stávající zařízení nebo řešíte provozní problémy, důkladné porozumění komponentám rozvaděče a jejich interakcím je zásadní pro úspěch.

Pro pomoc s výběrem komponent rozvaděče, návrhem rozvaděče na míru nebo technickou podporou kontaktujte odborníky na VIOX Electric— vašeho důvěryhodného partnera pro průmyslová elektrická řešení.