Εισαγωγή: Πέρα από την Ονομαστική Τιμή

Στον κόσμο της κατασκευής βιομηχανικών πινάκων, μια επικίνδυνη παρανόηση επιμένει: ότι η επιλογή ενός διακόπτη κυκλώματος αρχίζει και τελειώνει με το ονομαστικό ρεύμα (In). Αυτή η υπεραπλούστευση είναι η κύρια αιτία των “ενοχλητικών ενεργοποιήσεων” κατά τη διάρκεια της θέσης σε λειτουργία και, πιο καταστροφικά, της αστοχίας του πίνακα διανομής κατά τη διάρκεια πραγματικών συνθηκών σφάλματος.

Ένας διακόπτης 100A δεν είναι πάντα ένας διακόπτης 100A. Τοποθετήστε τον μέσα σε ένα περίβλημα IP54 στους 50°C, δίπλα σε έναν μετατροπέα συχνότητας (VFD), και αυτή η συσκευή μπορεί να μεταφέρει με ασφάλεια μόνο 85A. Συνδέστε τον σε έναν κινητήρα υψηλής αυτεπαγωγής και μπορεί να ενεργοποιηθεί αμέσως κατά την εκκίνηση, παρόλο που έχει “σωστή διαστασιολόγηση”.”

Στο VIOX Electric, σχεδιάζουμε τις συσκευές προστασίας μας σύμφωνα με IEC 60947-2 πρότυπα, σχεδιασμένα για τις αυστηρές απαιτήσεις των βιομηχανικών εφαρμογών. Αυτός ο οδηγός παρέχει ένα τυποποιημένο πλαίσιο 5 βημάτων για να ξεπεράσετε τις βασικές ονομαστικές τιμές αμπέρ και να διασφαλίσετε ότι τα σχέδιά σας είναι ασφαλή, συμβατά και ανθεκτικά.

Βήμα 1: Καθορίστε την Κατηγορία Εφαρμογής (Ποιοτική Ανάλυση)

Πριν εξετάσετε ένα φύλλο δεδομένων, πρέπει να καθορίσετε το προφίλ φορτίου. Διαφορετικές εφαρμογές ασκούν διαφορετικές θερμικές και μαγνητικές καταπονήσεις στις συσκευές προστασίας.

1. Φορτία Κινητήρα (Υψηλό Ρεύμα Εκκίνησης)

Οι κινητήρες είναι επαγωγικά φορτία με υψηλά ρεύματα εκκίνησης (συνήθως 6–10 φορές In). Ένας τυπικός θερμομαγνητικός διακόπτης με μια γενική καμπύλη ενεργοποίησης είναι πιθανό να ενεργοποιηθεί κατά τη διάρκεια της φάσης αύξησης του κινητήρα.

- Λύση: Χρήση Διακόπτες Κυκλώματος Προστασίας Κινητήρα (MPCBs) ή MCBs με Καμπύλες Τύπου D (10–14x μαγνητική ενεργοποίηση).

- VIOX Insight: Για ολοκληρωμένη ασφάλεια κινητήρα, διαβάστε τον οδηγό μας για Διακόπτες Κυκλώματος Προστασίας Κινητήρα: Ο Απόλυτος Οδηγός.

2. Υποδομή Φόρτισης EV (Συνεχές Φορτίο)

Οι φορτιστές EV ταξινομούνται ως “συνεχή φορτία”. Σε αντίθεση με μια μηχανή συγκόλλησης που ενεργοποιείται και απενεργοποιείται κυκλικά, ένας φορτιστής EV μπορεί να λειτουργεί σε πλήρη χωρητικότητα για ώρες.

- Ο Κανόνας Υποβάθμισης: Σύμφωνα με τα πρότυπα ασφαλείας, γενικά δεν μπορείτε να φορτώσετε έναν διακόπτη πέρα από το 80% της ονομαστικής του τιμής για συνεχή φορτία. Ένας φορτιστής 40A απαιτεί έναν διακόπτη 50A.

- Προστασία Διαρροής: Τα τυπικά RCD Τύπου AC τυφλώνονται από τη διαρροή DC από τις μπαταρίες EV. Πρέπει να χρησιμοποιήσετε Τύπος Β ή Τύπος EV κάψετε το σπίτι σας παρακάμπτοντας την.

- Πόρος: Δείτε τον Οδηγός Προστασίας Εμπορικής Φόρτισης EV.

3. Αποθήκευση Ενέργειας (BESS) & Συστήματα DC

Τα Συστήματα Αποθήκευσης Ενέργειας Μπαταρίας (BESS) παρουσιάζουν δύο μοναδικές προκλήσεις: υψηλά ρεύματα βραχυκυκλώματος DC και χαμηλή σύνθετη αντίσταση συστήματος. Οι τυπικοί διακόπτες AC δεν μπορούν να σβήσουν αποτελεσματικά τα τόξα DC, οδηγώντας σε συγκόλληση επαφών και πυρκαγιά.

- Απαίτηση: Χρησιμοποιήστε ειδικά κατασκευασμένους DC MCCBs ή Διακόπτες Κυκλώματος Αέρα (ACBs) με μη πολωμένους αγωγούς τόξου εάν η ροή ρεύματος είναι αμφίδρομη.

- Βαθιά Βουτιά: Κατανοήστε τους κινδύνους στο Γιατί οι Τυπικοί Διακόπτες DC Αποτυγχάνουν στο BESS.

Πίνακας 1: Μήτρα Επιλογής Προφίλ Φορτίου

| Τύπος φορτίου | Ρεύμα Εισροής | Θερμική καταπόνηση | Προτεινόμενη Καμπύλη/Συσκευή | Κρίσιμη Απαίτηση |

|---|---|---|---|---|

| Αντιστατικό (Θερμαντήρες) | 1x In | Μέτρια | Καμπύλη B ή C | Εστίαση στην προστασία καλωδίων |

| Επαγωγικό (Κινητήρες) | 8-12x In | Υψηλό (Εκκίνηση) | Καμπύλη D / MPCB | Απαιτείται ευαισθησία απώλειας φάσης |

| Φόρτιση EV | 1x In | Ακραίο (Συνεχές) | Καμπύλη C | Συντελεστής Υποβάθμισης 80% εφαρμοσμένος |

| Ηλεκτρονικά/PLC | Χαμηλή | Χαμηλή | Καμπύλη B | Γρήγορη μαγνητική ενεργοποίηση για την προστασία ευαίσθητων PCB |

Βήμα 2: Καθορίστε την Τάση Συστήματος & τους Πόλους (Αρχιτεκτονική)

Μόλις καθοριστεί το φορτίο, η αρχιτεκτονική του συστήματος υπαγορεύει τη φυσική διαμόρφωση της συσκευής.

Ονομαστικές Τάσεις AC έναντι DC

Οι κατασκευαστές πινάκων συχνά συγχέουν την τάση μόνωσης (Ui) με την τάση λειτουργίας (Ue).

- Ηλιακή/PV: Τα συστήματα έχουν μετακινηθεί από 600V σε 1000V και τώρα 1500V DC. Ένας διακόπτης με ονομαστική τιμή 1000V θα αναβοσβήσει σε ένα σύστημα 1500V.

- Πόρος: Ελέγξτε την ανάλυσή μας σχετικά με Ονομαστικές Τάσεις Ηλιακού Κιβωτίου Συνδυασμού.

Συστήματα Γείωσης (3P έναντι 3P+N έναντι 4P)

Η απόφαση για διακοπή του ουδέτερου αγωγού εξαρτάται από το σύστημα γείωσης σας (TN-S, TN-C, TT).

- TN-C: Μην αλλάζετε ποτέ τον αγωγό PEN (χρησιμοποιήστε 3P).

- TN-S / TT: Ο ουδέτερος πρέπει συχνά να αλλάζει/απομονώνεται για να αποφευχθούν πιθανοί βρόχοι ή κίνδυνοι κατά τη διάρκεια της συντήρησης (χρησιμοποιήστε 4P).

- Πόρος: Για σωστή επιλογή πόλων στους μεταγωγικούς διακόπτες, δείτε Πού να χρησιμοποιήσετε SP, TP, TPN και 4P διακόπτες κυκλώματος.

Βήμα 3: Υπολογισμός του πραγματικού ρεύματος λειτουργίας (Ποσοτική υποβάθμιση)

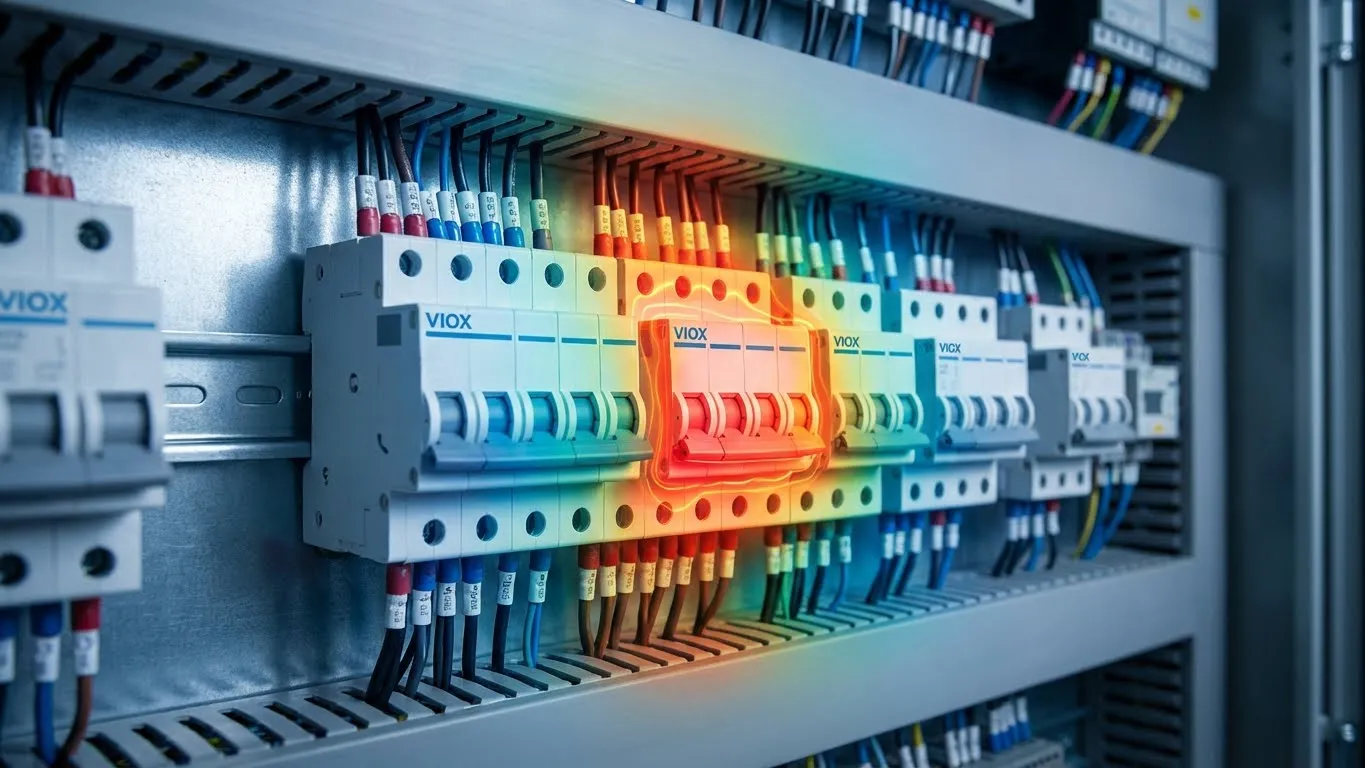

Εδώ συμβαίνουν το 80% των σφαλμάτων σχεδιασμού. Το Ονομαστικό Ρεύμα (In) ) δοκιμάζεται σε ανοιχτό αέρα στους 30°C ή 40°C. Ωστόσο, ο διακόπτης σας είναι πιθανό να βρίσκεται μέσα σε ένα γεμάτο περίβλημα στους 55°C.

Ο Τύπος του Πραγματικού Ρεύματος

Πρέπει να υπολογίσετε το επιτρεπόμενο ρεύμα (Iπραγματικό) χρησιμοποιώντας συντελεστές υποβάθμισης:

Iπραγματικό = In × Kt (Θερμοκρασία) × Ka (Υψόμετρο) × Kg (Ομαδοποίηση)

- Θερμοκρασία (Kt): Καθώς η θερμοκρασία περιβάλλοντος αυξάνεται, η διμεταλλική λωρίδα λυγίζει νωρίτερα. Ένας διακόπτης 100A στους 60°C μπορεί συνήθως να λειτουργεί σαν διακόπτης 80A.

- Ομαδοποίηση (Kg): Όταν οι διακόπτες είναι τοποθετημένοι δίπλα-δίπλα σε μια ράγα DIN, θερμαίνουν ο ένας τον άλλον.

- N=2-3 διακόπτες: Kg ≈ 0.9

- N=6-9 διακόπτες: Kg ≈ 0.7

- Υψόμετρο (Ka): Πάνω από 2000m, η πυκνότητα του αέρα μειώνεται, μειώνοντας την ψύξη και τη διηλεκτρική αντοχή.

Πλεονέκτημα VIOX: Οι διακόπτες VIOX είναι βαθμονομημένοι για να ελαχιστοποιούν τις απώλειες υποβάθμισης. Ωστόσο, η φυσική εξακολουθεί να ισχύει.

Πόρος: Χρησιμοποιήστε τα δεδομένα μας για να υπολογίσετε τους συντελεστές: Ηλεκτρική Υποβάθμιση: Συντελεστές Θερμοκρασίας, Υψομέτρου & Ομαδοποίησης.

Για τις ονομαστικές τιμές συγκροτημάτων διακοπτών, κατανοήστε επίσης τη διαφορά μεταξύ του ονομαστικού ρεύματος και της ονομαστικής τιμής συγκροτήματος στον οδηγό μας: Ονομαστικές Τιμές Ρεύματος Διακοπτών: InA vs Inc vs RDF.

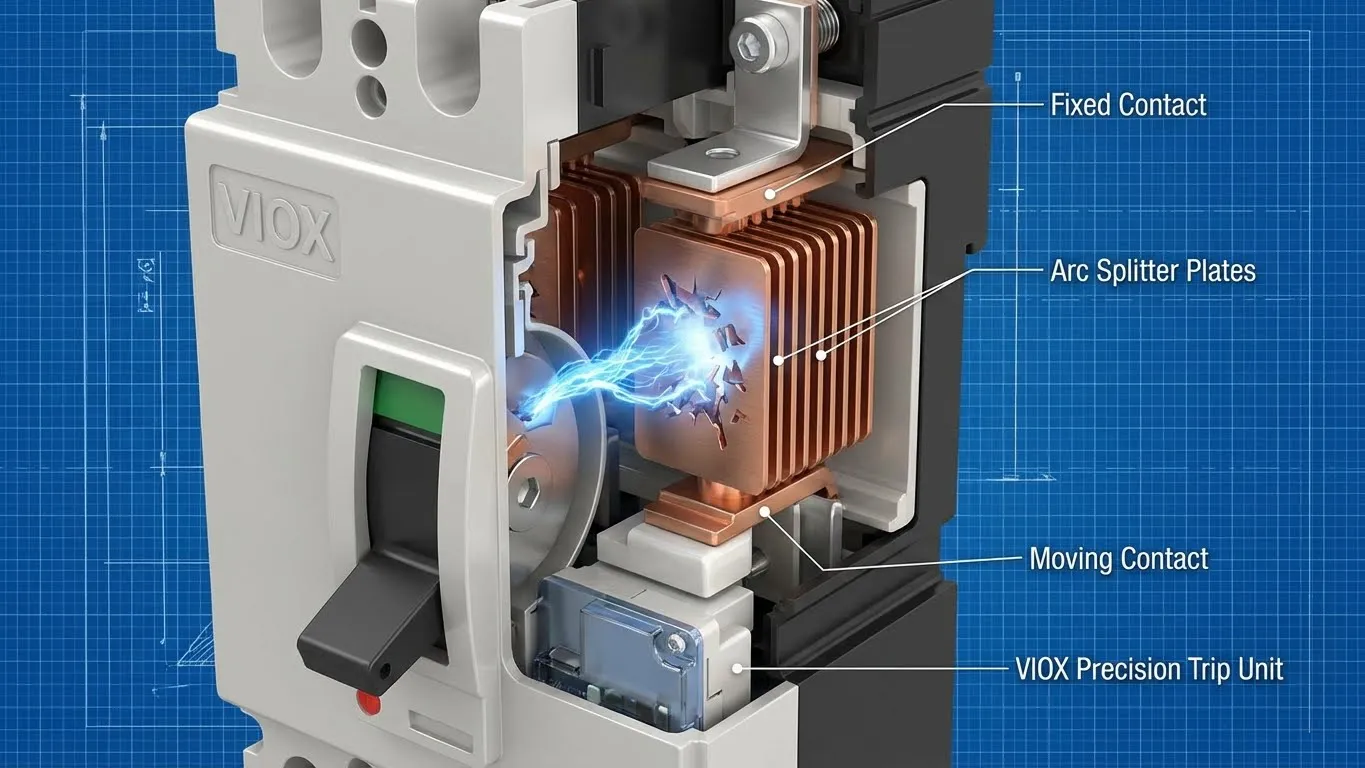

Βήμα 4: Διαχείριση του Ρεύματος Σφάλματος (Ασφάλεια & Ικανότητα Διακοπής)

Η διασφάλιση ότι ο διακόπτης μεταφέρει το φορτίο είναι το βήμα 3. η διασφάλιση ότι εκρήγνυται με ασφάλεια κατά τη διάρκεια ενός βραχυκυκλώματος είναι το βήμα 4.

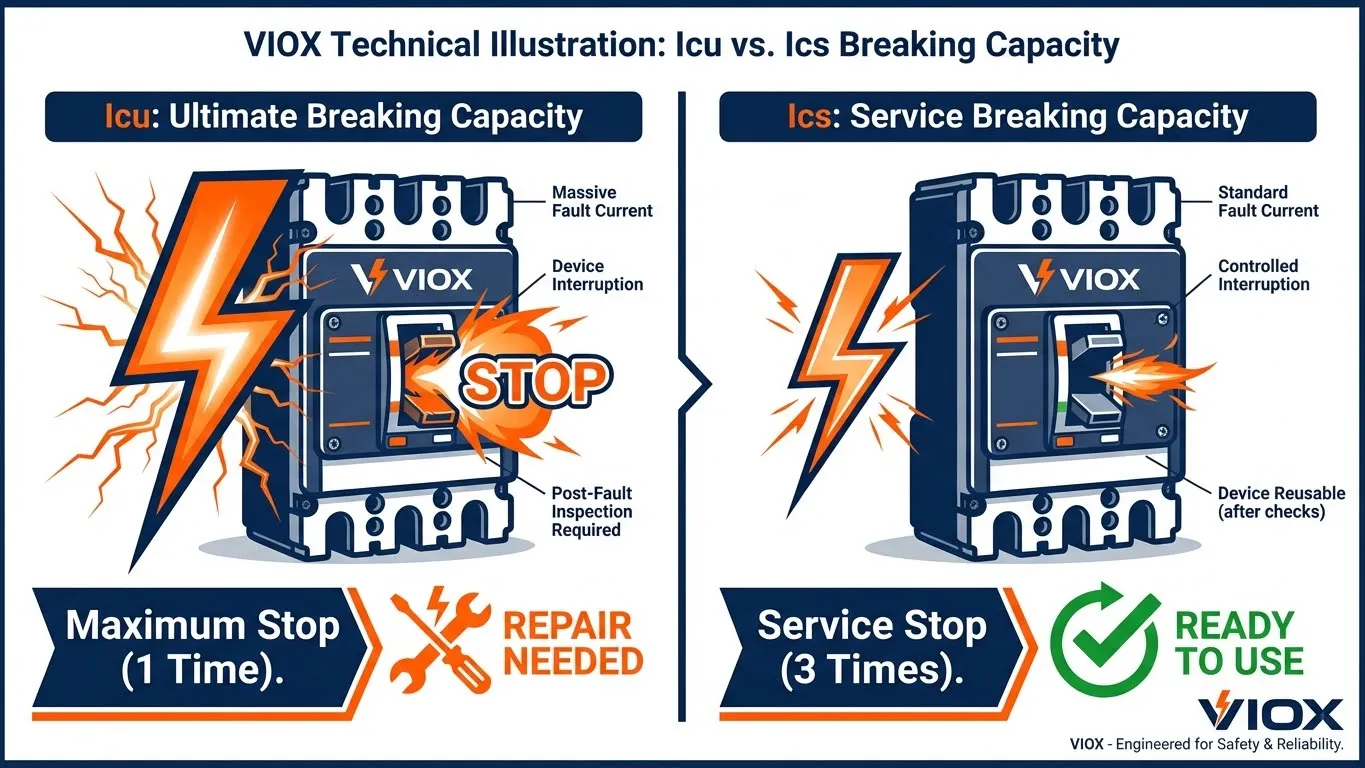

Icu εναντίον Ics: Η Κρίσιμη Διάκριση

- Icu (Τελική Ικανότητα Διακοπής): Το μέγιστο ρεύμα που μπορεί να διακόψει ο διακόπτης μία φορά. Μπορεί να μην είναι χρησιμοποιήσιμος μετά.

- Ics (Ικανότητα Διακοπής Υπηρεσίας): Το ρεύμα που μπορεί να διακόψει ο διακόπτης επανειλημμένα και να παραμείνει σε λειτουργία.

Για βιομηχανικά πάνελ κρίσιμης σημασίας (νοσοκομεία, κέντρα δεδομένων, ναυτιλία), η VIOX συνιστά να καθορίζεται Ics = 100% Icu. Δεν θέλετε να αντικαταστήσετε έναν κύριο διακόπτη μετά από ένα μόνο σφάλμα.

Εφεδρική Προστασία

Εάν το προοπτικό ρεύμα βραχυκυκλώματος (Isc) στο σημείο εγκατάστασης είναι 50kA, αλλά η χρήση ενός MCCB 50kA είναι πολύ ακριβή, μπορείτε να χρησιμοποιήσετε μια Εφεδρική Προστασία στρατηγική. Αυτό περιλαμβάνει την τοποθέτηση μιας ασφάλειας υψηλής χωρητικότητας ανάντη.

- Πόρος: Μάθετε πότε να χρησιμοποιείτε ασφάλειες για υψηλά ρεύματα σφάλματος στον Οδηγό Ασφαλειών Υψηλής Ικανότητας Διακοπής.

Πίνακας 2: Συστάσεις Ικανότητας Διακοπής IEC 60947-2

| Εφαρμογή | Συνιστάται Icu (Τυπικό) | Συνιστάται Ics Αναλογία | Γιατί; |

|---|---|---|---|

| Οικιακό (Τελικό) | 6 kA | 50-75% | Τα σφάλματα είναι σπάνια και χαμηλής ενέργειας. |

| Εμπορικό Κτίριο | 10 – 25 kA | 75% | Ισορροπία μεταξύ κόστους και συνέχειας. |

| Βιομηχανικό / Ναυτιλιακό | 35 – 100 kA | 100% | Ο χρόνος διακοπής λειτουργίας είναι απαράδεκτος. Ο διακόπτης πρέπει να επιβιώσει. |

| BESS / Αποθήκευση DC | 25 – 50 kA | 100% | Υψηλός κίνδυνος πυρκαγιάς εάν δεν περιοριστεί το τόξο. |

Βαθιά Βουτιά: Η κατανόηση των ονομαστικών τιμών είναι ζωτικής σημασίας. Διαβάστε Ονομαστικές Τιμές Αυτομάτων Διακοπτών: Icu, Ics, Icw, Icm.

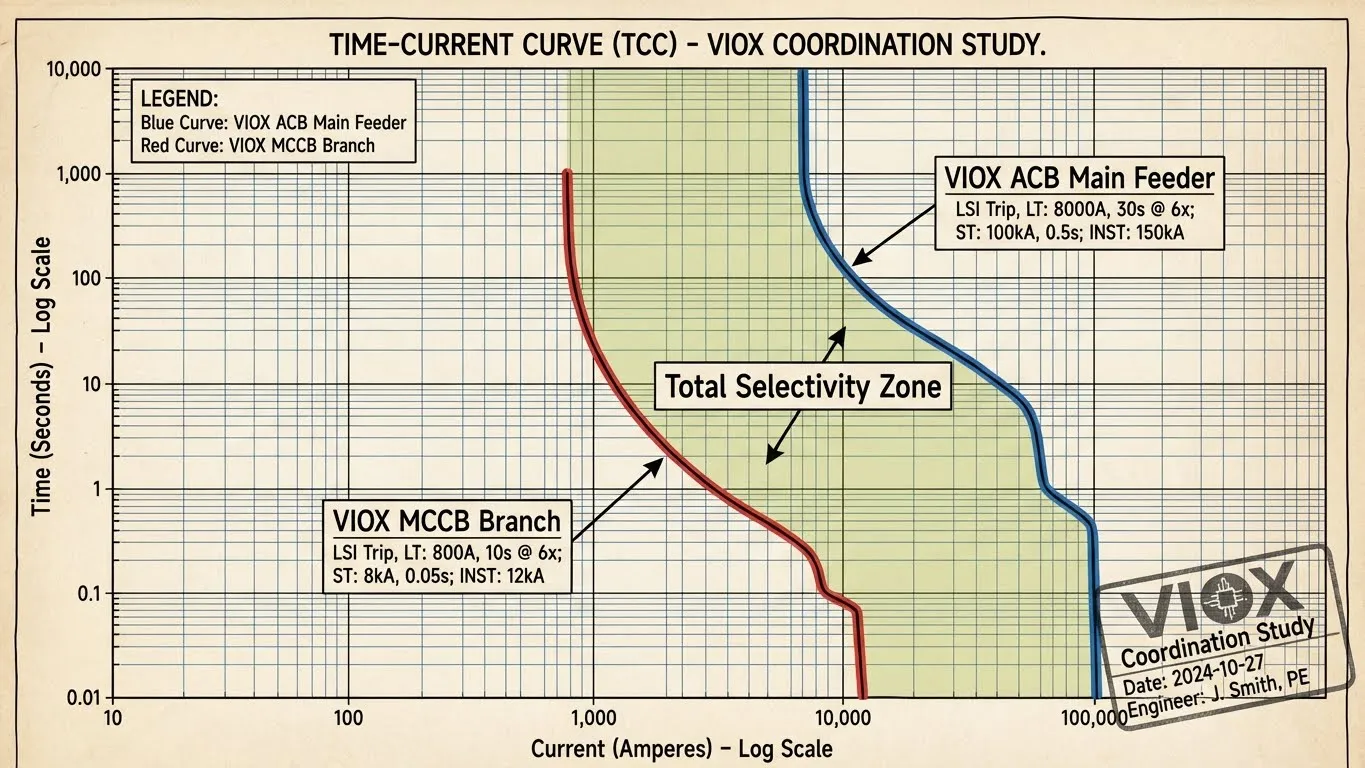

Βήμα 5: Συντονισμός & Εκλεκτικότητα (Αξιοπιστία Συστήματος)

Ο στόχος ενός καλά σχεδιασμένου πίνακα είναι Επιλεκτικότητα: όταν συμβεί ένα σφάλμα, μόνο η συσκευή ακριβώς πριν από το σφάλμα θα πρέπει να ενεργοποιηθεί. Ο κύριος τροφοδότης πρέπει να παραμείνει κλειστός για να διατηρηθεί η υπόλοιπη εγκατάσταση τροφοδοτούμενη.

Τεχνικές για Εκλεκτικότητα

- Διάκριση Έντασης Ρεύματος: Ονομαστική τιμή ανάντη διακόπτη > 2x Ονομαστική τιμή κατάντη διακόπτη (Βασικό).

- Χρονική Διάκριση: Χρήση διακοπτών Κατηγορίας B (ACBs ή MCCBs υψηλής τεχνολογίας) με ρεύμα αντοχής βραχυπρόθεσμου χρόνου (Icw). Στην ουσία λέτε στον κύριο διακόπτη: “Περιμένετε 300ms πριν ενεργοποιηθείτε για να δείτε αν το μικρότερο εξάρτημα το χειριστεί πρώτα.”

Πίνακας 3: Σύγκριση Μεθόδων Εκλεκτικότητας

| Μέθοδος | Μηχανισμός | Πλεονεκτήματα | Μειονεκτήματα | Καλύτερο για… | Εφαρμογή |

|---|---|---|---|---|---|

| Ρεύμα (Ένταση) | Διαφορά στα όρια ενεργοποίησης (Ir) | Απλό, χαμηλό κόστος | Κακή εκλεκτικότητα σε υψηλά ρεύματα σφάλματος | Τελικά κυκλώματα διανομής | Χαμηλή |

| Χρόνος (Χρονομετρική) | Ρυθμίσεις χρονικής καθυστέρησης (t_{sd}) | Καλή αξιοπιστία για διακόπτες Κατηγορίας B | Υψηλή θερμική καταπόνηση στο σύστημα κατά τη διάρκεια της καθυστέρησης | Κύρια διανομή / Τροφοδότες | Μεσαίο |

| Λογική (Επιλεκτική Ζώνη) | Σήμα καλωδίου επικοινωνίας | Ταχύτερη. Ολική εκλεκτικότητα. Χαμηλή καταπόνηση | Σύνθετη καλωδίωση. Υψηλότερο κόστος | Κρίσιμη Ισχύς / Κέντρα Δεδομένων | Υψηλή |

| Ενέργεια | Περιορισμός ενέργειας τόξου (I2t) | Αποτελεσματικό για συμπαγείς διακόπτες | Απαιτούνται πίνακες συγκεκριμένου κατασκευαστή | Πίνακες υψηλής πυκνότητας | Μεσαίο |

Δοκιμές Συστήματος VIOX: Παρέχουμε πίνακες εκλεκτικότητας που διασφαλίζουν ότι οι VIOX ACBs και MCCBs συντονίζονται τέλεια.

Πόρος: Κατακτήστε αυτό το σύνθετο θέμα με τον Οδηγό Συντονισμού ATS & Αυτομάτων Διακοπτών.

Συμπέρασμα: Η Διαφορά VIOX

Η τυποποιημένη επιλογή δεν αφορά μόνο την τήρηση κανόνων—αφορά την ευθύνη και την ασφάλεια. Ακολουθώντας το πλαίσιο IEC 60947-2 (Εφαρμογή → Τάση → Πραγματικό Ρεύμα → Ικανότητα Σφάλματος → Συντονισμός), οι κατασκευαστές πινάκων μπορούν να εξαλείψουν τις πιο κοινές αιτίες ηλεκτρικής βλάβης.

Στο VIOX Electric, δεν πουλάμε απλώς εξαρτήματα. Παρέχουμε επικυρωμένα συστήματα. Οι διακόπτες μας δοκιμάζονται σε διαμορφώσεις ομαδοποίησης και σε σκληρά περιβάλλοντα για να διασφαλιστεί ότι τα φύλλα δεδομένων ταιριάζουν με την πραγματικότητα.

Είστε έτοιμοι να καθορίσετε τον επόμενο πίνακά σας;

- Ελέγξτε τον Οδηγό Κατασκευής Βιομηχανικών Ηλεκτρικών Περιβλημάτων για να στεγάσετε την προστασία σας.

- Βεβαιωθείτε ότι οι ακροδέκτες σας ταιριάζουν με την προστασία σας με τον Οδηγό Επιλογής Ακροδεκτών.

Συχνές Ερωτήσεις: Επιλογή Προστασίας Κυκλώματος

Ε: Μπορώ να χρησιμοποιήσω έναν IEC 60898 (Οικιακό) MCB σε έναν βιομηχανικό πίνακα;

Α: Γενικά, όχι. Οι διακόπτες IEC 60898 έχουν σχεδιαστεί για λειτουργία από ανειδίκευτους χειριστές και χαμηλότερες ικανότητες διακοπής (συνήθως 6kA). Οι διακόπτες IEC 60947-2 έχουν σχεδιαστεί για βιομηχανικούς βαθμούς ρύπανσης, υψηλότερες τάσεις και ρυθμιζόμενα χαρακτηριστικά ενεργοποίησης που απαιτούνται για μηχανήματα.

Ε: Πώς επηρεάζει το υψόμετρο την επιλογή του αυτόματου διακόπτη μου;

Α: Πάνω από 2.000 μέτρα, ο αραιός αέρας ψύχει λιγότερο αποτελεσματικά και μονώνει ανεπαρκώς. Συνήθως μειώνετε το ρεύμα κατά περίπου 4% και την τάση κατά 10% για κάθε αύξηση 500 μέτρων. Δείτε τον Οδηγό Μείωσης Τιμής Λόγω Υψομέτρου για ακριβείς πίνακες.

Ε: Γιατί πέφτει ο αυτόματος διακόπτης μου παρόλο που το φορτίο είναι κάτω από το όριο; In?

Α: Αυτό πιθανότατα οφείλεται στη θερμική ομαδοποίηση. Εάν έχετε 10 αυτόματους διακόπτες τοποθετημένους σφιχτά μαζί που μεταφέρουν υψηλό ρεύμα, η θερμοκρασία περιβάλλοντος μέσα στο σύμπλεγμα αυξάνεται, προκαλώντας την πρόωρη ενεργοποίηση των θερμικών στοιχείων. Πρέπει να εφαρμόσετε έναν συντελεστή ομαδοποίησης (Kg) ή να προσθέσετε αποστάτες.

Ε: Χρειάζομαι έναν συγκεκριμένο αυτόματο διακόπτη για εφαρμογές ηλιακών/φωτοβολταϊκών συστημάτων;

Α: Ναι. Πρέπει να χρησιμοποιείτε αυτόματους διακόπτες με ονομαστική τάση DC (συχνά πολωμένοι). Η χρήση ενός αυτόματου διακόπτη AC για τάσεις DC άνω των 48V είναι επικίνδυνη επειδή οι αυτόματοι διακόπτες AC βασίζονται στο μηδενικό σημείο της ημιτονοειδούς κυματομορφής για να σβήσουν το τόξο. Το DC δεν έχει μηδενικό σημείο.

Ε: Ποια είναι η διαφορά μεταξύ της ειδικής ενέργειας διέλευσης (I2t) και της ικανότητας διακοπής;

Α: Η ικανότητα διακοπής (Icu) είναι το μέγιστο ρεύμα που μπορεί να χειριστεί η συσκευή. Η ενέργεια διέλευσης (I2t) είναι η ποσότητα θερμικής ενέργειας που περνάει στα καλώδια πριν όταν ανοίγει ο αυτόματος διακόπτης. Αυτή η τιμή είναι κρίσιμη για τη διαστασιολόγηση των καλωδίων, ώστε να διασφαλιστεί ότι δεν θα λιώσουν πριν από την ενεργοποίηση του αυτόματου διακόπτη.

Ε: Θα πρέπει να χρησιμοποιήσω ένα RCBO αντί για ένα MPCB για την προστασία του κινητήρα;

A: Οχι. Τα τυπικά RCBO δεν διαθέτουν τις συγκεκριμένες καμπύλες εκκίνησης κινητήρα (Τύπου D ή K) και την ευαισθησία απώλειας φάσης που απαιτούνται για τους κινητήρες. Είναι επίσης επιρρεπή σε ενοχλητικές ενεργοποιήσεις από ρεύματα διαρροής κινητήρα. Χρησιμοποιήστε ένα αποκλειστικό MPCB για τον κινητήρα και, εάν η προστασία από σφάλμα γείωσης απαιτείται νομικά, τοποθετήστε ένα κατάλληλο RCD Τύπου B ή F ανάντη.

Ε: Ποια είναι η συνιστώμενη συχνότητα συντήρησης για τους βιομηχανικούς διακόπτες VIOX;

Α: Σύμφωνα με τις οδηγίες του προτύπου IEC 60947-2, οι βιομηχανικοί διακόπτες (MCCB και ACB) θα πρέπει να υποβάλλονται σε οπτικό έλεγχο ετησίως. Μια πλήρης δοκιμή λειτουργίας (μηχανική και ηλεκτρική δοκιμή ενεργοποίησης) συνιστάται κάθε 3-5 χρόνια, ανάλογα με τις περιβαλλοντικές συνθήκες (βαθμός ρύπανσης) και την κρισιμότητα του φορτίου.

Περαιτέρω Ανάγνωση

Για περισσότερες λεπτομέρειες σχετικά με συγκεκριμένα εξαρτήματα που αναφέρονται σε αυτό το πλαίσιο, εξερευνήστε αυτούς τους τεχνικούς οδηγούς VIOX:

- Αυτόματος Διακόπτης έναντι Διακόπτη Απομόνωσης – Κατανόηση των θεμελιωδών διαφορών στην απομόνωση.

- Κατανόηση της προστασίας από σφάλματα γείωσης – Μια βαθύτερη εμβάθυνση στην προστασία του προσωπικού και του εξοπλισμού.

- Τι είναι ο Προστατευτής Υπέρ/Υπό Τάσης; – Προστασία από την αστάθεια του δικτύου.