Why Contact Material Selection Determines Contactor Performance

The contact material in an electrical contactor isn’t just a technical specification—it’s the critical factor determining whether your equipment delivers 5 years or 15 years of reliable service. A single wrong material choice can result in premature welding, excessive arc erosion, or catastrophic failure under load conditions that were entirely predictable.

For electrical contractors, OEMs, and facility managers specifying επαφείς for industrial applications, understanding the performance differences between Silver Tin Oxide (AgSnO₂), Silver Nickel (AgNi), and Silver Cadmium Oxide (AgCdO) is essential—particularly as regulatory deadlines eliminate AgCdO from new equipment by 2025.

This guide provides the technical data needed to select the optimal contact material based on current rating, load type, switching frequency, and environmental compliance requirements, backed by performance testing and industry research.

Understanding Contact Material Fundamentals

Why Material Selection Matters

Electrical contacts operate under extreme conditions: switching currents from 10A to over 1000A, enduring arc temperatures exceeding 6000°C, and cycling thousands to millions of times during their service life. The contact material must simultaneously deliver:

- High electrical conductivity to minimize voltage drop and heat generation

- Arc erosion resistance to prevent material loss during switching

- Welding resistance to avoid contacts fusing under high inrush currents

- Χαμηλή αντίσταση επαφής to maintain stable electrical connection

- Μηχανική αντοχή to withstand repeated physical impacts

Poor material selection manifests in predictable failure modes: contacts welding closed (defeating safety systems), excessive pitting reducing contact area, thermal runaway from increased resistance, or complete erosion requiring premature replacement.

Key Performance Metrics

Ηλεκτρική αγωγιμότητα: Measured in %IACS (International Annealed Copper Standard), higher values indicate better current-carrying capacity and lower heat generation.

Αντίσταση Διάβρωσης Τόξου: Material loss per switching operation, critical for applications with frequent switching or difficult loads.

Welding Resistance: Ability to resist contact fusion under high inrush currents, measured by peak current withstand capability.

Αντίσταση επαφής: Electrical resistance at the contact interface, affecting voltage drop and heating. Typically measured in microhms (μΩ).

Μηχανική Σκληρότητα: Affects wear resistance and contact pressure maintenance, measured in Vickers hardness (HV).

The Three Primary Contact Materials

Silver Cadmium Oxide (AgCdO): The Legacy Standard

Composition and Properties

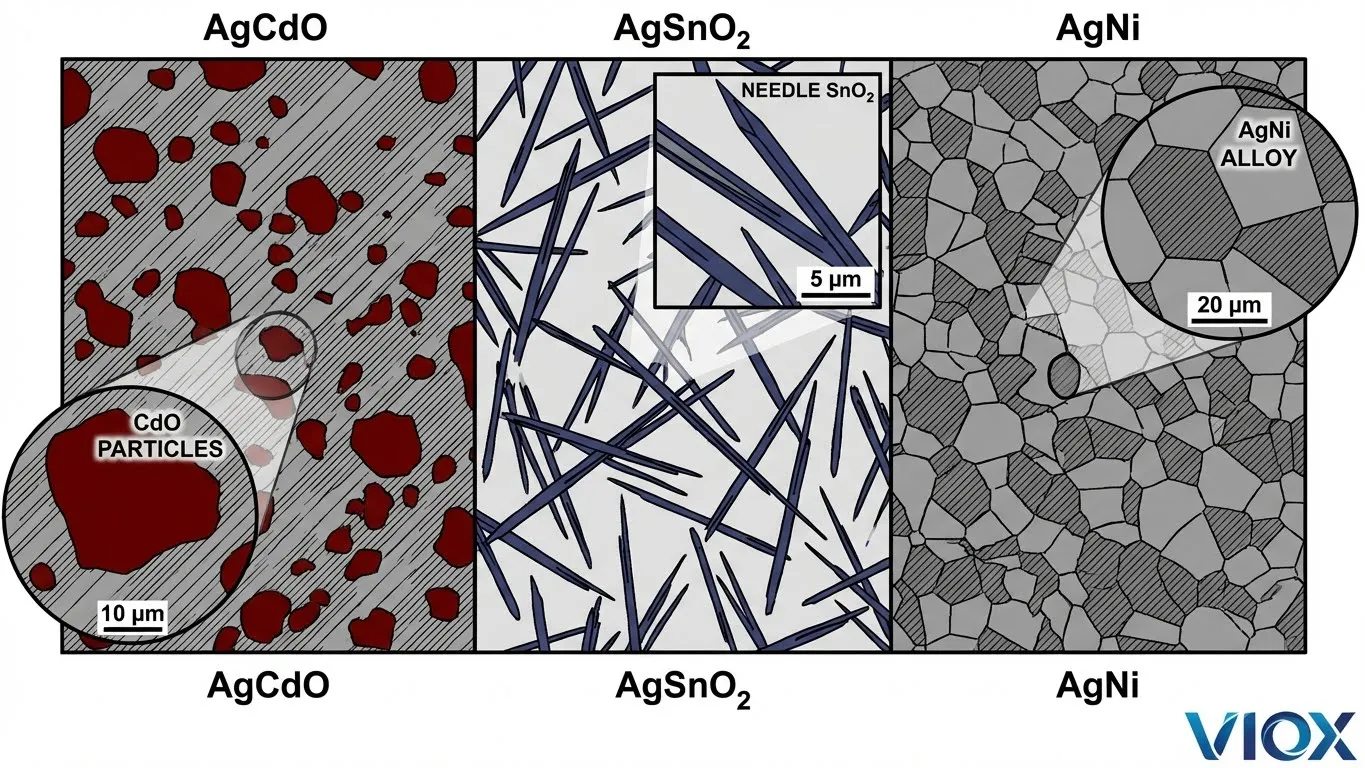

Silver Cadmium Oxide consists of 85-90% silver with 10-15% cadmium oxide (CdO) particles dispersed throughout the silver matrix. The material is produced through powder metallurgy, mixing finely ground silver and cadmium oxide powders, compacting under high pressure, and sintering at elevated temperatures.

The cadmium oxide particles provide exceptional arc-quenching properties while the silver matrix maintains excellent electrical conductivity—a combination that made AgCdO the “universal contact material” for nearly 50 years.

Χαρακτηριστικά απόδοσης

AgCdO delivers outstanding performance across multiple metrics:

- Ηλεκτρική αγωγιμότητα: 80-85% IACS

- Αντίσταση επαφής: Lowest and most stable among all materials (typically 20-40 μΩ)

- Arc erosion resistance: Excellent across 50-3000A range

- Welding resistance: Superior performance under high inrush currents

- Material transfer: Minimal under both AC and DC conditions

- Διάρκεια ζωής: Longest operational life in medium to high current applications

The material’s self-cleaning properties during switching operations maintain low contact resistance throughout its service life, and its excellent thermal conductivity dissipates heat effectively.

Applications and Historical Dominance

AgCdO became the dominant material in:

- Medium to high power contactors (50A-1000A+)

- Motor control applications with severe AC-4 duty (plugging, jogging)

- High inrush current switching (lamps, transformers, capacitors)

- Railway and traction control systems

- Industrial circuit breakers

Its reliability under diverse load conditions and long service life justified higher material costs compared to alternatives.

Regulatory Restrictions and Phase-Out

The European Union’s RoHS (Restriction of Hazardous Substances) Directive 2011/65/EU and subsequent amendments classify cadmium as a toxic heavy metal due to:

- Bioaccumulation in living organisms

- Carcinogenic properties

- Environmental persistence

- Kidney and bone damage from exposure

Critical deadline: RoHS exemptions for electrical contacts expire July 2025, prohibiting AgCdO in new equipment sold in the EU. Similar regulations exist in China, Japan, and other jurisdictions. Major manufacturers ceased AgCdO production in 2023-2024, with existing inventory depleting rapidly.

Silver Tin Oxide (AgSnO₂): The Environmental Alternative

Composition and Manufacturing

Silver Tin Oxide consists of 85-90% silver with 10-15% tin oxide (SnO₂) particles. Unlike AgCdO, the manufacturing process significantly affects performance:

Powder Metallurgy Method: Silver and tin oxide powders are mixed, compacted, and sintered. The incredibly fine grinding of SnO₂ into sub-micron particles and even dispersion throughout the silver matrix requires meticulous process control. Early AgSnO₂ materials suffered from inconsistent quality, but modern manufacturing techniques now deliver reliable performance.

Internal Oxidation Method: Silver-tin alloy ingots are heated in oxygen-rich atmospheres, causing tin to oxidize internally while remaining dispersed in the silver matrix. This process creates fine needle-shaped SnO₂ structures that enhance arc erosion resistance.

Extrusion Process: After powder compaction or internal oxidation, materials are extruded into wire or sheet form, increasing density and improving mechanical properties.

Χαρακτηριστικά απόδοσης

AgSnO₂ performance has evolved dramatically:

- Ηλεκτρική αγωγιμότητα: 75-82% IACS (slightly lower than AgCdO)

- Αντίσταση επαφής: Higher than AgCdO initially, stabilizes with use (40-80 μΩ typical)

- Arc erosion resistance: Excellent, particularly in 500-3000A range—often exceeding AgCdO

- Welding resistance: Superior to AgCdO under capacitive and lamp loads

- Material transfer: Lower than AgCdO in DC applications

- Hardness: 15% harder than AgCdO (95-105 HV vs. 80-85 HV)

Performance Optimization Through Additives

Modern AgSnO₂ formulations include performance-enhancing additives:

Indium Oxide (In₂O₃): Adding 2-4% In₂O₃ creates AgSnO₂In₂O₃ materials with:

- Enhanced resistance to high inrush currents

- Improved material dispersion (finer needle structures)

- Better performance under AC-4 duty cycles

- Lower material transfer rates

Rare Earth Elements: Cerium, lanthanum, and other rare earths improve:

- Molten silver pool viscosity during arcing

- Oxide particle suspension preventing surface accumulation

- Mechanical properties and contact force maintenance

Other Additives: Bismuth, antimony, and proprietary compounds optimize specific performance characteristics.

Why AgSnO₂ Leads AgCdO Replacement

AgSnO₂ has completed the replacement of AgCdO in European and North American markets for most applications:

- Non-toxic and environmentally friendly

- RoHS and WEEE compliant

- Comparable or superior performance in 80% of applications

- Available from all major manufacturers

- Competitive pricing as production scales

The material excels particularly in high current AC contactors, where its superior arc erosion resistance at 500A+ delivers longer service life than AgCdO.

Περιορισμοί

AgSnO₂ faces challenges in:

- Low current applications (<5A) where contact resistance instability affects signal integrity

- Specific DC aviation applications requiring ultra-stable contact resistance

- Applications with extremely frequent switching cycles where higher hardness increases mechanical wear

Silver Nickel (AgNi): The Economical Workhorse

Composition and Properties

Silver Nickel is a true alloy (not a composite) containing 85-90% silver with 10-15% nickel. The most common composition is AgNi10 (90% Ag, 10% Ni). Unlike the metal oxide materials, AgNi is produced through traditional alloying techniques—melting silver and nickel together to form a homogeneous material.

The nickel content mechanically hardens the silver, increasing erosion resistance while maintaining excellent electrical conductivity. AgNi has been used in electrical contacts for decades and remains the most economical silver-based contact material.

Χαρακτηριστικά απόδοσης

AgNi delivers reliable performance in appropriate applications:

- Ηλεκτρική αγωγιμότητα: 85-90% IACS (highest among the three materials)

- Αντίσταση επαφής: Very low and stable (15-30 μΩ typical)

- Arc erosion resistance: Good under light to medium loads (<100A)

- Welding resistance: Lower than AgCdO or AgSnO₂ under high inrush conditions

- Material transfer: Higher than other materials, particularly under inductive loads

- Hardness: Moderate (65-75 HV)

- Κόστος: 30-40% lower material cost than AgSnO₂

Applications and Optimal Use Cases

AgNi excels in:

- Light to medium duty contactors (5A-50A)

- General purpose relays

- Οικιακές και ελαφρές εμπορικές εφαρμογές

- Automotive auxiliary relays and switches

- Thermostats and temperature controllers

- Low inrush current applications

- Cost-sensitive applications requiring reliability

The material provides excellent value where arc energies are moderate and extremely high inrush currents are not present.

Περιορισμοί

AgNi is not suitable for:

- High current applications (>100A continuous)

- Motor starting applications with severe AC-4 duty

- High inrush current loads (capacitor banks, transformers, incandescent lamps)

- Applications requiring maximum welding resistance

- Long electrical life requirements under difficult loads

At higher currents and with difficult loads, AgNi experiences rapid erosion, material transfer, and increased welding tendency. The cost savings disappear when premature replacement is required.

When to Choose AgNi vs. AgSnO₂

Επιλέγω AgNi όταν:

- Current rating ≤50A continuous

- Resistive or light inductive loads

- Low to moderate switching frequency (<10 operations/hour)

- Cost optimization is critical

- Short to medium service life acceptable (5-8 years)

Επιλέγω AgSnO₂ όταν:

- Current rating >50A or peak inrush currents >200A

- Inductive motors, transformers, or capacitive loads

- High switching frequency or AC-4 duty cycles

- Maximum service life required (10-15+ years)

- Environmental compliance essential

Comprehensive Material Comparison

Physical and Electrical Properties

| Ακίνητα | AgCdO (10-15%) | AgSnO₂ (10-12%) | AgNi (10%) |

|---|---|---|---|

| Ηλεκτρική αγωγιμότητα | 80-85% IACS | 75-82% IACS | 85-90% IACS |

| Θερμική Αγωγιμότητα | 320-350 W/m·K | 280-320 W/m·K | 340-380 W/m·K |

| Σκληρότητα (HV) | 80-85 | 95-105 | 65-75 |

| Πυκνότητα | 10.2-10.4 g/cm³ | 9.8-10.1 g/cm³ | 10.3-10.5 g/cm³ |

| Σημείο τήξης | 960°C (Ag base) | 960°C (Ag base) | 960°C (Ag base) |

| Αντίσταση επαφής | 20-40 μΩ | 40-80 μΩ | 15-30 μΩ |

| Arc Erosion Rate (mg/1000 ops) | 2-4 | 2-5 | 4-8 |

| Material Cost (relative) | High (phasing out) | Μεσαίο-Υψηλό | Χαμηλή-Μεσαία |

| Environmental Status | ❌ Banned 2025 | ✅ RoHS Compliant | ✅ RoHS Compliant |

Performance by Load Type

| Τύπος φορτίου | AgCdO Rating | AgSnO₂ Rating | AgNi Rating | Συνιστώμενο υλικό |

|---|---|---|---|---|

| Resistive (heaters, incandescent) | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | AgSnO₂ or AgNi (current dependent) |

| Inductive AC-3 (motors normal start) | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | AgSnO₂ |

| Inductive AC-4 (motors plugging/jogging) | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | AgSnO₂ (AgCdO historical best) |

| Capacitive (PFC, lamp ballasts) | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | AgSnO₂ |

| High Inrush (transformers, lamps) | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | AgSnO₂ |

| Low Current (<5A signal/control) | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | AgNi |

| DC Breaking (batteries, solar) | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | AgSnO₂ |

Πίνακας Καταλληλότητας Εφαρμογών

| Εφαρμογή | Τρέχον εύρος | Best Material 2026+ | Alternative | Σημειώσεις |

|---|---|---|---|---|

| HVAC Contactors | 20-100A | AgSnO₂ | AgNi (<40A) | High inrush from compressors |

| Motor Control (AC-3) | 50-500A | AgSnO₂ | — | Standard motor starting |

| Motor Control (AC-4) | 50-500A | AgSnO₂ + In₂O₃ | — | Severe duty, plugging |

| Ρελέ ισχύος | 10-50A | AgNi | AgSnO₂ (>30A) | Cost vs. performance balance |

| Διακόπτες κυκλώματος | 16-1000A | AgSnO₂ | — | Arc interruption critical |

| Automotive Relays | 10-50A | AgNi | AgSnO₂ (high current) | Cost sensitive |

| Solar DC Contactors | 50-1000A | AgSnO₂ | — | DC arc breaking, long life |

| Επαφείς φωτισμού | 20-200A | AgSnO₂ | — | Υψηλά ρεύματα εισόδου |

| Generator Transfer | 100-1000A | AgSnO₂ + In₂O₃ | — | Reliability critical |

Cost vs. Performance Trade-offs

| Παράγοντας | AgCdO | AgSnO₂ | AgSnO₂In₂O₃ | AgNi |

|---|---|---|---|---|

| Material Cost per Contact | $$$ | $$-$$$ | $$$-$$$$ | $ |

| Manufacturing Complexity | Μεσαίο | Υψηλή | Υψηλή | Χαμηλή |

| Service Life (years, AC-3) | 12-15 | 10-15 | 12-15 | 5-8 |

| Replacement Availability | ❌ Depleting | ✅ Excellent | ✅ Good | ✅ Excellent |

| Design Changes Required | — | Minor-Moderate | Minor-Moderate | Minor |

| Total Cost of Ownership (10yr) | N/A (unavailable) | $$ | $$-$$$ | $ |

| Performance Reliability | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

Load-Specific Performance Analysis

AC vs. DC Switching Characteristics

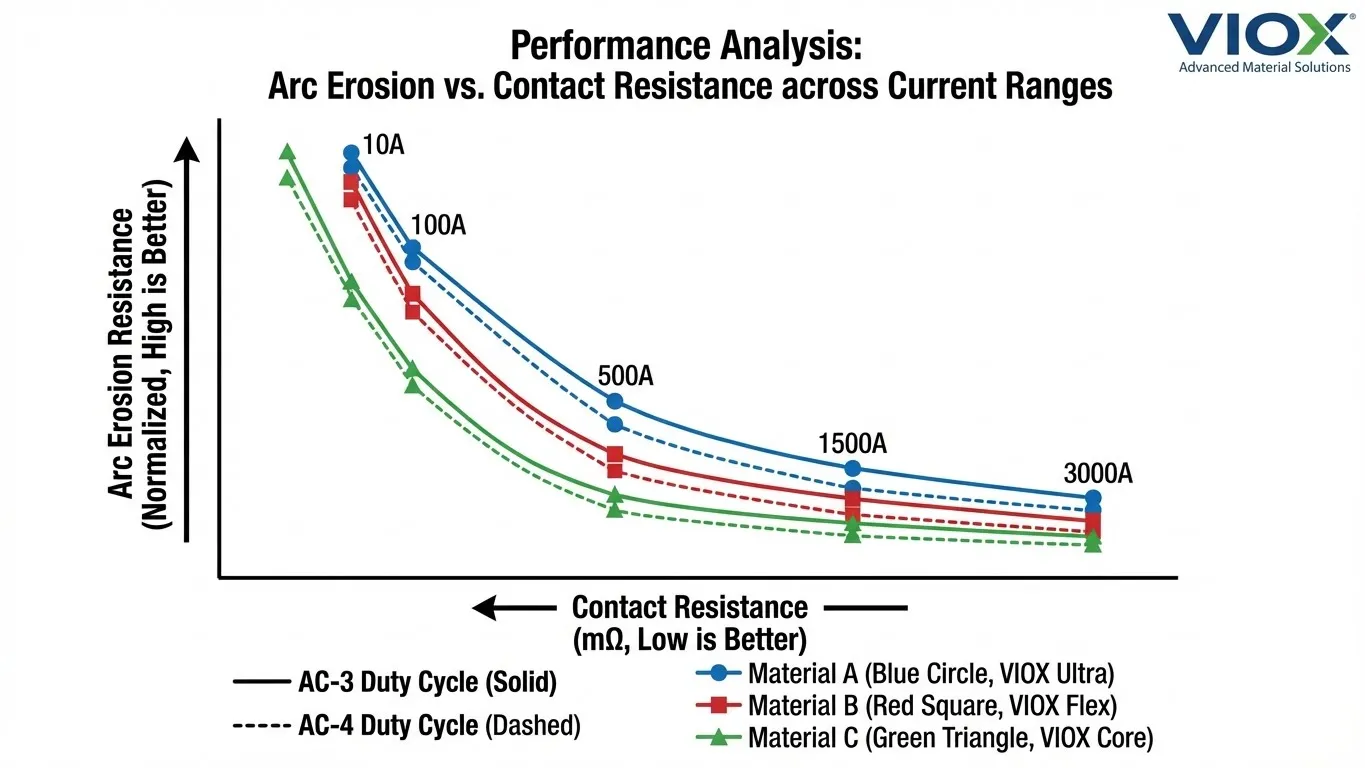

AC Switching: All three materials perform well under AC conditions where current naturally crosses zero twice per cycle, extinguishing arcs. AgSnO₂ shows particular advantage at high currents (>500A) with lower material transfer and superior arc interruption.

DC Switching: More demanding due to absence of zero-crossing. AgSnO₂ demonstrates superior performance with:

- Lower material transfer rates than AgCdO

- Better arc interruption capability

- More stable contact resistance over service life

- AgNi experiences higher erosion and material transfer in DC applications >50A

Resistive Load Performance

Pure resistive loads (heaters, incandescent lamps) present moderate switching demands. All materials perform adequately, with selection based primarily on current rating:

- <50A: AgNi provides economical solution

- 50-200A: AgSnO₂ standard choice

- >200A: AgSnO₂ with additives for extended life

Inductive Load Performance

AC-3 Duty (Normal Motor Starting): Moderate inrush currents (5-7× rated). AgSnO₂ and AgCdO both excel, with AgSnO₂ now the standard choice. AgNi suitable only for currents <40A.

AC-4 Duty (Plugging, Jogging, Reversing): Severe conditions with frequent high inrush. AgCdO historically best, but modern AgSnO₂In₂O₃ formulations deliver comparable performance:

- Arc erosion rates within 10-15% of AgCdO

- Service life 90-100% of AgCdO in properly designed contactors

- AgNi not suitable—rapid erosion and welding risk

Capacitive Load Performance

Capacitor switching (power factor correction, LED drivers) creates extremely high peak inrush currents (20-40× rated) during short duration (<1ms). This represents the most severe contact stress.

Performance Ranking: AgSnO₂ > AgCdO > AgNi

AgSnO₂’s superior welding resistance under capacitive loads makes it the preferred material, often outlasting AgCdO in modern applications. The hard SnO₂ particles prevent contact surface deformation during peak currents.

High Inrush Current Applications

Transformer magnetization, cold filament lamps, and motor locked-rotor starting create inrush currents 8-15× rated current. AgSnO₂ excels due to:

- High mechanical hardness preventing surface displacement

- Superior arc-quenching from SnO₂ particles

- Resistance to contact welding during bounce

AgNi should not be used where inrush currents exceed 10× rated continuous current—welding risk is unacceptable.

Low Current Applications

Signal circuits, control circuits, and auxiliary contacts (<5A) present unique challenges. Contact resistance stability and electrical noise become critical:

Material ranking: AgNi > AgCdO > AgSnO₂

AgSnO₂’s higher and less stable contact resistance in low current applications can cause signal integrity issues and higher voltage drops. AgNi’s low, stable resistance and self-cleaning properties make it ideal for these applications.

Πίνακας Απόφασης Επιλογής Υλικού

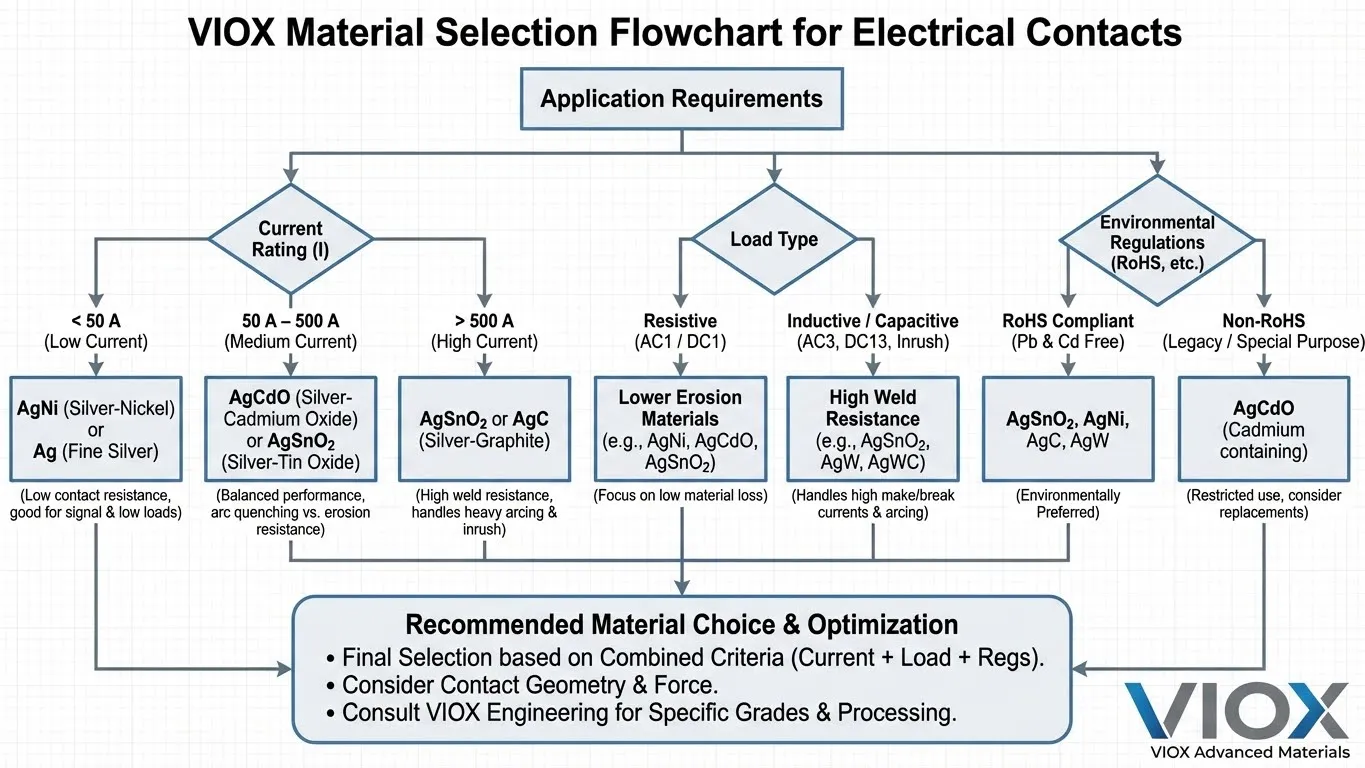

Step 1: Environmental Compliance Check

- Requires RoHS compliance or post-2025 production? → Eliminate AgCdO

Step 2: Current Rating Assessment

- ≤50A continuous, <200A peak → AgNi viable, proceed to Step 3

- >50A continuous or >200A peak → AgSnO₂ required, proceed to Step 4

Step 3: AgNi Qualification (if applicable)

- Load type: Resistive or light inductive → AgNi suitable ✓

- Load type: Motor (AC-3/AC-4), capacitive, high inrush → AgSnO₂ required

- Switching frequency: <10 ops/hour → AgNi suitable ✓

- Switching frequency: >10 ops/hour → AgSnO₂ preferred

- Service life requirement: 5-8 years → AgNi acceptable ✓

- Service life requirement: >10 years → AgSnO₂ required

Step 4: AgSnO₂ Specification

- Standard AC-3 motor control, resistive loads → AgSnO₂ standard formulation

- AC-4 duty, high inrush, capacitive loads → AgSnO₂In₂O₃ formulation

- DC contactors, solar applications → AgSnO₂ with additives

- Critical applications, maximum reliability → AgSnO₂In₂O₃ + rare earth elements

Step 5: Cost Optimization

- Calculate total cost of ownership including service life and replacement frequency

- For cost-sensitive, light-duty applications meeting all AgNi criteria, AgNi delivers 30-40% material cost savings

- For critical applications, AgSnO₂’s extended service life and superior reliability justify higher initial cost

Διαδικασίες παραγωγής

Powder Metallurgy Process

The dominant manufacturing method for AgSnO₂ and AgCdO:

- Powder Preparation: Silver and metal oxide powders ground to precise particle sizes (0.5-5 microns for oxides)

- Mixing: Powders blended in controlled atmosphere to ensure uniform distribution

- Compaction: Mixture pressed under high pressure (200-800 MPa) to form “green” compacts

- Sintering: Heating to 650-850°C in controlled atmosphere, causing silver particles to bond while oxides remain dispersed

- Sizing/Machining: Final forming to precise dimensions

Quality control of particle size distribution and mixing uniformity critically affects electrical properties—inconsistent early AgSnO₂ problems stemmed from inadequate process control.

Internal Oxidation Method

Alternative process producing fine oxide dispersion:

- Alloy Creation: Silver and tin melted together forming Ag-Sn alloy

- Forming: Alloy cast or extruded into wire/sheet form

- Heat Treatment: Exposure to oxygen-rich atmosphere at 700-900°C

- Οξείδωση: Tin diffuses to surface and oxidizes, creating internal SnO₂ particles

- Cooling/Finishing: Controlled cooling and final forming

Internal oxidation creates characteristic needle-shaped SnO₂ structures providing excellent arc erosion resistance. Process requires precise temperature and oxygen control to achieve uniform oxidation depth.

Extrusion and Secondary Processing

After powder compaction or internal oxidation, materials undergo:

- Hot or cold extrusion to achieve higher densities (>98% theoretical)

- Wire drawing for rivet and contact tip production

- Rolling for contact strip and sheet products

- Brazing layer application for bimetal contacts (Ag alloy bonded to copper backing)

Future Trends in Contact Materials

Silver Zinc Oxide (AgZnO)

AgZnO emerges as an economical AgCdO alternative for specific applications:

- Lower material cost than AgSnO₂ (15-20% reduction)

- Good welding resistance and arc erosion properties

- Higher contact resistance than AgSnO₂ (limits applications)

- Suitable for medium current contactors where cost optimization is critical

Current adoption remains limited due to AgSnO₂’s proven performance track record.

Nano-Technology Applications

Research focuses on nano-scale oxide particle dispersion:

- Sub-100nm SnO₂ particles create more uniform distribution

- Enhanced mechanical properties from grain boundary effects

- Improved arc-quenching from higher particle surface area

- Potential for silver content reduction (cost savings) while maintaining performance

VIOX collaborates with materials research institutes developing next-generation nano-enhanced contact materials.

Rare Earth and Dopant Optimization

Ongoing development of proprietary additive formulations:

- Cerium, lanthanum, yttrium additions for specific performance characteristics

- Bismuth, antimony dopants reducing contact resistance

- Multi-element formulations optimized for specific duty cycles

- Custom materials for extreme environments (high altitude, subsea, cryogenic)

VIOX Contact Material Solutions

VIOX Electric manufactures Επαφέα εναλλασσόμενου ρεύματος και αρθρωτοί επαφείς with optimized contact materials for diverse applications.

Προδιαγραφές προϊόντος

VIOX AC Contactor Series: Available with AgSnO₂ standard contacts or AgSnO₂In₂O₃ for severe duty. Ratings from 9A to 1000A, AC-3 and AC-4 duty ratings. All products RoHS compliant and certified to IEC 60947-4-1.

VIOX Modular Contactor Series: Compact design with AgSnO₂ contacts, ideal for control panels and switchboards. DIN rail mounting, 16A to 125A ratings, auxiliary contact options available.

Contact Material Customization

For OEM applications and special requirements, VIOX offers:

- Custom contact material formulations

- Application-specific testing and validation

- Endurance testing under actual load conditions

- Material recommendations based on duty cycle analysis

Τεχνική υποστήριξη

VIOX applications engineers provide material selection guidance considering:

- Load characteristics and duty cycle

- Περιβαλλοντικές συνθήκες

- Service life requirements

- Βελτιστοποίηση κόστους

- Regulatory compliance

For detailed επαφέας έναντι εκκινητή κινητήρα selection assistance or maintenance guidance, consult our comprehensive technical resources.

Συχνές Ερωτήσεις

What is the best replacement material for silver cadmium oxide (AgCdO) contacts?

Silver tin oxide (AgSnO₂) is the industry-standard AgCdO replacement for 80% of applications. For medium to high current contactors (50-1000A), AgSnO₂ delivers comparable or superior performance to AgCdO in arc erosion resistance, welding resistance, and service life. For severe AC-4 duty or high inrush current applications, AgSnO₂In₂O₃ formulations with indium oxide additives provide performance matching or exceeding AgCdO. For low current applications (<50A) with resistive or light inductive loads, AgNi offers economical alternative with adequate performance. All modern formulations are RoHS compliant and environmentally safe, eliminating cadmium toxicity concerns.

Why is AgSnO₂ harder than AgCdO and how does this affect performance?

AgSnO₂ is approximately 15% harder than AgCdO (95-105 HV vs. 80-85 HV) due to tin oxide’s higher hardness compared to cadmium oxide. This increased hardness provides advantages and disadvantages: it enhances resistance to contact surface deformation under high inrush currents, reducing welding tendency in capacitive loads; it improves mechanical wear resistance in high-frequency switching applications; however, it can slightly increase contact bounce duration and requires higher contact force to maintain low contact resistance. The hardness also makes AgSnO₂ more resistant to material transfer during DC switching. Modern contactor designs account for these characteristics through optimized spring forces and contact geometry.

Can I directly replace AgCdO contacts with AgSnO₂ in existing contactors?

Direct drop-in replacement is possible in many cases but not universally recommended. For contactors originally designed for AgCdO, AgSnO₂ replacement typically requires verification of: contact force (may need adjustment due to hardness difference), arc chute design (AgSnO₂ arc characteristics differ slightly), spring tension (to compensate for contact resistance differences), and thermal management (slightly different heating characteristics). In contactors rated >100A or severe duty (AC-4), engineering evaluation is strongly recommended. For optimal performance, specify contactors designed from the start for AgSnO₂ contacts. Consult VIOX applications engineers for retrofit assessments—improper replacement can reduce service life by 40-60%.

Why does AgNi cost less than AgSnO₂ but perform worse in high-current applications?

AgNi is a true silver-nickel alloy produced through traditional melting and alloying, a simpler and less expensive process than the powder metallurgy or internal oxidation required for AgSnO₂. The nickel simply hardens the silver mechanically but does not provide the arc-quenching properties of oxide particles. At currents >50A or with high inrush loads, arcing becomes severe—AgNi’s lack of specialized oxide particles results in rapid arc erosion (2-3× faster than AgSnO₂), higher material transfer rates, and increased welding tendency. The material cost savings (30-40%) are quickly offset by premature failure requiring replacement every 5-7 years vs. 12-15 years for AgSnO₂. AgNi remains economical for light-duty applications where arc energies are moderate.

What are the key performance differences between AgSnO₂ and AgSnO₂In₂O₃?

AgSnO₂In₂O₃ contains 2-4% indium oxide in addition to tin oxide, creating enhanced performance in specific applications. The indium oxide additions provide: 25-35% better resistance to contact welding under high inrush currents (>10× rated), finer and more uniform oxide particle dispersion creating needle-shaped structures that enhance arc-quenching, improved performance under capacitive loads (fluorescent lamps, power factor correction), lower material transfer rates in DC applications, and 15-20% longer service life in severe AC-4 duty cycles. The performance improvements come with 20-30% higher material cost. Specify AgSnO₂In₂O₃ for: motor plugging/jogging applications, capacitor switching, high-reliability critical loads, and maximum service life requirements. Standard AgSnO₂ remains optimal for general AC-3 motor control and most residential/commercial applications.

How do environmental regulations affect contact material selection in 2026?

RoHS Directive 2011/65/EU and amendments eliminate AgCdO from new equipment by July 2025 in the EU, with similar regulations in China, Japan, and other jurisdictions. All major manufacturers discontinued AgCdO production by end of 2023, with remaining inventory depleting in 2024-2025. For new equipment designs and production, only RoHS-compliant materials (AgSnO₂, AgNi, AgZnO) are permissible. Existing equipment with AgCdO can continue operation and maintenance parts remain available from specialty suppliers, but availability will decline 2026-2030. Organizations should transition specifications to AgSnO₂-based materials immediately to ensure long-term parts availability and regulatory compliance. VIOX eliminated AgCdO from product lines in 2023, offering comprehensive AgSnO₂ alternatives across all contactor ratings.

What is the expected service life difference between contact materials?

Service life varies dramatically with application conditions, but typical expectations for AC-3 duty motor control applications are: AgCdO delivered 12-15 years under proper maintenance (historical benchmark, no longer available); AgSnO₂ provides 10-15 years in properly designed contactors, with severe duty AgSnO₂In₂O₃ formulations matching AgCdO’s 12-15 year lifespan; AgNi offers 5-8 years in suitable applications (<50A, moderate switching frequency). In severe AC-4 duty, service life reduces by 40-50% for all materials. High-frequency switching (>20 operations/hour) reduces life by 30-40%. Actual service life depends critically on: proper material selection for load type, correct contactor sizing (operating at <80% rated current), adequate maintenance including contact inspection and cleaning, and environmental conditions (temperature, humidity, contamination). Undersized contactors or improper material selection can reduce service life by 60-80% regardless of material quality.

Selecting the Right Material for Your Application

Contact material selection directly determines contactor reliability, service life, and total cost of ownership. With AgCdO phase-out complete, the choice between AgSnO₂ and AgNi depends on current rating, load characteristics, and service life requirements.

For specification assistance: VIOX applications engineers analyze your specific requirements and recommend optimal materials and contactor configurations. Contact our technical support team with load data, duty cycle information, and environmental requirements.

For OEM partnerships: VIOX offers custom contact material development and validation testing for specialized applications. Our materials laboratory conducts endurance testing under actual operating conditions to verify performance before production implementation.

Explore VIOX’s complete line of industrial contactors και modular control equipment featuring optimized contact materials for diverse industrial applications.