Comprensione della corrente di cortocircuito nominale: Conoscenza essenziale per la sicurezza elettrica industriale

Nel complesso panorama dei sistemi elettrici industriali, la comprensione della corrente di cortocircuito nominale (SCCR) non è solo un requisito normativo, ma un imperativo di sicurezza fondamentale. Che tu stia progettando quadri elettrici, specificando apparecchiature elettriche o garantendo la conformità degli impianti, la SCCR influisce direttamente sulla sicurezza del personale, sulla longevità delle apparecchiature e sulla continuità operativa. Questa guida completa esplora cosa significa SCCR, perché è importante e come calcolarla e implementarla correttamente nelle tue applicazioni industriali.

Cos'è la corrente di cortocircuito nominale (SCCR)?

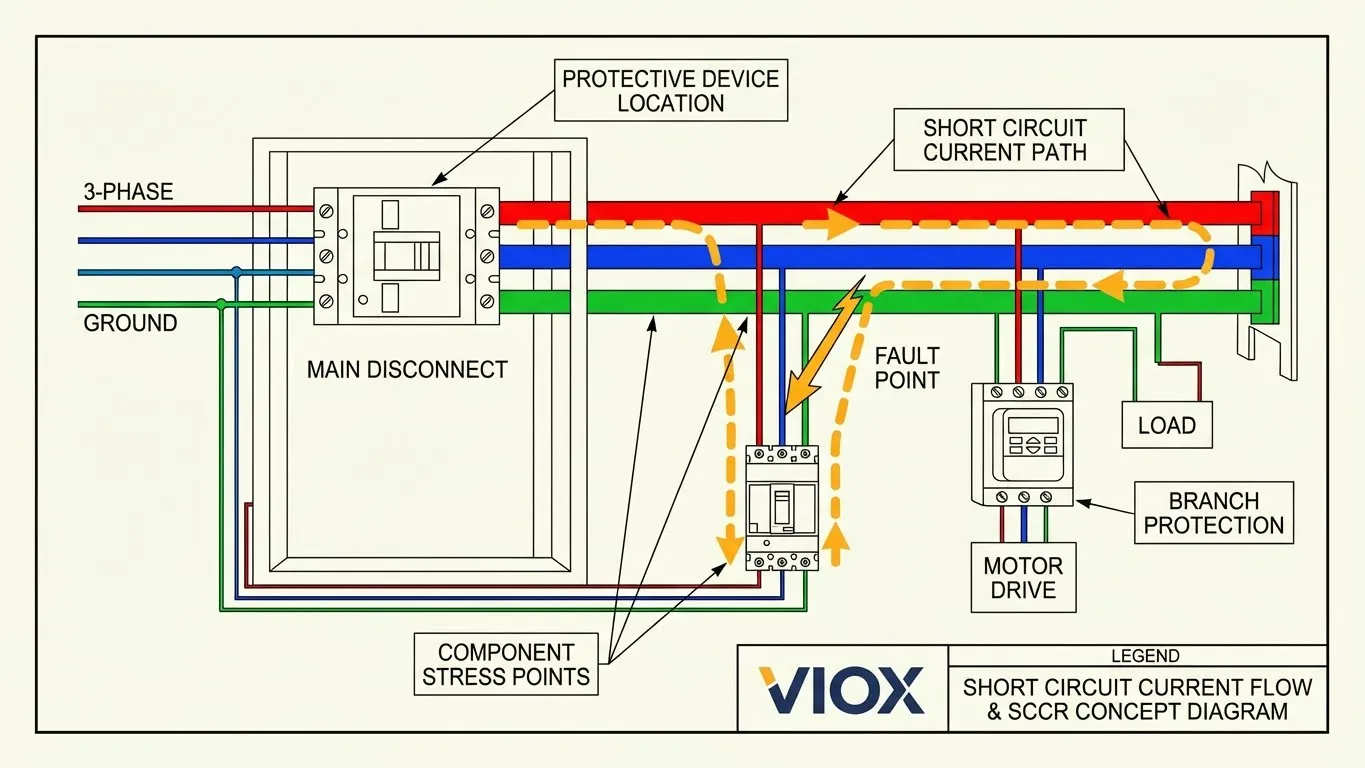

La corrente di cortocircuito nominale (SCCR) rappresenta il livello massimo di corrente di cortocircuito che un componente elettrico, un assemblaggio o un quadro elettrico industriale può sopportare senza subire danni o creare condizioni pericolose. Espressa in chiloampere (kA) a una tensione specifica, la SCCR funge da valutazione di sicurezza critica che garantisce che le apparecchiature elettriche possano sopravvivere a condizioni di guasto fino a quando i dispositivi di protezione non eliminano il guasto.

A differenza delle capacità di interruzione per interruttori o fusibili (che indicano la capacità del dispositivo di interrompere la corrente di guasto), la SCCR si applica a componenti passivi e assemblaggi completi che devono sopportare condizioni di cortocircuito. La valutazione comprende le forze elettromagnetiche, lo stress termico e la sollecitazione meccanica che le apparecchiature subiscono durante un evento di guasto.

SCCR vs. Capacità di interruzione: comprendere la differenza

| Caratteristica | SCCR (Corrente di cortocircuito nominale) | Capacità di interruzione (kAIC) |

|---|---|---|

| Applicazione | Componenti passivi e assemblaggi (pannelli, interruttori, contattori) | Dispositivi di protezione attivi (interruttori automatici, fusibili) |

| Funzione | Capacità di tenuta – capacità di sopravvivere alla corrente di guasto | Capacità di interruzione – capacità di interrompere la corrente di guasto |

| Determina | Corrente di guasto massima che l'apparecchiatura può sopportare in sicurezza | Corrente di guasto massima che il dispositivo può interrompere in sicurezza |

| Componenti tipici | Quadri elettrici industriali, avviatori motore, contattori, relè | Interruttori automatici, fusibili, interruttori di sezionamento |

| Richiesto da | NEC 409.110, UL 508A | Standard di prodotto dei componenti |

| Base di valutazione | Componente con la valutazione più bassa o assemblaggio testato | Test del dispositivo secondo gli standard UL/IEC |

Perché la SCCR è importante: l'imperativo di sicurezza e conformità

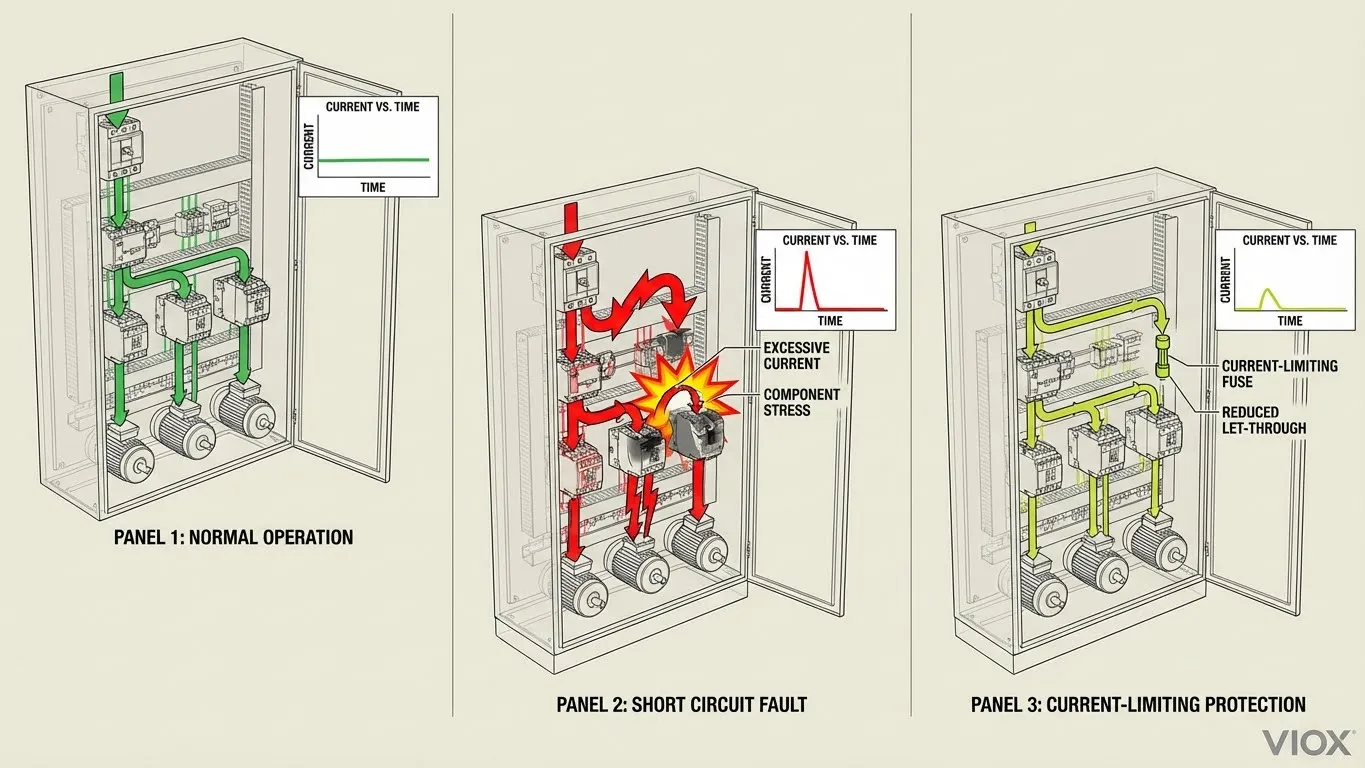

Prevenzione di guasti catastrofici

Quando le apparecchiature elettriche sono esposte a correnti di guasto superiori alla loro SCCR, le conseguenze possono essere gravi e immediate. Le forze elettromagnetiche generate durante i cortocircuiti possono distruggere fisicamente i componenti, mentre le temperature estreme possono innescare incendi o causare guasti esplosivi. Senza un'adeguata SCCR, anche brevi condizioni di guasto possono provocare:

- Distruzione delle apparecchiature con rischi di proiezione dovuti all'esplosione di componenti

- Incidenti di arco elettrico causando gravi ustioni o decessi

- rischi di incendio da conduttori e componenti surriscaldati

- Tempi di inattività della produzione della durata di giorni o settimane

- Esposizione alla responsabilità per installazioni non conformi

Requisiti normativi

Diversi organismi di regolamentazione impongono un'adeguata considerazione della SCCR:

Codice elettrico nazionale (NEC) richiede che la SCCR dell'apparecchiatura debba essere uguale o superiore alla corrente di guasto disponibile nel punto di installazione. Le sezioni chiave includono:

- NEC 110.10: L'apparecchiatura deve essere in grado di resistere e interrompere le correnti di guasto

- NEC 409.110: I quadri elettrici industriali devono essere contrassegnati con la loro SCCR

- NEC 670.3: Le targhette delle macchine industriali devono includere la SCCR

- NEC 408.6 (2020): I quadri e i pannelli di distribuzione devono avere la corrente di guasto disponibile contrassegnata sul campo

Standard OSHA richiedono che tutti i sistemi di quadri elettrici abbiano un'adeguata SCCR sia per le installazioni nuove che esistenti, rendendo la conformità un obbligo di sicurezza sul lavoro.

UL 508A fornisce la metodologia standard per determinare e contrassegnare la SCCR sui quadri elettrici industriali, con il Supplemento SB che offre procedure di calcolo dettagliate.

Come viene determinata la SCCR: metodi di calcolo

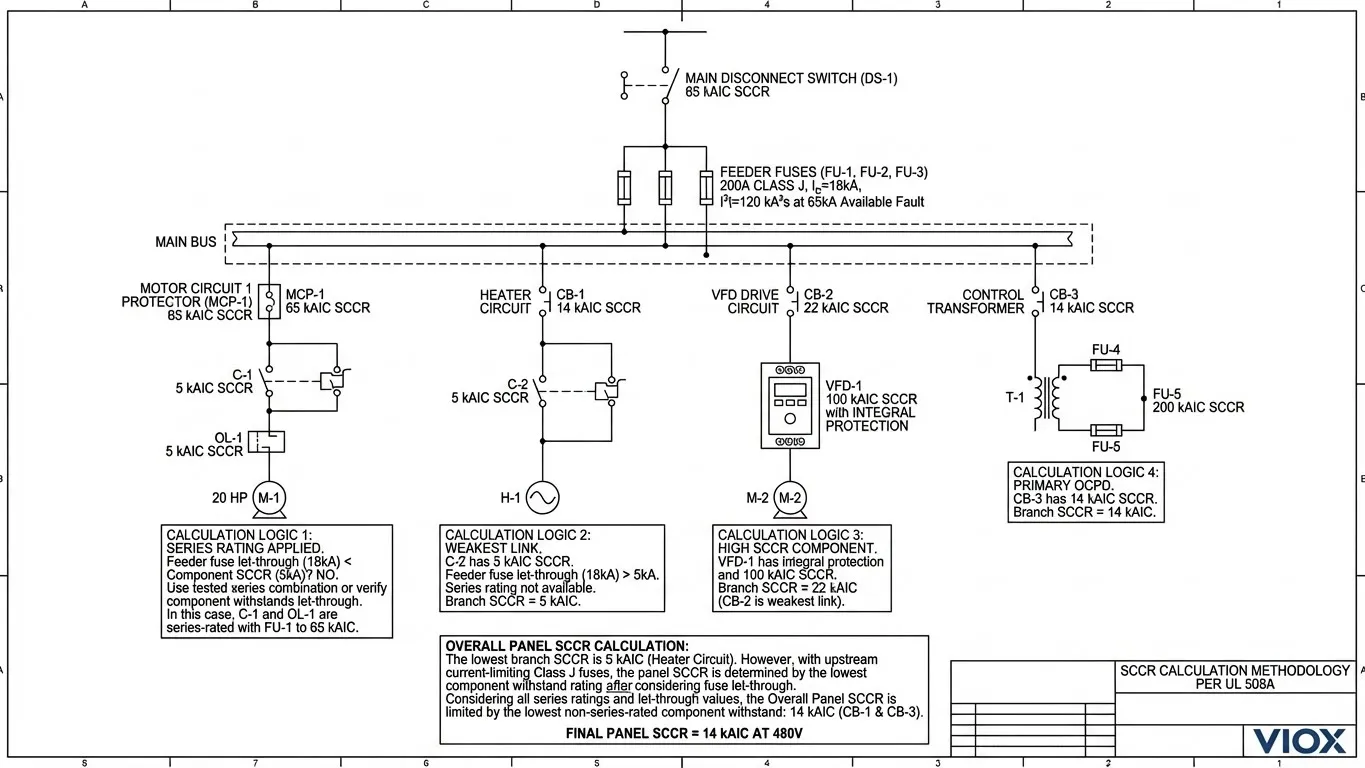

Metodo del Supplemento SB UL 508A

Il metodo più ampiamente accettato per determinare la SCCR dei quadri elettrici industriali segue la procedura delineata nel Supplemento SB UL 508A. Questo approccio analitico non richiede test fisici e segue un processo sistematico in quattro fasi:

Fase 1: identificare tutti i componenti del circuito di potenza

Catalogare ogni componente nel circuito di potenza che trasporta la potenza di linea principale ai carichi (motori, riscaldatori, illuminazione, ecc.). Questo include:

- Interruttori automatici e fusibili

- Contattori e avviatori motore

- Interruttori di sezionamento

- Relè di sovraccarico

- Morsettiere

- Blocchi di distribuzione dell'alimentazione

- Trasformatori (come modificatori di circuito)

Nota: i componenti del circuito di controllo (pulsanti, spie luminose, bobine di relè) non richiedono la valutazione della SCCR.

Fase 2: determinare la SCCR del singolo componente

Per ogni componente del circuito di potenza, stabilire la sua SCCR utilizzando uno dei tre metodi (in ordine di preferenza):

- Valutazione testata dal produttore: Trovato su etichette dei componenti, imballaggi o documentazione tecnica

- Valori predefiniti della tabella SB4.1 UL 508A: Valutazioni conservative per componenti non contrassegnati

- Valutazioni combinate: Valutazioni speciali testate ottenute con una specifica protezione da sovracorrente

| Tipo di componente | SCCR predefinito (se non contrassegnato) |

|---|---|

| Morsettiere | 10 kA |

| Contattori/Avviatori motore | 5 kA |

| Relè di controllo | 5 kA |

| Interruttori di sezionamento | 5 kA |

| Trasformatori di controllo | 5 kA |

| Dispositivi pilota | 5 kA |

Fase 3: Identificare i dispositivi limitatori di corrente

Determinare se fusibili o interruttori automatici limitatori di corrente proteggono il pannello. Questi dispositivi possono aumentare significativamente l'SCCR complessivo limitando la corrente di picco durante i guasti. I produttori forniscono grafici di corrente passante che mostrano i valori massimi di corrente a varie correnti di guasto disponibili.

Fase 4: Calcolare l'SCCR del pannello

L'SCCR complessivo del pannello è generalmente determinato dal componente con la valutazione più bassa nel circuito di potenza. Tuttavia, se viene utilizzata una protezione da sovracorrente limitatrice di corrente, l'SCCR può essere aumentato in base a:

- La corrente passante del dispositivo di protezione

- Valutazioni combinate testate dal produttore

- Coordinamento adeguato tra la protezione del circuito di alimentazione e del circuito derivato

Metodo di assemblaggio testato

In alternativa, i pannelli possono essere testati fisicamente per stabilire il loro SCCR. Questo metodo prevede di sottoporre un assemblaggio completo a correnti di guasto in condizioni di laboratorio controllate. Sebbene più costoso, il test può ottenere valutazioni più elevate rispetto ai metodi analitici ed è spesso utilizzato per progetti di pannelli standardizzati.

Strategie per aumentare l'SCCR

Quando l'SCCR calcolato si rivela insufficiente per il punto di installazione, diverse strategie possono ottenere valutazioni più elevate:

1. Utilizzare una protezione da sovracorrente limitatrice di corrente

I fusibili limitatori di corrente (Classe J, Classe CC, Classe T) e gli interruttori automatici limitatori di corrente riducono drasticamente la corrente di picco passante. Questa protezione consente ai componenti con valutazioni intrinseche inferiori di ottenere un SCCR a livello di sistema significativamente più elevato.

Esempio: Un contattore con una valutazione di base di 5 kA può raggiungere un SCCR di 100 kA se protetto da fusibili di Classe J appropriati, in base ai test del produttore.

2. Specificare componenti con valutazione più elevata

Sostituire i componenti con valutazione bassa con alternative che offrono un SCCR superiore. Molti componenti moderni sono testati e elencati per valutazioni di 65 kA o 100 kA, offrendo flessibilità di progettazione.

| Strategia di aggiornamento | Miglioramento tipico dell'SCCR |

|---|---|

| Contattore standard → Contattore con valutazione SCCR elevata | 5 kA → 65 kA |

| Interruttore scatolato → Interruttore limitatore di corrente | 10-25 kA → 65-100 kA |

| Fusibili standard → Fusibili limitatori di corrente di Classe J | N/A → 100-200 kA |

| Morsettiere di base → Morsettiere con valutazione SCCR elevata | 10 kA → 65 kA |

3. Sfruttare le valutazioni combinate

I produttori testano combinazioni specifiche di componenti insieme, certificando valori SCCR più elevati per i dispositivi accoppiati. Le combinazioni comuni includono:

- Avviatori motore con tipi specifici di fusibili o interruttori automatici

- Contattori con relè di sovraccarico coordinati

- Azionamenti a frequenza variabile con protezione del circuito particolare

4. Installare pannelli di distribuzione separati

Per le strutture con correnti di guasto disponibili molto elevate, l'installazione di pannelli di distribuzione intermedi con protezione limitatrice di corrente può creare zone con livelli di corrente di guasto gestibili, consentendo l'utilizzo di valutazioni di apparecchiature standard.

Requisiti di marcatura SCCR

Informazioni richieste sulle targhette dei pannelli

NEC 409.110 impone che i pannelli di controllo industriali visualizzino le seguenti informazioni:

- Nome e indirizzo del produttore

- Tensione, fase e frequenza del pannello

- Corrente di cortocircuito nominale (in kA, con tensione massima)

- Corrente nominale a pieno carico

- Corrente nominale massima del dispositivo di protezione da sovracorrente del circuito derivato

- Numero o riferimento dello schema elettrico

- Valutazione del tipo di involucro

La marcatura SCCR deve essere permanente, leggibile e visibile dopo l'installazione. Formato tipico:

“Corrente di cortocircuito nominale: 65 kA RMS simmetrici, 600 V massimo”

Requisiti di marcatura sul campo (NEC 2020)

Il NEC 2020 ha introdotto requisiti aggiuntivi per la marcatura sul campo della corrente di guasto disponibile su:

- Apparecchiature di servizio

- Quadri elettrici e apparecchiature di comando

- Quadri di distribuzione

- Pannelli di controllo industriali (nel punto di alimentazione)

Queste marcature devono includere il valore della corrente di guasto disponibile calcolata e la data del calcolo, garantendo che gli ispettori possano verificare la conformità con l'SCCR dell'apparecchiatura.

Sfide comuni di conformità SCCR

Sfida 1: Componenti legacy non contrassegnati

Molte installazioni esistenti contengono componenti fabbricati prima dei requisiti di marcatura SCCR. Gli approcci risolutivi includono:

- Applicazione dei valori predefiniti della Tabella SB4.1 della norma UL 508A

- Ricerca di dati storici del produttore

- Valutazione della sostituzione delle apparecchiature o dell'aggiornamento della protezione

- Installazione di una protezione di alimentazione a limitazione di corrente

Sfida 2: Posizioni con elevata corrente di guasto disponibile

I moderni collegamenti di utenza e i generatori di grandi impianti possono produrre correnti di guasto disponibili superiori a 100 kA. Per affrontare questo problema è necessario:

- Uso strategico della protezione a limitazione di corrente

- Analisi dell'impedenza per identificare i punti di connessione a corrente inferiore

- Specifica di componenti premium con valori nominali di 200 kA

- Progettazione di sistemi con valore nominale in serie (con cautela)

Sfida 3: Modifiche e alterazioni del progetto

Quando i pannelli subiscono modifiche, il calcolo SCCR originale potrebbe non essere più valido. Le migliori pratiche includono:

- Documentare tutte le modifiche con calcoli aggiornati

- Riverificare l'SCCR ogni volta che vengono aggiunti o sostituiti componenti

- Mantenere i registri di calcolo in conformità ai requisiti NEC

- Utilizzo di strumenti digitali per la gestione continua della conformità

Strumenti e risorse per il calcolo dell'SCCR

La moderna progettazione elettrica si affida sempre più a strumenti software per semplificare la determinazione dell'SCCR:

Piattaforme di calcolo digitale

- Software di conformità SCCR Bussmann OSCAR: Applicazione online che guida gli utenti attraverso l'inserimento dei componenti, il calcolo dell'SCCR del pannello e la generazione della documentazione

- Strumenti SCCR globali del produttore: Piattaforme basate su database che forniscono valori nominali di combinazione testati

- Calcolatore FC2: App mobili e web per il calcolo della corrente di guasto e la generazione di etichette NEC 110.24

- Soluzioni integrate CAD: Software di progettazione elettrica con moduli di calcolo SCCR integrati

Migliori pratiche per la documentazione

Mantenere registri completi che includano:

- Specifiche dei componenti con valori SCCR

- Fogli di lavoro di calcolo che mostrano la metodologia

- Schede tecniche del produttore e curve di let-through

- Schemi unifilari con valori nominali indicati

- Cronologia delle revisioni per le modifiche del pannello

- Valori di corrente di guasto disponibile contrassegnati sul campo

SCCR nel contesto globale

Sebbene questo articolo si concentri sugli standard nordamericani (NEC, UL 508A), i mercati internazionali hanno requisiti paralleli:

| Regione | Standard | Requisito chiave |

|---|---|---|

| Nord America | NEC, UL 508A | Marcatura SCCR, documentazione della corrente di guasto disponibile |

| Europa | IEC 60439, IEC 61439 | Corrente di tenuta al cortocircuito (Icw) |

| Internazionale | IEC 60947 | Potere di interruzione/chiusura in cortocircuito per i componenti |

I costruttori di macchine che esportano in Nord America devono garantire la conformità ai requisiti SCCR anche se le apparecchiature sono state progettate secondo altri standard. Ciò spesso richiede analisi aggiuntive, aggiornamenti dei componenti o coordinamento della protezione.

Domande frequenti sull'SCCR

Qual è la SCCR minima richiesta dal codice?

Il NEC non specifica un valore minimo universale di SCCR. Invece, l'SCCR dell'apparecchiatura deve essere uguale o superiore alla corrente di guasto disponibile nel punto di installazione. Tuttavia, la tabella SB4.1 di UL 508A fornisce valori nominali predefiniti a partire da 5 kA per la maggior parte dei componenti non contrassegnati, rendendolo un minimo pratico per molti quadri di controllo industriali. Alcune fonti indicano che le installazioni richiedono comunemente 35 kA, 65 kA o 100 kA a seconda delle caratteristiche elettriche dell'impianto.

I pannelli di solo controllo richiedono valori nominali SCCR?

No. In base all'eccezione NEC 409.110(4) e ai requisiti UL 508A, i quadri di controllo industriali contenenti solo componenti del circuito di controllo (bobine di relè, spie luminose, pulsanti, ecc.) non richiedono la marcatura SCCR. Solo i quadri con componenti del circuito di potenza che forniscono alimentazione di linea principale ai carichi necessitano della determinazione e della marcatura SCCR.

Posso utilizzare il potere di interruzione dell'interruttore principale come SCCR del quadro?

Questa pratica obsoleta precede i moderni requisiti SCCR e non è più accettabile. Il potere di interruzione del dispositivo principale di protezione da sovracorrente non tiene conto delle capacità di tenuta dei componenti a valle. La corretta determinazione dell'SCCR deve seguire la metodologia del Supplemento SB di UL 508A o le prove, considerando tutti i componenti del circuito di potenza.

In che modo i trasformatori influenzano i calcoli SCCR?

I trasformatori influenzano la corrente di guasto disponibile attraverso l'impedenza, ma non hanno i propri valori nominali SCCR. Quando i pannelli includono trasformatori, calcolare la corrente di guasto disponibile sul lato secondario considerando l'impedenza del trasformatore, quindi determinare i requisiti SCCR dei componenti in base a tale valore calcolato. I componenti lato carico devono resistere alla corrente di guasto lato secondario.

Cosa succede se la corrente di guasto disponibile supera la SCCR (Short-Circuit Current Rating) dell'apparecchiatura?

Ciò crea una violazione del codice e un grave pericolo per la sicurezza. Le apparecchiature esposte a correnti di guasto superiori al loro SCCR possono guastarsi in modo catastrofico, causando incendi, esplosioni e lesioni gravi. Le azioni correttive includono: installare una protezione di alimentazione a limitazione di corrente, aggiornare a componenti con una portata maggiore, riposizionare le apparecchiature in posizioni con corrente di guasto inferiore o modificare il sistema di distribuzione elettrica per ridurre la corrente di guasto disponibile.

Chi è responsabile per i calcoli SCCR: l'OEM o l'installatore?

La responsabilità dipende dalla situazione specifica. I produttori di apparecchiature originali (OEM) che costruiscono quadri di comando industriali devono determinare e contrassegnare il SCCR del quadro secondo UL 508A. Gli installatori sul campo devono verificare che il SCCR contrassegnato soddisfi o superi la corrente di guasto disponibile nel punto di installazione e fornire le marcature di campo richieste secondo NEC 2020. Entrambe le parti condividono la responsabilità per la corretta applicazione e conformità.

Con quale frequenza devono essere aggiornati i calcoli SCCR?

Ricalcolare l'SCCR ogni volta che: i componenti del quadro vengono modificati o sostituiti; le modifiche al sistema di distribuzione elettrica influiscono sulla corrente di guasto disponibile; l'apparecchiatura viene spostata in diverse sedi; oppure si verificano importanti aggiornamenti elettrici della struttura. Conservare la documentazione che mostri la data e la base di calcolo, come richiesto da NEC 408.6 per le marcature sul campo.

Conclusione: l'SCCR come fondamento della sicurezza elettrica

Comprendere e implementare correttamente i requisiti di Short Circuit Current Rating rappresenta una responsabilità fondamentale per tutti coloro che sono coinvolti nei sistemi elettrici industriali, dai progettisti e costruttori di pannelli ai responsabili degli impianti e al personale di manutenzione. L'SCCR non è semplicemente una casella di controllo di conformità, ma un parametro di sicurezza fondamentale che protegge persone, apparecchiature e strutture dalle conseguenze devastanti dei guasti elettrici.

Man mano che i sistemi elettrici diventano più complessi e le correnti di guasto disponibili continuano ad aumentare con l'aumento della capacità di utenza, l'importanza di una corretta considerazione dell'SCCR non fa che intensificarsi. Seguendo gli standard stabiliti, utilizzando moderni strumenti di calcolo e mantenendo una documentazione completa, i professionisti possono garantire che le loro installazioni elettriche soddisfino i requisiti del codice fornendo al contempo i robusti margini di sicurezza che proteggono vite e beni.

Per le apparecchiature elettriche industriali che combinano prestazioni SCCR superiori con un funzionamento affidabile, VIOX Electric offre una gamma completa di componenti e assemblaggi con certificazione UL progettati per soddisfare le applicazioni più esigenti. Contatta il nostro team tecnico per discutere le tue specifiche esigenze SCCR e scoprire soluzioni che garantiscano sia la conformità che la sicurezza nei tuoi sistemi elettrici industriali.