Direct Answer: The Critical Impact of Dust Contamination

Dust accumulation in switchgear creates five critical failure pathways that compromise electrical system reliability: it forms conductive bridges causing short circuits and arc flash incidents, acts as thermal insulation triggering overheating and component degradation, accelerates corrosion when combined with moisture, disrupts protective relay accuracy, and creates tracking paths on insulators leading to partial discharge. Studies indicate that 85% of disruptive failures in electrical substations are related to environmental contamination, with dust being a primary contributor. Even seemingly harmless dust particles measuring 50-100 microns can cause catastrophic failures in modern switchgear where component spacing has shrunk to accommodate compact designs.

Önemli Çıkarımlar

- Dust contamination causes 5 major failure modes: short circuits, thermal overload, corrosion acceleration, relay malfunction, and insulation breakdown

- IP ratings matter: Switchgear with IP54 or higher protection significantly reduces dust-related failures

- Maintenance intervals are critical: Facilities in dusty environments require quarterly inspections versus annual checks in clean environments

- Cost impact is substantial: Dust-related failures cost 3-5x more than preventive maintenance programs

- Modern equipment is more vulnerable: Tighter component spacing in compact switchgear increases sensitivity to particle contamination

Understanding Dust as an Electrical Threat

What Makes Dust Dangerous in Switchgear?

Dust particles are not electrically neutral. Depending on their composition—metal filings, carbon, mineral dust, or organic matter—they exhibit varying levels of conductivity. When dust accumulates on electrical components, it creates multiple hazard scenarios that traditional circuit protection cannot prevent.

The particle size matters significantly. Fine dust particles (under 100 microns) penetrate deeper into switchgear compartments and settle on critical surfaces like busbars, contacts, and insulation barriers. These microscopic particles, invisible to casual inspection, accumulate over months to create failure conditions. Understanding the construction of electrical components helps explain why dust poses such a persistent threat.

The Five Failure Mechanisms

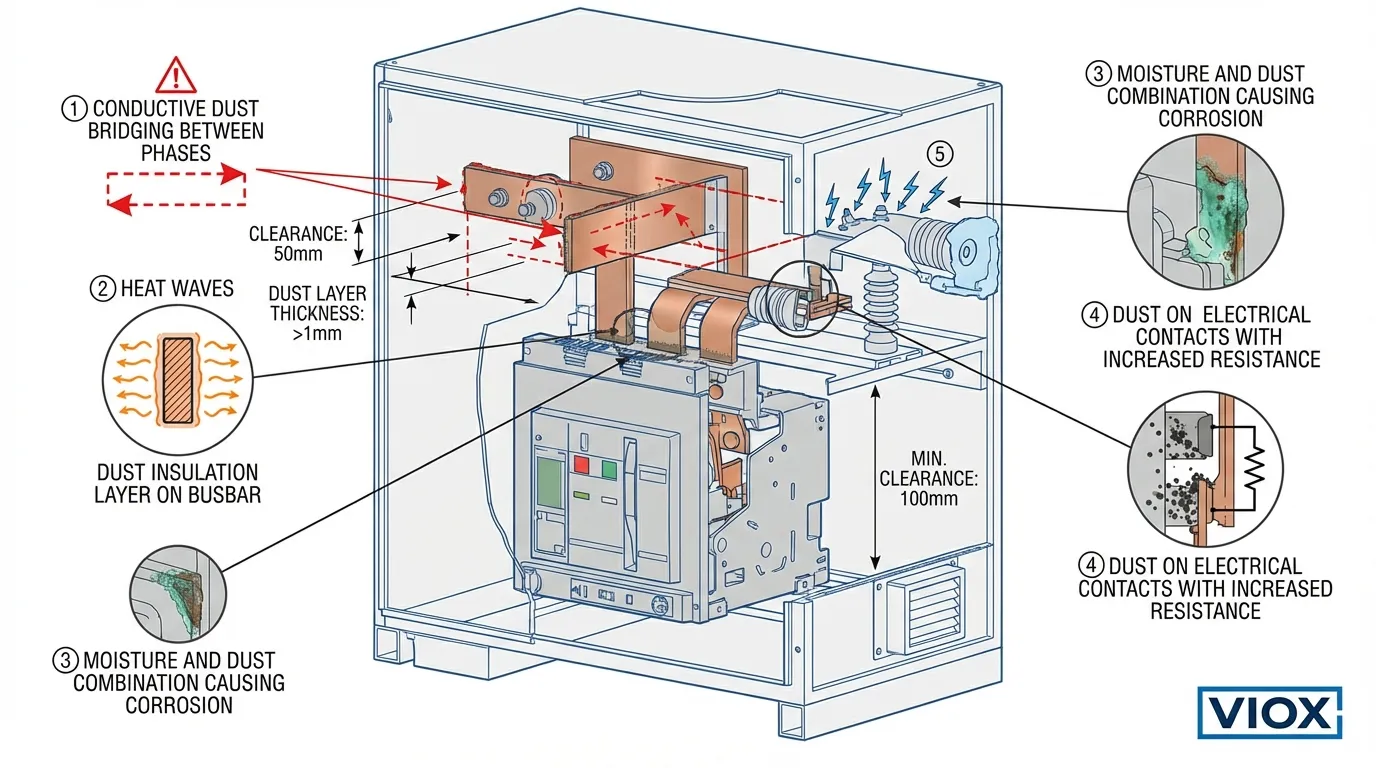

1. Conductive Bridging and Short Circuits

Metal-rich dust or carbon particles create conductive paths between phases or between energized parts and ground. In modern switchgear with compact designs, the clearance between conductors has decreased from historical 50mm spacing to as little as 20mm in some applications. This reduction makes equipment exponentially more vulnerable to dust bridging.

When conductive dust accumulates, it gradually reduces the effective air gap between conductors. Under normal operating voltage, partial discharge begins, carbonizing the dust and creating increasingly conductive paths. Eventually, a complete short circuit occurs, often resulting in arc flash incidents that can destroy equipment and endanger personnel.

2. Thermal Insulation and Overheating

Non-conductive dust acts as thermal insulation, coating heat-dissipating surfaces and trapping heat within components. Devre kesiciler, kontaktörler, and busbars generate heat during normal operation. Manufacturers design these components with specific thermal profiles assuming adequate air circulation and heat dissipation.

A 2mm layer of dust can reduce heat dissipation efficiency by 40-60%, causing components to operate above their rated temperature. This accelerated thermal aging reduces component lifespan from the expected 20-30 years to as little as 5-10 years. Temperature rise also affects calibration of thermal protection devices, potentially causing nuisance tripping or, worse, failure to trip during actual overload conditions.

3. Moisture Absorption and Corrosion

Dust is hygroscopic—it absorbs and retains moisture from the air. In environments with humidity fluctuations, dust layers act as moisture reservoirs, maintaining high local humidity even when ambient conditions improve. This creates ideal conditions for electrochemical corrosion of copper and aluminum conductors, silver-plated contacts, and steel enclosure components.

The combination of moisture and dust forms a weak electrolyte. When voltage is present, galvanic corrosion accelerates, particularly at connection points where dissimilar metals meet. Understanding corrosion resistance grades is essential for specifying switchgear in harsh environments.

4. Contact Resistance and Arcing

Dust contamination on electrical contacts increases contact resistance, which generates additional heat at connection points. This localized heating further degrades the contact surface, creating a progressive failure cycle. In contactors and circuit breakers, increased contact resistance affects both current-carrying capacity and interrupting performance.

High-resistance contacts also produce arcing during switching operations. Excessive arcing erodes contact surfaces, deposits carbon, and eventually leads to contact welding or complete failure. In motor control applications, this can result in inability to disconnect motors during emergencies.

5. Insulation Tracking and Partial Discharge

When dust accumulates on insulation surfaces, it creates a conductive or semi-conductive layer. Under voltage stress, particularly in high-humidity conditions, surface tracking occurs—a progressive degradation where carbonized paths form across the insulator surface. This phenomenon is especially problematic in medium voltage switchgear where voltage stress is significant.

Partial discharge activity accelerates insulation aging. Research indicates that 85% of disruptive failures in electrical substations are partial discharge-related, with dust and moisture being primary contributors. The discharge activity produces ozone, nitric acid, and heat, further degrading insulation materials in a cascading failure process.

Dust Impact Comparison Table

| Failure Mechanism | Time to Failure | Uyarı İşaretleri | Typical Repair Cost | Önleme Yöntemi |

|---|---|---|---|---|

| Conductive Bridging | 6-18 ay | Increased ground fault alarms, visible arcing | $15,000-$50,000 | IP54+ enclosures, quarterly cleaning |

| Termik Aşırı Yük | 12-36 months | Infrared hot spots, discoloration, insulation smell | $8,000-$25,000 | Thermal imaging, ventilation filters |

| Korozyon | 18-48 months | Green/white deposits, connection loosening | $5,000-$20,000 | Dehumidification, sealed enclosures |

| İletişim Bozulması | 12-24 months | Chattering, coil burnout, difficult operation | $3,000-$15,000 | Contact cleaning, proper lubrication |

| Insulation Tracking | 24-60 months | Partial discharge detection, corona visible at night | $20,000-$100,000+ | Regular cleaning, partial discharge monitoring |

Environmental Factors and Dust Accumulation Rates

Industry-Specific Dust Challenges

Different industries face varying dust contamination profiles:

Manufacturing and Metalworking: Metal dust from grinding, cutting, and machining operations is highly conductive. Facilities with CNC machines, welding operations, or metal fabrication generate fine metallic particles that travel through ventilation systems and settle in electrical rooms.

Mining and Cement: Mineral dust with high silica content is abrasive and hygroscopic. These facilities experience some of the highest dust accumulation rates, often requiring monthly maintenance intervals instead of the standard quarterly schedule.

Gıda İşleme: Organic dust combined with high humidity creates particularly aggressive conditions. Flour, sugar, and grain dust can become conductive when moist and also attracts pests that create additional contamination.

Data Centers and Clean Rooms: Even in controlled environments, dust from outside air intake, construction activities, or equipment wear accumulates over time. The high value of uptime in these facilities makes dust-related outages especially costly.

Climate and Seasonal Variations

Geographical location significantly impacts dust accumulation patterns. Facilities in arid regions face higher airborne dust concentrations, while coastal installations deal with salt-laden dust that accelerates corrosion. Seasonal variations matter too—spring pollen, fall agricultural dust, and winter heating system particulates all contribute to contamination cycles.

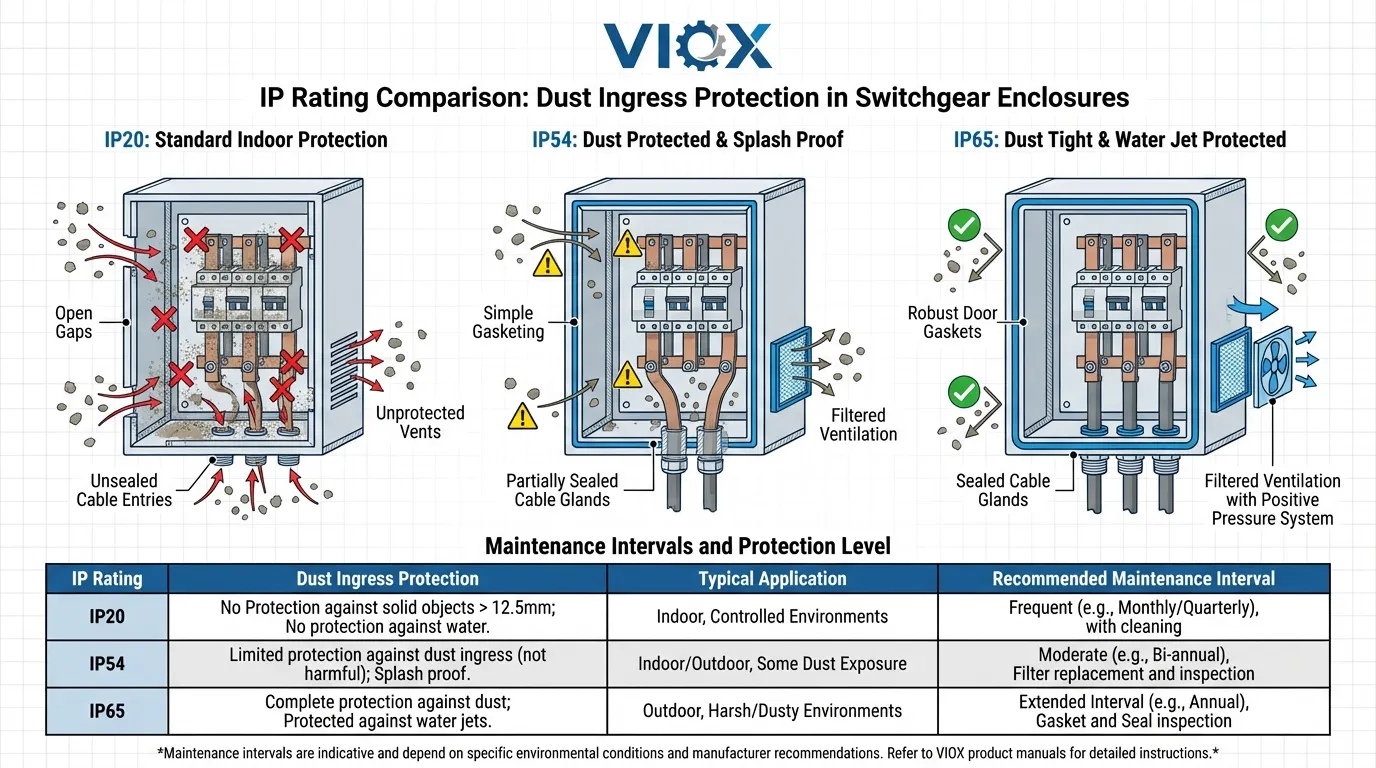

IP Rating Protection Levels

Anlamak IP derecelendirmeleri is essential for specifying appropriate switchgear protection. The IEC 60529 standard defines ingress protection levels using a two-digit code.

IP Rating Comparison for Switchgear Applications

| IP Derecesi | Toz Koruması | Nem Koruması | Typical Application | Bakım Aralığı |

|---|---|---|---|---|

| IP20 | Protected against fingers/large objects only | Hiçbir koruma yok | Indoor, clean environments only | Monthly inspection |

| IP31 | Protected against objects >2.5mm | Protected against dripping water | Standard indoor switchgear | Üç ayda bir temizlik |

| IP41 | Protected against objects >1mm | Protected against splashing water | Hafif sanayi | Üç ayda bir temizlik |

| IP54 | Dust protected (limited ingress) | Protected against water spray | Endüstriyel ortamlar | Semi-annual cleaning |

| IP65 | Dust tight (no ingress) | Protected against water jets | Harsh industrial, outdoor | Annual cleaning |

| IP66 | Dust tight | Protected against powerful water jets | Marine, offshore, extreme environments | Annual cleaning |

For most industrial applications, IP54 represents the minimum acceptable protection level. This rating ensures that dust ingress is limited to amounts that do not interfere with equipment operation. Electrical enclosure material selection should consider both IP rating requirements and environmental corrosion factors.

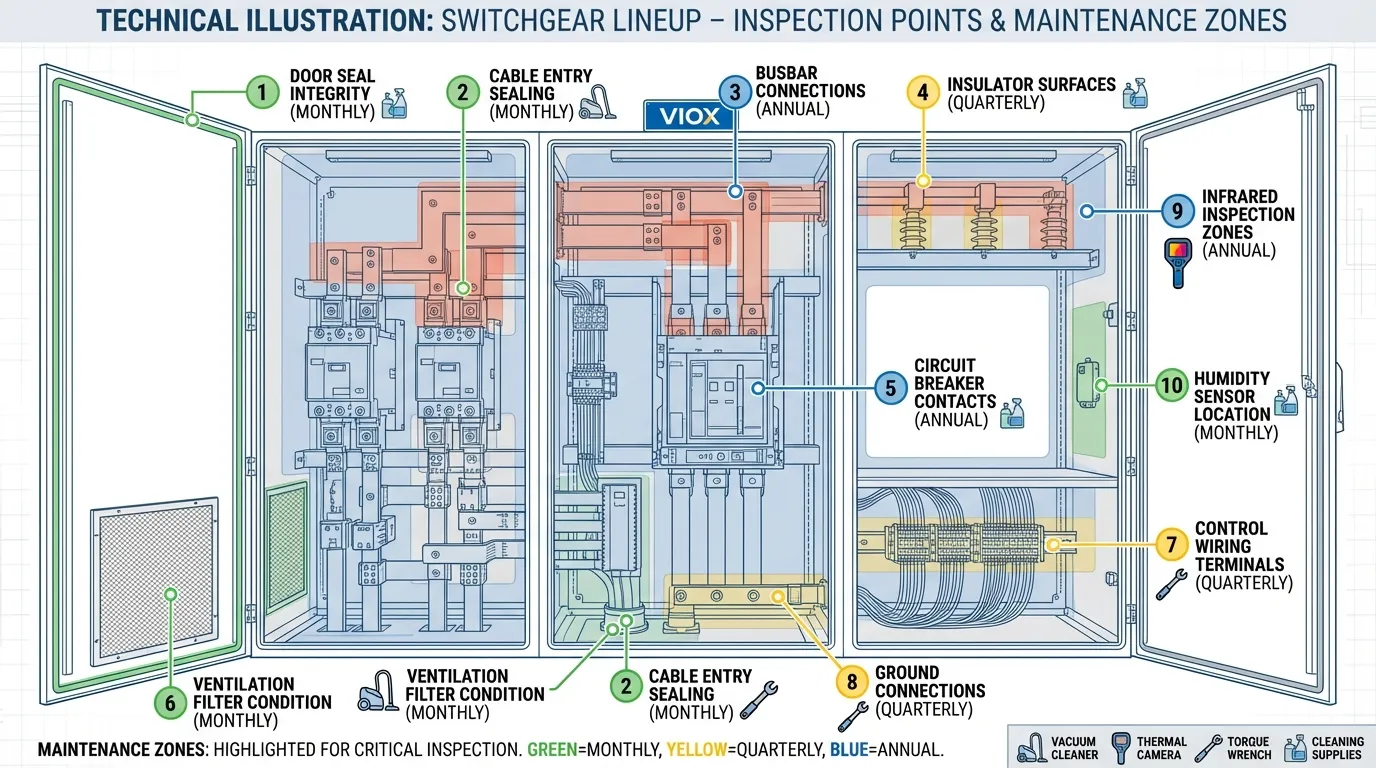

Önleyici Bakım Stratejileri

Inspection and Cleaning Protocols

Effective dust management requires systematic inspection and cleaning programs tailored to environmental conditions. Building an electrical maintenance program should include these dust-specific elements:

Görsel Denetim (Monthly in dusty environments):

- Check for visible dust accumulation on enclosure surfaces

- Inspect door seals and gaskets for integrity

- Look for evidence of dust ingress around cable entries

- Document conditions with photographs for trend analysis

Infrared Thermography (Quarterly):

- Scan busbars, connections, and switching devices for hot spots

- Compare thermal signatures to baseline measurements

- Identify areas where dust insulation is causing temperature rise

- Schedule cleaning before thermal damage occurs

Detailed Internal Cleaning (Frequency based on environment):

- De-energize equipment following kilitleme/etiketleme prosedürleri

- Use HEPA-filtered vacuum equipment (never compressed air, which redistributes dust)

- Clean insulators with approved solvents

- Inspect and clean contacts, checking for pitting or erosion

- Verify torque on all bolted connections

- Test operation of mechanical interlocks and operating mechanisms

Monitoring Technologies

Modern switchgear monitoring systems provide early warning of dust-related degradation:

Partial Discharge Monitoring: Ultrasonic and electromagnetic sensors detect partial discharge activity caused by surface contamination before catastrophic failure occurs.

Temperature Monitoring: Continuous temperature sensors on critical components identify thermal issues caused by dust insulation. Understanding temperature rise limits helps establish appropriate alarm thresholds.

Humidity Monitoring: Tracking relative humidity inside enclosures helps predict corrosion risk and optimize dehumidification systems.

Design Solutions for Dust Mitigation

Enclosure Design Features

Modern switchgear incorporates multiple design features to minimize dust ingress:

Positive Pressure Systems: Filtered air supply maintains slight positive pressure inside enclosures, preventing dust infiltration through small gaps. This approach is common in low voltage switchgear for critical applications.

Labyrinth Seals: Door designs with overlapping surfaces and tortuous paths dramatically reduce dust ingress without requiring perfect gasket compression.

Kablo Giriş Sızdırmazlığı: Kablo rakorları with proper IP ratings prevent dust ingress through cable penetrations, which are often the weakest point in enclosure integrity.

Compartmentalization: Separating high-voltage, low-voltage, and control sections limits contamination spread and allows targeted maintenance.

Malzeme Seçimi

Choosing corrosion-resistant materials reduces vulnerability to dust-accelerated corrosion:

- Paslanmaz çelik panolar for marine and chemical environments

- Tin-plated or silver-plated busbars to resist oxidation (busbar plating comparison)

- Sealed contactors with enclosed contact chambers

- Conformal coating on control circuit boards

Cost Analysis: Prevention vs. Repair

Financial Impact of Dust-Related Failures

The true cost of dust contamination extends beyond immediate repair expenses:

Doğrudan Maliyetler:

- Emergency repair labor (often 2-3x normal rates)

- Replacement components and expedited shipping

- Testing and commissioning after repair

- Regulatory inspection and documentation

Indirect Costs:

- Production downtime ($50,000-$500,000+ per hour in many industries)

- Spoiled product or interrupted processes

- Customer penalties for missed deliveries

- Damage to company reputation

Comparative Cost Analysis:

- Annual preventive maintenance program: $5,000-$15,000 per switchgear lineup

- Typical dust-related failure repair: $25,000-$75,000 plus downtime costs

- Catastrophic arc flash incident: $100,000-$500,000+ plus potential injuries

The return on investment for proper dust prevention typically ranges from 300-500%, making it one of the most cost-effective reliability improvements available.

Standartlar ve Uyumluluk Gereksinimleri

Relevant International Standards

- IEC 62271-200: Specifies requirements for AC metal-enclosed switchgear and controlgear, including environmental testing and IP rating requirements.

- IEC 60529: Defines IP rating test procedures and classification for protection against dust and water ingress.

- IEC 61439: Low-voltage switchgear and controlgear assemblies standard, including requirements for internal separation and protection against environmental factors.

- NFPA 70B: Recommended practice for electrical equipment maintenance, providing guidance on inspection intervals and cleaning procedures.

Anlamak IEC vs. NEC terminology helps navigate requirements across different regulatory frameworks.

FAQ: Dust in Switchgear

Q: How often should switchgear be cleaned in industrial environments?

A: Cleaning frequency depends on environmental conditions. Light industrial environments typically require quarterly cleaning, while heavy manufacturing, mining, or outdoor installations may need monthly attention. Establish a baseline through initial monthly inspections, then adjust frequency based on actual dust accumulation rates.

Q: Can dust cause devre kesiciler to fail without warning?

A: Yes. Dust accumulation can cause thermal calibration drift, making breakers trip at incorrect current levels or fail to trip during actual fault conditions. This is why thermal imaging inspections are critical—they detect problems before failure occurs.

Q: What IP rating is recommended for dusty environments?

A: IP54 is the minimum for industrial environments with moderate dust. Heavy dust environments require IP65 or IP66. The first digit (5 or 6) indicates dust protection level—6 means completely dust-tight, while 5 allows limited ingress that won’t affect operation.

Q: Is compressed air safe for cleaning switchgear?

A: No. Compressed air redistributes dust to other areas and can force particles deeper into equipment. Use HEPA-filtered vacuum equipment specifically designed for electrical maintenance. Always de-energize equipment before cleaning.

Q: How does dust affect aşırı gerilim koruma cihazları?

A: Dust accumulation on SPD components can create tracking paths that cause premature failure or reduce surge suppression effectiveness. Regular inspection of SPD status indicators and thermal imaging of connections is essential.

Q: Can modern sealed switchgear eliminate dust problems?

A: While sealed switchgear with IP65/66 ratings dramatically reduces dust ingress, no enclosure is completely immune. Cable entries, door seals, and ventilation paths remain potential ingress points. Regular inspection remains necessary even for high-IP-rated equipment.

Conclusion: Proactive Dust Management Saves Money and Prevents Failures

Dust contamination represents one of the most preventable causes of switchgear failure, yet it remains a leading contributor to unplanned outages and equipment damage. The five failure mechanisms—conductive bridging, thermal insulation, corrosion acceleration, contact degradation, and insulation tracking—work individually and synergistically to degrade electrical system reliability.

Implementing a comprehensive dust management strategy delivers measurable returns through extended equipment life, reduced failure rates, and eliminated emergency repairs. The combination of proper IP-rated enclosures, systematic maintenance protocols, and modern monitoring technologies provides robust protection against dust-related failures.

For facility managers and electrical engineers, the message is clear: dust is not a cosmetic issue—it’s a reliability threat that demands systematic attention. Investing in prevention costs a fraction of responding to failures, while delivering superior uptime and safety performance.

Ready to protect your electrical infrastructure? VIOX Electric üretmektedir industrial-grade switchgear with advanced dust protection features and provides comprehensive maintenance guidance for maximum reliability in challenging environments.