V moderním elektrotechnickém prostředí se “volné místo” v rozvodné desce stalo luxusem. S rychlou integrací nabíječek pro elektromobily, solárních invertorů, modulů pro automatizaci chytré domácnosti a přepěťových ochran (SPD) čelí výrobci panelů kritické výzvě v oblasti hustoty.

Po desetiletí zahrnovala standardní konfigurace pro ochranu proti zbytkovému proudu desku “Split Load”: jeden proudový chránič (RCCB) napájející banku jističů (MCB). Nicméně, protože se snadná údržba a kontinuita podnikání stávají prvořadými, průmysl se posouvá směrem k Jistič s ochranou proti zbytkovému proudu a nadproudovou ochranou (RCBO).

Tato technická příručka analyzuje kompromisy mezi těmito dvěma architekturami, se zaměřením na prostor na DIN liště, celkové náklady na vlastnictví (TCO) a selektivitu v souladu s IEC 61009 a BS 7671.

Technické definice a architektura

Abychom mohli učinit informované rozhodnutí o nákupu, musíme nejprve definovat architektonické rozdíly definované mezinárodními standardy.

Konfigurace RCCB + MCB (skupinová ochrana)

Tato architektura používá dvě odlišná zařízení:

- RCCB (IEC 61008): Detekuje zemní svodové proudy (zbytkový proud), ale nenabízí ne ochranu proti přetížení nebo zkratům. Funguje jako “vrátný” pro skupinu obvodů.

- MCB (IEC 60898): Chrání jednotlivé obvody proti přetížení a zkratům, ale ignoruje zemní svody.

V typické desce “Split Load” chrání jeden RCCB sekci přípojnice napájející 4–8 MCB. Pokud RCCB vypne, všech 8 obvodů ztratí napájení.

Konfigurace RCBO (individuální ochrana)

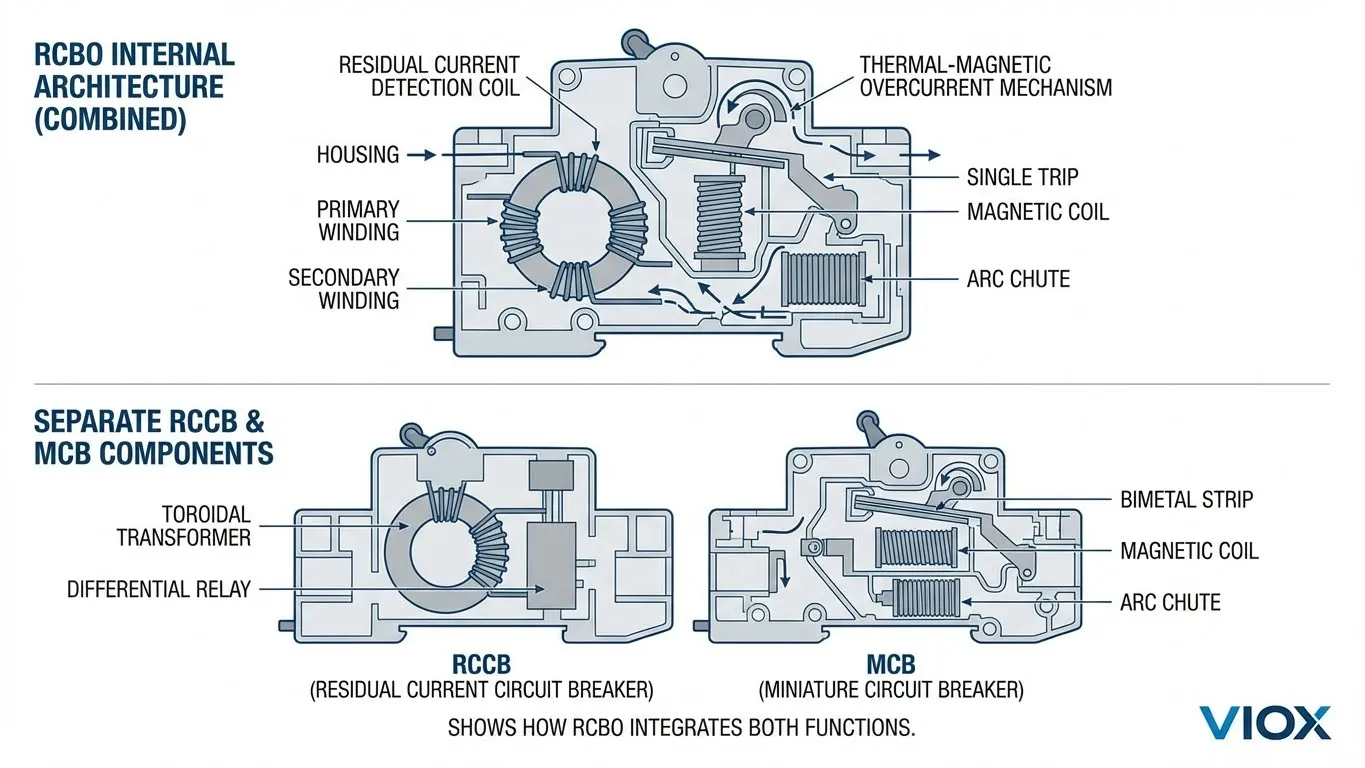

. RCBO (IEC 61009) kombinuje funkce MCB a RCCB do jednoho zařízení. Poskytuje:

- Ochrana proti přetížení (tepelná)

- Ochrana proti zkratu (magnetická)

- Ochrana proti zemnímu svodu (transformátor s vyváženým jádrem)

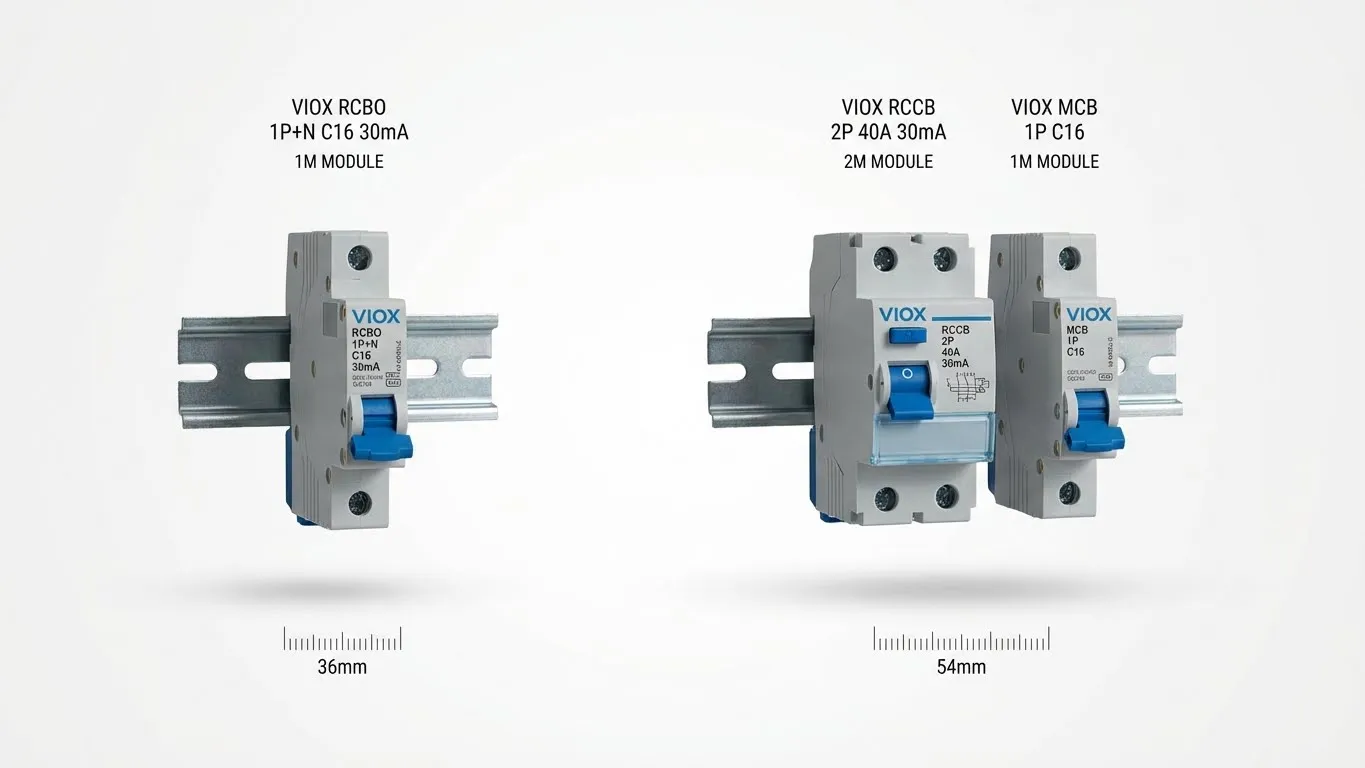

Zásadní je, že moderní RCBO integrují tuto funkčnost do jednoho modulu o šířce 18 mm, což odpovídá velikosti standardního MCB.

Analýza prostoru: Výpočet modulu 18 mm

Prostor je často primárním důvodem pro přechod na RCBO. V normě IEC je šířka jednoho modulu (1TE) 17,5 mm až 18 mm.

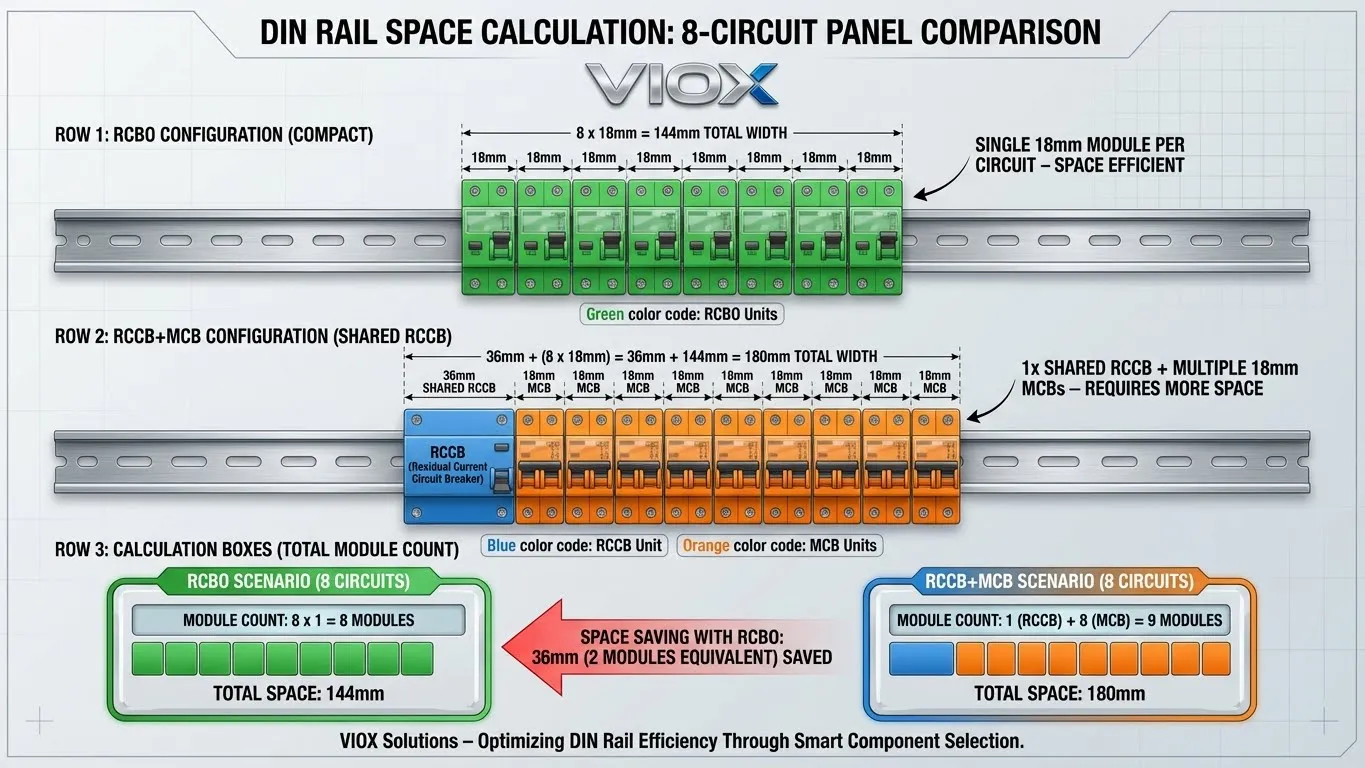

Při návrhu Montáž panelu v rozvodných deskách, je výpočet přímočarý. RCBO chrání jednu fázi a nulový vodič (1P+N) typicky v rámci jednoho modulu. RCCB vyžaduje dva moduly (36 mm) pro jednofázové nebo čtyři moduly (72 mm) pro třífázové.

Tabulka 1: Výpočet využití prostoru (12-obvodový jednofázový panel)

| Konfigurace | Ochranná zařízení | Celková šířka modulu | Efektivita využití prostoru |

|---|---|---|---|

| Varianta A: Duální Split Load | 2 x RCCB (2-pólový) + 12 x MCB (1-pólový) | (2 x 2) + 12 = 16 modulů | Nízká: Vyžaduje další prostor pro RCCB a kabelové smyčky. |

| Varianta B: Všechny RCBO | 12 x RCBO (velikost 1-pólového) | 12 = 12 modulů | Vysoká: Ušetří 4 moduly (72 mm) – dostatek pro přepěťovou ochranu nebo chytrý elektroměr. |

Pro výrobce panelů znamená úspora 4 modulů často rozdíl mezi osazením standardní skříně nebo upgradem na větší a dražší zakázkovou skříň.

Selektivita a izolace poruch: Faktor “obtěžování”

I když je prostor důležitý, selektivitu (nebo diskriminace) je provozní argument pro RCBO.

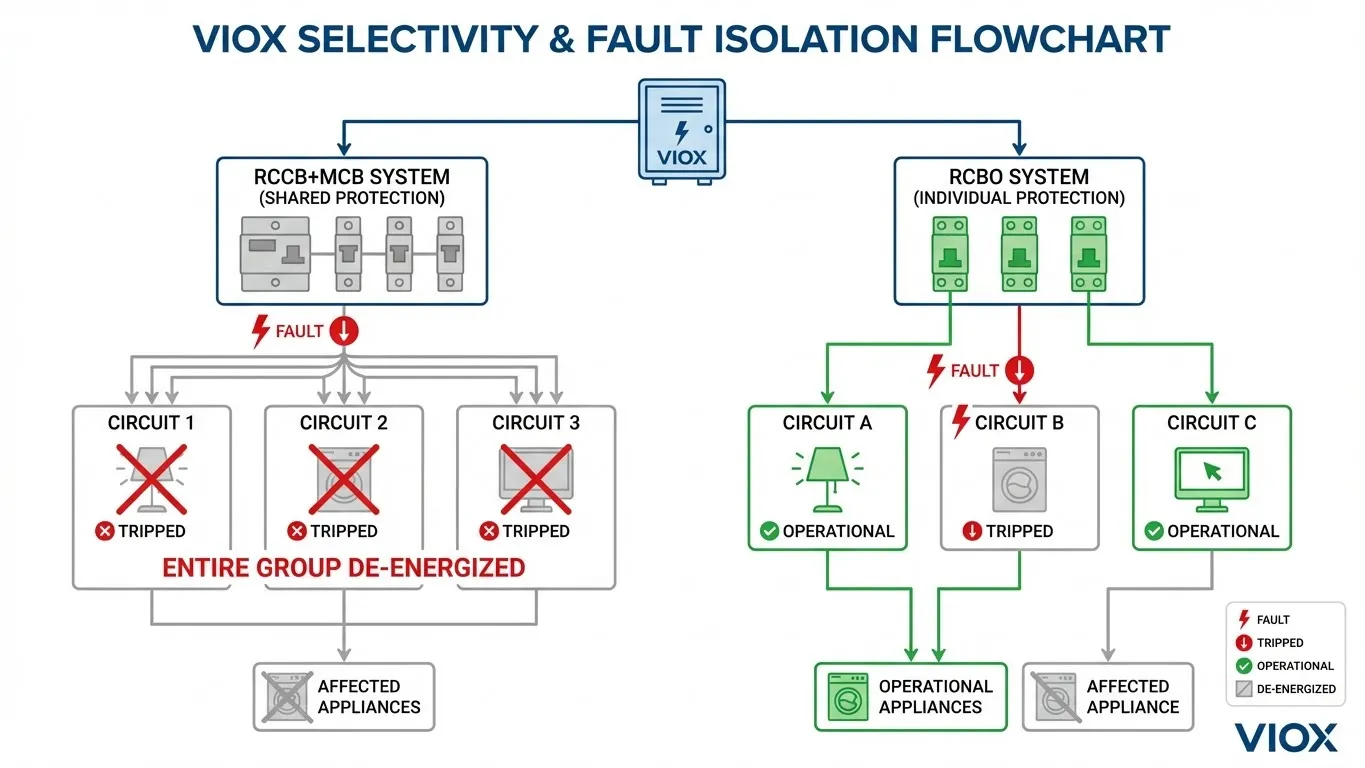

V Skupinová ochrana (RCCB + MCB) scénáři způsobí jediná zemní porucha na malém spotřebiči (např. zahradní světlo nebo toustovač) vypnutí hlavního RCCB. Tím se odpojí napájení každého MCB v této skupině.

- Důsledek: Porucha v garáži by mohla vypnout Wi-Fi router, lednici a počítač v domácí kanceláři. Toto je známé jako nedostatek diskriminace.

V RCBO instalaci je každý obvod nezávislý. Porucha na zahradním světle vypne pouze RCBO zahradního světla. Zbytek domu zůstává napájen. Pro komerční aplikace, jako jsou datová centra nebo nemocnice, je tato úroveň Selektivita povinná, aby se zabránilo nákladným prostojům.

Tabulka 2: Matice porovnání selektivity

| Funkce | RCCB + MCB (skupinové) | RCBO (individuální) |

|---|---|---|

| Diskriminace poruch | Špatná. 1 porucha ovlivňuje více obvodů. | Výborně. 1 porucha ovlivňuje 1 obvod. |

| Kumulativní svod | Vysoké riziko. Běžný svod z více PC/zařízení se sčítá a může vypnout sdílený proudový chránič (RCCB). | Žádné riziko. Svod je řízen pro každý obvod zvlášť. |

| Diagnostika | Obtížná. Uživatel musí ručně zkontrolovat 4-8 jističů (MCB), aby našel vadný obvod. | Okamžitá. Vypnutá páčka okamžitě identifikuje přesný vadný obvod. |

| Kritická doba provozuschopnosti | Nedoporučuje se pro servery/zdravotnická zařízení. | Vřele doporučeno. |

Analýza nákladů: Hardware vs. Instalace vs. Životní cyklus

Hlavní námitkou proti RCBO je obvykle počáteční cena jednotky. Výroba RCBO je složitější než výroba jednoduchého MCB. Nicméně, dívat se na náklady na hardware izolovaně je chyba, které se často dopouštějí nákupní týmy. Je nutné vypočítat Celkové instalované náklady.

Tabulka 3: Rozpis nákladů na 10 let (příklad komerční kanceláře)

| Nákladová složka | Strategie RCCB + MCB | Strategie RCBO | Analýza |

|---|---|---|---|

| Náklady na hardware | Nízké ($) | Střední ($$) | RCCB + MCB jsou přibližně o 20-30% levnější v čistých materiálech. |

| Instalační práce | Vysoké ($$$) | Nízké ($) | Rozdělené rozvaděče vyžadují složité zapojení nulového můstku a řezání přípojnic. RCBO jsou plug-and-play. |

| Materiály pro zapojení | Střední ($$) | Nízké ($) | RCBO eliminují potřebu rozsáhlých sad nulových kabelů. |

| Údržba/Prostoje | Vysoké ($$$) | Nízké ($) | Náklady na jeden výpadek kanceláře způsobený vypnutím sdíleného RCCB obvykle přesahují úspory na hardwaru. |

| Celkové náklady na 10 let | Vysoká | Nízká | RCBO vítězí v celkových nákladech (TCO). |

Kromě toho zjednodušené zapojení snižuje riziko chyby instalatéra, konkrétně “půjčování nuly” nebo “zkřížené nuly”, které se v rozdělených rozvaděčích obtížně odstraňují.

Aplikační matice: Výběr správné strategie

Ne každá instalace vyžaduje 100% RCBO. Hybridní přístup často přináší nejlepší rovnováhu mezi náklady a výkonem.

Tabulka 4: Doporučené aplikace

| Aplikace | Doporučená strategie | Odůvodnění |

|---|---|---|

| Rezidenční (rozpočet) | Hybridní | Používejte RCBO pro kritické obvody (lednička, alarm, domácí kancelář). Používejte RCCB+MCB pro osvětlení/zásuvky. |

| Rezidenční (špičkové) | Plné RCBO | Zabraňuje rušivému vypínání moderních spotřebičů (pračky, nabíječky EV) s vysokým zemním svodem. |

| Komerční kancelář | Plné RCBO | Náklady na prostoje počítačů jsou neúnosné. Vysoká hustota IT zařízení způsobuje kumulativní svod, který vypíná sdílené RCCB. |

| Průmyslové řízení | Plné RCBO | Pohony motorů (VFD) zavádějí harmonický svod. Jednotlivé RCBO typu A nebo B jsou nezbytné. |

| Exteriér/Krajina | RCBO | Venkovní obvody jsou náchylné k vniknutí vlhkosti. Izolujte je, abyste zabránili vypnutí hlavního napájení budovy. |

Technické aspekty: Moderní zátěže a normy

Zpracování DC svodu (typ A, F a B)

Moderní elektronika – včetně LED driverů, praček a nabíječek EV – generuje DC složky ve svodovém proudu. Standardní AC typ RCCB mohou být tímto DC proudem "oslepeny".

- Nabíjení elektromobilu: Vyžaduje Typ B ochranu nebo typ A s detekcí 6mA DC. Instalace RCCB typu B pro ochranu skupiny MCB je neuvěřitelně drahá. Použití jednoho Proudový chránič typu B pro EV obvod je mnohem nákladově efektivnější.

Vnitřní součásti

Inženýrskou výzvou RCBO je miniaturizace. Kombinace toroidního transformátoru RCCB a zhášecích komor MCB do 18 mm vyžaduje precizní tepelné hospodaření. Inženýři VIOX používají vysoce kvalitní bimetaly a kompaktní elektronické desky plošných spojů, aby zajistili, že odvod tepla odpovídá IEC 61009 limitům nárůstu teploty.

Závěr

Zatímco RCCB + MCB konfigurace zůstává platným a nízkonákladovým řešením pro jednoduché rezidenční aplikace, RCBO se stalo profesionálním standardem pro moderní elektrickou distribuci.

“Prostorová krize” v rozvaděčích, způsobená obnovitelnou energií a integrací automatizace, činí 18mm půdorys RCBO neocenitelným. V kombinaci s provozními výhodami plné selektivity a snížením nákladů na kabeláž nabízí RCBO vyšší návratnost investic (ROI) pro dodavatele i koncové uživatele.

Pro partnery VIOX není doporučování RCBO jen o navýšení prodeje hardwaru; jde o poskytování odolného a do budoucna připraveného elektrického systému, který minimalizuje prostoje a zjednodušuje údržbu.

ČASTO KLADENÉ DOTAZY

Může RCBO plně nahradit kombinaci RCCB+MCB?

Ano. RCBO poskytuje přesně stejné ochranné funkce (přetížení, zkrat a zemní svod) jako kombinace RCCB a MCB, často s lepším výkonem ohledně selektivity.

Jaká je úspora místa v typickém 12-obvodovém panelu?

V jednofázové desce s 12 obvody použití RCBO obvykle ušetří 2 až 4 moduly šířky (36-72 mm) ve srovnání s uspořádáním RCCB s dvojitým děleným zatížením, což umožňuje menší skříň nebo více prostoru pro kabeláž.

Je RCBO dražší než RCCB+MCB?

Z hlediska hardwaru jsou jednotlivé RCBO obecně dražší než nákup jednoho RCCB a několika MCB. Nicméně, když zohledníte zkrácenou dobu instalace (práce) a jednodušší kabeláž, celkový rozdíl v nákladech na projekt je minimální a v případě složitých rozvaděčů je často levnější varianta s RCBO.

Která konfigurace nabízí lepší selektivitu?

RCBO nabízejí vynikající selektivitu. Pokud dojde k poruše, vybaví pouze specifické RCBO pro daný obvod. U sestavy RCCB+MCB vybaví hlavní RCCB, čímž odpojí napájení všech MCB, které jsou k němu přidruženy (často 4-8 obvodů).

A co údržba a dlouhodobá spolehlivost?

RCBO zjednodušují údržbu, protože vyhledávání poruch je okamžité – přesně víte, ve kterém obvodu došlo k zemnímu spojení. Spolehlivost je srovnatelná, ačkoli RCBO snižují počet připojovacích bodů (potenciálních bodů selhání) uvnitř rozvaděče.

Kdy bych měl zvolit kombinaci RCCB+MCB namísto RCBO?

Zvolte RCCB+MCB pro rozpočtově kritické rezidenční projekty, kde je minimalizace počátečních nákladů na hardware jedinou prioritou a kde je “nežádoucí vypínání” (ztráta více obvodů najednou) považováno za přijatelnou nepříjemnost.