産業用および安全用アプリケーションで一般的に使用される非常停止ボタンは、通常、ノーマルクローズ(NC)接点で設計されています。この構成により、フェイルセーフ機構が確保され、作動時に機械への電力を即座に遮断できるため、安全性と動作信頼性が向上します。

NO接点とNC接点の比較

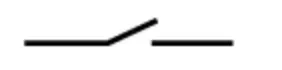

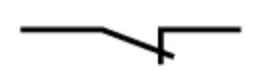

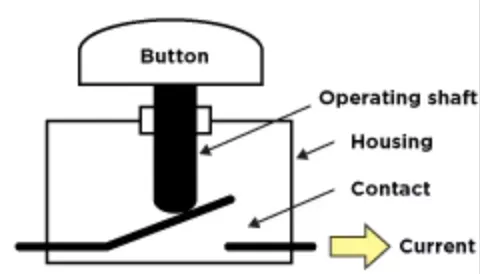

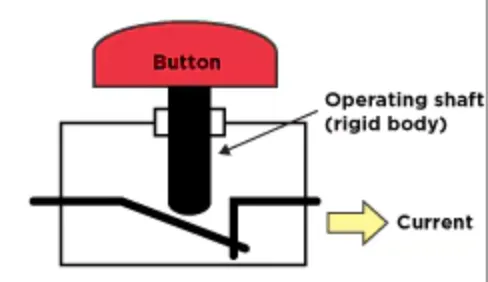

| NO コンタクト | NCコンタクト | |

|---|---|---|

| 電気記号 |  |

|

| スイッチ構造の概要(操作前の状態) |  |

|

| 説明 |

|

|

| 緊急停止回路として使用 | No | あり |

| 回路の断線や導通不良が発生した場合の動作 | 動作中は電流が流れない。 ->非常停止回路として使用した場合、ボタンを押しても停止しない。(機械の危険な故障) |

ボタンをリセットしても電流は流れない。 ->回路の構造上、ボタンリセットが認識できず、操作できない。(機械の安全な故障) |

非常停止ボタンの構成

緊急停止ボタンは、通常、電気接点が作動し、回路に電流が流れるデフォルトの状態を確保するために、その設計において通常クローズ(NC)接点を採用しています。この構成は、産業環境における操作の安全性を維持するために非常に重要です。作動すると、ボタンの接点が開き、接続された機械への電力供給が直ちに遮断され、迅速なシャットダウンが開始されます。国際安全規格では、ノーマルオープン(NO)構成と比較して、より信頼性が高く、応答性の高い緊急停止メカニズムを提供するため、このアプローチを推奨しています。E-ストップ・ボタンにNC接点を使用することは、作業員の安全と機器の保護を優先し、様々な産業で広く採用されています。

即時対応メカニズム

ノーマルクローズ(NC)非常停止ボタンの迅速な応答能力は、産業環境における重要な安全機能です。これらのボタンが作動すると、即座に回路が開き、機械への電力が数ミリ秒で切断されます。この即時の遮断は、事故を防止し、緊急事態における潜在的な負傷を最小限に抑えるために極めて重要です。閉状態から開状態への素早い移行は、ボタンが完全に押されていなくても、効果的に作業を停止できることを保証します。この設計の選択は、ほぼ瞬時のシャットダウンメカニズムを提供することにより、作業者の安全を優先し、NC接点を様々な産業における緊急停止システムに適した構成にしています。

フェイルセーフの安全設計

ノーマルクローズ(NC)非常停止ボタンのフェールセーフ設計は、産業環境においてさらなる安全層を提供します。断線や断線など、回路に障害が発生した場合、NC構成により、機器の動作が自動的に停止します。この本質的な安全機能により、作動すべきでないときに機械が作動するのを防ぎ、事故や装置破損のリスクを低減します。フェイルセーフ機構は、システム障害や電源喪失が発生した場合でもデフォルトで安全な状態になるため、連続運転が危険となるような状況では特に有用です。この設計思想は、緊急停止システムの国際安全基準とベストプラクティスに合致しており、潜在的に危険な環境における作業員の保護と機器の完全性を優先しています。

運用信頼性のメリット

非常停止ボタンのノーマルクローズ構成は、いくつかの点で操作の信頼性を高めます。通常動作中に閉回路を維持することで、これらのボタンは部分的な作動を検出して応答することができ、完全に押されていなくても安全が確保されます。この設計はまた、回路の完全性を継続的に監視することを可能にし、障害や切断が発生した場合、直ちにシャットダウンをトリガーします。さらに、NCセットアップは、回路を遮断するために意図的な動作を必要とするため、誤報や意図しない作動の可能性を低減します。これらの機能は、迅速で信頼性の高い対応が不可欠な産業環境における安全基準の維持に不可欠な、より堅牢で信頼性の高い非常停止システムに貢献します。