Proč ta průhledná pojistka, skrz kterou “vidíte”, může být nejnebezpečnější součástkou ve vaší elektrické skříni.

Osudná pohodlnost

Začíná to nevinně.

Otevřete průmyslový ovládací panel. Pojistka je spálená. Zkontrolujete zásuvku s náhradními díly a najdete skleněnou pojistku. Má rozměry 6,3 × 32 mm – přesně stejná fyzická velikost. Hodnota proudu odpovídá: 10A. Perfektně zapadne do držáku s uspokojivým cvaknutím.

A co je nejlepší? Je průhledná. Vidíte vnitřní drátěný prvek. Až příště selže, nebudete muset ani sahat po multimetru pro testování.

Zavřete dvířka panelu. Problém vyřešen.

Právě jste nainstalovali miniaturní výbušné zařízení do vašeho 480V elektrického systému.

I když ta skleněná trubice vypadá jako pojistka, sedí jako pojistka a má stejnou jmenovitou hodnotu proudu jako pojistka, fyzika se o pohodlí nestará. V průmyslových prostředích s vysokou energií není rozdíl mezi sklem a keramikou kosmetický – je to rozdíl mezi řízeným přerušením obvodu a prudkou explozí elektrického oblouku, která odpařuje kov a posílá šrapnel skrz váš panel nadzvukovou rychlostí.

Vítejte v “Past průhlednosti”– nejnebezpečnější předpoklad v průmyslové údržbě elektrických zařízení.

Myšlení 12V: Pochopení pojistek AGC

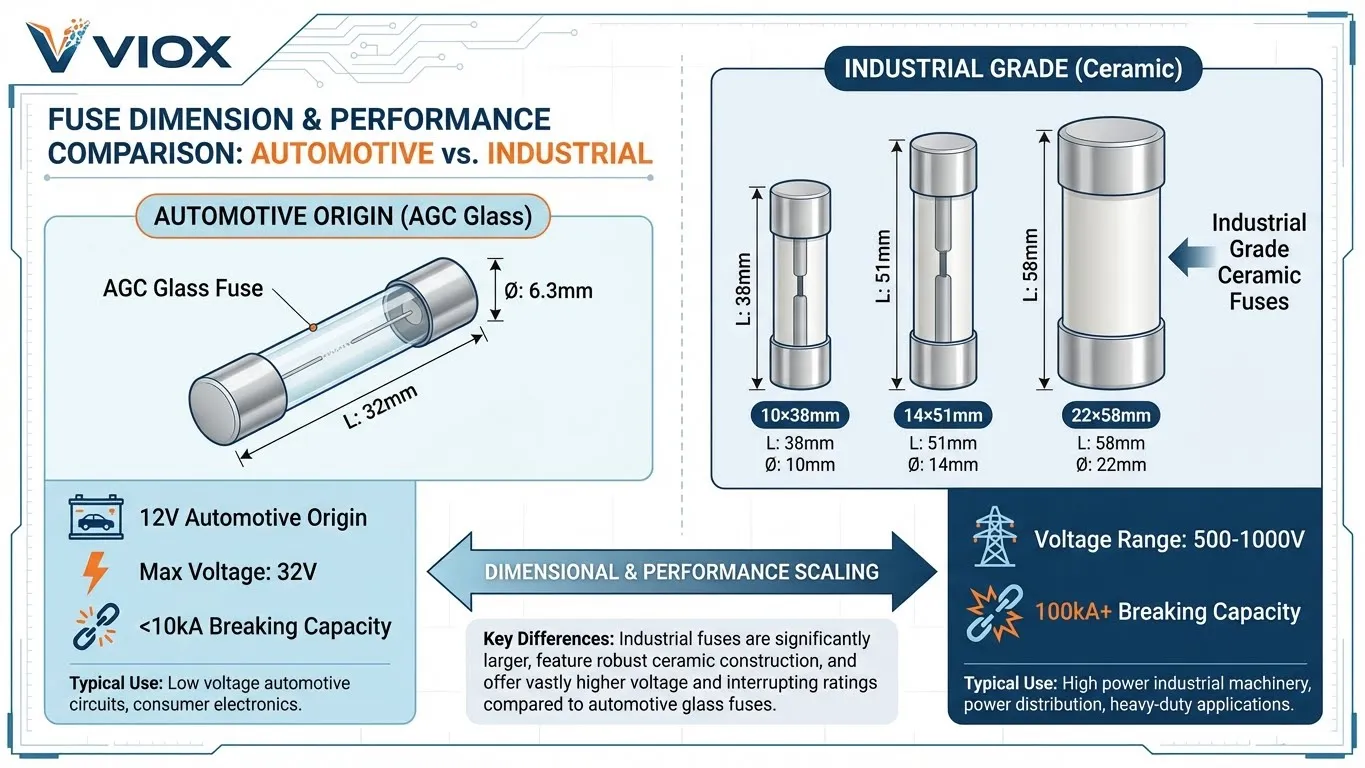

Abychom pochopili, proč je tato výměna smrtelná, musíme dekódovat, co ta nevinně vypadající skleněná trubice vlastně je. S největší pravděpodobností držíte pojistku AGC.

AGC = Automotive Glass Cartridge (automobilová skleněná patrona)

Přečtěte si ta první dvě slova znovu: Automobilové sklo.

Tyto pojistky byly navrženy v éře 12V a 24V DC automobilových elektrických systémů. Vynikají v ochraně autorádia, stropních světel nebo klasických elektronkových zesilovačů vašeho vozu. V těchto nízkonapěťových scénářích je energetický potenciál ze své podstaty omezený. Když dojde ke zkratu ve vašem vozidle, baterie může dodat pouze konečné množství proudu, než se drátěný prvek bezpečně roztaví a otevře obvod.

Skleněné tělo bylo navrženo pro pohodlí na silnici – vytáhněte pojistku, podržte ji proti slunečnímu světlu a okamžitě uvidíte, zda je drátěný spoj neporušený nebo přerušený. Je to funkce pro odstraňování problémů určená pro motoristy, nikoli pro průmyslové bezpečnostní inženýry.

Technická realita:

Podle specifikací společnosti Eaton jsou skleněné pojistky AGC dimenzovány na maximálně 32 voltů s přerušovací schopností obvykle mezi 200 ampéry a 10 000 ampéry při jmenovitém napětí. Porovnejte to s průmyslovými aplikacemi, kde dostupný poruchový proud běžně přesahuje 20 000–30 000 ampér při 480 V nebo 690 V.

Když přinesete to “Myšlení 12V” do 480V řídicího centra motoru nebo rozvodného panelu, žádáte cyklistickou helmu, aby zastavila srážku nákladního vlaku.

Fyzika “Bum” vs. “Klik”

Kritická specifikace, která odděluje ochranu života od katastrofálního selhání, je Přerušovací kapacita (také nazývaná přerušovací schopnost nebo AIC – Ampere Interrupting Capacity). Nejde o to, kolik ampér pojistka přenáší během normálního provozu. Jde o to, kolik ampér pojistka může bezpečně zastavit během masivní poruchy zkratu bez výbuchu.

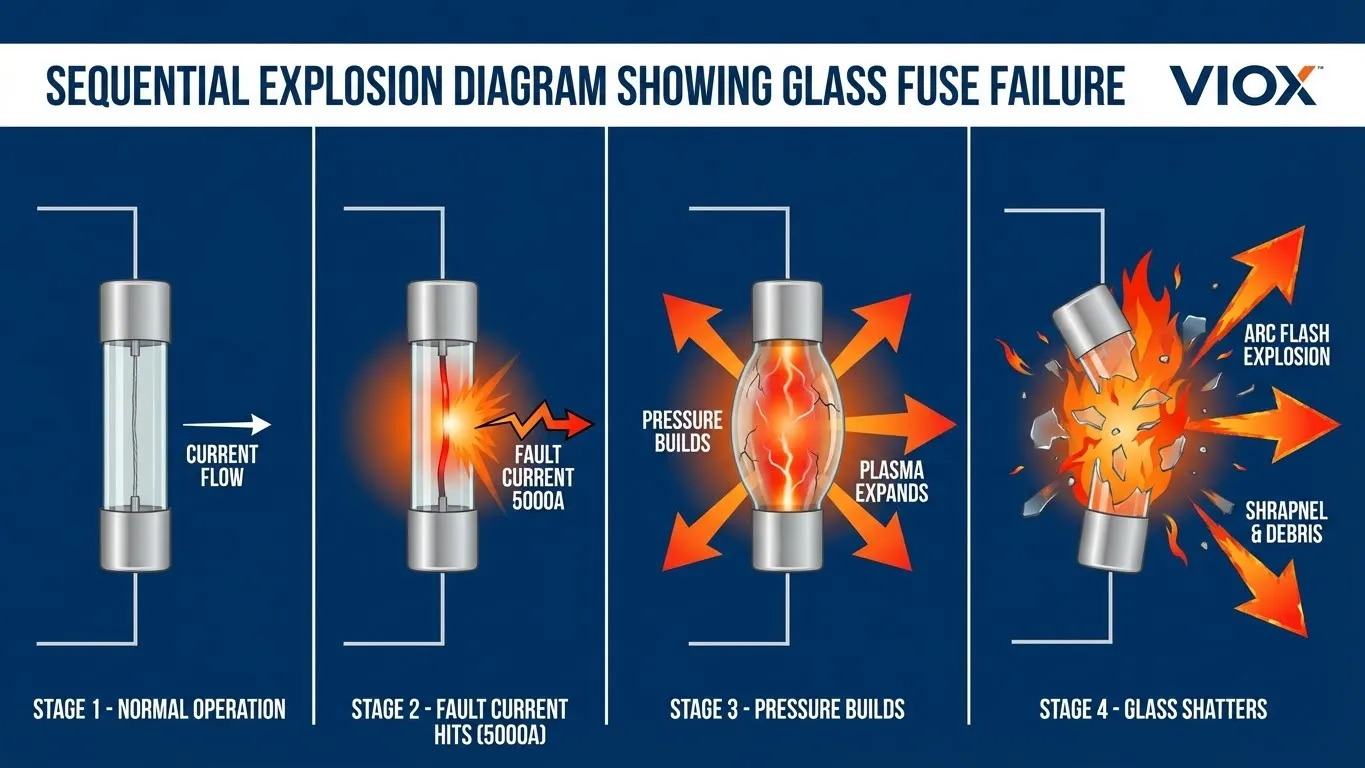

Selhání skleněné pojistky: Výbušný scénář

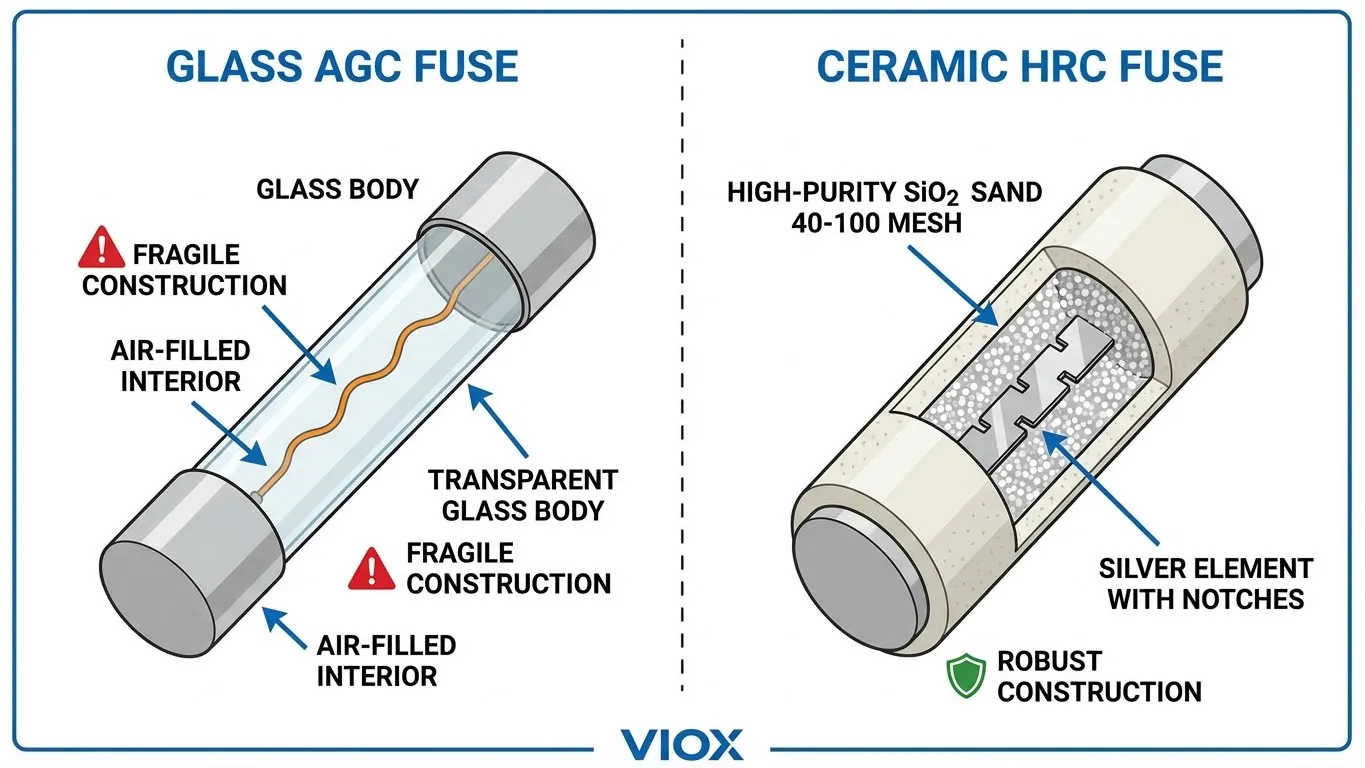

Sklo je křehké. Má nízkou pevnost v tahu. Uvnitř skleněné pojistky AGC je drátěný prvek obklopen vzduchem – nic víc.

Když katastrofální poruchový proud (řekněme 5 000 až 30 000 ampér) zasáhne tenký drát:

- Okamžité odpaření: Drát se nejen roztaví – okamžitě se odpaří na přehřáté kovové plazma

- Výbušná expanze: Okolní vzduch se zahřeje na extrémní teploty a prudce expanduje

- Tlaková špička: Vnitřní tlak prudce stoupá, aniž by se měl kam rozptýlit

- Katastrofické prasknutí: Skleněná trubice se výbušně roztříští

Výsledek: Přehřáté kovové páry (tisíce stupňů), skleněné střepiny a ionizované plazma jsou vymrštěny do vašeho elektrického panelu. Tento vodivý oblak může snadno překlenout sousední fáze a spustit masivní Obloukový výboj událost – elektrickou explozi produkující teploty 35 000 °F (19 400 °C)– téměř čtyřikrát vyšší než teplota povrchu Slunce.

Skleněná pojistka nezastavila poruchu. Stala se součástí výbuchu.

Keramická pojistka HRC: Inženýrské řešení

Nyní prozkoumejte HRC (vysoká přerušovací schopnost) keramickou pojistku VIOX.

podobných fyzických rozměrů. Vypadá nezajímavě – neprůhledná bílá nebo hnědá keramická trubice. Nevidíte vnitřní prvek. Ale zvedněte ji a jemně s ní zatřeste u ucha.

Slyšíte to jemné chrastění? To není vada. To jevysoce čistý krystalický křemenný písek.

– technologie zhášení oblouku, která zachraňuje životy.

- Odpařování prvků: Když stejný poruchový proud 5 000–30 000 ampér zasáhne keramickou pojistku HRC:

- Tvorba oblouku: Stříbrný nebo měděný prvek se odpaří na plazma (stejně jako u skleněné pojistky)

- Elektrické oblouky se tvoří ve více zúžených bodech podél prvku Zhášení pískem:

- Tvorba fulguritu: Roztavený oxid křemičitý (SiO₂) se mísí s odpařeným kovem a rychle tuhne do sklovité, nevodivé struktury zvané fulgurit

- Absorpce energie: Fázová změna písku na sklo absorbuje obrovské množství tepelné energie

- Zhasnutí oblouku: Ztuhlý fulgurit vytváří trvalou izolační bariéru, která potlačuje oblouk a zabraňuje opětovnému zapálení proudu

Výsledek: Žádná exploze. Žádné vnější střepiny. Žádné nebezpečí obloukového výboje. Pouze kontrolované “cvaknutí”, když se obvod bezpečně otevře. Robustní keramické tělo – navržené tak, aby vydrželo vnitřní tlaky přesahující 100 bar– obsahuje celou událost uvnitř.

Realita vypínací schopnosti: Čísla nelžou

Převeďme abstraktní pojmy do konkrétních specifikací. Následující tabulka ukazuje, proč jsou skleněné a keramické pojistky v průmyslovém prostředí zásadně nekompatibilní.

Skleněné AGC vs. keramické HRC pojistky: Kritické bezpečnostní srovnání

| Charakteristický | Skleněná pojistka AGC | Keramické Pojistka HRC |

|---|---|---|

| Původ/Účel návrhu | Automobilové 12V/24V DC obvody | Průmyslové AC/DC napájecí systémy |

| Materiál těla | Borosilikátové sklo (křehké) | Vysoce pevná keramika (oxid hlinitý/steatit) |

| Vnitřní zhášení oblouku | Plněné vzduchem (žádné zhášecí médium) | Vysoce čistý křemenný písek (SiO₂ >99,5 %) |

| Maximální jmenovité napětí | Typicky 32V DC; 250V AC absolutní maximum | 500V-1000V AC; až 1500V DC |

| Přerušovací kapacita | Maximálně 200A-10 000A | 100 000A-300 000A (100kA-300kA) |

| Typické aplikace | Autorádia, spotřebiče, spotřební elektronika | Řídicí centra motorů, rozvodné panely, průmyslové stroje |

| Režim selhání při poruše | Explozivní prasknutí, skleněné střepiny, obloukový výboj | Řízené vnitřní zhášení, žádná vnější událost |

| Vizuální kontrola prvku | Možná (průhledné tělo) | Není možné (neprůhledné; vyžaduje elektrické testování) |

| Bezpečnost pro průmyslové použití | NEBEZPEČNÉ – NIKDY NEPOUŽÍVEJTE | Požadováno normami IEC 60269 |

Kontrola reality vypínací schopnosti

Zde je to, co se stane, když se poruchový proud setká s nedostatečnou vypínací schopností:

| Typ pojistky | Jmenovitý vypínací proud (AIC) | Vhodné aplikace | Průmyslové použití (>240V) |

|---|---|---|---|

| Skleněná AGC (1/4″ × 1-1/4″) | 200A-10 000A @ 32V | Automobilový průmysl, spotřební elektronika | ❌ ZAKÁZÁNO |

| Skleněná miniaturní (5×20mm) | Až 10 000A @ 250V | Spotřebiče s nízkým výkonem, obvody PCB | ⚠️ Omezeno (pouze obvody <15A) |

| Keramická patrona (10×38mm) | 100 000A (100kA) @ 500V | Řídicí obvody, rozvodné přívody | ✅ POŽADOVÁNO |

| Keramická NH/BS88 | 120 000A-200 000A @ 690V | Ochrana motorů, hlavní rozvod | ✅ POŽADOVÁNO |

Kritický kontext: Moderní průmyslové provozy připojené k rozvodným sítím obvykle čelí dostupným poruchovým proudům o velikosti 20kA až 30kA v hlavních panelech, s ještě vyššími úrovněmi v blízkosti transformátorů. Skleněná pojistka s vypínací schopností 10kA není jen nedostatečná – je to zdokumentované porušení bezpečnosti podle předpisů NFPA 70E a OSHA pro elektrickou bezpečnost.

Dvě dimenze “vysokého proudu”

Když se inženýři ptají: “Zvládne tato pojistka vysoký proud?”, ve skutečnosti se ptají na dvě odlišné otázky. Skleněné a keramické pojistky se chovají radikálně odlišně v obou ohledech.

Dvě dimenze vysokého proudu

| Rozměr | Definice | Výkon skleněné pojistky | Výkon keramické HRC pojistky |

|---|---|---|---|

| A: Kapacita zátěžového proudu (Pomalé vaření) |

Maximální trvalý proud, který pojistka může vést během normálního provozu bez přehřátí | Omezeno na maximálně 30-40A. Teplo generované při vyšších proudech praská sklo nebo roztaví pájené koncové krytky. | Zvládne 100A-1250A nepřetržitě. Keramika je žáruvzdorný materiál určený pro vysoké tepelné zatížení. |

| B: Kapacita poruchového proudu (Rychlé zabití) |

Maximální zkratový proud, který pojistka může bezpečně přerušit bez prasknutí | Maximálně 200A-10 000A (nedostatečné pro průmyslové systémy) | 100 000A-300 000A (100kA-300kA), v souladu s IEC 60269 |

Inženýrská realita:

Pokud vaše zařízení odebírá energii z moderního transformátoru, potenciální zkratový proud na vašem hlavním rozvaděči pravděpodobně přesahuje 20 kA. Mnoho průmyslových areálů v blízkosti rozvoden čelí dostupnému poruchovému proudu 40 kA-50 kA. Instalace skleněné pojistky dimenzované na 10 kA nebo méně se rovná ochraně přehrady lepicí páskou – zaručuje katastrofální selhání, když dojde k poruše.

IEC 60269: Mezinárodní bezpečnostní norma

Průmyslové keramické pojistky nejsou libovolné předimenzování. Jsou navrženy tak, aby splňovaly IEC 60269, mezinárodní normu upravující nízkonapěťové pojistky pro napájecí systémy do 1 000 V AC a 1 500 V DC.

IEC 60269 nařizuje:

- Minimální vypínací schopnost: 6 kA pro jakoukoli pojistku klasifikovanou jako “průmyslová”

- Standardní jmenovité hodnoty: 80kA, 100kA, 120kA typické pro všeobecné (gG) a motorové (aM) kategorie

- Ultra-vysoká kapacita: Specializované pojistky testované na 200kA-300kA pro extrémní poruchová prostředí

- Materiály pro zhášení oblouku: Písková výplň vyžadována pro pojistky s vysokou vypínací schopností

- Časově-proudové charakteristiky: Standardizované výkonové křivky zajišťující koordinaci s ochranou proti proudu/po proudu

Všechny pojistky splňující normy IEC 60269 a nesoucí stejnou kategorii použití (gG, aM, gPV atd.) budou mít podobné elektrické vlastnosti bez ohledu na výrobce. To umožňuje globální zaměnitelnost a předvídatelný výkon v poruchových podmínkách.

Skleněné pojistky nesplňují a nemohou splňovat průmyslové požadavky IEC 60269. Jsou zahrnuty v samostatných spotřebitelských normách (IEC 60127) s mnohem nižšími očekáváními výkonu.

Nebezpečí obloukového výboje: Proč záleží na vypínací schopnosti

Obloukový výboj není jen bezpečnostní módní slovo – je to zdokumentované, smrtelné nebezpečí na pracovišti, které zraní více než 2 000 pracovníků ročně jen ve Spojených státech, což má za následek vážné popáleniny, trvalé invalidity a úmrtí.

Co se stane během obloukového výboje:

Když poddimenzovaná pojistka (jako skleněná AGC) nedokáže přerušit vysoký poruchový proud, vytvoří se elektrický oblouk – v podstatě trvalý blesk uvnitř elektrického krytu. Tento oblouk:

- Generuje teploty 19 400 °C (35 000 °F)– dostatečně horké na odpaření mědi a oceli

- Produkuje nadzvukové tlakové vlny pohybující se rychleji než rychlost zvuku, vytvářející otřesové vlny

- Odpařuje vodiče do expandujícího kovového plazmatu, které funguje jako vodič, udržující oblouk

- Uvolňuje intenzivní UV a IR záření způsobující okamžité popáleniny a potenciální slepotu

- Vymetá roztavené kovové střepiny ve všech směrech vysokou rychlostí

Role pojistky: Správně dimenzovaná keramická HRC pojistka s dostatečnou vypínací schopností přeruší poruchový proud během 0,002 až 0,004 sekundy– než se může vyvinout významná energie oblouku. Poddimenzovaná skleněná pojistka buď okamžitě exploduje, nebo nedokáže přerušit oblouk, což mu umožní pokračovat po dobu více AC cyklů (0,016+ sekund), exponenciálně zvyšující uvolněnou energii.

Požadavky OSHA a NFPA 70E: Zaměstnavatelé jsou ze zákona povinni provádět analýzu nebezpečí obloukového výboje a zajistit, aby pojistky instalované v zařízeních pod napětím měly vypínací schopnosti, které splňují nebo překračují dostupný poruchový proud v daném bodě elektrického systému. Používání skleněných pojistek v průmyslových panelech není jen špatná praxe – představuje to úmyslné porušení OSHA s přísnými sankcemi.

Přestaňte kupovat past transparentnosti

Lidská psychologie upřednostňuje vizuální potvrzení. Preferujeme skleněné pojistky, protože poskytují okamžitou zpětnou vazbu – můžete vidět, kdy se prvek přepálil.

Ale v průmyslových elektrických systémech, vizuální pohodlí je luxus, který může stát životy.

Pravidlo pro výběr pojistek

Používejte skleněné pojistky pro:

- Automobilové 12V/24V systémy

- Spotřební elektronika a spotřebiče

- Nízkonapěťové DC řídicí obvody (<50V)

- Miniaturní pojistky montované na PCB v neprůmyslových zařízeních

Používejte keramické HRC pojistky pro:

- Jakékoli napětí překračující 240V AC

- Řídicí centra průmyslových motorů (MCC)

- Rozvodné panely a rozvaděče

- Stroje a zařízení připojené k síti

- Jakýkoli obvod, kde dostupný poruchový proud překračuje 10kA

Pokud je napětí nad 240V a zdrojem energie je elektrická síť, jsou keramické HRC pojistky povinné pro bezpečnost a dodržování předpisů.

Řešení keramických pojistek VIOX

Ve společnosti VIOX Electric je naše portfolio průmyslových pojistek navrženo speciálně pro ochranu proti vysoké energii:

- Válcové keramické pojistky (10×38mm, 14×51mm): Vypínací schopnost 100kA při 500V-690V, jmenovité proudy 2A-63A

- Nožové pojistky NH (NH00-NH4): Vypínací schopnost 120kA při 690V, jmenovité proudy až 1250A

- Šroubové pojistky BS88: Vypínací schopnost 80kA-200kA, optimalizováno pro hlavní distribuci a ochranu transformátorů

Každá keramická pojistka VIOX obsahuje:

- Vysoce čistý křemenný písek (SiO₂ >99,5%)

- Robustní keramické tělo navržené tak, aby vydrželo vnitřní tlak 100+ bar

- Stříbrné nebo měděné pojistkové prvky s přesně vroubkovaným designem omezujícím proud

- Plný soulad s IEC 60269 s doloženými zkušebními protokoly

- Jasné označení vypínací schopnosti a varování před nebezpečím obloukového výboje

Nevyrábíme keramické pojistky proto, že jsou “prémiové”. Vyrábíme je proto, že chápeme, co 30 000 ampér poruchového proudu udělá s nedostatečnými ochrannými zařízeními.

Přestaňte se spoléhat na své oči – důvěřujte svým přístrojům

Vizuální kontrola spálených pojistek je pohodlí, nikoli nutnost. Moderní protokoly údržby vyžadují:

- Testování multimetrem pro kontinuitu obvodu

- Termovize pro horká místa a stavy přetížení

- Pravidelné plány kontrol na základě kritičnosti zařízení, nikoli průhlednosti pojistky

Když jsou v sázce životy a kritická aktiva, je těch několik sekund ušetřených vizuální kontrolou pojistky nevýznamných ve srovnání s katastrofálními následky použití nedostatečné ochrany.

Chraňte své lidi. Chraňte své vybavení. Specifikujte keramické HRC pojistky pro všechny průmyslové aplikace.

Často Kladené Otázky

Proč nemohu použít skleněnou pojistku, pokud má stejnou velikost a jmenovitý proud?

Fyzické rozměry a jmenovité proudy neříkají celý příběh. Kritická specifikace je vypínací schopnost—maximální poruchový proud, který může pojistka bezpečně přerušit. Skleněné pojistky mají obvykle vypínací schopnost maximálně 200A-10 000A, zatímco průmyslová zařízení běžně čelí poruchovým proudům 20 000-50 000A. Když poruchový proud překročí vypínací schopnost, pojistka násilně exploduje namísto bezpečného přerušení obvodu. Kromě toho jsou skleněné pojistky omezeny napětím (maximálně 32V pro typy AGC, absolutní maximum 250V), což je činí nevhodnými pro průmyslové systémy 480V nebo 690V.

Co znamená “vypínací schopnost” a proč na tom záleží?

Vypínací schopnost (také nazývaná jmenovitá vypínací schopnost nebo AIC – Ampere Interrupting Capacity) je maximální zkratový proud, který je pojistka schopna bezpečně přerušit bez prasknutí jejího pouzdra nebo způsobení vnějšího oblouku. Během poruchy může dostupný proud dosáhnout desítek tisíc ampér. Pojistka s dostatečnou vypínací schopností udrží oblouk uvnitř a přeruší proud během milisekund. Pojistka s nedostatečnou vypínací schopností buď exploduje, nebo neuhasí oblouk, což vede k výbuchům elektrického oblouku s teplotami přesahujícími 19 400 °C. Průmyslové normy IEC 60269 vyžadují minimální vypínací schopnost 6 kA, s typickými hodnotami 80 kA–120 kA.

Co je to pojistka AGC a kde by se měla používat?

AGC znamená Automotive Glass Cartridge (automobilová skleněná patrona).. Tyto pojistky byly navrženy pro 12V a 24V DC automobilové elektrické systémy (autorádia, světla, příslušenství). Pojistky AGC jsou dimenzovány na maximálně 32V s vypínací schopností 200A-10 000A. Mají průhledné skleněné tělo pro vizuální kontrolu – praktická funkce pro odstraňování problémů na silnici. Pojistky AGC by nikdy neměly být používány v průmyslových AC systémech nad 50V. Jsou vhodné pouze pro automobilové aplikace, spotřební elektroniku a nízkonapěťové DC řídicí obvody, kde je poruchový proud přirozeně omezen kapacitou baterie.

Jak poznám, zda moje zařízení potřebuje keramické pojistky HRC?

Pokud vaše zařízení splňuje kterékoli z těchto kritérií, jsou keramické HRC pojistky povinné: (1) Napětí systému překračuje 240 V AC, (2) Napájení je zajištěno transformátory nebo generátory schopnými dodávat poruchový proud >10 kA, (3) Zařízení zahrnuje motory, transformátory nebo vysoce výkonné stroje, (4) Elektrické panely jsou umístěny v průmyslovém nebo komerčním prostředí. Pro přesné určení proveďte studii koordinace zkratu, která vypočítá dostupný poruchový proud v každém distribučním bodě. Dostupný poruchový proud v moderních průmyslových zařízeních se typicky pohybuje od 20 kA do 50 kA – což výrazně přesahuje možnosti skleněných pojistek. Požadavky IEC 60269 a NEC vyžadují pojistky s vypínací schopností překračující maximální dostupný poruchový proud.

Co se stane během obloukového výboje při selhání skleněné pojistky?

Pokud skleněná pojistka s nedostatečnou vypínací schopností narazí na vysoký poruchový proud (v průmyslovém prostředí >10 000 A), následuje katastrofální sled událostí: (1) Tavný prvek pojistky se vypaří na plazmu, (2) Vnitřní tlak explozivně narůstá, protože se vzduch zahřívá na tisíce stupňů, (3) Skleněné tělo se rozletí a vymrští horkou plazmu, páry kovu a skleněné střepiny, (4) Ionizované páry vytvoří vodivou cestu, která umožní oblouku pokračovat mimo pojistku, (5) Tento trvalý oblouk dosahuje teploty 35 000 °F, vypařuje okolní vodiče a vytváří nadzvukové tlakové vlny. Výsledek: vážné popáleniny personálu, zničení zařízení, potenciální požár a prodloužená doba odstávky. Správně dimenzované keramické HRC pojistky zabraňují tomuto scénáři tím, že uhasí oblouk interně během 0,002-0,004 sekundy.

Mohu vizuálně zkontrolovat keramickou pojistku?

Keramické pojistky mají neprůhledné tělo, které neumožňuje vizuální kontrolu vnitřního prvku. Jedná se o záměrné konstrukční rozhodnutí – robustní keramická konstrukce a písková výplň, které umožňují vysokou vypínací schopnost, eliminují průhlednost. K otestování keramické pojistky použijte multimetr v režimu kontinuity nebo specializovaný tester pojistek. Moderní protokoly údržby upřednostňují elektrické testování před vizuální kontrolou. Některé pokročilé HRC pojistky obsahují indikační kolíky nebo úderné mechanismy, které poskytují vizuální potvrzení provozního stavu bez nutnosti viditelnosti prvku. I když to eliminuje pohodlí kontroly skleněné pojistky, je to malý kompromis pro ochranu života.

Existuje situace, kdy jsou skleněné pojistky akceptovatelné v průmyslovém prostředí?

Ano, ale pouze ve striktně omezených scénářích: (1) Nízkonapěťové řídicí obvody izolované od hlavního napájení (např. 24V DC napájecí zdroje PLC), kde je ověřeno, že maximální dostupný poruchový proud je <1kA, (2) Přístrojové obvody s napájecími zdroji s inherentním omezením proudu, (3) Spotřební zařízení (kancelářské spotřebiče, počítače) zapojené do standardních 120V zásuvek, kde je na úrovni budovy jističe zajištěna primární ochrana. I v těchto případech jsou keramické pojistky lepší volbou pro spolehlivost. Nikdy přijatelné: Hlavní rozvod energie, motorové obvody, ochrana transformátorů nebo jakýkoli obvod >240V připojený k elektrické síti. Rozdíl v nákladech mezi skleněnými a keramickými pojistkami je zanedbatelný ve srovnání s riziky odpovědnosti a bezpečnosti spojenými s použitím nedostatečné ochrany.

Proveďte akci: Vylepšete svou ochranu ještě dnes

Past průhlednosti je skutečná. Skleněné pojistky nemají v průmyslových elektrických systémech nad 240V co dělat. Každý den, kdy zůstanou nainstalovány, čelí vaše zařízení zvýšenému riziku obloukového výboje, potenciálním porušením OSHA a možnosti katastrofálního poškození zařízení.

Doporučení VIOX Electric:

Proveďte okamžitý audit všech instalací pojistek ve vašem zařízení. Vyměňte všechny skleněné pojistky v panelech pracujících nad 240V za správně dimenzované keramické HRC pojistky v souladu s normami IEC 60269. Pro pomoc s:

- Výběrem pojistek a výpočty dimenzování

- Analýza a označování nebezpečí obloukového výboje

- Souladem s normami NFPA 70E a OSHA

- Specifikacemi produktů a křížovými referenčními příručkami

Kontaktujte tým technické podpory VIOX Electric. Vyrábíme keramické pojistky průmyslové kvality speciálně navržené pro aplikace s vysokou vypínací schopností – protože ochrana kritické infrastruktury vyžaduje více než jen průhlednost; vyžaduje osvědčenou technologii zhášení oblouku.

Nepokoušejte osud s bezpečností. Vyberte si keramiku. Vyberte si VIOX.

Tento článek odkazuje na IEC 60269-1 (Nízkonapěťové pojistky – Všeobecné požadavky), NFPA 70E (Standard pro elektrickou bezpečnost na pracovišti) a OSHA 29 CFR 1910 Podčást S (Elektrické). Vždy ověřte, zda se jmenovité hodnoty vypínací schopnosti rovnají nebo překračují dostupný poruchový proud v místě instalace. Pro doporučení specifická pro dané zařízení se poraďte s kvalifikovanými elektroinženýry.