Havalı Devre Kesici Nedir?

Bir Hava Devre Kesici (ACB) Aşırı yük, kısa devre veya arıza durumlarından kaynaklanan elektrik devrelerini hasardan korumak için tasarlanmış, otomatik olarak çalışan bir elektrik anahtarıdır. Yağ dolu devre kesicilerin aksine, ACB'ler ark söndürme ortamı olarak basınçlı hava veya atmosferik basınçta ortam havası kullanır, bu da onları endüstriyel ve ticari uygulamalar için daha güvenli ve çevre dostu hale getirir.

Hava Devre Kesicilerinin Temel Özellikleri

- Gerilim Aralığı: ACB'ler genellikle 1 kV ile 15 kV arasında değişen düşük ve orta gerilim uygulamalarında çalışır, bazı özel üniteler ise 38 kV'a kadar gerilimleri idare edebilir.

- Mevcut Kapasite: Bu dayanıklı cihazlar, genellikle 400A ile 6300A veya daha yüksek arasında değişen önemli akım yüklerini idare edebilir ve bu da onları ağır hizmet tipi endüstriyel uygulamalar için ideal hale getirir.

- Ark Sönme Yöntemi: ACB'ler yüksek dirençli kesinti prensiplerini kullanır, ark gerilimi sistem gerilimini aşana kadar soğutma, uzatma ve bölme teknikleri yoluyla ark direncini hızla artırır.

Havalı Devre Kesiciler Nasıl Çalışır?

Hava Devre Kesicilerin Çalışma Prensibi

Bu hava devre kesici çalışma prensibi Arıza durumlarında akım akışını kesecek yeterli ark voltajı oluşturmaya odaklanır. İşte detaylı süreç:

Normal Çalışma Durumu

Normal çalışma sırasında akım, nominal yük akımını minimum direnç ve ısı üretimiyle karşılayacak şekilde tasarlanmış ana bakır kontaklardan geçer.

Arıza Tespiti ve Ark Oluşumu

ACB aşırı akım durumu (aşırı yük veya kısa devre) tespit ettiğinde, koruma röleleri açma mekanizmasını tetikler. Kontaklar ayrıldığında, boşluktaki hava moleküllerinin iyonlaşması nedeniyle bir elektrik arkı oluşur.

Ark Sönme Süreci

Hava devre kesicisi arkı söndürmek için çeşitli teknikler kullanır:

- Ark Germe: Ark, ark kılavuzları ve manyetik alanlar kullanılarak mekanik olarak gerilir, uzunluğu ve direnci artar.

- Ark Soğutma: Basınçlı hava veya doğal konveksiyon ark plazmasını soğutarak iletkenliğini azaltır.

- Ark Bölme: Metal plakalı ark olukları arkı birden fazla küçük arka bölerek toplam ark voltajını önemli ölçüde artırır.

- Yüksek Dirençli Yol Oluşturma: Gerilme, soğuma ve bölünmenin birleşik etkisi, sistemin arkı koruma yeteneğini aşan yüksek dirençli bir yol yaratır.

İletişim Tasarımı

Çoğu ACB'de çift kontak sistemi bulunur:

- Ana Bağlantılar: Bakırdan yapılmış, normal yük akımını taşır

- Arklanan Kontaklar: Karbon veya özel alaşımlardan yapılmış olup, anahtarlama işlemleri sırasında arkı kontrol eder

Bu tasarım, ana kontakları ark hasarından koruyarak kesicinin çalışma ömrünü uzatır.

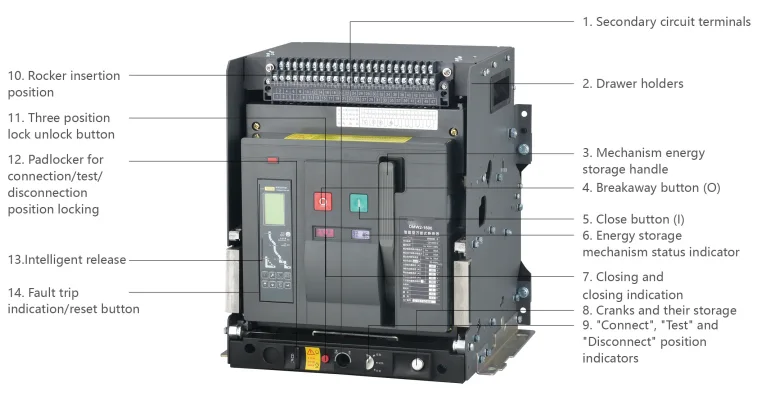

Ayrıntılı ACB Yapı Bileşenleri

Birincil Yapısal Elemanlar:

- İletişim Sistemi:

- Ana Bağlantılar: Kısa devre akımının kesilmesi sırasında aşınmaya karşı etkili koruma sağlayan ark dayanıklı bakır kontaklar

- Arklanan Kontaklar: Aşırı ısınmadan yüksek sıcaklıklara dayanacak şekilde tasarlanmış özel temas malzemesi

- Temas Basınç Sistemi: Paralel çoklu temas bağlantıları elektriksel itmeyi azaltır ve kararlılığı artırır

- Ark Söndürme Sistemi:

- Ark Bastırma Odası: Mekanik dayanıklılığı artıran ve dışarıdan gelen müdahaleleri önleyen yalıtımlı bölme muhafazası

- Arc Chutes: Yayları soğutan, geren ve daha küçük parçalara bölen yalıtım bariyerlerine sahip yapılandırılmış odalar

- Arc Koşucuları: Arkı ana kontaklardan uzaklaştırıp söndürme odasına yönlendirin

- Çalışma Mekanizması:

- Enerji Depolama Sistemi: Hızlı kapanma işlemleri için enerji depolayan yaylı mekanizma

- Manuel Enerji Depolama Sapı: Otomatik sistemler mevcut olmadığında yayların manuel olarak şarj edilmesine olanak tanır

- Elektrik Enerjisi Depolama Mekanizması: Otomatik yay yüklemesi için motor tahrikli sistem

- Beş Bağlantılı Serbest Bırakma Mekanizması: Sap konumundan bağımsız olarak güvenilir, takılmaya neden olmayan bir çalışma sağlar

- Koruma ve Kontrol Sistemleri:

- Akıllı Kontrolör: Koruma, izleme ve iletişim işlevleri sağlayan mikroişlemci tabanlı ünite

- Akım Trafoları: Doğru akım ölçümü ve koruması için dahili CT'ler

- Düşük Gerilim Salınımı: Gerilim önceden ayarlanmış seviyelerin altına düştüğünde devre kesiciyi devre dışı bırakan koruyucu cihaz

- Şant Serbest Bırakma: Acil kapatma için uzaktan tetikleme yeteneği

- Kapanış Elektromıknatısı: Elektrikli kapatma işlemi sağlar

- Çekmece Tipi Mekanizma (uygulanabilir olduğu yerde):

- Çekmece Tabanı: Üç farklı çalışma pozisyonuna sahip sabit montaj yapısı

- İkincil Devre Terminalleri: Kontrol devrelerinin otomatik bağlanması/bağlantısının kesilmesi

- Pozisyon Göstergeleri: Bağlantı/Test/Ayrı pozisyonlarının net bir şekilde gösterilmesi

- Güvenlik Kilitleri: Mekanik kilitleme, güvenli olmayan işlemleri önler

Havalı Devre Kesici Çeşitleri

Farklı olanı anlamak hava devre kesici türleri Belirli uygulamalar için doğru cihazın seçilmesine yardımcı olur:

1. Düz Kesmeli (Çapraz Patlamalı) Hava Devre Kesicileri

İnşaat: Açık havada ve atmosferik basınçta kontakların ayrıldığı en basit tasarım.

Uygulamalar: Ark enerjisinin yönetilebildiği 1kV'a kadar düşük akım uygulamaları için uygundur.

Avantajlar:

- Basit yapı ve bakım

- Daha küçük kurulumlar için uygun maliyetli

- Düşük enerjili uygulamalar için güvenilir

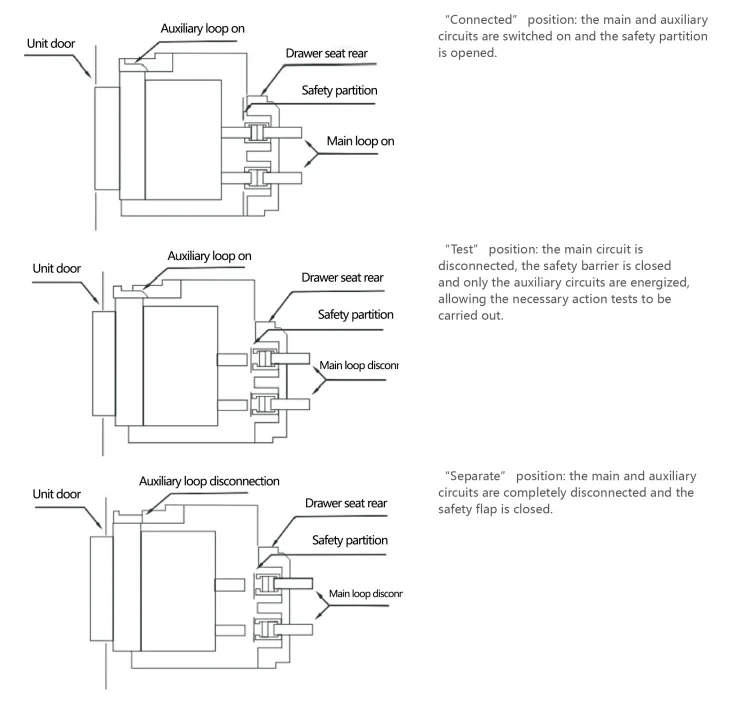

Çekmece Tipi ACB Çalışma Pozisyonları

Birçok modern ACB, gelişmiş güvenlik ve bakım kolaylığı için üç farklı çalışma pozisyonuna sahip çekmece tipi bir yapıya sahiptir:

"Bağlantılı" Pozisyon

- İşlev: Ana ve yardımcı devreler açılır, emniyet bölmesi açılır

- Operasyon: Kesici tamamen devreye girmiş ve normal hizmete hazır

- Güvenlik Özellikleri: Tüm koruyucu sistemler aktif, tam elektrik bağlantısı kuruldu

- Uygulamalar: Güç dağıtımı için normal çalışma durumu

"Test" Pozisyonu

- İşlev: Ana devre bağlantısı kesilmiş, güvenlik bariyeri kapalı, yalnızca yardımcı devreler enerjilendirilmiş

- Operasyon: Gerekli eylem testlerinin güvenli bir şekilde gerçekleştirilmesine olanak tanır

- Güvenlik Özellikleri: Kontrol gücü korunurken yüksek voltaj devreleri izole edildi

- Uygulamalar: Bakım testi, röle kalibrasyonu, fonksiyonel doğrulama

"Ayrı" Pozisyon

- İşlev: Ana ve yardımcı devreler tamamen ayrılmış, emniyet kapağı kapalı

- Operasyon: Maksimum güvenlik için tam elektriksel izolasyon

- Güvenlik Özellikleri: Tüm elektrik sistemlerinden tamamen bağlantı kesilmesi

- Uygulamalar: Büyük bakım, kontak muayenesi, mekanizma revizyonu

Güvenlik Kilitleme Özellikleri

- Mekanik Kilitleme: Çalışma sırasında güvenli olmayan pozisyon değişikliklerini önler

- Pozisyon Göstergeleri: Mevcut çalışma konumunun net görsel göstergesi

- Kilit Hükümleri: Bakım sırasında güvenlik için herhangi bir konumda kilitlemeye izin verir

- Kapı Çerçevesi Entegrasyonu: IP40 koruma derecesine sahip kapalı tasarım

2. Manyetik Patlamalı Hava Devre Kesicileri

İnşaat: Ana devreye seri olarak bağlanmış elektromanyetik bobinleri (patlama bobinleri) içerir.

Çalışma Mekanizması: Arıza akımının oluşturduğu manyetik alan arkın ark oluklarına doğru sapmasına ve gerilmesine yardımcı olur.

Uygulamalar: Daha hızlı ark söndürmenin gerekli olduğu orta gerilim uygulamaları.

Temel Özellikler:

- Manyetik kuvvetle geliştirilmiş ark kontrolü

- Daha hızlı kesinti süreleri

- Daha yüksek arıza akımlarında daha iyi performans

3. Hava Kanalı Hava Devre Kesicileri

İnşaat: Özel olarak tasarlanmış ark olukları, metal ayırıcı plakalar ve izolasyon bariyerleri ile donatılmıştır.

Ark Sönme Yöntemi: Ark, soğutulduğu, uzatıldığı ve birden fazla seri arklara bölündüğü kanallara yönlendirilir.

Uygulamalar: Endüstriyel tesisler, ticari binalar ve enerji dağıtım sistemleri.

Avantajlar:

- Mükemmel ark söndürme kabiliyeti

- Sık operasyonlar için uygundur

- Daha düşük bakım gereksinimleri

4. Hava Patlamalı Devre Kesiciler

İnşaat: Arkları zorla söndürmek için yüksek basınçlı sıkıştırılmış hava sistemleri kullanılır.

Çalışma Prensibi: Basınçlı hava (genellikle 20-30 bar basınç) arkı hızla soğutan ve söndüren güçlü bir patlama yaratır.

Uygulamalar: 15kV'a kadar yüksek gerilim uygulamaları ve hızlı arıza giderme gerektiren kritik tesisler.

Özellikler:

- En hızlı ark söndürme yöntemi

- Yüksek arıza akımı uygulamaları için uygundur

- Hava kompresör sistemleri gerektirir

Gelişmiş Koruma ve Kontrol Sistemleri

Akıllı Kontrolör Özellikleri

Modern ACB'ler, aşağıdakileri sağlayan gelişmiş mikroişlemci tabanlı denetleyicileri bünyesinde barındırır:

Koruma Fonksiyonları:

- Aşırı Akım Koruması: Optimum koordinasyon için ayarlanabilir zaman-akım özellikleri

- Kısa Devre Koruması: Yüksek arıza akımları için anlık açma

- Topraklama Hatası Koruması: Toprak kaçağı akımlarının hassas tespiti

- Düşük Gerilim Koruması: Zaman gecikmeleriyle yapılandırılabilir gerilim izleme

- Faz Kaybı Koruması: Üç fazlı sistemlerde tek fazlı koşulların tespiti

İzleme ve Ölçüm:

- Akım Ölçümü: Her üç fazın gerçek zamanlı izlenmesi

- Gerilim İzleme: Sürekli voltaj seviyesi değerlendirmesi

- Güç Kalitesi Analizi: Harmonik analiz ve güç faktörü izleme

- Enerji Ölçümü: Enerji tüketiminin doğru ölçümü

- Sıcaklık İzleme: Aşırı yük tespiti için dahili sıcaklık algılama

İletişim Yetenekleri:

- Dijital İletişim Arayüzleri: Modbus, Profibus veya Ethernet bağlantısı

- Uzaktan İzleme: SCADA ve bina yönetim sistemleriyle entegrasyon

- Veri Kaydı: Analiz ve trend belirleme için geçmiş veri depolama

- Alarm Üretimi: Çeşitli çalışma koşulları için yapılandırılabilir alarmlar

Elektronik Gezi Üniteleri

Elektronik koruma üniteleri, geleneksel termal-manyetik korumaya kıyasla önemli avantajlar sunar:

Hassas Koruma:

- Ayarlanabilir Ayarlar: Optimum koordinasyon için koruma parametrelerinin ince ayarı

- Çoklu Koruma Eğrileri: Farklı uygulamalar için çeşitli zaman-akım özellikleri

- Bölge Seçici Kilitleme: Yukarı ve aşağı akış cihazlarıyla koordinasyon

- Ark Flaş Azaltma: Ark flaş enerjisini en aza indirmek için özel ayarlar

Gelişmiş Özellikler:

- Yük Profili: Öngörücü bakım için yük modellerinin analizi

- Arıza Kaydı: Dalga formu yakalama ile ayrıntılı arıza analizi

- Kendi Kendine Tanılama: Koruma sistemi sağlığının sürekli izlenmesi

- Şifre Koruması: Kritik ayarlara güvenli erişim

Yardımcı Kontaklar ve Aksesuarlar

Yardımcı Kontak Sistemleri:

- Yapılandırma Seçenekleri: Çeşitli kontak kombinasyonlarında mevcuttur (NO/NC)

- Elektriksel Değerler:

- AC Uygulamaları: 230V/400V, 6A'ya kadar

- DC Uygulamaları: 110V/220V, 6A'ya kadar

- Mekanik Ömür: 300.000'e kadar operasyon

- Uygulamalar: Pozisyon göstergesi, alarm sinyali, kilitleme devreleri

Özel Aksesuarlar:

- Kapanma/Açılma Bobinleri: Uzaktan elektriksel operasyon kabiliyeti

- Düşük Gerilim Salınımları: Gerilim kaybında otomatik devreye girme

- Şant Salınımları: Acil uzaktan tetikleme işlevi

- Motor Çalışma Mekanizmaları: Otomatik yaylı şarj sistemleri

- İletişim Modülleri: Dijital kontrol sistemleriyle entegrasyon

ACB ve Diğer Devre Kesici Türleri

Hava Devre Kesicisi ve Yağ Devre Kesicisi

| Özellik | Hava Devre Kesici | Yağ Devre Kesici |

|---|---|---|

| Arc Medium | Hava/Basınçlı Hava | Mineral Yağı |

| Yangın Riski | Minimal | Petrol nedeniyle yüksek risk |

| Bakım | Daha düşük | Daha yüksek (yağ değişimi gerekli) |

| Çevresel Etki | Çevre dostu | Petrol bertarafı endişeleri |

| Kurulum | Daha basit | Yağ işleme sistemleri gerektirir |

| Maliyet | Orta düzeyde | Daha düşük başlangıç maliyeti |

Hava Devre Kesici ve SF6 Devre Kesici Arasındaki Farklar

| Özellik | Hava Devre Kesici | SF6 Devre Kesici |

|---|---|---|

| Arc Medium | Hava | Kükürt Heksaflorür Gazı |

| Gerilim Aralığı | Tipik olarak 15kV'a kadar | Daha yüksek voltaj uygulamaları |

| Çevresel | Sıfır çevresel etki | SF6 bir sera gazıdır |

| Bakım | Standart prosedürler | Gaz işleme uzmanlığı gerektirir |

| Boyut | Daha büyük ayak izi | Daha kompakt |

| Maliyet | Daha düşük | Daha yüksek |

Hava Devre Kesici ve Vakum Devre Kesici Arasındaki Farklar

| Özellik | Hava Devre Kesici | Vakum Devre Kesici |

|---|---|---|

| Arc Medium | Hava | Vakum |

| Gerilim Aralığı | Düşük ila orta gerilim | Orta gerilim tercih edilir |

| Bakım | Düzenli temas denetimi | Minimum bakım |

| Yaşam Beklentisi | 10.000-20.000 operasyon | 30.000'den fazla operasyon |

| Boyut | Daha büyük | Daha kompakt |

| Uygulamalar | Endüstriyel/Ticari | Güç dağıtımı |

Kurulum Kılavuzu ve Güvenlik Prosedürleri

Kurulum Öncesi Gereksinimler

Çevresel Koşullar

Sıcaklık Gereksinimleri:

- Çalışma Aralığı: -5°C ile +40°C ortam sıcaklığı

- Ortalama Günlük Sıcaklık: Maksimum +35°C (24 saatlik ortalama)

- Depolama Sıcaklığı: Çalışmayan koşullar için genişletilmiş aralık

Nem Özellikleri:

- Maksimum Bağıl Nem: 50% +40°C maksimum sıcaklıkta

- Yoğuşma Önleme: Daha düşük sıcaklıklarda daha yüksek nem kabul edilebilir

- Aylık Ortalamalar: Nem kaynaklı sorunları önlemek için en yağışlı aylara ilişkin belirli sınırlamalar

Kurulum Alanı Gereksinimleri:

- Maksimum Yükseklik: Deniz seviyesinden 2000 m yükseklikte, herhangi bir azalma olmadan

- Kirlilik Seviyesi: Standart uygulamalar için Kategori B koruma seviyesi

- Titreşim Limitleri: IEC standartlarına göre mekanik kararlılık gereksinimleri

- Montaj Yönü: Dikey konumdan maksimum 5° eğim

Güç Kaynağı ve Kontrol Gereksinimleri

Ana Devre Özellikleri:

- Gerilim Değerleri: Tipik olarak 400V/690V AC sistemleri

- Frekans: 50Hz/60Hz çalışma

- Kurulum Kategorileri: Ana devreler için Kategori IV, yardımcı devreler için Kategori III

Yardımcı Güç Sistemleri:

- Kontrol Voltajı: Çoklu seçenekler (24V, 110V, 230V DC/AC)

- Güç Tüketimi: Minimum bekleme gücü için optimize edilmiştir

- Yedekleme Sistemleri: Kritik uygulamalar için pil yedekleme yeteneği

ACB Model Tanımı ve Seçimi

ACB Model Kodlarını Anlama

Hava devre kesici model tanımları, temel özellikleri belirten standart adlandırma kurallarını takip eder:

Tipik Model Kod Yapısı:

- İşletme/Marka Kodu: Üretici kimliği

- Evrensel Tanımlama: ACB tipini gösterir (örneğin, evrensel devre kesici için “W”)

- Tasarım Oluşturma: Sürüm veya tasarım yineleme numarası

- Çerçeve Boyutu: Maksimum akım kapasitesini gösterir (örneğin, 1600A, 3200A, 6300A)

- Direk Konfigürasyonu: Kutup sayısı (3 kutuplu standart, 4 kutuplu mevcuttur)

Çerçeve Sınıfı Derecelendirmeleri:

- 800A Çerçeve: Orta ölçekli endüstriyel uygulamalar için uygundur

- 1600A Çerçeve: Büyük motor kontrol ve dağıtım merkezleri için yaygındır

- 3200A Çerçeve: Ağır sanayi ve kamu hizmetleri uygulamaları

- 6300A Çerçeve: Ana dağıtım ve yardımcı trafo merkezi uygulamaları

Teknik Parametre Özellikleri

Kesme Kapasitesi Değerleri:

- Nihai Kısa Devre Kesme Kapasitesi (Icu): Kesicinin kesebileceği maksimum arıza akımı

- İşletme Kısa Devre Kesme Kapasitesi (Ics): Servis kesme kapasitesi (tipik olarak 75% Yoğun Bakım Ünitesi)

- Kısa Devre Yapma Kapasitesi: Kesicinin kapatabileceği tepe akımı

Elektriksel Ömür Derecelendirmeleri:

- Mekanik Ömür: Yüksüz operasyon sayısı (genellikle 10.000-25.000)

- Elektriksel Ömür: Nominal yük altında işlem sayısı

- Bakım Aralıkları: İşlem sayısına göre önerilen servis süreleri

Adım Adım Hava Devre Kesici Kurulumu

Güvenlik Prosedürleri

KRİTİK: Kuruluma başlamadan önce mutlaka kilitleme/etiketleme prosedürlerini izleyin.

- Sistemin enerjisini kesin ve uygun test ekipmanlarını kullanarak sıfır enerji durumunu doğrulayın

- Güvenlik bariyerleri kurun ve çalışma alanındaki uyarı işaretleri

- Uygun KKD kullanın: Yalıtımlı eldivenler, güvenlik gözlükleri, ark derecesine sahip giysiler ve baretler

- Uygun topraklamanın sağlanması kurulum sırasında tüm ekipmanların

Mekanik Kurulum

Adım 1: Temel Hazırlık

- Montaj yüzeyinin düz, sağlam ve ACB ağırlığını destekleyebilecek kapasitede olduğundan emin olun

- Gerekirse titreşim sönümleyici malzemeler takın

- Üretici spesifikasyonlarına göre yeterli boşlukların olduğunu doğrulayın

Adım 2: ACB Montajı

- Ağır üniteler için uygun kaldırma ekipmanlarını kullanın

- ACB'yi montaj noktalarıyla hizalayın

- Üretici tarafından belirtilen cıvataları kullanarak ve uygun tork değerlerine sahip olarak sabitleyin

- Yerel yönetmelikler gerektiriyorsa sismik kısıtlamalar takın

Adım 3: Elektrik Bağlantıları

- Giriş ve çıkış iletkenlerini belirlenmiş terminallere bağlayın

- Üreticinin önerdiği tork değerlerini tüm bağlantılara uygulayın

- Uygun kablo pabuçları ve bağlantı donanımları kullanın

- Faz dönüşünü ve uygun topraklama bağlantılarını sağlayın

Kontrol ve Koruma Kablolaması

Koruma Rölesi Bağlantıları:

- Akım trafolarını (CT'ler) uygun polarite ile bağlayın

- Gerekirse gerilim trafolarını (VT) bağlayın

- Gösterge ve kontrol için yardımcı kontakları takın

Kontrol Devresi Kablolaması:

- Kapanma ve açılma bobinlerini bağlayın

- Yardımcı güç kaynaklarını kablolayın

- Gerektiğinde birbirine geçen devreleri takın

- Enerjilendirmeden önce tüm kontrol fonksiyonlarını test edin

Test ve Devreye Alma

Görsel Muayene Kontrol Listesi:

- Tüm bağlantıların sıkı ve düzgün şekilde etiketlenmiş olduğunu doğrulayın

- Yabancı cisim veya kalıntı olup olmadığını kontrol edin

- Uygun temas hizalamasını onaylayın

- Koruma ayarlarının tasarım gereksinimleriyle eşleştiğini doğrulayın

Elektrik Testi:

- Tüm devrelerin yalıtım direnci testi

- Temas direnci ölçümü

- Gezi ünitesi kalibrasyonu ve testi

- Kontrol devresi işlevselliğinin doğrulanması

- Yüksüz koşullarda operasyonel test

En İyi Bakım Uygulamaları

Önleyici Bakım Programı

Aylık Denetimler

Görsel Kontroller:

- Aşırı ısınma belirtilerini (renk bozulması, yanık kokuları) kontrol edin

- Gevşek bağlantılar veya hasarlı bileşenler olup olmadığını kontrol edin

- Kontrol paneli göstergelerinin düzgün çalıştığını doğrulayın

- Ark kanallarını hasar veya kirlenme açısından inceleyin

Operasyonel Doğrulama:

- Manuel çalıştırma mekanizmalarını test edin

- Gezi göstergesi işlevlerini doğrulayın

- Yardımcı kontak çalışmasını kontrol edin

- Monitör koruma rölesi ekranları

Üç Aylık Bakım

İletişim Denetimi:

- Ana temas direncini ölçün

- Temas hizalamasını ve aşınmasını kontrol edin

- Ark oluşturan kontakları aşınma açısından inceleyin

- Uygun temas silme ve basıncı doğrulayın

Mekanik Bileşenler:

- İşletme mekanizmalarını üretici talimatlarına göre yağlayın

- Yay gerginliğini ve enerji depolama sistemlerini kontrol edin

- Bağlantıları aşınma veya hizalama hatası açısından inceleyin

- Uygun kapanış ve açılış saatlerini doğrulayın

Yıllık Kapsamlı Bakım

Elektrik Testi:

- Tüm devrelerde yalıtım direnci testleri gerçekleştirin

- Yüksek potansiyel (hi-pot) testi yapın

- Test koruma rölesi doğruluğu ve zamanlaması

- Akım trafosunun doğruluğunu doğrulayın

Mekanik Revizyon:

- Çalışma mekanizmalarını sökün ve inceleyin

- Aşınmış bileşenleri ve sarf malzemelerini değiştirin

- Tüm bağlantılarda tork ayarlarını kalibre edin

- Sistem genelinde yağlamayı güncelleyin

Kritik Bakım Prosedürleri

İletişim Değiştirme Yönergeleri:

- Direnç üretici sınırlarını aştığında ana kontakları değiştirin

- Aşınma minimum kalınlığa ulaştığında ark kontaklarını değiştirin

- Uygun temas malzemesi özelliklerini sağlayın

- Üretici montaj prosedürlerini tam olarak takip edin

Arc Chute Bakımı:

- Yalıtım levhalarını onaylı çözücülerle temizleyin

- Çatlakları veya karbon izlerini kontrol edin

- Hasarlı bileşenleri derhal değiştirin

- Uygun montaj ve hizalamayı doğrulayın

Bakım Dokümantasyonu

Kayıt Tutma Gereksinimleri:

- Tüm denetimlerin ve testlerin ayrıntılı kayıtlarını tutun

- Herhangi bir anormal bulguyu veya düzeltici eylemi belgelendirin

- Parça bileşeni değiştirme geçmişini takip edin

- Üretici kılavuzlarını ve teknik belgeleri güncel tutun

Performans Trendleri:

- Zaman içinde temas direnci eğilimlerini izleyin

- Gezi ünitesi çalışma geçmişini takip edin

- Hizmet sırasında çevresel koşulları belgelendirin

- Öngörücü bakım için arıza modellerini analiz edin

Sık Karşılaşılan Sorunları Giderme

ACB Kapatılmayacak

Olası Nedenler ve Çözümler

Düşük Gerilim Salınım Sorunları:

- Belirti: Kesici, kapatma girişiminden hemen sonra devreye giriyor

- Tanı: Kontrol voltaj seviyelerini ve bağlantılarını kontrol edin

- Çözüm: Düşük voltajlı bobine nominal voltaj beslemesini doğrulayın; gevşek bağlantıları veya atmış sigortaları onarın

Yay Enerji Depolama Sorunları:

- Belirti: Kapatma mekanizması yeterli güce sahip değil

- Tanı: Yay şarj motorunun çalışmasını ve yay gerginliğini kontrol edin

- Çözüm: Enerji depolama yaylarını değiştirin veya şarj motorunu onarın; yayların düzgün sıkıştırıldığını doğrulayın

Mekanik Bağlama:

- Belirti: Yavaş veya eksik kapanış işlemi

- Tanı: Yabancı cisimler veya yetersiz yağlama açısından çalışma mekanizmasını kontrol edin

- Çözüm: Mekanizmayı iyice temizleyin; uygun yağlayıcıları uygulayın; yabancı maddeleri çıkarın

Kontrol Devresi Arızaları:

- Belirti: Kapatma komutlarına yanıt yok

- Tanı: Test kontrol devresi sürekliliği ve bileşen fonksiyonu

- Çözüm: Kırık kabloları onarın; arızalı röleleri veya kontrol anahtarlarını değiştirin; yardımcı kontak çalışmasını doğrulayın

İstenmeyen Gezinmeler (Rahatsız Edici Geziler)

Koruma Sistemi Sorunları

Aşırı Akım Ayarları:

- Sorun: Gezi ayarları gerçek yük koşulları için çok hassas

- Tanı: Gerçek yük akımını gezi ayarlarıyla karşılaştırın

- Çözüm: Koruma ayarlarını güvenli parametreler dahilinde ayarlayın; sistem çalışmasıyla koordine edin

Akım Trafosu Sorunları:

- Sorun: CT yükü çok yüksek veya bağlantılar gevşek

- Tanı: CT ikincil devre bütünlüğünü ve yük hesaplamalarını kontrol edin

- Çözüm: CT yükünü azaltın; tüm bağlantıları sıkın; CT oranının doğruluğunu doğrulayın

Çevresel Faktörler:

- Sorun: Sıcaklık, nem veya titreşim çalışmayı etkiliyor

- Tanı: Çalışma sırasında çevre koşullarını izleyin

- Çözüm: Havalandırmayı iyileştirin; titreşim sönümleyici takın; gerekirse yerini değiştirin

İletişim Sorunları

Temas Aşırı Isınması

Gevşek Bağlantılar:

- Tanı: Sıcak noktaları belirlemek için kızılötesi termografi kullanın

- Çözüm: Tüm bağlantıları teknik özelliklere uygun şekilde yeniden sıkın; hasarlı donanımı değiştirin

İletişim Bozulması:

- Tanı: Temas direncini ölçün ve temel değerlerle karşılaştırın

- Çözüm: Gerektiğinde kontakları temizleyin veya değiştirin; aşırı aşınmanın nedenini araştırın

Ark Sorunları

Ark Şutu Sorunları:

- Tanı: Karbon birikimi veya hasarlı yalıtım plakalarını kontrol edin

- Çözüm: Ark oluğu bileşenlerini temizleyin veya değiştirin; montajın doğruluğunu doğrulayın

Temas Hizalaması:

- Tanı: Temas yüzeylerinin ve hizalamanın kontrol edilmesi

- Çözüm: Temas konumunu ayarlayın; aşınmış bileşenleri değiştirin; silme işleminin doğruluğunu doğrulayın

Elektronik Gezi Ünitesi Arızaları

Dijital Ekran Sorunları

- Sorun: Boş veya yanlış ekranlar

- Çözüm: Güç kaynağını kontrol edin; aygıt yazılımını güncelleyin; arızalı üniteyi değiştirin

İletişim Hataları

- Sorun: Uzaktan izleme yeteneğinin kaybı

- Çözüm: İletişim kablolarını doğrulayın; protokol ayarlarını kontrol edin; ağ bağlantısını test edin

Uygulamalar ve Kullanım Örnekleri

Endüstriyel Uygulamalar

Üretim Tesisleri

Güç Dağıtım Merkezleri: ACB'ler, alçak gerilim motor kontrol merkezlerinde ana kesiciler olarak görev yaparak, birden fazla motor devresini ve dağıtım besleyicilerini korurlar.

Ağır Makine Koruması: Çelik fabrikaları, madencilik faaliyetleri ve kimyasal işleme tesisleri gibi büyük endüstriyel ekipmanlar, güvenilir aşırı akım koruması için ACB'lere güvenir.

Vaka Çalışması: Bir çelik üretim tesisi, elektrik ark ocağı besleyicilerini korumak için 4000A ACB'ler kullanıyor ve bu sayede bakım işlemleri sırasında duruş süresini en aza indirirken güvenilir koruma sağlıyor.

Enerji Üretim Tesisleri

Jeneratör Koruması: ACB'ler, enerji santrallerinde jeneratörleri ters güç, aşırı akım ve kısa devre durumlarından korur.

Yardımcı Güç Sistemleri: Soğutma pompaları, havalandırma sistemleri ve kontrol güç kaynakları dahil olmak üzere enerji santrali yardımcı sistemlerinin korunması için gereklidir.

Ticari Uygulamalar

Yüksek Binalar

Ana Dağıtım Panoları: ACB'ler ticari bina elektrik sistemlerinde ana kesiciler olarak görev yaparlar ve genellikle 1600A ile 4000A arasında değişirler.

Acil Güç Sistemleri: Acil jeneratör bağlantıları ve otomatik transfer şalteri uygulamaları için kritiktir.

HVAC Sistem Koruması: Büyük ticari HVAC sistemleri, özellikle soğutma sistemleri ve büyük motor yükleri için ACB'lerin sağladığı güçlü korumaya ihtiyaç duyar.

Veri Merkezleri

Kesintisiz Güç Kaynağı (UPS) Koruması: ACB'ler UPS sistemlerini korur ve kritik güç uygulamaları için güvenilir anahtarlama sağlar.

Güç Dağıtım Birimleri: Veri merkezi güç dağıtımında koruma ve izolasyon yetenekleri sağlayan temel bileşenler.

Yardımcı Uygulamalar

Elektrik Trafo Merkezleri

Dağıtım Besleyicileri: ACB'ler, genellikle 15kV sınıfında olan, elektrik dağıtım trafo merkezlerindeki giden dağıtım devrelerini korur.

Trafo Koruması: Dağıtım trafoları ve ekipman korumaları için sekonder koruma.

Demiryolu Elektrifikasyonu

Çekiş Gücü Sistemleri: Demiryolu uygulamaları için tasarlanmış özel ACB'ler, elektrikli ulaşım sistemleri için koruma sağlar.

Sinyal Sistemi Koruması: Demiryolu sinyal ve haberleşme sistemleri güç kaynakları için kritiktir.

Maliyet Değerlendirmeleri ve Yatırım Getirisi

İlk Yatırım Analizi

Satın Alma Fiyatı Faktörleri

- Boyut ve Derecelendirme: Maliyetler genellikle daha küçük 1000A üniteler için $5.000'den, gelişmiş özelliklere sahip büyük 6300A üniteler için $50.000+'ya kadar değişmektedir.

- Koruma Özellikleri: Elektronik gezi üniteleri, haberleşme yetenekleri ve gelişmiş izleme maliyetleri 20-40% oranında artırır.

- Marka ve Kalite: Üst düzey üreticiler daha yüksek fiyatlar talep ederler ancak genellikle daha iyi güvenilirlik ve daha uzun hizmet ömrü sunarlar.

Kurulum Maliyetleri

- İşgücü Gereksinimleri: Profesyonel kurulum genellikle karmaşıklığa ve saha koşullarına bağlı olarak 15-25% ekipman maliyetine mal olur.

- Destekleyici Altyapı: Temeller, kablo bağlantıları ve kontrol kabloları toplam proje maliyetine 10-20% ekleyebilir.

- Test ve Devreye Alma: Uygun test ve devreye alma hizmetlerinin maliyeti genellikle ekipman değerinin 5-10%'si kadardır.

İşletme Maliyeti Avantajları

Bakım Tasarrufu

- Azaltılmış Kesinti Süresi: Yüksek kaliteli ACB'ler minimum bakımla 20+ yıl çalışabilir ve operasyonel kesintileri azaltır.

- Öngörücü Bakım: İzleme yeteneklerine sahip modern ACB'ler, duruma bağlı bakıma olanak sağlayarak gereksiz servis aralıklarını azaltır.

- Parça Bulunabilirliği: Standartlaştırılmış tasarımlar, uzun vadeli parça bulunabilirliğini ve makul değiştirme maliyetlerini garanti eder.

Enerji Verimliliğinin Faydaları

- Düşük Temas Direnci: Bakımı doğru yapılan ACB'ler elektrik dağıtım sistemlerindeki enerji kayıplarını en aza indirir.

- Güç Faktörü İyileştirme: Gelişmiş gezi üniteleri güç kalitesi izleme ve iyileştirme önerileri sağlayabilir.

Yatırım Getirisi Hesaplamaları

Risk Azaltma Değeri

- Ekipman Koruması: $500.000 alt akım ekipmanını koruyan $30.000 ACB mükemmel sigorta değeri sağlar.

- İş Sürekliliği: Güvenilir koruma, saatte binlerce dolara mal olabilen maliyetli üretim kesintilerini önler.

- Sigorta Avantajları: Uygun koruma genellikle elektrik sigorta primlerini %5-15% oranında azaltır.

Tipik ROI Zaman Çizelgesi

- Endüstriyel Uygulamalar: Azaltılmış bakım ve geliştirilmiş güvenilirlik sayesinde 3-5 yıl.

- Ticari Binalar: Enerji tasarrufu ve azalan servis çağrıları sayesinde 5-7 yıl.

- Kritik Tesisler: Yüksek duruş ve ekipman değiştirme maliyeti nedeniyle 2-3 yıl.

Endüstri Standartları ve Yönetmelikler

Uluslararası Standartlar

IEC Standartları

- IEC 61439: Alçak gerilim şalt cihazları ve kontrol düzenekleri – ACB tesisatları için performans gereksinimlerini tanımlar.

- IEC 62271: Yüksek gerilim şalt ve kontrol düzenekleri – orta gerilim ACB uygulamalarını kapsar.

- IEC 60947: Alçak gerilim şalt ve kontrol donanımları – ACB performans özelliklerini ve test gereksinimlerini belirtir.

IEEE Standartları

- IEEE C37.04: AC yüksek gerilim devre kesicileri için standart derecelendirme yapısı.

- IEEE C37.09: AC yüksek gerilim devre kesicileri için standart test prosedürleri.

- IEEE C37.06: Simetrik akım esasına göre derecelendirilen AC yüksek gerilim devre kesicileri için standart.

Ulusal ve Bölgesel Kodlar

Birleşik Devletler

- Ulusal Elektrik Kanunu (NEC): Madde 240, aşırı akım koruma gerekliliklerini ve ACB uygulamalarını kapsamaktadır.

- UL 489: Kalıplanmış kasa devre kesiciler ve devre kesici muhafazaları için standarttır.

- NEMA Standartları: ACB performansını, testini ve uygulama yönergelerini kapsayan çeşitli standartlar.

Avrupa Birliği

- EN 61439: Alçak gerilim şalt düzenekleri için Avrupa standardı.

- EN 62271: Yüksek gerilim şalt cihazları standartları.

- CE İşaretleme Gereksinimleri: AB pazarlarında satılan ACB'ler için zorunlu uygunluk işareti.

Güvenlik ve Çevre Mevzuatı

İşyeri Güvenliği

- OSHA Standartları: 29 CFR 1910 Alt Bölüm S, ACB kurulumu ve bakımı için elektrik güvenliği gerekliliklerini kapsar.

- NFPA 70E: ACB bakım prosedürleri de dahil olmak üzere işyerlerinde elektrik güvenliği standardı.

Çevresel Uyumluluk

- RoHS Yönergesi: Elektrikli ekipmanlarda tehlikeli maddelerin kısıtlanması.

- WEEE Yönergesi: Atık elektrikli ve elektronik ekipmanların bertarafına ilişkin gereklilikler.

- ISO 14001: ACB üretimi ve bertarafı için çevre yönetim sistemi standartları.

Uyumluluk Belgeleri

Test ve Belgelendirme

- Tip Testi: Performansın yayınlanmış standartlara göre doğrulanması için fabrika testleri.

- Rutin Testler: Tutarlı kalite ve performansı garantilemek için üretim testleri.

- Üçüncü Taraf Sertifikasyonu: Uygulanabilir standartlara uygunluğun bağımsız olarak doğrulanması.

Kayıt Tutma Gereksinimleri

- Kurulum Dokümantasyonu: Kurulum prosedürlerinin ve test sonuçlarının ayrıntılı kayıtları.

- Bakım Kayıtları: Tüm bakım faaliyetlerinin ve bulgularının düzenli olarak belgelenmesi.

- Olay Raporları: Herhangi bir koruma operasyonu veya ekipman arızasının belgelenmesi.

Sıkça Sorulan Sorular (SSS)

Temel Anlayış

S: Hava Devre Kesicinin (ACB) temel işlevi nedir?

A: Bir ACB, genellikle 450 V'un altındaki düşük voltajlı uygulamalarda, 800 ila 10.000 amperlik elektrik devreleri için aşırı akım ve kısa devre koruması sağlar. Arıza durumlarında elektrik ekipmanını korumak ve hasarı önlemek için akım akışını otomatik olarak keser.

S: Hava devre kesicisi normal devre kesicisinden nasıl farklıdır?

A: Hava devre kesicileri, ark söndürme ortamı olarak havayı kullanır ve genellikle daha düşük akımları (6A-125A) idare eden standart minyatür devre kesicilere (MCB'ler) kıyasla daha yüksek akım uygulamaları (800A-10kA+) için tasarlanmıştır. ACB'ler ayrıca daha sağlam bir yapıya ve gelişmiş koruma özelliklerine sahiptir.

S: Hava devre kesicisindeki “hava” ne anlama geliyor?

C: "Hava", bir arıza sırasında kontaklar ayrıldığında oluşan elektrik arkını söndürmek için kullanılan ortamı ifade eder. Hava, arkın soğutulmasına, gerilmesine ve artık sürdürülemeyecek hale gelene kadar bölünmesine yardımcı olur ve böylece devreyi etkili bir şekilde keser.

Teknik Operasyon

S: Hava devre kesicisinin atmasına ne sebep olur?

A: ACB'ler üç ana durumdan dolayı devre dışı kalır: aşırı yük (uzun süreler boyunca nominal kapasiteyi aşan akım), kısa devreler (ani yüksek akım yükselmeleri) ve topraklama arızaları (toprağa akım kaçağı). Koruyucu röleler bu durumları algılar ve tetikleme mekanizmasını tetikler.

S: Hava devre kesicim neden tetiklendikten sonra sıfırlanmıyor?

A: Yaygın nedenler şunlardır: düşük voltaj tahliye valfinin uygun voltajı alamaması, çalışma mekanizmasında mekanik sıkışma, enerji depolama yayının arızalanması veya toz ya da yağlama eksikliği nedeniyle tetikleme mekanizmasının sıkışması. Sıfırlama işlemini denemeden önce arıza durumunu daima belirleyin ve giderin.

S: Hava devre kesicilerin ömrü ne kadardır?

C: Uygun bakımla, ACB'ler genellikle 20-30 yıl veya 10.000-20.000 operasyon dayanır. Kullanım ömrü, çalışma koşullarına, bakım kalitesine ve arıza kesintilerinin sıklığına bağlıdır. Düzenli temas kontrolü ve aşınmış bileşenlerin zamanında değiştirilmesi, hizmet ömrünü uzatır.

Bakım ve Sorun Giderme

S: Hava devre kesicilerinin bakımı ne sıklıkla yapılmalıdır?

A: Aylık: Aşırı ısınma belirtileri ve gevşek bağlantılar için görsel kontroller. Üç Aylık: Temas direnci ölçümleri ve mekanik çalışma kontrolleri. Yıllık: Yalıtım direnci, tetikleme zamanlaması ve koruyucu röle kalibrasyonu dahil olmak üzere kapsamlı testler.

S: ACB'nin acil müdahale gerektirdiğine dair işaretler nelerdir?

A: Dikkat edilmesi gerekenler: yanık kokuları veya gözle görülür kavuruculuk, çalışma sırasında alışılmadık sesler, düzensiz veya rahatsız edici takılma, kapatılamama veya kapalı kalamama, aşırı ısı birikimiveya kontaklarda veya ark kanallarında gözle görülür hasar.

S: ACB kontaklarını kendim değiştirebilir miyim?

C: Kontak değişimi yalnızca uygun eğitim ve araçlara sahip kalifiye elektrik teknisyenleri tarafından yapılmalıdır. Yanlış montaj, düşük kontak basıncına, hizalama hatalarına ve tehlikeli çalışma koşullarına yol açabilir. Üretici prosedürlerini ve kilitleme/etiketleme protokollerini her zaman izleyin.

S: ACB'm neden aşırı ısınıyor?

A: Aşırı ısınma genellikle şu durumlardan kaynaklanır: gevşek bağlantılar yüksek direnç oluşturarak, aşırı yüklenmiş devreler anma kapasitesini aşan, zayıf temas durumu ek direnç yaratmak veya yetersiz havalandırma kesici muhafazasının etrafında.

Diğer Kesici Türleriyle Karşılaştırmalar

S: Çekmece tipi ACB'nin üç konumu nelerdir?

A: Çekmeceli tip ACB’lerin üç çalışma pozisyonu vardır: "Bağlantılı" (tüm devreler aktifken normal çalışma), "Test" (ana devre bağlantısı kesildi, yardımcı devreler test için enerjilendirildi) ve "Ayırmak" (Bakım için tam izolasyon). Her pozisyon için özel güvenlik kilitleri ve uygulamaları mevcuttur.

S: ACB'de akıllı kontrolör nedir?

C: Akıllı kontrolör, aşırı akım koruması, topraklama hatası tespiti, voltaj izleme, güç kalitesi analizi, iletişim yetenekleri ve veri kaydı sağlayan mikroişlemci tabanlı bir koruma ve izleme sistemidir. Geleneksel termal-manyetik koruma ünitelerine kıyasla daha hassas koruma ve gelişmiş özellikler sunar.

S: ACB model tanımlamasını nasıl okurum?

A: ACB model kodları genellikle şunları içerir: üretici kodu, evrensel tanımlama ("W" gibi), tasarım üretim numarası, gövde boyutu (akım kapasitesi) ve kutup konfigürasyonu. Örneğin, "OMW2-1600/4"te "OM" üreticiyi, "W" evrensel kesiciyi, "2" nesli, "1600" 1600A gövde boyutunu ve "4" 4 kutuplu konfigürasyonu belirtir.

S: ACB ile VCB (Vakumlu Devre Kesici) arasındaki fark nedir?

A: Ark Ortamı: ACB'ler havayı, VCB'ler ise vakumu kullanır. Gerilim Aralığı: ACB'ler genellikle 15kV'a kadar; VCB'ler ise 38kV'a kadar. Bakım: VCB'ler kapalı vakum odaları sayesinde daha az bakım gerektirir. Boyut: VCB'ler daha kompakttır. Maliyet: VCB'ler başlangıçta genellikle daha pahalıdır ancak uzun vadede daha iyi değer sunabilirler.

S: Diğer devre kesici tipleri yerine ACB'yi ne zaman tercih etmeliyim?

A: ACB'leri şunlar için seçin: endüstriyel uygulamalar yüksek akım kapasitesi (800A+) gerektiren, ortamlar yağ dolu kesicilerden kaynaklanan yangın riskinin kabul edilemez olduğu durumlarda, sık sık çalışma gereksinimler ve uygulamalar Çevresel kaygıların SF6 gazı yerine havayı tercih ettiği yerlerde.

S: Hava devre kesicileri yağ devre kesicilerinden daha mı iyidir?

A: ACB'ler birçok avantaj sunar: yangın riski yok petrol, daha kolay bakım yağ değişimi olmadan, çevre dostu operasyon ve daha hızlı çalışma Ancak, belirli yüksek gerilim uygulamaları için yine de yağlı kırıcılar tercih edilebilir.

Kurulum ve Güvenlik

S: Hava devre kesicileri dış mekanlarda kullanılabilir mi?

C: Standart ACB'lerin çoğu, kontrollü ortamlarda iç mekan kullanımı için tasarlanmıştır. Dış mekan uygulamaları için, çevre koşullarına (sıcaklık, nem, UV maruziyeti) uygun özel hava koşullarına dayanıklı muhafazalar gereklidir. Bazı üreticiler, dış mekan kullanımına uygun ACB modelleri sunmaktadır.

S: ACB'lerle çalışırken hangi güvenlik önlemleri esastır?

A: Her zaman takip edin kilitleme/etiketleme prosedürleri, kullanmak uygun KKD (ark derecesine sahip giysiler, yalıtımlı eldivenler), sıfır enerjiyi doğrula işe başlamadan önce, emin olun uygun topraklama, sürdürmek güvenli yaklaşma mesafelerive asla enerjili ekipman üzerinde tek başınıza çalışmayın.

S: Bir ACB'nin etrafında ne kadar boşluk alanı gereklidir?

A: Minimum boşluklar voltaj ve üreticiye göre değişir ancak genellikle şunları gerektirir: ön erişim: Bakım için 3-4 feet, arka/yan boşluklar: NEC ve üretici spesifikasyonlarına göre, üst boşluk: ısı dağılımı ve kablo yönlendirmesi için yeterlidir.

S: Yardımcı kontaklar nelerdir ve neden önemlidir?

A: Yardımcı kontaklar, ana kesici kontaklarıyla birlikte çalışan ve konum göstergesi, alarm sinyali ve kilitleme devreleri için kullanılan ek kontak setleridir. Daha düşük akımlar (genellikle 6A) için derecelendirilmiştir ve çeşitli NO/NC kombinasyonlarında mevcuttur. Uzaktan izleme, otomatik kontrol sistemleri ve karmaşık elektrik tesisatlarında emniyet kilitlemesi için gereklidirler.

S: ACB montajı için hangi çevresel koşullar gereklidir?

A: ACB'ler şunları gerektirir: Sıcaklık: -5°C ile +40°C ortam sıcaklığı (24 saatlik ortalama +35°C'yi aşmayan), Nem: +40°C'de maksimum 50%, Yükseklik: Deniz seviyesinden 2000 m'ye kadar, Kurulum: Dikeyden maksimum 5° eğim ve Kirlilik Seviyesi: Kategori B koruması. Uygun havalandırma ve nem, toz ve aşındırıcı atmosferlerden korunma esastır.

Başvurular ve Seçim

S: Uygulamam için hangi boyutta ACB'ye ihtiyacım var?

A: ACB boyutlandırması şunlara bağlıdır: maksimum yük akımı (sürekli yük kırıcı boyutu 125%), kısa devre akımı kurulum noktasında, koordinasyon yukarı/aşağı akış cihazlarıyla ve belirli uygulama gereksinimleri (motor çalıştırma vb.) Yük hesaplamalarına ve üretici talimatlarına bakınız.

S: ACB'ler yenilenebilir enerji sistemlerinde kullanılabilir mi?

A: Evet, ACB'ler genellikle güneş ve rüzgar santrallerinde kullanılır. DC birleştirici kutuları, invertör koruması, şebeke bağlantısıve enerji depolama sistemleriDC devrelerinde kullanıldığında ACB'nin DC uygulamaları için derecelendirildiğinden emin olun.

S: Akıllı ACB'ler yatırıma değer mi?

A: İletişim yeteneklerine sahip akıllı ACB'ler şunları sunar: gerçek zamanlı izleme, tahmini bakım uyarıları, enerji kullanım takibi, uzaktan operasyon yeteneğive bina yönetim sistemleriyle entegrasyonÖzellikle kritik tesislerde ve büyük tesislerde çok değerlidirler.

Maliyet ve Ekonomik Hususlar

S: ACB'ler neden standart devre kesicilerden daha pahalıdır?

A: ACB'lerin maliyeti şu sebeplerden dolayı daha yüksektir: sağlam yapı yüksek akım taşıma için, gelişmiş koruma sistemleri ayarlanabilir ayarlarla, kaliteli malzemeler uzun hizmet ömrü için, kapsamlı test ve sertifikasyon ve gelişmiş özellikler elektronik gezi üniteleri gibi.

S: ACB yükseltmelerinin tipik geri ödeme süresi nedir?

A: Geri ödeme uygulamaya göre değişir ancak genellikle şu aralıktadır: 3-7 yaş başından sonuna kadar: azaltılmış bakım maliyetleri, geliştirilmiş güvenilirlik, enerji verimliliği kazanımları, daha düşük sigorta primlerive kaçınılan kesinti maliyetleri.

Acil Durumlar

S: Acil bir durumda ACB açılmazsa ne yapmalıyım?

A: Acil servislerle hemen iletişime geçin eğer acil bir tehlike varsa. Yukarı akış bağlantılarını kes güvenli bir şekilde erişilebilirse enerjisini kesmek. Bölgeyi boşaltın Yangın veya patlama riski varsa. Nitelikli elektrik personeliyle iletişime geçin Acil onarımlar için. Sıkışan mekanizmaları asla elle zorlamaya çalışmayın.

S: ACB'min bir arıza nedeniyle hasar gördüğünü nasıl anlarım?

A: Şunları kontrol edin: görünür hasar temaslara veya konutlara, gezi göstergesi arıza işlemi gösteriliyor, alışılmadık direnç okumaları, mekanik bağlama çalışır durumda, aşırı ısınma belirtileriveya kontaklarda veya ark kanallarında gözle görülür hasarHerhangi bir önemli arıza kesintisinden sonra kesicinin profesyonel olarak kontrol edilmesini sağlayın.

Sonuç

Hava Devre Kesiciler, elektrik sistemi güvenliği ve güvenilirliği açısından kritik bir yatırımdır. Hava Devre Kesicilerin doğru seçimi, montajı ve bakımı, optimum performans sağlar, arıza süresini en aza indirir ve değerli ekipman ve personeli korur.

Önemli Çıkarımlar

- Seçim Kriterleri: ACB'leri gerilim değerine, akım kapasitesine, kesme kapasitesine ve özel uygulama gereksinimlerine göre seçin.

- Kurulum Mükemmelliği: Güvenli ve güvenilir kurulum için üretici yönergelerini ve endüstri standartlarını izleyin.

- Bakım Stratejisi: Ekipman ömrünü ve güvenilirliğini en üst düzeye çıkarmak için kapsamlı önleyici bakım programları uygulayın.

- Maliyet Yönetimi: Satın alma fiyatı, kurulum, bakım ve operasyonel faydalar dahil olmak üzere toplam yaşam döngüsü maliyetlerini göz önünde bulundurun.

- Mevzuata Uygunluk: Ekipmanın yaşam döngüsü boyunca geçerli kodlara ve standartlara uyumu sağlayın.